Poultryinternational201011 dl

-

Upload

mohsen-albashbeeshi -

Category

Entertainment & Humor

-

view

256 -

download

0

description

Transcript of Poultryinternational201011 dl

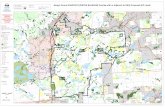

www.WATTAgNet.com November 2010

Digital version at www.poultryinternational-digital.com

Expansion of Asian egg production

remarkable and dynamic

Digital version at www.poultryinternational-digital.comDigital version at www.poultryinternational-digital.comDigital version at www.poultryinternational-digital.comDownload fre

e Poultry

International iP

hone, iPad

Apps from iTunes.

Download free Poultr

y

International iP

hone, iPad

Plus:Campylobacter, welfare under spotlight at European Poultry Conference

Compartmentalization in the poultry industry

Enriching the free range and reducing feather pecking

1011PIcov_1_C2201R14544.BK.indd 35 10/14/2010 11:01:48 AM

1011PIads_1_C2201R14551.BK.indd 36 10/14/2010 11:02:21 AM

November 2010 | www.WATTAgNet.com

11www.WATTAgNet.com NOVEMBER 2010Volume 49 Number 11

8 Expansion of Asian egg production remarkable and dynamicWhile Asian egg production has had its di� culties over the last two decades, its performance has been dynamic and its expansion remarkable.

12 Campylobacter, welfare under spotlight at European Poultry ConferenceDelegates hear how, despite progress in welfare and disease issues, more work still needs to be done.

16 Compartmentalization in the poultry industryHow compartmentalization works and what it could mean for the industry.

18 Enriching the free range and reducing feather peckingStudies by Australia’s Poultry CRC have looked at whether encouraging birds into the range leads to less feather pecking.

22 Second-processing tackles labor and yieldSaving labor and capturing yield are driving investment in poultry second-stage processing, while processors seek to add value and exploit real-time data.

Features

Departments

2 Web Site News

4 Editor’s Comment

6 Around the World

26 Products

31 Marketplace

32 Advertisers’ Index

November 2010 | www.WATTAgNet.com

1

1011PItoc_1_C2201R14545.BK.indd 1 10/14/2010 3:12:17 PM

www.WATTAgNet.com | November 2010

More information and exclusive Web-only articles from Poultry International are just a mouse-click away

www.WATTAgNet.com

WATTAgNet Exclusives

Social Media

Community

WATT AgNet.comCorporate Headquarters

303 N. Main St. Ste. 500, Rockford, Illinois 61101-1018 USATel: +1 815 966 5400; Fax: +1 815 968 0941

Publisher, International: Greg Watt, [email protected]: +1 815 966 5517; Fax: +1 815 968 0941

Publisher, N. America: Steve Akins, [email protected]: +1 919 387 7961; Fax: +1 815 968 0941

VP/Director of Content: Bruce Plantz, [email protected]

Editorial Of� ceEditor: Mark Clements, [email protected]

Tel: +44 7866 475 388Managing Editor: Kathleen McLaughlin, [email protected]

Tel: +1 815 966 5423Content Director - Agri business: Gary � ornton, [email protected]

Consulting Editor: Peter Best, [email protected] Desk Team

Managing Content Editor: Ken JennisonCommunity Manager/SEO Editor: Kathleen McLaughlin

Senior Content Editor: Tara LeitnerAssociate Editors: Lindsay Beaton, Kayla Kling, Andrea Saladino

Art/Production TeamSenior Art Director: Elizabeth Crosby

Production Manager: Jim Riedl, [email protected]: +1 815 966 5426

Advertising Production Coordinator: Connie Miller

Sales TeamEurope, Asia, Africa

Frans Willem van Beemen, [email protected] Tel: +31 344 653 442; Fax:+31 344 653 261

Michael van den Dries, [email protected] Tel: +31 79 323 0782; Fax: +31 79 323 0783

Latin America, Classi� ed Sales and Digital ProductsTineke van Spanje, [email protected]: +31 495 526 155; Fax: +31 495 525 126

Southeast AsiaDingding Li, [email protected]; Tel: +86 21 54136853

IsraelPhilip Staal, [email protected]

Tel: +972 4 6270381; Fax: +972 4 6270382USA/Canada

Sue Snyder - Southern USA, [email protected]: +1 815 966 5523; Fax: +1 815 968 0941

Pam Ballard - Midwest, Western USA & Canada, [email protected]; Tel: +1 815 966 5576; Fax: +1 815 968 0941

USA Classi� ed SalesGinny Stadel, [email protected]

Tel: +1 815 966 5591, Fax: +1 815 968 0941

For article reprints and reprint quotes contact: FosteReprints+1.866.879.9144 www.fosterprinting.com

Video: Fibers off er clean labels in further processed poultryDr. Shelly McKee talks about the use of fibers as phosphate replacers to achieve clean labels in further processed poultry.www.WATTAgNet.com/17813.html

www.WATTAgNet.com | November 2010

WATT Poultry TVwww.youtube.com/user/WattPoultryTV

Daily Tweetswww.twitter.com/wattpoultry

Connect to ushttp://companies.to/wattagnet/

www.facebook.com/AnimalAgNet

See AnimalAgNet on your smart phonewww.animalagnet.com/profiles/blogs/see-animalagnet-on-your

AnimalAgNet.com

Subscriptions: www.WATTAgNet.com or contact customer service at +1.800.869.6882 or +1.763.746.2792. Business and occupation information must accompany each subscription order. Change of address: Give both old and new address when reporting change of address to [email protected] or fax to +1.866.658.6156© Copyright 2010 WATT Publishing Co. All rights reserved.

POULTRY INTERNATIONAL (ISSN 0032-5767) is published monthly by WATT, 303 N Main St Ste 500 Rockford, IL, 61101 USA. All rights reserved. Reproduction in whole or in part without written permission from the publisher is strictly prohibited. Poultry International and its logos are registered trademarks of WATT Publishing Co.

POSTMASTER: Please send change of address to KMPS, 15301 Highway 55, Suite #3A, Plymouth, MN 55447 Periodicals postage paid at Rockford, IL, USA and additional mailing o� ces. Canada Post International Publication Mail Product 1686224.

2

Go mobile with us

One-touch access to the latest issue of Poultry International?

There’s an app for that.Poultry International now available on the iPhone and iPad.Get the app now. Search Poultry on iTunes.

http://itunes.apple.com/us/app/poultry-international/id395749661?mt=8

1011PItoc_2_C2201R14545.BK.indd 2 10/14/2010 3:12:36 PM

www.WATTAgNet.com | November 2010

4

Turkey genome news is timely celebrationWith turkey consumption reaching its peak over the coming weeks in many markets, the announcement that an international consortium of researchers has completed the majority of the genome sequence of the domestic turkey is particularly timely.

For the turkey industry, the achievement opens up the possibility of improved meat quality, better disease control and reduced cost.

In 2008, the consortium set out to map the genetic blueprint for the domesticated turkey. Turkey is only the fourth-most popular meat in the U.S., yet the country is predicted to consume almost 2.4 million metric tons this year. EU consumption is expected to be in the region of 1.8 million metric tons.

Assistant Professor of Animal and Poultry Sciences at Virginia Tech’s College of Agriculture and Life Sciences (which contributed to the initiative) Rami Dalloul commented: “In the short term, the genome sequence will provide

scientists with knowledge of specific genes that are important in meat yield and quality, health and disease resistance, fertility and reproduction. For example, we don’t always know the mechanism for how post-pathogen interactions work. The genome sequence will allow us to better understand this process, which will in turn give us a better understanding of disease prevention and treatment.”

Additionally, the sequence should have long-term benefits for turkey producers. They may be able to use this new knowledge to grow turkeys more quickly and more healthily. Should they be able to produce the same-sized bird in a shorter period of time, they would also be able to reduce costs.

An improved understanding of genetic variation in the species and in breeding populations would also lead to the development of new tools that producers could use to breed turkeys that have desirable texture, flavor and leanness.

The genome sequence may also have applications in the biomedical field. Ed Smith, professor of animal and poultry sciences at Viginia Tech, is investigating an avian condition similar to dilated cardiomyopathy in humans, while other consortium members are studying the effects that aflatoxins have on turkeys.

Some 93% of the turkey’s genome had been sequenced at the time of the announcement. How the remainder will be sequenced has yet to be decided, but the work provides food for thought as we approach the turkey season. □

Editor’s Comment Mark Clements

The Wellcome Trust Sanger Institute is a charitably funded genomic research center located in Hinxton, near Cambridge, UK. Focused on health and disease, it aims to produce results that can be translated into diagnostics, treatments or therapies that reduce global health burdens.

