Poultry Digest April/May 2015

-

Upload

primary-media -

Category

Documents

-

view

236 -

download

7

description

Transcript of Poultry Digest April/May 2015

Salmonella and eggs from production to plate

poultrydigestApril/May 2015

www.primarymedia.com.au

RSPCA Australian Animal Welfare Seminar

Testing the efficacy of Vaxsafe ST vaccine

Third time lucky visiting solar saver

Print Post Approved PP243096/00007 ISSN 1444-8041

Volume 30, Number 5

AECL 21st Industry Forum held in Adelaide

Vaxsafe® PM is a new product funded by the Australian Poultry CRCfor the Australian poultry farmer to help control Fowl Cholera.

This live vaccine oers signi�cant improvements in controlof Pasteurella multocida (PM) over previous vaccines.

Its broad protection means it is the �rst stop forPM control irrespective of what PM you have.

Brought to you by Bioproperties to help prevent blood from staining the wattle**Apologies to Henry Lawson

Phone (03) 9876 0567Fax (03) 9876 0556bioproperties.com.au

Vaxsafe PM

The new vaccine for Fowl Cholera

PDJuneJuly2012:PDFEBMAR09 24/07/12 6:55 PM Page 2

poultrydigestwww.primarymedia.com.au

April/May 2015

EDITORIAL & DESIGN

Features

News

ADVERTISING

SUBSCRIPTIONS

ENQUIRIES

EDITOR:JOURNALIST/PHOTOGRAPHERPRODUCTION EDITOR

Peter BedwellMob: 0419 235 288Email: [email protected] [email protected]

OFFICE ADDRESS:250 Hawthorne Pde, Haberfield NSW, 2045Ph: (02) 9797 2406Mob: 0419 235 288Production: 0409 944 472Email: [email protected] [email protected]

Poultry Digest consists of a bi-monthly management magazine and an annual industry review, Poultry Industry YearbookPublished by CD Supplies Pty Ltd trading as Primary Media (ACN 091 560 557).All material copyright (editorial and advertisements) and may not be reproduced without the written consent of the publishers. Whilst every care is taken to ensure the accuracy of the contents of POULTRY DIGEST, the publishers do not accept any responsibility or liability for the material herein.

AUSTRALIAOne Year - $55.00*NEW ZEALAND One Year - NZ$80OTHER COUNTRIESOne Year: Airmail - $A90Please send payment in Australian dollars.Send payment and full details to:250 Hawthorne Parade, Haberfield NSW, 2045*Australian subscription rate includes GST

Peter BedwellAlex Bedwell

Rosemary Embery

3

for the .This

of

*

VaThe new v

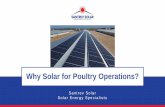

Page 18: Third time lucky visiting solar saver by Peter Bedwell

Page 30: Testing the efficacy of Vaxsafe ST vaccineby Y. Abs El-Osta, S. Mohotti, F. Carter, S. Kuchipudi, R.Youil, G. Underwood, P.C. Scott and C.J. Morrow

Page 44: Salmonella and eggs: from production to plate (Part 1).by Harriet Whiley and Kirstin Ross

Page 4: AECL 21st Industry Forum held in Adelaide

Page 10: RSPCA Australian Animal Welfare Seminar: ‘Why welfare matters’.

Page 26: Intensive ag must reduce costs says Nuffield scholar

Volume 30, Number 5

Waverly Phillipson (left) from the Modern Group with broiler farmer Ken Wake.

New ProductsPage 38: Energy saving poultry shed dimmable lightingPage 42: Managing aviary birds is easy with Bolegg Gallery multi-tier systemPage 40: New Polytex thermal curtains for Poultry IndustryPage 50 Danisco launches advanced phytase Axtra PHYPage 52: Roxell develops CE-approved Quad heater

NEWS

4

AECL 21st Industry Forum held in Adelaide

w

1. Jackie Healing, General Manager, Coles Brand & Quality. 2. AECL Chair-man Jeff Ironside. 3. Shane Landon, Senior Manager Food Supply, Heart Foundation. 4. Jono McCauley, Director/Creative Strategy Elevencom. 5. Kate Harcher, Sydney University. 6. Dr Greg Parkinson, Avian scientist.7. Dr Kapil Chousalker, University of Adelaide.

