Pow Powertrain Products PDF En

-

Upload

jesse-davis -

Category

Documents

-

view

122 -

download

5

Transcript of Pow Powertrain Products PDF En

PowertrainProducts ’09Benefi ts and Technical Information

The Powertrain Division integrates innovative and effi cient system solutions for vehicle powertrains within the automotive supplier Continental AG. These systems increase performance and driving comfort while at the same time lowering consumption and emissions.

As a partner of the automotive industry, the division develops and produces a comprehensive range of products at more than 60 sites around the world. These include gasoline and diesel injection systems, engine management, transmission control units in-cluding sensors & actuators and fuel supply systems as well as components and systems for hybrid & electric drives.

2

System Overview

8 Gasoline Piezo Stratifi ed Direct Injection 10 Gasoline Solenoid Direct Injection 12 Gasoline Port Injection – Flex Fuel 14 Diesel Piezo Common Rail Injection

16 Engine Systems – ES

18 Diesel Piezo Common Rail Injector 19 Diesel New Generation Injector 20 Diesel High Pressure 2-Piston Pump 21 ECU Diesel Piezo Common Rail 22 DEKA SCR Injector 23 DEKA Injector for Diesel Dosing into Exhaust Gas 24 Gasoline Piezo Injector 25 Gasoline DI XL2 Solenoid Injector 26 Gasoline DI XL3 Solenoid Injector 27 Gasoline DEKA VII Fuel Injector 28 Gasoline High Pressure Single-Piston Pump 29 Gasoline High Pressure Multi-Piston Pump 30 Gasoline Turbocharger 31 ECU Gasoline Piezo Direct Injection 32 ECU Gasoline Solenoid Direct Injection 33 Engine Control Unit Gasoline Easy-U

Mobility and naturein harmony

3

Light and/or Medium, Heavy Duty Commercial Vehicles Application

Passenger CarApplication

Powertrain Products

Content

4

60 Sensors & Actuators – S & A

62 Actuators

62 Air Control Valve (ACV) 63 Canister Purge Solenoid (CPS) 64 Digital Linear Actuator for Idle Control Valve 65 Digital Linear Actuator for Idle Control Valve 66 Electronic Throttle Control 67 Exhaust By-pass Valve (EBV) 68 Exhaust Control Valve (ECV-3) 69 Exhaust Control Valve Low Pressure 70 Exhaust Throttle Valve 71 General Purpose Actuator (GPA) 72 Linear Purge Valve (LPV) 73 Mini Electric EGR (EEGR) 74 Natural Vacuum Leak Detection (NVLD II) 75 Smart Air Control Valve (Smart ACV) 76 Smart Coolant Pump (SCP) 77 Transmission Oil Pump (TOP) 78 Variable Valve Train Actuator (Brushless DC) 79 Variable Valve Train Actuator

80 Sensors

80 Door Handle Sensor 81 Fluid Level – Oil Level Switch 82 Fluid Level Sensor – Active Electrothermic 83 Fluid Level Sensor – Active QLT 84 Fluid Level Sensor – Active Ultrasonic 85 Fluid Level Sensor – Passive Electrothermic 86 Fluid Quality – Flex Fuel Sensor

Content

5

Powertrain Products

Engine Systems – ES

34 Light Duty ECU for Emerging Markets 35 Light & Medium Duty ECU for Emerging Markets 36 ECU for Light & Medium Duty Applications 37 Medium & Heavy Duty Motor Control Module 38 ECU for Heavy Duty Applications 29 Control Unit for Exhaust Gas Aftertreatment

40 Hybrid Electric Vehicle – HEV

42 Power Electronics 43 Modular Li-Ion Energy Storage System 44 High Voltage Electric Motor 45 High Voltage Side-Mounted Starter Generator 46 High Voltage Axel Drive System 47 14V Modular Power Net System

48 Transmission – TR

50 Mechatronic Transmission Module 51 Electro-Hydraulic Control Module 52 Control Unit for Double Clutch Transmissions 53 External Transmission Control Unit 54 Transfer Case Control Unit 55 All-Wheel Drive Control Unit 56 East TCU Platform 57 Transmission Control Unit for Commercial Vehicles 58 External Transmission Control Unit for Commercial Vehicles

6 7

114 Fuel Supply – FS

116 Modular Fuel Supply Unit 117 EC Fuel Pump G50D/EC 118 Code Description for Names of Fuel Pumps 119 Modular Fuel Level Sensor with MAPPS 120 Fuel Supply Electronics 121 Modular Function Carrier (MFC)

122 Catalytic Converters – CC

124 METALIT® (3-Way-Cat) 125 NOX-Adsorber 126 Pre Turbo METALIT TM 127 Compact Cat® 128 PM-METALIT® 129 SCRi-System®

130 LS-Design®

131 PE-Design®

Content

Powertrain Products

Sensors & Actuators – S & A

87 In Cylinder Pressure Sensors: Glow Plug Pressure Sensor & Stand Alone Pressure Sensor 88 Knock Sensor – New Design 89 Mass Airfl ow Sensor 90 Position Sensor – Clutch Master Cylinder 91 Position Sensor – Contactless Angular 92 Position Sensor – Fork Linear 93 Position Sensor – Linear Contactless 94 Position Sensor – Neutral Position 95 Position Sensor – Park, no Park 96 Position Sensor – Rotary Covers 97 Position Sensor – Variable Valve Train 98 Position Sensor – 360° Angle Contactless 99 Pressure Sensor – Brake Pressure 100 Pressure Sensor – Diesel Particle Filter 101 Pressure Sensor – Differential Manifold Vacuum 102 Pressure Sensor – High Pressure 103 Pressure Sensor – Manifold Absolute Family 104 Pressure Sensor – Truck Application MAP 105 Pressure Sensor – Relative 106 Pressure Switches 107 Smart NOx Sensor 108 Temperature Sensor – Coolant / Fuel /Oil 109 Temperature Sensor – Cylinder Head 110 Temperature Sensor – High Temperature 111 Temperature Sensor – Intake Air 112 Temperature Sensor – Intake Air (High EGR) 113 Temperature Sensor – Outside Air

8 9

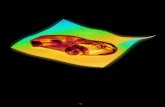

Gasoline Piezo Stratifi ed Direct Injection System

1 Mass Airfl ow-Sensor with integrated Temperature Sensor (Frequency Output) 2 Turbo Speed Sensor 3 Manifold Air Pressure Sensor 4 Electronic Throttle Control 5 Electrical Exhaust Gas Recirculation Valve (EEGR) 6 Exhaust Bypass Valve 7 Piezo Injector 8 In-Cylinder Pressure Sensor (Optional) 9 Single Coil Ignition with Diagnosis Feedback

10 Dual Variable Camphaser 11 Active Camshaft Position Sensor 12 Canister Purge Solenoid 13 Low Pressure Fuel Pump (PWM-controlled) 14 Gasoline High Pressure Pump with Flow Control Valve (Single Piston) 15 Fuel Pressure Sensor 116 Manifold Absolute Pressure Sensor with Integrated Temperature Sensor 17 Active Electrothermic Oil Level Sensor 18 Coolant (Water) Temperature Sensor 19 Knock Sensor 20 Active Crankshaft Position Sensor (also with Direction Detection) 21 Turbo Charger 22 Linear O2 Sensor 23 High Temperature Sensor 24 DEKA SCR-Injector 25 NOX Sensor

No. Technology

No. Technology

12 161513 2017 18 1914

6 8 9 10 1171 2

21 22 23 2524

3 4 5

SCR(optional

LNT)

Lambda SensorCatalyst

System Overview

10 11

Gasoline SolenoidDirect Injection System

1 Manifold Air Pressure Sensor 2 Electronic Throttle Control 3 Manifold Absolute Pressure Sensor with Integrated Temperature Sensor 4 Electrical Exhaust Gas Recirculation Valve 5 SMART NVLD 2 6 Canister Purge Solenoid 7 Fuel Supply Unit 8 Flex Fuel Sensor (Optional) 9 Gasoline High Pressure Pump with Flow Control Valve (Single Piston) 10 Fuel Pressure Sensor