Founded in 1993, the institute has participated in some of the important advances in genomic research, developing new understanding of genomes and their role in biology.

Its research builds understanding of gene function in health and disease as well as creating resources of lasting value to biomedical research.

As one of the largest sequencing centers in the world, for more than 15 years the Wellcome Trust Sanger Institute has produced more than 100 finished genomes, all of which can be downloaded from its web page.

Employing some 800 staff, more than 90% of its research is carried out in collaboration with other organizations.

The institute played a major part in finding the genes and other functionally important features of the zebra finch genome and was also responsible for sequencing the genome of Campylobacter jejuni.

For more information, go to: www.sanger.ac.uk □

EDITOR’S FOCUS

The Wellcome Trust Sanger Institute

Knowledge of specific

genes that are

important in meat

yield and quality

1011PIedit_1_C2201R14467.BK.indd 4 10/14/2010 10:44:31 AM

take a seat,2012Dino PozzatoSKA Managing Director

SKA srl via Agosta, 3 - Sandrigo (VI) Italy - Tel. + 39 0444 659700 www.ska.it

new EU regulations

55 yearsof experience

ready for your future

Shift from the old cages to the new systems as per EU regulations

is here

1011PIedit_2_C2201R14467.BK.indd 5 10/14/2010 10:44:22 AM

www.WATTAgNet.com | November 2010

6

Around the World

Reports suggest some caged EU hens will remain Jan. 2012Recent reports suggest up to a third of EU hens will still be in cages at the Jan. 1, 2012, deadline for transition to colony housing or floor systems.

Providing non-compliant producers with an extension could be considered unfair to those who have made investments and would possibly operate at a financial disadvantage. Banning the sale of cage-derived eggs would represent hardship for consumers who would be obliged to pay more for eggs due to reduced supply. Even if eggs were imported to supply demand, in all probability, product would be derived from caged-housed hens, which would be inconsistent with the intended improvement in welfare.

Vets ask companies to rethink all-Halal menusFollowing a recent news investigation into the widespread use of meat and meat products from animals not stunned before slaughter, the British Veterinary Association (BVA) is writing to the companies involved to express its concern that the use of this meat in the wider food chain may lead to an increase in the number of animals slaughtered without stunning.

The BVA has also renewed its call for clearer food labeling so that consumers are aware when they buy meat or meat products how the animals were slaughtered.

The report found that meat slaughtered under certain religious rules without pre-

✸ Jansen Poultry Equipment has appointed Joos Decock as new area manager for Asia. Decock will be responsible for Jansen’s

markets in all Asian countries.

✸ Aviagen has expanded its global veterinary technical team with Dr. Roberto Soares. He will provide poultry health and management advice to customers in North and Latin America, as well as work with the global team focused on poultry health research efforts.

APPOINTMENTS

Keep up to date with industry news at www.WATTAgNet.com.

You don’t need an iPhone to access digital issues of Poultry International — all you need is a smart phone with a Web browser.

Go to your smart phone’s Web browser and type www.poultryinternational-digital.com, which will take you to Poultry International’s mobile Web reader.

From there, you can access back issues, search for keywords in an issue and see a complete Table of Contents.

Poultry International’s mobile Web reader toolbar (at the top of the page) is a powerful navigation tool.Home: On the far left, the home icon takes you back to the issue and a listing of articles.

Search: To search an issue for a keyword type it into the search box at the top of the page and tap the icon. Search results feature a thumbnail of each page your keyword appears and are highlighted in yellow.

Navigation: The top arrows navigate search results from page to page and the window pane on the far left lets you view an entire issue in thumbnail form.

Read: You can read full text articles by tapping on a headline in the Table of Contents. Links in the text version are live and will open a new browser window.

Once you’re in an article make sure to take advantage of more features in our Web reader’s tool bar.

The upturned page takes you to the actual page in the magazine. The T inside a square takes you back to the text-only version. To click on a link in this view, go to the globe icon with an arrow. From that page, you can access links featured in the issue.

Share: In the text version or the magazine version of an article, the icon of a person with an arrow is a quick way to e-mail an article or share with a colleague.

Read Poultry International on any smart phone

VIV China took place in Beijing in early September, at the New China International Exhibition Center. With a technical program and commercial exhibition, the event’s organizers note that this year attracted a particularly high volume of visitors from overseas.

Some 370 exhibitors took part in the

event and, while mainly from China, the exhibition halls attracted companies from at least 67 countries.

Doing business in China is different than in many other countries, and WATT has made a number of videos available to offer insight across the poultry, pig and feed industries. To watch the videos, go to www.wattagnet.com/MediaList.aspx

Doing business at VIV China

The New China International Exhibition Center, home to VIV China.

1011PInews_1_C2201R14552.BK.indd 6 10/14/2010 10:45:29 AM

November 2010 | www.WATTAgNet.com

7

stunning (including kosher and some halal meat), is entering the mainstream food chain without being labeled as such.

The BVA supports moves by the European Parliament to introduce mandatory labeling of meat from non-stunned animals, including use of the meat in other products. The BVA also supports the concept of an EU-wide label to indicate higher welfare throughout the food chain.

Russia to halt poultry meat imports by 2013Russia is looking to stop poultry imports by 2013, and says it may beat that goal, according to reports.

The country has been developing domestic poultry breeding to cut its dependency on imports. The recently lifted ban on American poultry imports, which lasted more than six months, served as an

unexpected test. “Imports from the start of the year to July 1 were some 150,000 tons,” said Russian meat producer Cherkizovo’s CEO Sergei Mikhailov. “We survived and can make a preliminary conclusion that maybe imports are not necessary.”

✸ January 26: 2011 International Poultry and International Feed Expo, Georgia World Congress Center, Atlanta, GA, www.ipe11.org

EVENTS

Get more industry events at www.WATTAgNet.com

January 2011S M T W T F S

1

2 3 4 5 6 7 8

9 10 11 12 13 14 15

16 17 18 19 20 21 2223/30

24/31 25 26 27 28 29

Naturally ahead

Trials and more information you will find at:

www.pep.biomin.net

Biomin® P.E.P. is made with a unique blend of essential oils and prebiotics to provide a synergistic formula. It is designed specifically to support digestion and improve feed conversion.

up to 5% improved feed efficiency!

Singapore destroys contaminated eggs: The Singapore Agri-Food and Veterinary Authority has destroyed eggs valued at approximately $700,000 as a result of alleged antibody residues.

China’s domestic egg prices soar: China’s domestic egg prices have been rising since June. A full one-third of the country is experiencing egg retail prices

over RMB10 (US$1.49) per kilogram. While prices may drop slightly after the holidays, breeding and feed costs are expected to remain high, influencing egg numbers.

Marfrig reports £18.3 million profit: Marfrig has reported a profit of £18.3 million, just 12 months after reporting a very different £38 million loss. The company increased its sales by almost 6%, from £737.7 million in 2008 to £780.6 million in 2009.

SNIPPETS

1011PInews_2_C2201R14552.BK.indd 7 10/14/2010 10:45:17 AM

www.WATTAgNet.com | November 2010

8

Expansion of Asian egg production remarkable and dynamic

The dynamics in Asian egg production over the past two decades have been remarkable. The reason for this has been not only the rapid production increase in China, but also changes in other Asian countries, particularly India and Japan. These three countries alone currently contribute some 46% to global egg production, reveals Professor Hans-Wilhelm Windhorst in his report for the International Egg Commission Patterns and dynamics of egg production in the sub-regions of Asia.

Between 1990 and 2008, Asian egg production increased from 13.8 million tons to 35.7 million tons, by 158.5%. This sharp increase was mainly due to the dynamics in Eastern Asia, where production volume grew by 16.5 million tons; however, the sharpest relative increase occurred in Southern Asia, where a rate of 223.8% was recorded.

Eastern Asia The contribution of Eastern Asian countries to the

continent’s egg production increased from 69.0% in 1990 to 72.9% in 2008, after a peak of 76.7% in 1999. Analysis

of development in individual countries reveals that China

witnessed remarkable change in its production. Over the period, volumes increased by 16.2 million tons, or 246.7%. A sharp increase occurred in the

fi rst half of the 1990s, slowing in the period to 2006, after which a new phase of sharp growth began.