The Australian Egg Corporation Limited held its 21st Industry Forum at the Stamford Plaza Hotel in Adelaide from May 20-21, 2015.

For a relatively small industry the turnout for this event is amazing as is the quality of the speakers and the information they deliver.

Above all of that however is a simple number – 220. That’s not how many people attended, though it is around that figure, but the number of eggs each Australian consumes on an annual basis!

No wonder then that consumers, retailers, health experts as well as (sadly) regulators and animal/consumer activist groups are all so interested in the industry: because Eggs are Big!

If Jono McCauley, the Director of creative strategy at AECL’s advertising agency, Elevencom achieves his aim, stated at the Forum, Australians will soon be eating 240 eggs PPPA.

The new campaign, based on TV and social media, builds on the icons of past campaigns but moves the emphasis to the start of the day with slogans such as ‘Eggs are the simply amazing way to start your day’ and ‘unbeatable for breakfast’.

The focal point for the new ads are the antics of comedian Jimmy James Eaton whose cranium is by a remarkable coincidence not unlike the product he so assiduously promotes.

Jimmy later entertained dinner guests at the spectacular National Wine Centre of Australia where after drinks and canapés (sponsored by Big Dutchman) an excellent dinner (sponsored by Moba) was appreciated by all.

The first speaker in Forum Session 1 was Jackie Healing – General Manager Coles Brand & Quality who expanded on ‘The future of Coles and Eggs’.

“Customers tell us that they want their eggs to be fresher and not from birds kept in cages, however they also say that they can’t afford to pay any more,” Ms Healing stated.

She then further explained that a worrying trend of ‘lack of consumer confidence’ was probably driven by a rising cost of living. Real wages had hardly increased for a prolonged period, which was contributing to the cost consciousness of shoppers today.

1

2

4

6

3

5

7

advert_AA_poultrydigest_A4_23.09.11.pdf 1 23/09/11 10:04 AM

Ph: (03) 5979 [email protected]

VictoriaAgriculturalAutomationPh: (03) 5979 1666

6

NEWSv

1. Kylie Hewson, R&D Project Manager, AECL. 2. Peter Mathews, AAS spoke about PIX. 3. Abe Moses, Farm Extension Services Manager AECL. 4. Greg Mills, Go-Ahead Business Solutions.

She also expressed some concerns about quality leading to high level of rejections and the possible under investment in grading and packing.

“The cage free policy was part of continuing ‘the welfare journey’ that was a key component of our egg sales strategy.

“There has been some difficulty in getting consumers to understand what barn eggs (as applied to the cage free initiative) actually meant,” she said.

Shane Landon, Senior Manager Food Supply, Heart Foundation spoke on the topic of ‘Eggs and the Heart Foundation’.

The egg industry alliance with the Heart Foundation has proved to be an enduring partnership that may have moved on from the cholesterol debate to one of helping to reduce obesity.

Interesting statistics were shown revealing national obesity levels were in general far greater in rural and regional areas than in the inner city suburbs of capital cities. Inactivity was considered as a key factor.

His talk concluded with a simple message, ‘An egg a day for healthy adults’.

Jono McCauley next presented details of the ‘Making eggs unbeatable’ strategies.

No doubt the presentation, prepared some days before the Forum, showed a healthy increase in consumption to 217 eggs PPPY which was welcome by delegates but incorrect.

Bang up to date statistics revealed by AECL CEO James Kellaway on May 21 had that figure at more than 220 eggs PPPY.

“We need to use consistency of message to make eggs ‘unbeatable’ for years to come,” Mr McCauley concluded.