11 Active Crankshaft Position Sensor (also with Direction Detection) 12 Variable Valvelift 2-step 13 Knock Sensor 14 Coolant (Water) Temperature Sensor 15 Solenoid Injector 16 Single Coil Ignition with Diagnosis Feedback 17 Dual Variable Camphaser 18 Active Camshaft Position Sensor 19 Turbo Charger 20 Binary O2 Sensor

No. Technology No. Technology

11 13 1412 15 16 17 18 19

20

2 3 41

8 9 1065 7

3-WayCatalyst

System Overview

12 13

Gasoline Port Injection System – Flex Fuel

1 Electronic Throttle Control 2 Manifold Air Pressure Sensor with integrated Temperature Sensor 3 Integrated Intake Manifold 4 SMART NVLD 2 5 Canister Purge Solenoid 6 Fuel Supply Unit 7 Flex Fuel Sensor (Optional)

8 Active Crankshaft Position Sensor (also with Direction Detection) 9 DEKA VII Multipoint Injector 10 Knock Sensor 11 Coolant (Water) Temperature Sensor 12 Ignition Coil 13 Dual Variable Camphaser 14 Active Camshaft Position Sensor 15 Binary O2 Sensor

No. Technology No. Technology

5 64 8 9 10 11 12 13 14

15

7

1 2 3

3-WayCatalyst

System Overview

14 15

Diesel Piezo Common Rail Injection System

1 Mass Airfl ow Sensor 2 Turbo Speed Sensor 3 Air Control Valve 4 Electrical Exhaust Gas Recirculation Valve (EEGR) 5 Manifold Absolute Pressure Sensor with Integrated Temperature Sensor 6 Exhaust Bypass Valve 7 Active Camshaft Position Sensor 8 Diese Piezo Common Rail Injector 9 Glow Plug Pressure Sensor

10 Fuel Supply Unit 11 Diesel High Pressure Pump 12 Fuel Pressure Sensor 13 Engine Coolant or Cylinder Head Temperature Sensor 14 Active Electrothermic Oil Level Sensor 15 Knock Sensor 16 Active Crankshaft Position Sensor (also with Direction Detection) 17 Pre Turbo Cat 18 General Purpose Actuator 19 High Temperature Sensor 20 Diesel Dosing Injector 21 Linear/Binary O2 Sensor 22 Relative Pressure Sensor 23 DEKA SCR-Injector 24 NOX Sensor

No. Technology

No. Technology

OxidationCatalyst

SCR(optional

LNT)

10 11

17 18 19 19 242320 21 22

1615141312

6 8 971 2 3 4 5

Diesel Particulate

Filter

System Overview

ES

16 17

Engine SystemsES

Engine Systems – ES

q High speed piezo actuator for a faster & more fl exible injection controlq Extra fi ne fuel atomization & minimized pressure loss in the hydraulic systemq Excellent multiple injection accuracy & lifetime stability even for smallest quantities

Technical Information

q Pressure up to 2,000 bar

q Min. quantity 0.80 mm3

with quantity drift correction 0.65 mm3

q Max. no. of injections 7

q Min. injection separation 100 µs

q Continuous leakage 35 ml /min

q Diameter nozzle holes > 90 µm

Diesel Piezo Common Rail Injector

18 19

ES

q Excellent multiple injection stability due to needle direct drive and needle closed loop controlq Reduced CO2 emissionsq Fulfi ll future emission standards Euro 6/US Tier 2q Piezo inline design for optimized injector packagingq Outstanding low noise (NVH)

Technical Information

q Pressure 2,000 bar and above

q Min. quantity 0.65 mm3/shot

q Max. no. of injections 7

q Min. injection separation no hydraulic dwell

q Total leakage 10 ml /min

q Diameter nozzle holes > 90 µm

Diesel New Generation Injector

Engine Systems – ES

20 21

ES

q Minimized pump leakage for reduced fuel consumption and CO2 emissionsq Weight and package optimized high pressure pump

Technical Information

q Pressure up to 2,000 bar

q Displacement 0.596 up to 0.795 cm3/rev

q Piston (max. Ø) 7.5 mm

q Stroke (max.) 9 mm

q Max. speed at full load 4,000 rpm

q Engine Control Unit for Diesel Piezo Common Rail Injection Systemsq Standardized scalable and modular electronic hardwareq Chassis mountedq Supporting Euro 5

Technical Information

q Core TC1796, 150 MHz

q Flash size 2 MB

q Interfaces CAN bus: 1 incl. wake up

q Injection drivers 4, single bank

q Driver outputs 24

q Housing sealed IP5k9k, connector 154 pin

Diesel High Pressure 2-Piston Pump

ECU Diesel Piezo Common Rail

Engine Systems – ES

q Robust approach for Diesel Particle Filter (DPF) regenerationq Avoidance of oil dilution by post injectionq Uses existing injection technologies q Improved fuel economy

Technical Information

q Nominal fl ow Qs = 2 up to 6 g/s, Qd = 20 mg/stroke

q Input pressure range 3.5 up to 8 bar

q Sauter Mean Diameter (SMD) 50 up to 100 µm (n-heptane)

q Accuracy of fl ow +/– 6%

q Max. control valve temp. 120°C

q Max. spray nozzle temp. 600°C

q System minimum pulse width 10 ms 22 23

ES

DEKA Injector for DieselDosing into Exhaust Gas

Engine Systems – ES

DEKA SCR Injector

q Optimized design for airless SCR dosing systemsq Reliable delivery of urea with excellent spray performanceq Frost-proof (no emptying of dosing system at shutdown)q Part of Continental’s approach to SCR systems

Technical Information

q Nominal fl ow Qs = 1.7 g/s, Qd = 3.8 mg/stroke (5 bar, AUS 32)

q Fluid pressure range 3.8 up to 7.5 bar

q Sauter Mean Diameter < 75 µm (SMD) (5 bar, AUS 32)

q Injector spray type Cone/42° cone angle

q Max. injector temperatures 120°C (injector body) >180°C (injector tip)

Gasoline DI XL2 Solenoid Injector

q Improved linear fl ow range for turbocharged enginesq World wide fuel compatibilityq High fl exibility of spray characteristic to meet the requirements of each target engineq O-Ring or metal-to-metal sealing

Technical Information

q System pressure 40 up to 150 bar

q Working fl ow range > 20

q Static fl ow range 5 up to 17 g/s (at 100 bar at 70°C)

q Min. dynamic fl ow < 4 mg/stroke

q SMD size < 15 µm

q Opening/Closing min. 300 µs

q Cone angle range 35° up to 90°

q Bent angle range 0° up to 30° 24 25

ES

Gasoline Piezo Injector

q Very fast & precise injection (up to 4 injections/combustion cycle)q Extended linear fl ow range, high fl ow capabilityq World wide fuel compatibility

Technical Information

q System pressure 50 up to 200 bar

q Working fl ow range > 50

q Static fl ow > 35 g/s

q Dynamic fl ow 14.5 mg/ injection ± 10% at 0.4 ms PW

q Min. dynamic fl ow < 2 mg/stroke

q SMD size ~ 15 µm

q Opening/Closing time ≥ 150 µs

q Spray angle 94°/98°± 4°

q Temperature range – 30 up to +140°C

Engine Systems – ES

26 27

Gasoline DI XL3 Solenoid Injector

q Improved linear fl ow range for high-turbocharged enginesq World wide fuel compatibilityq High fl exibility of spray characteristics to meet the requirements of side or central mounted enginesq O-Ring or metal-to-metal sealingq Multiple injection capabilityq No needle bouncing

Technical Information

q System pressure 40 up to 200 bar

q Working fl ow range > 24*

q Static fl ow range > 20* g/s (at 100 bar at 70°C)

q Min. dynamic fl ow < 3* mg/stroke at 40 bar

q Max. functioning pressure 260 bar

q Multiple injection < 500 µs dwell time

q Multi-stream technology max. 8 holes

q Family layout short, long, extended* D

epen

din

g o

n ca

libra

tion

cons

trai

ns

Gasoline DEKA VII Fuel Injector

q Fast opening/closing, various packaging optionsq Flexible orifi ce confi gurationsq Low pulse width with high linear performance and low voltage sensitivity