In Japan, production volumes grew by only 5.6%, or 135,000 tons, while in the Republic of Korea growth reached 41.5%, or an additional increase of 163,000 tons.

China and Japan together accounted for 97.3% of egg production in Eastern Asia in 2008, and with the predicted increase in buying power of China’s middle classes, growth in Chinese egg production can be expected to continue.

Southern Asia The contribution of the Southern Asian countries to

Asia’s egg production fl uctuated between 13.1% and 11.9% between 1990 and 2008, peaking at 12.6% in 2006. The slight decrease post-2006 is due to increasing output in Eastern Asia and a fall in Indian production.

Over the 18 years to 2008, India achieved the highest absolute growth with an additional 1.6 million tons (+136%)

Mark Clements

While Asian egg production has

had its difficulties over the last

two decades, its performance has

been dynamic and its expansion

remarkable.

The ten leading countries in Asian egg production in 2008

Country Sub-regionProduction

(1,000 t)Share

(%)

China Eastern Asia 22,749.2 63.8

India Southern Asia 2,740,0 7.7

Japan Eastern Asia 2,554.0 7.2

Indonesia South Eastern Asia 1,266.9 3.6

Turkey Western Asia 824.4 2.3

Iran Southern Asia 711.0 2.0

Republic of Korea

Eastern Asia 566.1 1.6

Thailand South Eastern Asia 562.0 1.6

Philippines South Eastern Asia 550.0 1.5

Pakistan Southern Asia 503.4 1.4

10 countries 33,027.0 *92.6

Asia 35,679.6 100.0

* sum does not add because of rounding(Source: FAO database)

Ten countries alone account for over 92% of production in Asia.

1010PIasia_1_C2201R14468.BK.indd 8 10/14/2010 10:49:07 AM

November 2010 | www.WATTAgNet.com

9

of eggs produced. The country was followed by Iran, which expanded production by 416,000 tons (+141%) and Pakistan where output rose by 283,000 tons (+129.3%). Despite India’s impressive record, egg production declined in both 2007 and 2008 as a result of the global fi nancial crisis.

Southeastern Asia Between 1990 and 1998 the contribution of

Southeastern Asian countries to total production fell from 11.8% to 7.8%. However, between 1998 and 2008, it expanded to 9.4%.

This has been a region where growth has been far more uneven. The upward trend in Indonesia was interrupted in 1997-1998 because of the Asian economic crisis, which hit Indonesia particularly hard, and the avian infl uenza outbreaks of 2004 and 2005. The avian infl uenza outbreaks

were also signifi cant for production in Thailand and the Philippines. In Thailand production failed to return to 2003’s level until 2008.

Between 1998 and 2008 egg production in Southeastern Asia grew by 1.25 million tons, to which Indonesia contributed 874,000 or 70%.

Almost 71% of egg production in this region is accounted for by Indonesia, Thailand and the Philippines, 37.7% in Asia alone. Indonesia is expected to strengthen its dominating role, however avian infl uenza remains a threat in the region, as the volume of backyard fl ocks and trade in live birds remain common.

Western Asia Despite production in this sub-region growing from

879,000 tons to almost 1.7 million tons, or 92%, over the

Expansion of Asian egg production remarkable and dynamic

The ranking of the South-Eastern Asian countries in egg production in 2008

Country Production (1,000 t) Share (%)

Indonesia 1,267 37.7

Thailand 562 16.7

Philippines 550 16.4

Malaysia 465 13.8

Myanmar 231 6.9

Viet Nam 225 6.7

Singapore 22 0.7

Lao People´s Democr. Republic

15 0.4

Cambodia 13 0.4

Brunei Darussalam 7 0.2

Timor-Leste 2 0.1

South-Eastern Asia 3,359 100.0

(Source: FAO database)

The ranking of the Southern Asian countries in egg production in 2008

Country Production (1,000 t) Share (%)

India 2,740 64.3

Irana 711 16.7

Pakistan 503 11.8

Bangladesh 197 4.6

Sri Lanka 59 1.4

Nepal 31 0.7

Afghanistan 17 0.4

Bhutan <1 0.0

Southern Asia 4,258 *100.0

(Source: FAO database)

The ranking of the Eastern Asian countries in egg production in 2008

Country Production (1,000 t) Share (%)

China 22,749 87.5

Japan 2,554 9.8

Republic of Korea 566 2.2

Dem. Peoples Republic of Korea

142 0.5

Mongolia <1 0.0

Eastern Asia 26,012 100.0

(Source: FAO database)

China's dominance means that regional concentration is high.

Regional concentration is high in Southern Asia, with three countries accounting for over 90% of output.

Three countries account for over 70% of output in this region.

Patterns and dynamics of egg production in the sub-regions of Asiais available in full to members of the International Egg Commission.www.internationalegg.comthe International Egg Commission.

Patterns and dynamics of egg production in the sub-regions of Asiais available in full to members of the International Egg Commission.

1010PIasia_2_C2201R14468.BK.indd 9 10/14/2010 10:49:23 AM

www.WATTAgNet.com | November 2010

10

18 years to 2008, its contribution to Asia’s total production shrank from 6.4% to 4.7%.

In Turkey, production volumes increased constantly between

1990 and 1998, reaching a peak of 865,000 tons. Since then, production has fl uctuated greatly, but never returned to high

point reached in the 1990s.Egg production in

Saudi Arabia grew by 60,000 tons (+53.6%) between 1990 and 2008, allowing the

country to reduce imports and increase exports, while Israel has seen its imports increase with home production falling from 117,000 tons in 1994 to 97,000 tons in 2008.

Turkey, Saudi Arabia and Syria together dominate this region, accounting for 69.3% of total production.

Central Asia Data for this region is only available from 1992 to 1998.

Between 1992 and 1996, volumes decreased by 58.4%, or over 153,000 tons, and its contribution to total egg production in Asia fell from 2.7% to only 0.6%. Despite Central Asia’s production almost returning to 1992 levels, its share of the continent’s output was only 1.0% in 2008.

With the exception of Turkmenistan, all the countries of the region reached a low point in 1996. Since then there has been an upwards trend, yet in many countries 1992’s levels are yet to be achieved. The exceptions to this have been Uzbekistan (+27,900 tons) and Turkmenistan (+17,900).

Kazakhstan and Uzbekistan, the two leading countries in this region, account for 82.6% of total output; nevertheless, Kazakhstan remains a major egg importer.

Trade Because of China’s dominant position in Asia, the

regional concentration in the continent’s egg production is very high. The leading 10 countries share over 92% of total production, with the top three countries accounting for 78.7%.

In contrast to Europe, where some 10% of egg production is traded, trade in eggs in Asia accounts for only 1% of the volumes produced. In 2007, two of the fi ve sub-regions recorded an egg defi cit and three a surplus.

In 2008, Asia achieved a small surplus in egg production. The main exporters were China, Malaysia, India and Turkey, while the main importers were Hong Kong (the primary destination for Chinese exports), Singapore and Iraq. □

www.WATTAgNet.com | November 2010

The ranking of the Central Asian countries in egg production in 2008

Country Production (1,000 t) Share (%)

Kazakhstan 166 45.9

Uzbekistan 133 36.7

Turkmenistan 34 9.4

Kyrgyzstan 21 5.8

Tajikistan 8 2.2

Central Asia 362 100.0

(Source: FAO database)

Significantly, over three-quarters of production in this region is accounted for by two countries alone.

The ranking of the Western Asian countries in egg production in 2008

Country Production (1,000 t) Share (%)

Turkey 842 48.8

Saudi Arabia 174 10.3

Syria 172 10.2

Israel 97 5.7

Azerbaijan 61 3.6

Yemen 54 3.2

Jordan 51 3.0

Iraq 50 3.0

Lebanon 46 2.7

Occup. Palestine Territory

38 2.3

Armenia 32 1.9

Georgia 25 1.5

Kuwait 22 1.3

United Arab Emirates 17 1.0

Cyprus 10 0.6

Oman 9 0.5

Qatar 4 0.2

Bahrain 3 0.2

Western Asia *1,688 100.0

* sum does not add because of rounding(Source: FAO database)

Turkey accounts for almost half of this market.