The Forum 2 session on May 20 was given over to more scientific aspects of the industry.

Kate Hartcher from the Poultry Research Foundation at Sydney University, spoke about her PhD studies, shortly to be completed, on severe feather pecking in free range layer hens.

Kate described her experiments including, “the effects of beak trimming and environmental enrichment in the rearing period, the use of predictive behavioral tests in the rearing period and the use of behavioral tests in birds performing feather-pecking”.

Other aspects of her research include tests on feather eating and investigating the association between feather pecking, fearfulness and range use as measured by RFID technology.

One conclusion is that there is plenty of scope for further research into this topic.

“There is potential for genetic selection against (undesirable) traits to eliminate them from the population as there is thought to be a genetic component to feather pecking activity,” Kate concluded.

Veteran avian scientist Dr Greg Parkinson discussed the possibility of ‘The great leap forward for the egg industry by achieving flock uniformity’.

His conclusions on the topic, after revealing much research on bird weight and diet was that, “weight management in lay was important and that control of obese birds was very important,” Greg said.

“Equations accurately predict required feed intake and feed can be allocated without impacts on production,” he concluded.

The final paper in this session was presented by two former research post graduates that have found valuable work relevant to their considerable skills.

Dr Kapil Chousalker, now a Senior Lecturer at the University of Adelaide and Dr Kylie Hewson R&D Project Manager at AECL, reviewed practical ways to protect consumers from Salmonella.

Kapil described the various processes around the reporting of salmonella outbreaks and his charts revealed a near doubling of cases particularly in the later summer periods over a five year period.

Kylie Hewson mirrored Kapil’s concern over the statistics of Salmonella.

“Australia wide there has been a significant increase in human salmonellosis cases and in some States the cases have doubled just in the past two years,” Kylie commented.

Possible causes for this significant rise were many and varied but included better and faster diagnosis leading to a higher notification rate, also changes in eating habits – eating out more – more catering and increasing consumption of organic and raw egg bases dishes,” she said.

In more detail, poor refrigeration and handling of potentially dangerous ingredients and even the use of absorbent cardboard trays (rather than recycled plastic material) where a cracked egg could develop into a potentially toxic element in certain conditions.

Solutions to the problem, Kylie suggested were firstly a through chain

CONTINUED ON PAGE 53 w

1

2

3

4

With 95% accuracy in targeting the effective vaccination location in the egg,it’s obvious why Embrex® Inovoject® is the in ovo vaccination leader. These numbers make it even clearer: When vaccinating 1.5 million eggs in ovo,* Inovoject helps ensure that 1.425 million receive proper vaccination at the correct site of injection. Compared to the competition, that is 34% greater protection against disease challenge.1 Can you afford ineffective vaccination and disease risk in 510,000 birds per week?

Smarter is greater accuracy. Smarter is Embrex Inovoject.

For more information talk to Mark Bennett 0427 627 774.

DUAL-NEEDLE INJECTION TOOLING

*Based on assumed weekly volume of 1.5 million eggs injected.1 Williams CJ, Hopkins BA. Field evaluation of the accuracy of vaccine deposition by two different commercially available

in ovo injection systems. Poultry Science 2011; 90:223–226.

SMARTERIS RELIABLEVACCINATION.

© 2014 Zoetis Inc. All rights reserved. Zoetis Australia Pty Ltd Level 6, 5 Rider Boulevard, Rhodes, NSW 2138. www.zoetis.com.au 12/14 PAL1202

PAL1202_A_EmbxInovo_A4-v01.indd 1 15/12/2014 1:42 pm

10

On May 1 2015, RSPCA Australia held its Animal Welfare Seminar at the Australian War Memorial in Canberra with the theme ‘Why animal welfare matters’.

“Animal welfare is and always has been core business for the RSPCA,” said Heather Neil, CEO of RSPCA Australia, in a statement to explain the reasons for hosting the seminar.

“How much does ensuring the welfare of animals actually matter in today’s society and in our ‘human-centered’ day to day lives?