Technical Information

q Fuel pressure range 1 up to 6 bar

q Fuel compatibility Gasoline & Flex Fuel (up to E100)

q Static fl ow rate per applic. 0.95 up to 6.0 g/s

q SMD size ~ 60 up to 100 µm with ASQUARED

q Opening time < 1.10 ms

q Closing time > 0.70 ms

q Min. linear pulse 1 up to 20 ms

q Possible cone spray 10° up to 30° spray patterns bent stream 5° up to 25° split stream 15° up to 30°

Engine Systems – ES

Gasoline High Pressure Single-Piston Pump

28 29

ES

q World wide fuel compatibilityq Low friction due to running components in permanent oil fi llingq Dry run capabilityq Mounted on top of the camshaft

Technical Information

q Max. fuel pressure up to 200 bar

q Supply pressure 4.5 up to 6 bar

q Temperature range – 40 up to +130°C

q Control fl ow controlled

q Drive cam driven

q Integrated (inlet) fl ow control valve

Engine Systems – ES

Gasoline High Pressure Multi-Piston Pump

q World wide fuel compatibilityq Low friction due to running components in permanent oil fi llingq Dry run capability

Technical Information

q Max. fuel pressure up to 200 bar

q Supply pressure 4.5 up to 6 bar

q Temperature range – 40 up to +130°C

q Control fl ow controlled

q Drive end of camshaft or belt driven

q Maximum fl ow up to 240 l /h (at 3500 rpm, depending on the # of pistons 2 up to 6)

q Integrated (inlet) fl ow control valve

30 31

ES

Engine Systems – ES

Gasoline Turbocharger

q Designed for a fully integrated robotized assembly processq Outstanding thermodynamicsq Robust and reliable design

Technical Information

q Gasoline application up to 1050°C exhaust gas temperatures

q Engine power up to 90 kW per Turbo

q Turbine wheel Ø 30 up to 39 mm

q Air fl ow max. 0,1 kg/s

q Speed max. 330,000 rpm

q Integrated recirculation valve

q Electric actuated wastegate control

q Milled compressor wheel

ECU Gasoline Piezo Direct Injection

q Engine Control Unit for Gasoline Piezo Direct Injectionq Standardized scalable and modular electronic hardwareq Engine compartment, option for water coolingq Supporting Euro 5

Technical Information

q Core TC1796, 150 MHz

q Flash size 2 MB, optional 2 MB external

q Interfaces BSD, LIN-Bus, FlexRay, 2*CAN

q Injection drivers 8

q Driver outputs 32

q Housing sealed, IP6K4K, connector 177 pin

32 33

Engine Systems – ES

ECU Gasoline Solenoid Direct Injection

q Engine Control Unit for Solenoid Direct Injectionq Standardized and modular electronic hardwareq Chassis mountedq Supporting Euro 5

Technical Information

q Core TC1796, 150 MHz

q Flash size 2 MB + 2 MB external

q Interfaces Lin, 2*CAN

q Injection drivers 6 (8 optional)

q Driver outputs 32

q Housing sealed, IP6k9, connector 154 pin

Engine Control UnitGasoline Easy-U

q Ready-to-use Gasoline Engine Management System for worldwide applications: Europe low budget vehicle segment, Russia, China, India, ASEAN, Middle East, South Americaq Modular and scalable system approach to cover various engine and vehicle confi gurations including Euro 5 and EOBD

Technical Information

q ECU with predefi ned set of sensors and actuators

q Core Coral, 40 MHz

q Flash size 1 MB

q Interfaces 1*CAN, 1*K-line

q Injection drivers 4 MPI

q Driver outputs 20

q Housing sealed, IPX7, connector 32 + 64 pins

34 35

Engine Systems – ES

Light Duty ECU (Emerging Markets)

q Engine Control Unit for Light Duty Vehicle Applicationsq Chassis mountedq Supporting Euro IV Technical Information

q Core Freescale MPC5566 (UIPER)

q Clock frequency 80 MHz

q Flash size 24 MBit

q RAM 4 MBit

q CAN BUS 2

q H-Bridges 2

q Injection drivers 4

q Driver outputs 20

q Connector pins 154

Light & Medium Duty ECU (Emerging Markets)

q Engine Control Unit for Light & Medium Duty Vehicle Applicationsq Cab mountedq Supporting Euro III, IV

Technical Information

q Core Freescale MPC555

q Clock frequency 40 MHz

q CAN BUS 2

q Injection drivers 6

q Driver outputs 15

q Connector pins 121

ECU for Light & Medium Duty Applications

36 37

ES

q Engine Control Unit for Piezo Common Rail and Amplifi ed Common Rail Injection Systemsq Engine mounted with dampersq Supporting EPA 07

Technical Information

q Core Green Oak

q Flash size 16 Mbit

q RAM 32 kB

q CAN BUS 2

q H-Bridge output up to 2

q Injection drivers up to 8

q Connector pins 2 x 76; 1 x 36

Engine Systems – ES

Medium & Heavy Duty Motor Control Module

q Motor Control Module for Common Rail, Amplifi ed Common Rail and Pump-Line-Nozzle Injection Systemsq On-engine mounted with damping elementsq Supporting Euro VI, EPA 10

Technical Information

q Core TriCore TC1766

q Flash size 1,5 MB

q CAN BUS 3

q H-Bridge output 1

q Injection drivers 12

q Driver outputs 21

q Connector pins 1 x 120; 1 x 21

38 39

Engine Systems – ES

ECU for Heavy DutyApplications

q Engine Control Unit for high pressure Solenoid Injection Systemq On-engine mounted w/o damping elementsq Supporting Euro V w/o SCR

Technical Information

q Core Green Oak

q Flash size 2.5 MB

q RAM 2 Mbit

q CAN BUS 3

q H-Bridge output 2

q Injection drivers 8

q Connector pins 14 x 10

Control Unit for Exhaust Gas Aftertreatment

q Control Unit for Selective Catalytic Reduction (SCR)q Chassis mountedq Supporting Euro IV, V

Technical Information

q Core 16 bit

q Clock frequency 20 MHz

q CAN BUS 1

q Ubat 12/24 V

q Connector pins 62

40

Hybrid Electric Vehicle – HEV

41

HE

V

Hybrid ElectricVehicleHEV

42

Hybrid Electric Vehicle – HEV

43

Modular Li-Ion Energy Storage System

Power Electronics

q Application in hybrid, electric and fuel cell vehiclesq Safety and lifetime optimized cellsq Synergy effect through modular systemq Variable cooling system

Technical Information

q Power: 18 kW–120 kW

q Li-Ion ultra high power cells

q Integrated battery management

q Integrated safety system

q Integrated cooling system

q Modular design q Control module for electric machine in hybrid elec- tric vehicle, electric vehicle and fuel cell vehicle

Technical Information

q Water cooling

Inverter

q Power: up to 150kW at 450V

q Converts energy in both directions – drive electric machine in motor and generator mode

Converter

q Power: up to 3kW

q Bi-directional potential free energy transport between HV traction battery and 14V power net

q Replaces conventional 14 V generator

HE

V

Single Inverter

Single DC/DCConverter

New GenerationPower Electronics

High Voltage Electric Motor

HV Side-Mounted Starter Generator

44

Hybrid Electric Vehicle – HEV

45

q Pure electric driving (zero emission)q Permanent synchronous or induction machineq Transmission integrated

Technical Information

q Operates up to 450 V

q Power up to 75 kW

q Fast start < 300 ms

q Cold start < 800 ms

q Speed up to 7.000 rpm

q High speed asynchronous machine q High power densityq High effi ciencyq Low weightq Short axial lengthq Cost-optimized

Technical Information

q High speed up to 18000 rpm

q High voltage up to 150 V

q Regenerative Power 5 kW continuous, 20 kW peak

q Water-cooling

q Aluminium housing

q Special stator winding design

HE

V

In cooperation with ZF

High Voltage Axle Drive System

14V Modular Power Net System

46

Hybrid Electric Vehicle – HEV

47

q High speed synchronous machine (external excited)q High power densityq High effi ciencyq Cost-optimized

Technical Information

q High speed up to 12,000 rpm

q High voltage up to 450 V

q Regenerative power 35 kW continuous, 70 kW peak

q Water-cooling

q Aluminum housing

q Mechanical integration gear/e-machine

q Energy storage for limited regenerative braking (up to 4% CO2 reduction)q Provides second voltage level for high power applicationsq Support of start-stopq High number of load cyclesq Modular and integrated designs available