Asian egg production

1010PIasia_3_C2201R14468.BK.indd 10 10/14/2010 10:49:39 AM

T H E S I M P L E A N D H I G H L Y E F F E C T I V E C O O L I N G S Y S T E M

RainMaker is the simple and highly effective pad cooling system from Big Dutchman featuring an innovative frame system:

■ snap-in pad retainers allowing for simple and quick pad replacement

■ simple installation, supervision and maintenance

■ open system – water supply visible, no nesting for rodents

■ new frame system with one-piece top profile

■ top profile with perforated pipe and easily removable water deflector for ideal water distribution

■ for cellulose or plastic pads

■ integrated high-capacity water reservoir for excess water collection and recycling

And only fromBig Dutchman.

Unique features.

HOUSING SYSTEMS

FEEDING SYSTEMS

ENVIRONMENT CONTROL

FEED STORAGE

SLURRY SYSTEMS

RainMaker. The only pad cooling system forpoultry houses featuring an innovative framesystem with open top profile and pad retainer.

Big Dutchman International GmbH · GermanyTel. +49-4447-801-0 · Fax [email protected] · www.bigdutchman.comBig Dutchman Inc. · USATel. +1-616-392-5981 Fax +1-616-392-6899 [email protected] · www.bigdutchman.comBD Agriculture (Malaysia) Sdn BhdTel. +60-(0)3-33615555 · Fax +60-(0)[email protected] · www.bigdutchman.comBig Dutchman (Brasil) Ltda. Tel.: +55-54-2101 5900 · Fax: +55-54-2101 [email protected] · www.bigdutchman.com.br

Visit us at IPEin Atlanta —Booth 2011

1010PIasia_4_C2201R14468.BK.indd 11 10/14/2010 10:46:17 AM

www.WATTAgNet.com | November 2010

12

The XIII European Poultry Conference took place in Tours, France, in late August. Among the papers presented at the event were an examination of campylobacter contamination and farm evaluations of broiler welfare.

Persistent problem Campylobacter remains the main

cause of gastroenteritis among European consumers, and poultry products are very often the source. However, the poultry chain is now looking to control this bacterium in the wake of its success in controlling salmonella.

Gilles Salvat, from the French agency for food, environmental and occupation health safety (Anses) commented: “Great efforts have been made in Europe over the last 20 years, and especially in France, to eradicate salmonella from poultry farms, slaughter and further processing facilities.”

The situation regarding salmonella across Europe remains patchy, but some countries have been able to bring the bacterium firmly under control within the poultry industry. However, this has not been the case with campylobacter.

Routes of contamination Within slaughterhouses,

contamination it primarily due to two factors: the degree to which good hygiene practices are followed and the microbiological status of the birds received. Once meat leaves the slaughterhouse, cross contamination tends to occur at the consumer level through the spread of bacteria from contaminated meat to the surfaces where it is prepared.

While the factors contributing to the infection of live birds with salmonella and campylobacter may be very different, the measures required to control them at slaughterhouse and at consumer level are similar.

Salmonella and campylobacter are bacteria originating in the gut and not from surfaces. Overcrowding has been clearly identified as a risk factor for campylobacter contamination in many studies. The cleaning and disinfection of transport crates is a critical control point for controlling contamination.

Scalding is another critical point. A

hard scalding seems to lower contamination rates but increase further contamination, perhaps due to the better adhesion of bacteria to damaged skin, while a soft scalding increases immediate contamination but decreases further contamination during washing. The use of a scald additive, for example 1% sodium hydroxide, reduces contamination; however, this is banned in Europe.

Defeathering can also be a point of contamination due to plucking finger hygiene, fecal material released from the cloaca, the contamination of feather follicles by soiled water from the scalding tank, airborne contamination due to the aerosol made by water droplets and removal of the cuticle during plucking in the case of hard scalding.

Evisceration also increases the risk of contamination — more than 50% of carcasses are soiled following crop or gut leakage.

“Efforts have been made to improve slaughter techniques to reduce contamination of carcasses; however,

Campylobacter, welfare under spotlight at European Poultry ConferenceDelegates hear how,

despite progress in

welfare and disease

issues, more work still

needs to be done.

Jointly sponsored by Watt PoultryUSA, the event will help producers meet new USDA performance standards.

✸ Georgia World Conference Center, Atlanta

✸ January 26th and 27th 2011, 8.30am-12.00

To register, go to: www.IPE11.org

Salmonella and Campylobacter Reduction Conference

Yanne Boloh

1010PIconference_1_C2201R14478.BK.indd 12 10/14/2010 10:52:57 AM

November 2010 | www.WATTAgNet.com

13

the origin of contamination remains with live birds,” continued Gilles Salvat.

Lupo Ellerbroek of Germany’s BSFH noted that the screening of broiler fl ocks for campylobacter on farm, and at slaughter, could help to identify hygiene control points.

A study across three German regions of 51 broiler fl ocks looked for thermophilic campylobacter. Forty-fi ve percent of fl ocks were found to be contaminated, with the highest rate being recorded during June, July and August. The study found no horizontal contamination from one fl ock to the next via persistent contamination in housing.

Sampling during processing confi rmed that the entrance of a positive fl ock resulted in the contamination of the abattoir environment. Campylobacter spp were isolated from all sampling stages along the processing line.

New welfare approaches Delegates were also told about the

Welfare Quality project, a monitoring system for farmers and researchers based on birds’ perceptions and how they cope with their environment.

European consumers still believe that production animals are not kept in conditions that respect their welfare. A Eurobarometer survey in 2005 revealed that 82% of those surveyed ranked farm animal welfare as bad or very bad, with poultry welfare consistently scoring worse than that of pigs or cows.

One of the industry’s responses to consumers’ animal welfare concerns has been the adoption of quality labels such as the UK’s Freedom Food or France’s Label Rouge. However, European regulations are now also addressing the area. There are six non-binding recommendations that have been issued by the Council of

Europe, and two EU Directives, one for laying hens and one for broilers.

However, according to Cecile Arnould of the French National Institute for Agricultural Research (Inra) it was felt that a robust on-farm welfare monitoring program should be developed with requirements for specifi c species, and this was one of the aims behind the project “Welfare Quality,” co-funded by the EU.

Animal focus The system that has been

developed is focused on animal, rather than on environmental or management, factors, and welfare is managed according to four principles — good feeling, good housing, good health and appropriate behavior. For each of these principles several criteria have been adopted, such as thermal comfort for good housing or absence of injuries for health.

Practical measures to allow the evaluation of these criteria have been selected and tested on 90 commercial farms from three countries and across three diff erent production systems to assess on-farm feasibility of the protocol.

This new scheme diff ers from some existing systems, and takes into account the environment of the animal, as is the case with the Animal Needs Index in Austria, and the Swedish welfare program for broilers, which evaluates both a bird’s environment and management.

The link between environmental and animal-based measures is not always obvious. For example, several studies in broilers have shown that the link between stocking density and welfare measures, such

Gilles Salvat notes that great strides have been made in Europe to erradicate salmonella.

www.WATTAgNet.com/14806.html

For a review of campylocacter, salmonella in turkey farms, watch:Wesley identifies campy, salmonella interventions Wesley identifies campy, salmonella interventions Wesley identifies campy, salmonella interventions

www.WATTAgNet.com/14806.html

For a review of campylocacter, salmonella in turkey farms, watch:Wesley identifies campy, salmonella interventions

Campylobacter remains the main cause of gastroenteritis among European consumers.

1010PIconference_2_C2201R14478.BK.indd 13 10/14/2010 10:52:47 AM

Get Focused

Not having answers to your business needs can

affect your top and bottom line results. Through

a team of global consulting partners, CentreFocus,

LLC provides independent economic and business

advice to animal agribusiness producers and

integrators worldwide. The CentreFocus team will

provide data, new ideas and develop plans which

are customized to help you achieve your business,

financial and management goals.

Services include:

• StrategicPlanning

• NutritionAssessment;

Poultry,Pig,Ruminant

• FeasibilityStudies&

Start-upPlanning

• UtilityBillTariff&

TaxAudit

• PollutionReduction

• RegulatoryCompliance

• SustainabilityPlanning

• Export&ImportPlanning

• MarketIntelligence

• Feed/FoodSafety

If you need additional insight to drive new

initiatives, or are underperforming with any

portion of your current business contact

CentreFocus,LLCtoday.

Onimprovingyourbusinessperformance

www.CentreFocusLLC.com•Tel:+1.815.966.5580JamesC.Munch,President,[email protected]

1010PIconference_1_C2201R14478.BK.indd 14 10/14/2010 10:53:06 AM

as contact dermatitis (for which the main risk factor is poor litter quality) is not direct. Ventilation, temperature, humidity and litter are more important than, for example, stocking density alone.

Examining bird behavior and pathology could be more relevant, yet measures applied directly to the bird may not always be enough. For chicken, the most well known system is the foot-health program, which was developed in Sweden and is also used in Denmark. If focuses on the prevalence and severity of foot-pad dermatitis, but fails to cover all aspects of animal welfare.

Stakeholder agreement The European Welfare Quality

project comprises a monitoring system focusing on measures applied to birds as the most important aspect in considering how animals cope with their environment. To gather additional information, poultry producers must answer questions on housing and management practices, among other areas, and the analysis

of this data is fed back to improve welfare management practices.

As welfare is a multidisciplinary concept, several criteria should be taken into account to assess it properly.

Four measures have been drawn up to evaluate animal welfare: good feeling, good housing, good health and appropriate behavior. These measures are exhaustive and agreed upon by stakeholders, and their interpretation is independent.

For each of these four principles 12 criteria have been presented to consumer/citizen focus groups for approval: absence of prolonged hunger and thirst for the fi rst one; comfort around resting, thermal comfort and ease of movement for the second; absence of injury, disease and pain induced by management procedures for the third; and expression of social and other behaviours, good human-animal relationships and a positive emotional state for the fourth. □

November 2010 | www.WATTAgNet.com

15

Quality products and customer service.

Focus on innovative ideas.

BEST Poultry Technologyvia Polveriera Vecchia 31 I-37134 Verona - Italy

www.bestpoultrytech.comtel. +39-045-9231307fax +39-045-9235202

e-mail: [email protected]

Setter Trays and Hatcher Baskets

Trays and Baskets for every incubation machine.

Visit us at IPE stand 4813

PFC-1 PICKING FINGER CUTTER

90 psi / 6.2 bar min. - AIRLength - 8.0 inches / 203 mmWeight - 5.5 lbs / 2.5 kg

View PFC-1 information at our website

• Lightweight• Easy-to-use• Fast and powerful• Durable• Also available, Picking Finger Installer

Jarvis Products Corporation 33 Anderson Road, Middletown, CT 06457

Tel: (860) 347-7271 Fax (860) 347-9905 E-mail [email protected] http:// www.jarvisproducts.com

European Poultry Conference

❯ Yanne Boloh is a freelance writer based in France. She can be reached at: [email protected]

1010PIconference_1_C2201R14478.BK.indd 15 10/14/2010 10:53:16 AM

www.WATTAgNet.com | November 2010

16

Compartmentalization in the poultry industry

Avian Infl uenza. These two words can strike fear into many poultry professionals. The popular press will of course focus on the H5N1 strain, but there are many other types that can present problems to the industry.

What do we mean by that? Well, of course the loss of a fl ock is a tragedy for all involved, but it can have a devastating impact on farmers whose fl ocks are unaff ected, too. Compartmentalization is an industry solution which tries to alleviate some of the problems caused by restrictions to intenational trade that arise once a case of Avian Infl uenza is confi rmed in a country.

What is compartmentalization?

Essentially, compartmentalization is the recognition by (in the case of Aviagen Ltd.) the UK government that its farms reach such a high standard of biosecurity that, if there is an outbreak of Avian Infl uenza, or Newcastle Disease, in the UK, Aviagen birds can still be exported and the receiving country can be confi dent that the fl ock will be free from the viruses.

In 2004, the World Animal Health Organisation (the OIE, which is

the organization that sets out the rules for international trade of live animals) recognized the problem and devised a new set of principles for international trade based on a company’s biosecurity rather than its geographic location.

That is the key element. It recognizes that, because there has been an outbreak in one area of a country, trade should still be allowed to proceed based on the biosecurity of the farming operation.

So why is it needed? Without compartmentalization,

an incident of Avian Infl uenza in one region of the UK would result in restrictions to the poultry trade from the entire UK to many countries around the world. This has been the traditional approach to disease outbreaks in many countries, i.e., to use geographical boundaries as a way to mitigate risk, without recognition of the diff erences in levels of biosecurity within a country.

The industry recognized this problem and is taking action. A ban on exports has a catastrophic eff ect on a farmer’s business and also damages the primary breeder.

In an age of austerity, management of working capital and running as effi ciently as possible are vital. Farmers invest a great deal of time and money in their business and need to be sure that they can rely on supply at all times.

What does the process involve? Aviagen was the fi rst

company in the world to reach

Bill Stanley

Inch Farm, where biosecurity is key to compartment success.

Trade should

proceed based on the

farming operation's

biosecurity

How

compartmentalization

works and what it could

mean for the industry.

1010PIcompartment_1_C2201R14479.BK.indd 16 10/14/2010 11:03:37 AM

November 2010 | www.WATTAgNet.com

17

compartmentalization status and it was a hard journey, facilitated by a large number of staff . To qualify, Aviagen has been recognized as having met a number of strict biosecurity standards, including shower-in facilities, full record keeping of all staff and vehicle movements and disease surveillance protocols.

Regular inspections are carried out by specially trained veterinarians from the Veterinary Laboratories Agency (VLA), which then reports to Animal Health and the Department for Environment, Food and Rural Aff airs (DEFRA) for fi nal approval. The UK now has a team of government veterinarians certifi ed to audit facilities that want to have a compartment recognized.

The inspections are rigorous with a large volume of paperwork involved to make sure that all requirements are met. This should provide trading partners with more confi dence in Aviagen’s security of supply and so facilitate uninterrupted exports.

So where are we? All of Aviagen’s pedigree

farms and facilities in the UK have been recognized by DEFRA as a compartment, and the company is going through the same process with its Great Grand Parent and Grand Parent farms and facilities. Compartmentalization off ers a mechanism for governments to recognize high standards of biosecurity. This should allow us, and any other recognized company, to

continue exporting UK eggs and chicks to customers around the world in the event of another disease outbreak.

The UK has been outbreak free since the compartmentalization was recognized, but it will be up to the receiving countries to determine whether they accept the shipments. □

The UK operates a compartmentalization scheme for Great Britain with separate arrangements for Northern Ireland. The GB scheme is open to any poultry breeding company that has administrative headquarters in GB, and must be under the full management control of the company. Initial approval of compartments can only be granted when there are no restrictions in place in the country for avian influenza (AI) in line with EU operation.

Companies may apply for approval according to two separate standards. The EU Standard implements conditions in EU Regulation 616/2009, which came into force on Oct. 1, 2009. The GB Enhanced Standard incorporates all the requirements of the EU Standard, with additional specific instructions.

Companies that receive recognition as an approved compartment will have a compartment approval date, which is the date the compartment approval certificate is issued once all the sites comprising the compartment have been successfully inspected.

Approval is not time limited, and remains in place as long as the company continues to observe

all the rules of the scheme and the results of the necessary re-inspections are satisfactory.

Following initial approval, the re-inspection process will follow a two year cycle with 50% of compartment sites inspected each year. The re-inspection cycle will commence 12 months after the issue date of the original certificate and continue thereafter annually on the anniversary of that date. It is the company’s responsibility to contact VLA each year shortly before the anniversary of the approval date to request re-inspection of their premises. Any company found not to have carried out re-inspection of all sites in any two year-cycle will automatically have their approval suspended until full re-inspection has been completed.

In the event of a disease outbreak, disease control regulations under EU and UK legislation will take precedence over compartment rules. In the case of exports which are not prohibited under EU or UK legislation, dispatches to those third countries which are willing to accept consignments from approved compartments will be accompanied by a supplementary certificate attesting to the compartment status of the premises of origin.

� e UK compartmentalization scheme for Great Britain

❯ Bill Stanley is European health director with Aviagen.

The Aviagen team receive their certificate of recognition.

1010PIcompartment_2_C2201R14479.BK.indd 17 10/14/2010 11:03:29 AM

www.WATTAgNet.com | November 2010

18

Enriching the free range and reducing feather pecking

An Australian research project has examined how greater provision of pasture, shaded areas and shelter belts can attract birds into the free range, following recommendations from a Poultry Cooperative Research Centres (CRC) project that explored enrichment strategies under Australian free range conditions.

The welfare of beak-trimmed birds and the potential negative long-term eff ects of the procedure are becoming increasingly recognized by consumers. In modern pullet and layer houses it is possible to minimize the light intensity within the house and reduce the risk of outbreaks of feather pecking. However, in barn and free-range systems the problem of feather pecking and cannibalism will persist, and alternatives to beak trimming were investigated by the study.