Technical Information

q DC/DC converter 0,4k W up to 2,6 kW – Voltage level 14 V up to 60 V – Effi ciency up to 94% – Bidirectional – Potential-free and potential-connected designs availableq Energy Storage 3,6 Wh up to 50 Wh – Based on Double Layer Capacitors – Includes active or passive balancingq Energy management & diagnosis (e.g. SOC, SOH)q CAN or LIN communication

HE

V

48

Transmission – TR

49

TR

TransmissionTR

Mechatronic Transmission Module

Electro-Hydraulic Control Module

50 51

q Controls 6-speed automatic transmissionq Mechatronic Module assembled in the gear boxq Integration of all transmission sensorsq Weight reduction due to integrationq Higher reliability of the electronics due to reduced number of internal connections

Technical Information

q E-Module based on fl ex technology

q Position, speed and temperature sensors integrated

q LTCC (Low temperature co-fi red ceramics) substrate for electronic components

q Temperature range from – 40°C up to +143°C

q Powerful 32 bit microcontroller

q Communication via CAN bus

q Controls 6-speed automatic transmission q Integrated transmission control unit including manifold and solenoidsq Monitors transmission performance and com- pensates for normal wear in components such as clutch plates, so transmission performance remains consistent for the life of the transmission

Technical Information

q Operating temperature – 40°C up to +140°C

q 32-bit processor with external fl ash memory

q Low temperature co-fi red ceramics (LTCC) substrate for electronic components

q 14-pin vehicle interface connector system

q Communication via CAN bus

TR

Transmission – TR

Control Unit for Double Clutch Transmissions

External Transmission Control Unit

52 53

q Controls 7-speed dry double clutch transmissionq Integration of all transmission sensors into the control unitq Higher reliability of the electronics due to the reduced number of internal connectionsq Weight reduction due to integration

Technical Information

q Direct connection of actuators to the control unit

q Only one plug connection to the vehicle

q Control of BLDC motor of oil pump

q Operating temperature range – 40°C up to +140°C

q Maximum permissible acceleration

q 32 bit processor

q Controls 5-speed automatic transmissionq Stand-alone conceptq Control of 6 valves

Technical Information

q 16 bit processor

q Communication via CAN-Bus

q Power outputs for 6 electromechanical hydraulic valves:

– 2 control valves for the hydraulic of the transmission – 3 control valves for the gear changing – 1 valve for bypass converter

TR

Transmission – TR

All-Wheel Drive Control Unit

Transfer Case Control Unit

54 55

q Controls the torque distribution of All-Wheel-Drive vehicles by actuating a limited slip couplingq Directly attached to All-Wheel-Drive coupling device

Technical Information

q Powerful 16 bit processor

q Flame Retardant 4 (FR4) substrate for electronic components

q Power outputs for one valve and feeder pump

q Protection class IP 6K9K

q Communication via CAN bus

q Operating temperature up to 120°C

q Integrated connectors for solenoid and pressure sensor

q Controls high/low shift and active torque distribution of transfer cases used in Four-Wheel-Drive vehiclesq For improved traction on-road and off-road

Technical Information

q Powerful 16 bit processor

q Flame Retardant 4 (FR4) substrate for electronic components

q Power output for one actuator motor

q Protection class IP40

q Communication via CAN bus

q Stand-alone housing with integrated cooling plate

q Operating temperature up to 85°C

TR

Transmission – TR

56 57

Transmission Control Unit for CV

q Controls 6-speed automatic transmissionq Control unit for retarder truck applicationsq Control unit directly mounted on the transmission or retarderq Improved performance characteristicsq Higher service lifeq Reduced driving noise developmentq Reduced harness length and complexity

Technical Information

q Ceramic substrate and direct copper bonded technology

q IP6k9 housing with overmolded leadrame

q 32 bit microcontroller

q 24 V/12 V capable

q Temperature: – 40°C up to +140°C

q 2 x Can Bus and current control outputs (10)

TR

East TCU Platform

q Controls of stepped AT, CVT, DCT, hydraulic AMTq Stand alone conceptq Reduced time-to-market thanks to existing platformq Cost effi cient solution

Technical Information

q Environment: engine or passenger compartment

q 32-bit Microcontroller with internal fl ash memory

q Flame retardant FR4 printed circuit board substrate

q State of the art input/output stages

q Communication via CAN-Bus

q Start of production in 2009

Transmission – TR

58 59

TR

Development of transmissioncontrol units.

External Transmission Control Unit for CV

q Controls 6-speed automatic transmissionq External control unitq Improved shift comfortq Reduced life cycle costsq Higher reliability

Technical Information

q Powerful 32 bit processor

q HDI organic substrate

q 10 power outputs for solenoids

q 3 VRS speed inputs

q CAN, J1708, J1850, K-Line communication

q 18 switch inputs

q Operating temperature up to 105°C

Transmission – TR

60 61

S&

A

Sensors& ActuatorsS&A

Sensors & Actuators – S & A

S&

A

62 63

Air Control Valve (ACV)

q Non-contacting MR sensor not sensitive on environmental infl uencesq Version with plastic housing lighter than aluminiumq Version with electronics easy to integrate in existing ECU

Technical Information

q Operating – 40 up to +125°C temperature range (up to +160°C on specifi c designs)

q Intake manifold air 100 up to 2500 hPa pressure (absolute) (up to 3500 hPa on specifi c designs)

q Response time < 150 ms (< 100 ms on spec. designs)

q Excess torque > 1.0 Nm (> 1.6 Nm on spec. designs)

S & A Actuators

Canister Purge Solenoid (CPS)

q Canister regeneration with a PWM solenoid q Linear fl ow curve, sonic nozzle fl ow controlq Fast response, light weight, compact sizeq Various mounting options availableq Direct manifold mount with NVH suppression feature

Technical Information

q Flow at 500 mm Hg 50 up to 85 SLPM

q Nominal operating voltage 14 VDC

q Coil resistance 17 Ohms

q Control circuit PWM

q Operating frequency 5 Hz up to 32 Hz

q Operating temperature – 40 up to +140°C

q Total leakage at 500 mm Hg < 20 SCCM

q Sonic regulated above 100 mm Hg

S&

A

64 65

Digital Linear Actuator for Idle Air Control Valve

Digital Linear Actuator for Idle Air Control Valve

q The idle air control system provides a consistent, stable idle speed throughout the service life of the vehicle (maintenance free).q The air fl ow characteristic is tuned to the appli- cation needs by changing the pintle profi le.q The actuator (DLA) can be integrated into air induction system

Technical Information

q Operating Voltage 12 V (7.5 V/14 V)

q Inductance per winding 38 mH

q Resistance per winding 48 Ohms

q Resolution 0.04167 mm/step

q Total travel 9.35 mm (224 steps)

q Operating temperature – 40 up to +150°C

q Weight 90 g

q Vibration 35 up to 40 G

q The idle air control system provides a consistent, stable idle speed throughout the service life of the vehicle (maintenance free).q The air fl ow characteristic is tuned to the appli- cation needs by changing the pintle profi le.q The actuator (DLA) can be integrated into air induction system

Technical Information

q Operating Voltage 12 V (7.5 V/14 V)

q Inductance per winding 33.5 mH

q Resistance per winding 53 Ohms

q Resolution 0.04167 mm/step

q Total travel 8.5 mm (204 steps)

q Operating temperature – 40 up to +125°C

q Weight 110 g

q Vibration 35 up to 40 G

S & A Actuators

S&

A

66 67

Electronic Throttle Control

q Non-contacting MR sensor not sensitive on environmental infl uences; can be used in close proximity e.g. to alternatorsq Version with plastic housing lighter and with better crash performance than aluminium

Technical Information

q Operating temperature range – 40 up to +125°C

q Storage temperature range – 40 up to +140°C

q Intake manifold air pressure Plastic housing 100 up to 2500 hPa (absolute) Aluminum housing 100 up to 3000 hPa (absolute)

q Typical response time ( t 90, room temperature) Plastic housing < 130 ms Aluminum housing < 90 ms

q Excess torque Plastic housing > 1.0 Nm Aluminum housing > 2.0 Nm

Exhaust By-pass Valve(EBV)

q Design options available to fi t customer requirementsq Easy integration into EGR coolerq Flexible housing designq Leakage to atmosphere < 0.5 kg/h at 3 barq Internal MR sensor for position accuracy within 2°q Max. DC motor current draw 6 A, running current 2 A typ.

Technical Information

q Operating ambient temperature range – 40 up to +140°C

q Exhaust gas temp. 600°C (short term 650°C)

q Actuator opening – design capability range 100 ms up to 1000 ms

q Mechanical closing – design capability range 100 ms up to 1000 ms

q Noise level < 60 dB

S & A Actuators

S&

A

68 69

Exhaust Control Valve(ECV-3)

Exhaust Control ValveLow Pressure

q Provides both accurate low fl ow precision (improves engine performance) and high volume fl ow (improves emission reduction) by maintaining low gas pressure dropq Contactless MR sensor, fl exible output, not sensitive against magnetic fi elds, well known control strategy q Compact, light weighted size and water cooled additional shaft bearing to withstand high pressure pulsation

Technical Information

q Torque at fl ap: 230 Ncm

q Response time (85%): < 80 ms

q Nominal supply voltage: 13.5 V

q Position sensor supply voltage: 5.0 V

q Maximum fl ow: up to 190 kg/h at 50 hPa

q Exhaust temperature: up to 700°C

q Provides both accurate low fl ow precision (improves engine performance) and high volume fl ow (improves emission reduction) by maintaining low gas pressure dropq Contactless MR Sensor, fl exible output, not sensitive against magnetic fi elds, well known control strategy q Compact, light weighted size and water cooled

Technical Information

q Nom. supply voltage: 13.5 VDC

q Position sensor supply voltage: 5.0 VDC

q Maximum fl ow: up to 350 kg/h at dp 50 hPa

q Valve seat leakage: max. 1,5 kg/h at dp 600 hPa

q Max. differential pressure over fl ap: 600 kPa

q Max. backpressure (p3): 900 kPa

q Exhaust gas temperature: max. 500°C, permanent 400°C

S & A Actuators

S&

A

70 71

Exhaust Throttle Valve

q Resistant to external aggression: stone projection, gravel, water splashes…q Resistant to corrosion using specifi c materials, i.e. fl ap housing off precision casting or welded stainless steel technologyq Existing serial proven actuator portfolio

Technical Information

q GPA technology used for actuation

q Nominal supply voltage: 13.5 VDC

q Position sensor supply voltage: 5.0 VDC

q Maximum fl ow: up to 420 kg/h at dp 50 hPa

q Response time – Valve opening: < 100 ms (from 0 % to 85 % of max. opening angle) – Valve closing: < 100 ms (from 0 % to 15 % of max. opening angle)

q Exhaust gas temperature: 800°C

General Purpose Actuator (GPA)

q Continuous position control of intake fl ap and turbo charger applicationsq More precise and independent from vacuum based systemsq Version with electronics easy to integrate in existing ECU

Technical Information

q Available as version with integrated electronics, or position control sensor

q Various motor sizes available

q Worm gear or spur gear

q Return spring for self return functionality

q Typical data for M-28 GPA at room temperature and 13.5 V: – Response time (for t90 and 90° travel) 130 ms – Stall torque 140 Ncm – Continuous output torque 55 Ncm

S & A Actuators

72 73

Linear Purge Valve (LPV)

q Canister regeneration with a linear proportional solenoidq Very low operating noise due to constant current inputq Fast response for incremental fl ow control at all operating conditionsq Excellent low end fl ow control to prevent unwanted surges of fuel vapor

Technical Information

q Typical fl ow 70 SLPM at 57 kPa

q Operating voltage 14.0 VDC

q Coil resistance 14.0 Ohms

q Maximum current 500 mA

q Control circuit Constant current at 150 up to 200 Hz

q Weight 200 g

S&

A

Mini Electric EGR(EEGR)

q Electric Actuation has faster response and more control than conventional vacuum systemsq Eliminates vacuum regulator and connecting hosesq Can be tailored to customer fl ow requirements

Technical Information

q Nominal operating voltage 13.5 VDC

q Current consumption at max fl ow 1.0 A at 20°C

q Max current consumption 1.5 A

q Nominal coil resistance 8.0 Ohms at 20°C

q Nominal operating frequency 90 Hz up to 175 Hz

q Position sensor supply voltage 5.0 VDC

q Response time (total stroke) < 50 ms (open to close or close to open)

S & A Actuators

74 75

Natural Vacuum LeakDetection (NVLD II)

Smart Air Control Valve(Smart ACV)

q With Integrated Electronic (NVLD II integrated)q Diagnostic performed after key offq Stand-alone or canister mounted versionsq Temperature sensing; Switch sensingq Timer function

Technical Information

q Vacuum sensing switch with – 2.5 ± 0.3 mbar calibration

q Damping feature to avoid noise

q Weight approx. 100 g

q Bit serial communication with ECU

q Average current consumption < 50 µA

q High In Use Monitor Performance Ratio (IUMPR > 100%)

q Improves EGR-function by increased and/or more exact EGR-ratio under all driving conditions. Helps to meet exhaust gas legal requirementsq Avoids typical diesel engine vibration during engine shut-off by closing the air channelq Easy to integrate into existing engine management system related to simple communication

Technical Information

q Integrated control unit with processor and H-bridge for DC motor on-board

q Aluminum housing and throttle plate

q Non-contacting position sensor

q Temperature range – 40 up to +125°C

q Response time (full stroke, RT) < 150 ms

S&

A

S & A Actuators

76 77

S&

A

Smart Coolant Pump(SCP)

Transmission Oil Pump(TOP)

q Precise engine temperature control through variation of coolant volume fl owq Operation independent from engine for fuel economy, comfort, and advanced propulsion applications

Technical Information

q Electronically commutated 12 V DC-motor

q Integrated electronics in thick fi lm technology

q Wet running permanent magnet rotor

q Volume fl ow 9000 l /h

q Differential pressure 800 hPa

q Hydraulic power 200 W

q Supply current at Pmax 32 A

q Coolant temperature range – 40 up to +128°C

q Continental as system supplier for all three components q E-Motor and electronics from one sourceq Already serial production history with integration of motor, pump, and electronics in one unit

Technical Information

q EC-Motor; commutation with or without sensor

q Electric power ~ 150 W up to 700 W

q Electronics ambient temperature capabilities up to 140°C

q Available pump types depending on requirements – Vane-type – G-Rotor

S & A Actuators

78 79

S&

A

Variable Valve Train Actuator

Variable Valve Train Actuator

q Continuous positioning of eccentric shaft to adjust valve liftq Closed loop control via separate position sensor and position control electronicsq Reliable and proved concept in serial production engines

Technical Information

q DC Motor M60

q Diameter 60.5 mm

q Length 91.0 mm

q Weight 998 g

q Max. DC motor power 355 W

q Stall torque 215 Ncm; current limited by the ECU

q Operating temperature range – 40 up to +140°C

q Continuous positioning of eccentric shaftq Adjusts valve liftq High dynamics (low inertia)q Closed loop control via integrated position sensorq EC-motor mounted in cylinder head (small package)

Technical Information

q EC motor M-42

q Diameter 42.6 mm

q Length 70.0 mm w/o connector

q Weight 567 g

q Max. EC motor power 480 W

q Stall torque 70 Ncm with current limited by the ECU

q Temperature range – 40 up to +140°C

S & A Actuators

Brushless DC Motor

80 81

S&

A

S & A Sensors

Door Handle Sensor

q Easy to integrate into the door handleq Low power consumption (<100 µA for double zone sensor)q Reduced false detection thanks to adaptation of environment conditions (rain, fog, snow...)