While pecking is a natural means by which poultry investigate their surroundings and establish a stable social order, the behaviour can escalate to the stage where brids will peck each other to death.

This cannibalism is a behavioral problem that often develops into a vice that will spread within a fl ock

as a learned behavior, even after the initial causes have been corrected.

Research carried out in Europe has suggested that feather pecking in free-range fl ocks is greatest when a low percentage of the fl ock uses the outside range; decreasing the stocking density within the house should be benefi cial.

Lack of security Infrequent and uneven use of the

hen run is one of the main problems in all free-range systems for laying hens. Birds do not feel safe in a non-roofed run area. When a range has

cover, trees or hedges, however, birds are more evenly distributed and the risk of feather pecking is reduced.

The CRC project revealed that only 9% of birds on free-range farms use the range area. Factors found to infl uence range use include the weather, the season, the time of day, shade and variety of overhead structures, as well as the age of a bird and the size of a fl ock.

The CRC project looked at the design of facilities and products that may deter pecking under local conditions. The objective was to reduce the need for beak trimming

Mark Clements

Studies by Australia’s

Poultry CRC have

looked at whether

encouraging birds into

the range leads to less

feather pecking.

Unique sustainable layer house opens in the Netherlands www.WATTAgNet.com/16034.html

For more on encouraging birds to use the free range, read:Unique sustainable layer house opens in the Unique sustainable layer house opens in the

www.WATTAgNet.com/16034.html

For more on encouraging birds to use the free range, read:

Shade provision trialed during the study.

1011PIshade_1_C2201R14553.BK.indd 18 10/14/2010 10:53:58 AM

www.WATTAgNet.com | November 2010

20

and re-trimming by: developing design principles for free-range systems that minimize cannibalism, developing products that deter the onset of cannibalism and feather pecking and evaluating if light control during rearing and laying periods in modern poultry houses reduces the need for beak trimming.

The Poultry CRC project involved researchers at the South Australian Research and Development Institute (SARDI), the University of New England (UNE) and Queensland

Primary Industries (DEEDI). Trials under free-range conditions were conducted in South Australia, Queensland and New South Wales.

Environmental enrichment increases desirable behaviors, reduces harmful ones, sustains the birds’ long-term interest and enables them to cope with challenges. Enrichment involves increasing environmental complexity to encourage birds to interact with their environment.

Natural behaviors Project leader SARDI’s Phil Glatz

explained that the main benefit of enrichment is that it gets birds out of the shed to engage in a wide range of natural behaviors. Trials at SARDI examined the role of shaded areas, the role of forage and the influence of shelter belts in the range. One trail suggested that forage availability has an impact on the percentage of birds using the range during the day.

Dr. Glatz commented: “There is

Enriching

DEEDI’s poultry extension officer Tanya Nagle setting up cameras to record the number of hens that use the shadecloth

PoultryPoultryInternationalProduction, Processing and Marketing Worldwide

One-touch mobile access to the latest issue of Poultry International?

There’s an App for that.

Poultry International now available on the iPhone and iPad.

Search “Poultry” in iTunes to download the App now.

www.WATTAgNet.com October 2010

Digital version at www.poultryinternational-digital.com

An exclusive look at the industry’s major players

around the globe

Download free Poultr

y

International iP

hone, iPad

Apps from iTunes.

The trick with free range is to provide the birds

with an environment that encourages them to

make full use of the range.

1011PIshade_3_C2201R14553.BK.indd 20 10/14/2010 10:54:21 AM

the perception that birds on free-range farms in Australia are free to range but hardly ever go outside.

“This work has shown that birds will utilize the free range when the environment is enriched and, hence, their behavioral repertoire is enhanced. From an industry point of view, however, the health risks to birds increase when they make greater use of the range, due to increased exposure to wild birds and other factors.”

The Queensland trials, conducted by

DEEDI’s poultry extension officer Tanya Nagle, showed that on commercial free-range farms, the addition of shadecloth shelters, shelterbelts and forage to the range area did attract more hens to utilize the area.

Lloyd Thomson, commecial manager at CRC, commented: "The trick with free range is to provide the birds with an environment that encourages them to make full use of the range, and therefore reduce feather pecking behaviors while not creating a 'jungle' in which the birds will lay making collection of their eggs economically unviable."

Trials at UNE conducted by Associate Professor Geoff Hinch suggest that initial exposure of chicks to repellents may be associated with a reduced incidence of cannibalism and could provide another option in a multiple strategy approach to reducing potential cannibalism in layers. □

November 2010 | www.WATTAgNet.com

21

Safe cleaning & disinfection

• Dual effect: - Removes biofi lm - Disinfection• Best registered product: CTGB PT02, 03, 04• Recommended by respected poultry organizations,

hatcheries and health services.

“Intra Hydrocare has a lot of benefi ts compared to products like, peracetic acids, chlorine or acids. Don’t take risks and fi nd out what Intra Hydrocare can mean for your organization”.

Tel.: +31 (0)413 354 105 | www.intracare.nl

Mr. C.A.J.M. Vulders Bsc HvK

Please visit us atEuroTier 2010, Hall 15,

Stand D53

Shade provision trialed during the study.

1011PIshade_4_C2201R14553.BK.indd 21 10/14/2010 10:53:47 AM

Coming off a seven-month ban of poultry exports to Russia, U.S. poultry processors are responding with adjustments to sales mix and more deboning of dark meat.

Much of the increased production of deboned meat has been marketed domestically, and dark meat prices have held up surprisingly well during the trade stoppage. Potentially helping margins is the fact that value is being added to commodity cuts — legs and thighs.

A major challenge in this value-addition strategy, however, is a labor squeeze created by U.S. immigration enforcement, which has reduced the availability of skilled workers in some areas of the country. Processors across the U.S. are now weighing the tradeoff s in manual versus automated deboning as they try to resolve shortages of skilled labor.

Investment is up signifi cantly in 2010, especially in equipment for second-stage processing, as processors seek to achieve effi ciencies and better margins on existing volume.

Processing trends in 2010WATT PoultryUSA interviewed equipment suppliers about

processing sector investment and trends. They identifi ed the following trends: ❯ Deboning of dark meat has increased signifi cantly with a

number of processors continuing to raise bird weights to accommodate the deboning activity.

❯ Processors are seeking ways to automate processes wherever labor saving can be profi tably realized, but investment decisions are on a plant-by-plant basis.

❯ Processors continue adopting electrical stimulation (ES) in fi rst-stage processing in order to reduce or eliminate the need to age meat prior to deboning.

❯ Processors continue to focus on processes and equipment that allow them to harvest and sell poultry organs and by-products — an important source of revenue.

❯ Water conservation and reuse is a major concern and will continue to grow in importance.

❯ There’s continued adoption of IT systems that centralize data and permit its distribution and use throughout processing operations.

Investment is up The year 2009 was the worst in memory for sellers of

poultry processing equipment. Not only did capital spending by processors virtually disappear, so did spending for spare parts. By the latter half of 2009, however, poultry processors were investing again in equipment and spending for parts.

“We saw a real pick up in investment by processors beginning in August of 2009,” said Heath Jarrett of Meyn. He foresees a slight decrease in investment by processors over the next 12 months compared with the very strong fi rst six months

www.WATTAgNet.com | November 2010

22

Gary Thornton

Saving labor and capturing yield

are driving investment in poultry

second-stage processing, while

processors seek to add value and

exploit real-time data.

Poultry Processing Worldwide

Second-processing tackles labor and yield

Shortages of skilled labor in some areas are resulting in more interest in automated deboning technology, such as the Rapid HQ breast deboner.

Worker accountability and incentives are possible with automated weighing and distribution management systems such as the YieldPlus.

1010PIprocessing_1_C2201R14522.BK.indd 22 10/14/2010 10:56:21 AM

November 2010 | www.WATTAgNet.com

23

of 2010, but investment should remain “pretty good” in 2011. Chuck Shiver of Murzan said, “Poultry processors had put

off capital purchases to the point that they did not have any choice but to start investing in much-needed replacement or new equipment.

“I’m optimistic about prospects for the poultry industry now. Processors have tightened their belts over the past couple of years, and even though feed prices and energy costs are high, they are in good position. There’s not much expansion in slaughter volume at this time, but there is an increase in value addition in second-processing and further-processing,” he said.

Turning point for industry The skyrocketing grain prices and recessionary

economy in 2008-09 were a turning point for the U.S. poultry industry.