Technical Information

q Capacitive sensor for Keyless Entry System

q Detection distance 0 up to 40 mm

q Response time < 5 ms up to 30 ms

q Optional: – Capacitive switch for door locking – Mechanical switch for door locking – Movement sensor – LED for ground / pocket illumination – LF antenna integration

Fluid LevelOil Level Switch

q Low oil level detectionq Different connectors possibleq Simple on/off output

Technical Information

q Measuring principle: magnetic reed switch

q Different switch heights possible

q Normally on (switch closed)

q Tolerance: ± 1 mm

82 83

S & A Sensors

Fluid Level SensorActive Electrothermic

q Overfi ll and low level indication q Absolute measurement of oil level in static and dynamic conditionsq Replacement of oil dipstickq Stand-alone sensor with integrated electronics („active“)q Temperature measurement optional

Technical Information

q Measuring principle thermoresistive heated wire

q Measuring range 110 mm betw. min. & max.

q Accuracy ± 2 mm

q First measurement available 0.6 s after key-on

q Measuring interval > 5 sec

q Current consumption 200 ± 1 mA (pulse mode)

q Operating temperature – 40°C up to 160°C

q Temperature accuracy ± 3°C

Fluid Level SensorActive QLT

q Overfi ll and low level indication q Absolute measurement of oil level in static and dynamic conditions. Replacement of oil dipstickq Stand-alone sensor with integrated electronics („active“)q Oil quality information (permittivity)q Extension of the oil change intervals

Technical Information

q Measuring principle capacitive

q Measuring range 40 up to 120 mm

q Accuracy ± 2 mm

q First measurement available in 1.4 sec after key-on

q Measuring interval ~ 1 sec.

q Permittivity measuring range (quality): 1 up to 6 Typical value for engine oils 2 up to 3

q Temperature measuring range – 40 up to + 160°C

QLT =QualityLevelTemperature

84 85

S&

A

S & A Sensors

q Overfi ll and low level indication q Absolute measurement of oil level in static and dynamic conditionsq Replacement of oil dipstickq Stand-alone sensor with integrated electronics („active“)q Low power consumptionq Temperature measurement optional

Technical Information

q Measuring principle ultrasonic echo

q Measuring range 18 mm up to 163 mm

q Accuracy ± 2 mm

q First measurement available 0.3 sec after key-on

q Measuring interval ~ 1 sec.

q Operating temperature – 40 up to + 160°C – Level – 10 up to + 150°C – Temperature – 40 up to + 160°C

Fluid Level SensorActive Ultrasonic

Fluid Level SensorPassive Electrothermic

q Overfi ll and low level indication q Absolute measurement of oil level in static and dynamic conditionsq Replacement of oil dipstickq Different mounting positionsq Temperature measurement optional

Technical Information

q Measuring principle thermoresistive heated wire

q Measuring range 110 mm betw. min. & max.

q Accuracy approx. ± 3 mm

q First measurement available 0.6 s after key-on

q Measuring interval > 5 sec

q Current consumption max. ~200 ± 1 mA (pulse mode)

q Operating temperature – 40°C up to 160°C

q Temp. measurement optional with NTC (± 2°C)

86 87

S&

A

S & A Sensors

Fluid QualityFlex Fuel Sensor

q In-line sensor mounted between fuel tank and engineq Meets OBD II functional requirementsq Allows usage of saddle tanks on fl ex fuel vehiclesq Provides safe car operation (no engine stall )q Active temperature and conductivity compensationq Simple Compact design, proven, safe and reliableq Various connector interfaces available

Technical Information

q Measures Ethanol content of Ethanol /Gasoline mix

q Accuracy ± 5% on Ethanol

q Frequency output based on percent Ethanol – PWM output

q Operating temperature – 40°C up to +125°C

q Supply voltage 9 up to 18 V

q Maximum fl ow 400 l /h (80 g/s)

In CylinderPressure Sensors

1 Glow Plug Pressure Sensor2 Stand Alone Pressure Sensor

q Easy to integrate q Allows closed-loop combustion control q Reduces emissions q Increases engine powerq Reduces fuel consumptionq Simple and robust solution

Technical Information

q Cylinder pressure measurement during compression and combustion stroke accuracy: 3.5%

q Integrated in the glow plug or stand-alone sensor

q Active sensor

q Small size sensor: M8 thread

1

2

88 89

S&

A

S & A Sensors

Knock Sensor –New Design

q High sensitivityq Compact design, nested bolt possibleq Increases engine powerq Decreases fuel consumption

Technical Information

q Acceleration sensor based on piezo ceramic technology with a range of: 0 up to 400 g

q Frequency range: 3 up to 25 kHz

q Possible integration of discharge resistor

q Integrated connector or cable version

Mass Airfl ow Sensor

q High fl ow measurement accuracy and exceptional signal stabilityq Integral protection against water and contaminationq Customer specifi c programmable output characteristicq Excellent performance with intake airfl ow pulsationq Low power consumption and fast start-up timeq Flow range adaptable for secondary airfl ow (SAF) and fuel cell applications

Technical Information

q Sensing technology Hot-fi lm bi-directional MEMS

q Flow range 5 up to 800 kg/h (62 mm tube)

q New-part tolerance 1.5%

q Supply voltage 5 ± 0.5 V

q Supply current 10 mA maximum

q Output signal Frequency or SENT digital

q Integrated intake air temperature sensor optional

1 In-Tube MAF Sensor2 Plug-In MAF Sensor

21

Position Sensor – Clutch Master Cylinder

90 91

q Some mechanical interface for either dual switch or linear position sensor confi guration q Small sensor package to fi t in small environment q Best cost magnetic system (sensor + magnet)

Technical Information

q Non contacting technology

q 23 to 36 mm range

q Dual switch (start of course, end of course) confi guration (± 1 mm accuracy) or linear position sensor confi guration (± 3% accuracy with possibility to reach ± 1.5% with on clutch calibration)

q Accuracy of 3% for linear position, ± 1 mm for switch

q Temperature – 40°C up to – 150°C

q Magnet integrated in piston

S&

A

S & A Sensors

Position Sensor – Contactless Angular

q Contactless sensors, no wear q High performance and best cost q Possible re-calibration to compensate for mechanical tolerances

Technical Information

q Magnetic technology

q Measurement range up to 360°C

q Temperature range – 40 up to 150°C

q Analog, PWM or digital output

q Through-wall (aluminum, plastic) possible measurement

q Compensated for airgap and temperature variations

q Stand alone sensor, can include the magnet target

92 93

S&

A

S & A Sensors

Position Sensor –Fork Linear

q Measures the fork position to enable fork actuation in Dual Clutch Transmission, Automatic Transmission or Step Automated Transmissionq Automatic Transmission Fluid compatible designq Mechanical interface compatible with transmission modules q Robust and proven magnetic design

Technical Information

q Hall effect technology

q Operation temperature – 40°C up to 150°C

q Supply voltage 4.5 V up to 5.5 V

q Measurement range 23 mm

q Airgap 4.5 mm

q Ratiometric output

Position Sensor –Linear Contactless

q Contactless sensor, no wear q High performance and best cost q Compact design, easily integrated q Possible re-calibration to allow better tolerances on the mechanics

Technical Information

q Magnetic technology

q Measurement range from 10 mm up to 55 mm

q Temperature range – 40°C up to 150°C

q Analog, PWM or digital output

q Through-wall (aluminum, plastic) possible measurement

q Compensated for airgap and temperature variations

q Stand alone sensor, can include the magnet target

94 95

q No magnet used: no iron particles pollutionq Insensitive to low frequency magnetic fi eldsq Best cost sensor system (sensor and target)

Technical Information

q Inductive technology the target is a metallic plate

q Measuring range linear: 10 mm up to 60 mm rotary: 0° up to 180°

q Signal output analog, PWM

q Temperature range – 40°C up to 160°C

q Supply voltage 5 V

S&

A

S & A Sensors

Position Sensor –Neutral Position

Position Sensor –Park, no Park

q Detects that gear lever is in neutral position to enable Stop & Start function with manual gearboxq Allows Stop & Start function on manual gearbox to reduce fuel consumption up to 10% q Robust and proven magnetic design

Technical Information

q Magnetic technology

q Operation temperature – 40°C up to 150°C

q Airgap up to 1.5 mm

q Insensitive to gearbox metallic debris up to 2 gr

Position Sensor – Rotary Covers

96 97

S&

A

Air Control Valve Application

q Fully integrated MR sensor in the coverq High temperatureq High accuracyq Ageing stability (MR technology)q Low cost design