Mitch Staugler of Prime Equipment Group observed, “When costs for grains and other inputs went through the roof in 2008, poultry industry managers said, ‘We’re not profi table anymore, so let’s start looking for ways to save money.’” The way in which processors evaluate

investments to gain effi ciencies has also changed, according to Keith Moffi tt of Bettcher Industries. “When processors are making money, opportunities are just that. But when they are not making money, those opportunities carry a lot more weight in their decision-making,” he said.

Focus on yield, sales mix Processors’ business approach has changed in other ways

as well, according to Sid Adkins of Gainco. “There aren’t many plants slaughtering additional birds.

Processors are looking for ways to get higher yields in existing capacity or moving to more profi table sales mixes. That may involve moving away from selling leg quarters and toward deboning as a way to add value. Or it may involve injecting marinades or producing portion-control boneless meat. Those are sales-driven projects as opposed to volume expansion. Processors are looking to add more value and realize more revenue from existing volume.

“I think the industry’s investment in fi rst-processing — where high-speed lines were installed in the past few years — is mostly behind us,” he continued. “Now, there is more

Imag

e co

urte

sy G

ainc

o, In

c.

P.O Box 394 - 56009 Vannes Cedex - FranceTél : +33 (0)2 97 48 53 83

www.invivo-nsa.com

A worldwide characterto feed and care about animals

of nutritionThe arthe

International leader in premixes, mineral supplements, nutritional specialties and mineral licks.• 18 million tonnes of feed under InVivo NSA technique.• Exports to more than 50 countries.• Production plants in Italy, Spain, Portugal, Romania,

Hungary, Brazil, China, India, Russia, South Africa, Mexico.

• Distribution subsidiaries in Czech Republic and Myanmar.

A global network of analysis expertise (France, China, Vietnam and Brazil) from standard-setting laboratories in animal and human food.

R&D: unique capacity for innovation• 130 experts in nutrition worldwide.• 12 applied research stations (France, Brazil, Vietnam,

Indonesia, India).• Numerous partnerships with private and public research

institutes.• An international network of test livestock farmers.

Visit us at EUROTIER Hall 16 - Booth E24

“Processing sector bounces back” at

www.WATTAgNet.com/15124.html.

New processing equipment is examined in “Processing sector bounces back” at “Processing sector bounces back” at “Processing sector bounces back” at “Processing sector bounces back” at

www.WATTAgNet.com/15124.html. www.WATTAgNet.com/15124.html. www.WATTAgNet.com/15124.html.

New processing equipment is examined in

Imag

e co

urte

sy M

eyn

1010PIprocessing_2_C2201R14522.BK.indd 23 10/14/2010 10:56:33 AM

www.WATTAgNet.com | November 2010

24

focus in second-processing in cut-up and deboning.”

Bigger birds for deboningAll the suppliers contacted agreed

that processors are deboning more white and dark meat, and several suppliers commented on seeing increases in bird weights.

“Some processors who were producing a tray-pack size of bird of around 5 pounds have moved to bigger birds in the past four to six months,” Heath Jarrett said. “Some of these changes involve going from 6-inch to 8-inch center shackle lines, and some are taking weights up about a pound. When plants move up in weights in that way, they are doing more cutting, slicing and portioning of the breast meat.”

Adjustments in stunning, killing

Wayne Austin of Simmons Engineering said business has been brisk as his firm helps processors adjust stunning and killing operations to accommodate the increased bird sizes.

“We’ve modified our stunners to better handle those large chickens, and we’ve sped up our killing machines for a better cut. More torque and blade speed is needed to cut the bigger chickens so that they bleed rapidly,” he said.

The company now installs a stunner cabinet which was originally designed for turkeys on big-bird chicken processing lines.

Electrical stimulationElectrical stimulation (ES) systems

are also being installed in first-stage processing in some plants in order to reduce or eliminate the need for aging of the meat prior to deboning.

“Electrical stimulation applied to the birds in first-processing, in combination with the dwell time in the chillers, allows the meat to be deboned straight from the chillers,” Austin said.

Colliding imperatives: Labor and yield

Yield is king in the deboning business, a supplier said, but skilled labor is the controlling factor in achieving top yields with cone deboning lines.

Cone lines manned by well-trained deboners can yield 1% to 2% more meat than automated deboning lines, according to supplier estimates. That could mean anywhere from $500,000 to $1.5 million a year, depending on the size of the deboning operation.

Nonetheless, where adequate numbers of skilled workers aren’t available to staff cone lines, processors are investing in automated deboning systems. Yields are said to be improving with each new generation of the automated deboning systems, and how close they come to manual deboning yields depends on the manual performance actually achieved.

There are nearly as many deboning strategies as there are products and plants, and these strategies are in flux. For example, some plants are currently moving away from whole-bird deboning, while others are moving to

whole-bird deboning. Similarly, some deboning operations are adopting automation while others are adopting manual cone lines. These and other shifts are being dictated by local labor availability, product requirements, markets served and other factors.

Capturing ‘other’ revenue A growing percentage of total

revenue for U.S. poultry processors comes from materials that were formerly discarded or which were low-value by-products (See “What’s driving poultry profitability” at www.WATTAgNet.com/16713.html). This includes everything from hearts, gizzards and other organs to poultry feet and paws. Some plants even recover and sell the keel bone for use in the cosmetics industry, while others supply chicken combs for the production of synthetic insulin.

Chuck Shiver observes, “Hearts, livers, necks, gizzards, feet, heads and viscera are valuable and captured and pumped in the plants, with every bit of it is being used in most cases.

“Feet and paws, for example, are bringing a better price than leg quarters at this time. Most of

Second processing

Processors are seeking real-time data to help manage plant processes, an example of which is a Wolf flock histogram shown in the photo.

Imag

e co

urte

sy C

ompu

terw

ay F

ood

Syst

ems

1010PIprocessing_3_C2201R14522.BK.indd 24 10/14/2010 10:56:45 AM

November 2010 | www.WATTAgNet.com

25

that goes for export to Asia, but there’s now also demand for those products in the U.S.”

Efficient gizzard processing Gizzards are another product

being recovered and upgraded. “Filleted gizzards are becoming

a popular product in Asia, and more plants are now harvesting gizzards because they have methods for efficiently producing product. Before, a lot of the processes were manual, but now gizzard harvesting is becoming automated,” Mitch Staugler said.

Centralized data As the poultry industry and

its customer base grows more consolidated, with processors’ operations becoming larger, more numerous and far flung, there’s a growing need for centralized data and communications.

“Processors are recognizing

that they must centralize product information and data, including testing records,” said Bill Altenpohl of Computerway Food Systems.

This is becoming a bigger issue as plants serve larger customers and must consolidate deliveries from

multiple plants. It can also be an issue when special deals and labeling requirements are involved.

“In the past, individual plants might have labeled the same products slightly differently, with differences in labels’ content and appearance — sell-by dates, treatment of weight data and typography,” he explained.

“The solution involves installing a central server at a company to define the product code, the weight limits and what the labels should look like. All of a product’s attributes are described centrally and sent electronically to servers in the plants. That information then filters down from those servers to the equipment on the plant floor,” Altenpohl said.

“Many companies have left it up to the complexes to do their own thing in the past,” he said. “But there’s a trend to centralized data, and even the guys who resisted it won’t be able to resist it any longer.” □

Healthy animals leads to a healthy farm, leads to healthy profi ts. It’s what we all want. But how do you get there. Simple. Just follow the Kanters way of treating animals with vitamins, minerals, organic acids and essential oils. All provided through the pipelines of your water system. Speaking of water systems, AQUA-CLEAN® will do a proper cleaning job and provides hygienically clean drinking water for your animals. Of course we have a lot to tell about the Kanters way. Therefore we are delighted to meet you during EUROTIER in Hall 15 – Stand D12.

Can’t wait? Go to www.kanters.nl or call us 0031 499 425 600.

Healthy animals lead to healthy farmsMeet us at EurotierHall 15 – Stand D12

Imag

e co

urte

sy B

ettc

her I

ndus

trie

s

Air-powered trimmers are an alternative to more skill-intensive solutions, such as straight knives or scissors, for the deboning of thigh meat.

1010PIprocessing_4_C2201R14522.BK.indd 25 10/14/2010 10:56:06 AM

www.WATTAgNet.com | November 2010

26

Products

DPI GlobalDPI Global offers advancements in saponin technology; Micro-Aid, which is an all-natural, environmentally safe feed additive; Cocci-Guard, which is an all-natural feed additive proven to control coccidiosis in broilers; and other products.

+1.559.781.0297www.dpiglobal.com

Dosatron International injectorDosatron injectors feature engineering to create the most

durable, easy-to-use, low-maintenance product on the market. Dosatron’s DM11F is built strong to medicate and sanitize via advanced diaphragm technology and dependable quality. The DM11F medicates day-old chicks, provides more flow as they grow, and has been tested and approved by top industry professionals. It works under the toughest water conditions, is easy to install and maintain, includes a bypass, and is backed by world-class customer service.

+1.727.443.5404www.dosatronusa.com

ComcoComco specializes in PLC control systems for grain elevators, feed mills, feed yards/lots and all agri-industrial facilities. Comco helps customers automate single processes such as batching or pelleting or complete facility automation solutions from receiving through loadout. PDA

control, comprehensive safe-feed features, PC hand-add stations, liquid application systems, as well as integrated maintenance and power management capabilities are offered.

+1.306.652.5005www.comco-controls.com

CWT Farms International Inc.CWT Farms International Inc. is known as a major producer and marketer of high quality broiler hatching eggs.

+1.770.532.3181www.cwtfarmsinternational.com

Coating Excellence International polypropylene bagCoating Excellence is a leader in high strength polypropylene woven bags for the animal feed market. The company’s SuperTube bags are stronger, thinner, stiffer, and have fewer damage claims than paper bags. Their 50 percent better yield takes up less space on pallets, in trucks, and in landfills. These bags are FDA-approved and AIB certified, printed up to 10 colors, and 100 percent recyclable.

+1.920.996.1964www.coating-excellence.com

To search a full list of products, go to www.WATTAgNet.com.

VEIT Electronicstel.: +420 545 235 252, fax: +420 545 235 256

email: [email protected]

Wireless installation: battery powered, GSM communication and memory module for data transfer. Optional RS–485 connection.

VEIT Electronicst l +420 545 235 252 f +420 545 235 256

Wireless installation: battery powered, GSMcommunication and memory module for data transfer. Optional RS–485 connection.

Bat2

Wirelesspoultryscales

Innov’ Space 2005, World

Poultry Award 2006

w w w . v e i t . c z

1011PIprod_1_C2201R14576.BK.indd 26 10/14/2010 10:59:24 AM

New generationACM-NT cut-up system

The perfect profit builder

Call to find out more: +31 (0)485 586 [email protected] | www.storkpoultry.com

ACM-NT is the solution for you if you are looking for:

Highest yield of A-grade cuts

Maximum harvesting per broiler

Broad range of weight flexibility

Unrivalled uptime

Low cost of ownership

More layout and control flexibility

The ACM-NT is the next generation platform for portioning. Stork’s cut-up system offers a new standard of performance and flexibility that no other system on the market can match. It is a modular solution that fits the needs of any facility or customer requirement. The ACM-NT takes processing to the next level of profitability.

Visit us at IPE, Atlanta, GA USA, from January 26 - 28, 2011, at Booth 4421/4429 in the B Hall

1011PIprod_2_C2201R14576.BK.indd 27 10/14/2010 1:02:11 PM

www.WATTAgNet.com | November 2010

28

CES GroupThe CES Group is a world leader in the engineering, design and manufacturing of freezing and chilling equipment for the food, pharmaceutical and metal treat-ment industries. The company’s knowledge and experience ensure the delivery of a fi rst-class product where performance, quality and safety come fi rst.

+1.513.761.4200www.cesgroup.com

Dhopeshwar Engineering Pvt. Ltd.Dhopeshwar supplies poultry dressing plants and equipment as well as poultry waste rendering plants. The range covers: fully conveyorized poultry dressing plants (capacity 500/1,000 birds per hour); poultry slaughter equipment for smaller capacities (from 1,000 birds to 3,000 birds per day); and poultry waste rendering plants with environment friendly Baro spray condensor for smell control.

+91.40.2377.1579www.dhopeshwar.in

Curuca - feed&food magazineCuruca is an organization that aims to develop environmental projects and social initiatives in defense consumer, through actions before society. It edits the magazine feed&food, a publication for all professionals

involved in the industry of animal protein production.

+55.15.3261.9450www.feedfood.com.br

Chore-Time Brock InternationalChore-Time Brock International is the CTB division responsible for sales and service of Chore-Time Poultry and Egg Production Systems and Brock Grain Systems outside the United States and Canada. Chore-Time off ers a complete line of equipment for poultry and egg production as well as Brock grain and feed storage, handling, conditioning and drying products. With offi ces in the USA and Europe, Chore-Time Brock International markets its products worldwide with customers in over 110 countries and a global distribution network.

+1.574.658.9323www.ctbworld.com

Products

Bioprotexion Box

VIROCID® is part of the Bioprotexion Box by CID LINES, a program to ensure food safety on your farm and to increase your benefits.

Increase your benefits by protecting your livestock

www.virocid.com

VIROCID®

The most powerful disinfectant! • most effective disinfectant

• worldwide proven efficacy (EN and AOAC)

• recommended in case of emergency

disease control

Methionine Global Outlook:

The Next Decade

Download this informative white paper at www.wattagnet.com

1011PIprod_3_C2201R14576.BK.indd 28 10/14/2010 10:59:48 AM

1011PIprod_4_C2201R14576.BK.indd 29 10/14/2010 1:12:41 PM

www.WATTAgNet.com | November 2010

30

ChemStation International Inc.ChemStation International Inc. offers custom-formulated, environmentally friendly, industrial cleaning process and sanitation chemicals delivered to refillable containers. There are no freight charges, no container deposits, no disposal costs, no contamination from discarded containers and no empty drums filling local landfills.

+1.937.294.8265www.chemstation.com

CARVALCARVAL is a recognized company that for over 50 years has been compro-mised with animal health and the well being of the livestock industry, by offering to its custom-ers integral solutions to improve their productiv-ity and profitability. The company researches, develops, manufactures and commercializes vet-erinarian products such as disinfectants, antimicrobi-als and feed additives.

+57.2687.4600www.carval.com.co

CARFED S.A. shipping basketsCARFED S.A., worldwide Swiss-Italian manufacturer of live chicken and

turkey plastic coops, has developed a basket measuring 110/108 x 58 x 27 centimeters, without a side door nor a top, to be used like a drawer in collapsible metal frames. The baskets are collapsible to allow shipping overseas at cheap freight rates. Advantages include less bruising/damaging to birds, quicker loading/unloading operations and better working conditions for workmen. The baskets are also available with solid bottoms and in the size 108/97 x 58 x 42 centimeters for turkeys.

+39.02.9881140www.carfed.it

Ciemmecalabria SRL chicken harvesterSince 1972, Ciemmecalabria has produced poultry loaders which are used daily all over the world. The company now offers the Apollo Universal -- a chicken harvester. Its wide harvesting header and automatic weighing system make the work of catching crews, processing plants and private farmers easier.

+39.03.0725.4118www.ciemmecalabria.com

Products

1011PIprod_5_C2201R14576.BK.indd 30 10/14/2010 10:59:59 AM

Marketplace

November 2010 | www.WATTAgNet.com

31

The Poultry International rate is: $210 per inch per

insertion (1-time rate), $200 per inch per insertion (6-

time rate), or $170 per inch per insertion (12-time rate).

The production charge is included except for ads with

excessive make-up demands. Logos are acceptable. Make

your classified stand out- add color for an additional $40

per color per insertion.

To place a Marketplace ad contact: Tineke van Spanje, Tel: +31.495.526.155,

Fax: +31.495.525.126; E-mail: [email protected].

Ginny Stadel, Tel: +1.815.966.5591, Fax: +1.815.968.0941,

E-mail: [email protected].

Great return on investment for all types of poultry: duck, turkey, breeder, pullet, broiler, layer, eggs, hatchery, etc.

Find us in Europe, China, North America, India, South Africa, Mexico, Russia, Brazil, Middle East, Turkey, Japan, etc.

The most affordable, effective & easiest POULTRY drinking water solution...

dutrion tablets + DutriClean dosing unit ...finally all the advantages in one concept

WWW. POULTRYWATER.COMTel. +31 88 0333 003 www.dutrion.com dealer positions available all around the world

• Lifting Devices for watering and feeding systems (winches and pulleys)• Metal Parts for poultry are being molded, stamped, forged, machines.• Plastic parts for poultry and hog farming.