Technical Information

q Angular range 180°

q Linearity ± 0.6% Vdd

q Hysteresis ± 0.15% Vdd

q Power supply 5 V

q Power consumption < 10 mA

q Magnet fi eld requirement 50 mT

q Temperature range – 40 up to 160°C

S & A Sensors

Position Sensor –Variable Valve Train

q Sensor assembly inclusive magnet wheelq Easy to install q Insensitive to air gap variation q Insensitive to magnet temperature coeffi cientq Analog and digital interfaceq Calibration possibleq Very robust to parasitic magnetic fi eld

Technical Information

q Non-Contacting Rotary Position Sensor

q Accuracy ± 1%

q High resolution 0.022°

q Programmable measuring range 0 up to 180°

q Temperature range up to 160°C

q Based on MR technology

Pressure Sensor –Brake Pressure

98 99

q Direct measurement of pressure and temperatureq Flexible calibration of transfer functionsq Precision programmable clip levelsq Internal and output diagnostic capabilityq Large measurement rangeq High accuracy and temperature stabilityq Excellent dynamic response

Technical Information

q Pressure Range 0 to 250 bar

q Pressure Accuracy

q Offset 2.5% full scale

q Span 0.7 up to 2.2% full scale

q Temperature Range – 40°C up to +125°C

q Temperature Accuracy 10°C

q Supply Voltage (Vs) 5.00 ± 0.5 VDC

S&

A

S & A Sensors

Position Sensor –360° Angle Contactless

q Contactless rotary sensor for transmission application with programmable Hall effect technologyq Full 360° rotationq Environmentally and electrically robust designq Electrical performance stable over temperatureq Locking clip fi xes rotor position for installation

Technical Information

q Rotational Range 360°

q Total Error ± 1.5° (over 360°), ± 1.0° over 40°

q Signal Output PWM, analog, digital (open collector output)

q Temperature Range – 40 up to 150°C

q Supply Voltage 4.5 up to 18 V

Pressure Sensor –Diesel Particle Filter

Pressure Sensor – Differ-ential Manifold Vacuum

100 101

q Direct measurement of pressureq Flexible calibration of transfer functionsq Precision programmable clip levelsq Internal and output diagnostic capabilityq High accuracy and temperature stabilityq Excellent dynamic responseq Fulfi lls toughest EMC requirementsq Flexible housing, connector, and mounting designs

Technical Information

q Pressure Range 0 up to 125 kPa

q Accuracy 1% full scale (10 up to 85°C)

q Temperature Range – 40°C up to +140°C

q Supply Voltage (Vs) 5.00 ± 0.5 VDC

q Supply Current at 5 V 10 mA maximum

q Load Resistance > 4.7 kΩ

q Response Time < 2 ms

q Direct measurement of pressureq Flexible calibration of transfer functionsq Precision programmable clip levelsq Internal and output diagnostic capabilityq High accuracy and temperature stabilityq Excellent dynamic responseq Fulfi lls toughest EMC requirementsq Flexible housing, connector, and mounting designs

Technical Information

q Pressure Range –105 up to 40 kPa (gauge)

q Accuracy 1% full scale (10 up to 85°C)

q Temperature Range – 40°C up to +140°C

q Supply Voltage (Vs) 5.00 ± 0.5 VDC

q Supply Current at 5 V 10 mA maximum

q Load Resistance > 4.7 kΩ

S&

A

S & A Sensors

Pressure Sensor –Fuel High Pressure

102 103

q Direct measurement of pressureq Flexible calibration of transfer functionsq Precision programmable clip levelsq Internal and output diagnostic capabilityq Large measurement rangeq High accuracy and temperature stabilityq Fulfi lls toughest EMC requirementsq Flexible housing, connector, and mounting designs

Technical Information

q Pressure Range 0 up to 2200 bar

q Accuracy 1% full scale (10 up to 85°C)

q Temperature Range – 40°C up to +140°C

q Supply Voltage (Vs) 5.00 ± 0.5 VDC

q Supply Current at 5 V 10 mA maximum

q Load Resistance > 4.7 kΩ

q Response Time < 1 ms

S&

A

S & A Sensors

Pressure Sensor – Mani-fold Absolute Family

MAP · T-MAP · BAP · BPS · EVAPO...

q High pressure signal accuracy over life timeq Low cost design and high quality q Customer specifi c output characteristics by electrical calibrationq Modular mechanical concept allows high mounting fl exibility

Technical Information

q Adjustable characteristic via electronic calibration

q Pressure range 0,1 up to 1 bar (MAP, BAP) 0,2 up to 3 bar (Turbo MAP)

q Temperature range – 40 up to 125°C (storage: 135°C)

q Supply voltage 5 V ± 0.5 V

q Transfer function linear to applied pressure, ratiometric, adjustable

Pressure Sensor –Truck Application MAP

104 105

Truck Applications

q High pressure signal accuracy over life timeq Low cost design and high quality q Customer specifi c output characteristics by electrical calibrationq Modular mechanical concept allows high mounting fl exibility

Technical Information

q Adjustable characteristic via electronic calibration

q Pressure range up to 5,2 bar absolute

q Operating temperature – 40 up to 125°C

q Supply voltage 5 V ± 0.25 V

q Transfer function linear, ratiometric

q Accuracy over full-scale 1% full span (10 up to 85°C)

S&

A

S & A Sensors

Pressure Sensor –Relative

Tank Leakage Control & Air Filter Diagnosis

q High pressure signal accuracy over life timeq Low cost design and high quality q Customer specifi c output characteristics by electrical calibrationq Modular mechanical concept allows high mounting fl exibility

Technical Information

q Adjustable characteristic via electronic calibration

q Pressure range 0 up to 100 mbar diff.

q Operating temperature – 40 up to 125°C

q Supply voltage 5 V ± 0.25 V

q Transfer function linear, ratiometric

q Accuracy over full-scale 3% full span (10 up to 85°C)

Pressure Switches

106 107

S&

A

q Various designs availableq Stable over life-time

Technical Information

q Switching points 0.1 up to 100 bar

q Burst pressure < 150 bar

q Switch characteristics Normally open and closed

q Applications Oil, air and brake pressure

S & A Sensors

Smart NOx Sensor

Modular »Stand-Alone« NOx Sensorq Standardized electronic interface with CAN-Busq Independent of catalyst supplier, ECU supplier and engine management systemq All Electronics including heater control and drivers integrated in the sensorq Self diagnosis capability regarding shortcut and open wireCalibrated High Accuracy Smart NOx Sensor

Technical Information

q Measuring principle ZrO2-based multilayer sensor with integrated heater and 3 oxygen pumps

q Triple output signal NOx, binary λ, linear λ or O2-conc.

q Supply voltage 12 V or 24 V

q Data link CAN 2.0 or SAE-J-1939

q Operating gas temperature: 100 up to 800°C

Temperature Sensor –Cylinder Head

108 109

q Short response timeq High accuracyq Stainless steel designq Robustnessq Certifi ed quality

Technical Information

q Temperature Measurement of cylinder head and other solid media

q Different NTC curves possible

q Cylinder-head temperature: – 40 up to 230°C

S&

A

S & A Sensors

Temperature Sensor –Coolant /Fuel /Oil

q Clip or screw-in designq Wide range of applicationsq High accuracyq Short response timeq Long-term stabilityq Certifi ed qualityq High worldwide volume productionq Plastic variant available for each type

Technical Information

q Oil, water, fuel, temperature measurement – Engine coolant – 40 up to 150°C – Engine oil – 40 up to 150°C – Fuel – 40 up to 140°C

Temperature Sensor –Intake Air

Temperature Sensor –High Temperature

110 111

q Clip, screw design or twist lock designq Wide range of applicationsq High resolutionq Short response timeq Long-term stabilityq Certifi ed qualityq High worldwide volume production

Technical Information

q Intake air temperature measurement

q Intake air temperature: – 40 up to 150°C

S&

A

S & A Sensors

q Active sensor for the comparable price as an passive q High accuracy (ECU will get the data digital, no further corruption of the signal at acquisition)q Price benefi t for costumer at ECU-system (no ADC, no precise pull-up)q One design for various application: catalyst monitoring, turbocharger monitoring, DPF, EGR, Selective Catalytic Reduction

Technical Information

q Temperature monitoring of exhaust gas temperatures in vehicles

q Response time: up to 7 s (10 m/s gas fl ow)

q Temperature range: – 40°C up to 1100°C

q Accuracy low temp. (< 500°C): ± 2°C + 0,75% FSO

q Accuracy high temp. (> 500°C): ± 7,5°C

q Supply voltage: 5 V DC (12 V DC, 24 V DC option)

Temperature Sensor –Outside Air

Temperature Sensor –Intake Air (High EGR)

112 113

q Snap-in designq High accuracyq Short response timeq Long-term stabilityq Certifi ed qualityq High worldwide volume production

Technical Information

q Outside air temperature measurement

q Outside air temperature: – 40 up to 120°C

q Slash-proof plastic housing

q Different NTC curves possible

S&

A

q Measures intake air with high EGR ratesq Clip or screw designq Very robustq Wide range of applicationsq Short response timeq Certifi ed qualityq No chemical and soot impact on NTC

Technical Information

q Overpressure up to 4 bar

q Response time T63,2 < 7 s (5 m/s air fl ow)

S & A Sensors

114 115

FS

Fuel SupplyFS

Fuel Supply – FS

116 117

Modular Fuel Supply Unit

EC Fuel PumpG50D/EC

q Various customer specifi c designs possible based on modular conceptq Flange geometry can be adapted to customer requirementsq Integrated tank managementq Variants: constant fl ow or fl ow controlled

Technical Information

q Different fuel pumps (Ø 38 mm/43 mm) with EC (electronically commutated) or DC (direct current) motor

q Integrated “lifetime” fuel fi lter

q Integrated pressure regulator

q MAPPS (MAgnetic Passive Position Sensor) fuel level sensor

q In-tank fuel pump with electronically commutated (EC) motorq Twin channel turbine pump principleq Emission reduction

Technical Information

q Performance data at 12 V:

– Pressure, KPa 400/600

– Flow, l /h typ. 325/250

– Current, A typ. 11.3/13.8

q Media Premium, regular, leaded, unleaded, tropical, Flex Fuel

q Weight 385 g

q Volume 175 cm3

FS

Fuel Supply – FS

M #

# P

[ P..]

f[ f

..] /

C

/C stan

ds

for

the

pum

p m

oto

rre

sp. t

he p

ump

com

mut

atio

n

/Cu

= C

op

per

Co

mm

utat

or

/Cu

= C

arb

on

Co

mm

utat

or

/EC

= E

lect

roni

cC

om

mut

ato

r(b

rush

less

)

f stan

ds

for

spec

ial f

eatu

res

(one

“f”

fo

r ea

chsp

ecia

l fea

ture

)

P stan

ds

for

the

pum

p p

rinc

iple

(one

“P

” fo

r ea

chp

ump

sta

ge,

mai

nst

age

on

first

po

sitio

n)

## stan

ds

for

the

dia

met

er

M stan

ds

for

the

med

ia

28

mm

38

mm

43

mm

50

mm

Gas

olin

e

Die

sel

LP

G

Tro

pic

al

Fle

x F

uel

Bio

Die

sel

Ger

oto

r

Tur

bin

e

Do

uble

tur

bin

e

pla

stic

pum

pst

age

sho

rt f

uel

pum

p

118 119

Code Description forNames of Fuel Pumps

Modular Fuel Level Sensor with MAPPS

q Redundant contactsq Best EMC because of passive systemq Longer life time (> 10 million cycles) because of wear-resistant measurement systemq Hermetically sealed contacts assure perfect pro- tection against contamination of all types of fuel

Technical Information

q Measuring range Angle up to 86°

q Operating current 1 up to 20 mA

q Resolution 1.7° =~ 2%

q Max. total error of resistor ± 1%

q Interface 2-wire resistance signal, 50 up to 1000 Ω linear voltage at ADC

q Operating temperature – 40°C up to + 125°C

q Dynamic strength 200 m/s² (0 Hz...1 kHz)

MAPPS (MAgnetic Passive Position Sensor)

FS

Fuel Supply – FS

120 121

Fuel Supply Electronics Modular FunctionCarrier (MFC)

q Enhanced fuel pump lifetime in comparison to systems without demand controlq Reduced consumptionq Noise and emission reduction

Technical Information

q Integrated in the fl ange of the fuel supply unit or stand-alone

q Enables an EC (electronically commutated) or DC (direct current) fuel pump to provide only the amount of fuel to the engine which is currently demanded

q Processing of fuel level sensor signals (optional)

q Integrated theft protection (optional)

q Suitable for almost all tank designsq Integrated carbon canister (optional)q Reduction of permeation

Technical Information

q Operating ventilation

q Refueling ventilation (optional)

q Roll over function

q Retaining vapor with integrated carbon canister (optional) F

S

Fuel Supply – FS

122 123

CC

CatalyticConvertersCC

Catalytic Converters – CC

METALIT® (3-Way-Cat) NOX-Adsorber

124 125

NOX-adsorption catalysts: Technology for lean-mixture Otto-DI and Diesel engines

Technical Information

q Capacity and regeneration are important for overall effi ciency and fuel economy

q High cell densities help to improve mass transfer and therefore conversion effi ciency

q Enhanced functionality due to included NOX Sensor

q Additional storage volume after the sensor increases safety margin

Leading metallic substrate technology

Technical Information

q Low heat capacity for quick light-off

q Foil thicknesses from 20 up to 110 µm

q Structured foils for enhanced effi ciency are possible

q Cell densities 50 up to 1600 cpsi

CC

Catalytic Converters – CC

Pre Turbo METALITTM Compact Cat ®

126 127

Excellent Cold Start Performance

Technical Information

q Use of higher exhaust gas temperature

q Increases HC/CO effi ciency (turbulent fl ow)

q Reduces the needed Diesel Oxidation Catalyst volume

q Signifi cant system cost reduction possible (Preturbo Catalyst + Diesel Oxidation Catalyst)

Compact design for close coupled applications with optimized heat management

Technical Information

q Compact design for close coupled applications especially for Diesel applications

q Mounted directly to the turbocharger for fast light-OFF

q High effi ciency due to optimized heat management

q Potential for cost savings by volume reduction

CC

Catalytic Converters – CC

PM-METALIT® SCRi®-System

128 129

Partial – fl ow deep bed fi lter for ultrafi ne particulate matter

Technical Information

q Particulates are deviated in the shovel and deposed in the fl eece layer

q In conjunction with NO2 from the oxidation catalyst continuous particle reduction

q Side-fl ow system guarantees discruption-free engine operation through deep-bed fi ltration

q EU 4/5 without urea

Catalyst system with integrated particle reduction and turbulent substrates

Technical Information

q Future fi lter strategies have to be adapted to changing particulate sizes

q Continuously working particle system without regeneration

q Above-average elimination in smallest particles

q High performance reduction catalyst turbulence generating LS/PE-Design with optimized coating allows volume reduction

CC

LS- & PE-DesignTM PM-METALIT®

Urea

PM-METALIT®Oxicat SCR-Cat

LS-Design®

Catalytic Converters – CC

LS-Design® PE-DesignTM

130 131

Turbulent Catalyst

Technical Information

Longitudinal Structure Design

q Reduction of material /weight

q Improvement of cold start performance

q Increased mass transfer

q Catalyst effi ciency

Turbulent Catalyst

Technical Information

Perforated Metal Foil Design

q Lower backpressure

q Faster light off

q Improved turbulent mass transfer

CC

Catalytic Converters – CC

The information provided in this brochure con-tains only general descriptions or performance characteristics, which do not always apply as described in case of actual use or which may change as a result of further development of the products. This information is merely a technical description of the product. This information is not meant or intended to be a special guarantee for a particular quality or particular durability. An obligation to provide the respective characte-ristics shall only exist if expressly agreed in the terms of contract. We reserve the right to make changes in availability as well as technical chan-ges without prior notice.

© Continental Automotive GmbHPri

nted

in G

erm

any

· 04

/20

09

· E

N ·

2.0

k

Continental Automotive GmbHSiemensstrasse 12 93055 Regensburg GermanyPhone +49 941 790-0Fax +49 941 790-14www.continental-corporation.com