“You don’t need to be an activist or a radical to regard animal welfare as a priority issue, and nor does this mean that animal use should be abandoned altogether,” she said.

“The latest figures released by RSPCA Australia show that more than 220 million farm animals lived a better quality of life thanks to the RSPCA Approved Farming Scheme in 2014.

“Tough but fair, is how RSPCA approved producers describe the scheme which has seen more than 842,000 layer hens, 773,000 pigs, 990,000 turkeys and 313 million meat chickens benefit from the RSPCA’s standards since the scheme started.

“We’re incredibly proud of the positive impact that the scheme and its many dedicated producers have made to the welfare of some of Australia’s most intensively farmed animals,” said Ms Neil.

“The scheme is part of the RSPCA’s efforts to improve the lives of animals and is underpinned by robust, science based animal welfare standards and rigorous on-farm assessments.

“RSPCA approved products are the trustworthy choice to supply this consumer driven demand.

“At the same time, our standards provide a starting point for industry, retail and government to develop animal welfare policies that will result in truly meaningful improvements to the lives of the millions of farm animals across Australia,” Ms Neil stated.

Bidda Jones, Chief Scientist RSPCA Australia, welcomed delegates and the first speaker, Professor Paul McGreevy, animal behavior and animal welfare science expert from the University of Sydney who explained ‘Why animal welfare matters in veterinary education’.

NEWS

RSPCA Australian Animal Welfare Seminar: ‘Why welfare matters’

Andrew Wilkie, the independent member for Denison in Tasmania, explained ‘Why animal welfare matters to me’.

Perhaps the most relevant speaker for the poultry industry was Jackie Healing, General Manager, Brand and Quality at Coles supermarkets.

‘Is it just a ‘nice’ to do? A retailer’s perspective’, was her topic.

Ms Healing and Mark Field (now head of product technology ‘Coles’ brand) were very much involved with the establishment of the RSPCA approved broiler chicken meat scheme, firstly with Hazeldene Chickens and then into ever expanding production volumes through other integrators.

Their experience with similar (but different in certain aspects), RSPCA supported protocols in the UK market, certainly gave them a greater understanding of the market potential in the suddenly more competitive retail sector in Australia.

Apart from broiler meat production, RSPCA approved schemes for both barn laid and free range layers have also achieved market penetration in recent times.

“In 2014, according to ABARES statistics, there was a total of 587.3 million meat chickens produced in Australia.

“During that year approximately 202 million chickens were raised under the (RSPCA) Approved Farming Scheme Standards, therefore around 34% of all chicken grown in Australia during 2014 met the approved RSPCA standards.

“For 2015, this figure is projected to rise to more than 70% of the total of meat chicken production,” a statement from RSPCA Australia revealed.

1. Jackie Healing, Coles. 2. Prof. Paul McGreevy, Sydney University. 3. Terry Nolan, Nolan Meats. 4. Andrew Wilkie, Member for Denison, Tasmania.

1

2

3

4

Ross ® 308 is Simply the Better Bird

The Ross 308 facts:

• Leading FCR

• Excellent Meat Yield

• Low Cost Production

Choose the better bird.

www.Aviagen.com/Ross

Ross 308 Better Bird_Poultry Digest.indd 1 8/11/14 11:55 AMPoultry Digest Magazine 210mm X 297mm

The biggest success stories

start with a little chat.

In an industry that’s constantly innovating and adapting to get better results,

you need a bank that’s agile enough to help you to stay ahead of the game.

With the ups and downs of farming, the relationship between farmer and

bank is critical to your success. That’s why our Agribusiness Specialists

strive to build long term relationships with customers.

They’re from the land too, so they’ve got what it takes to understand your

plans and make them happen. We’ll even come to you, wherever you are.

To write the next chapter of your own success story, talk to your Suncorp Bank Agribusiness team today.

the genuine alternative

Banking products are issued by Suncorp-Metway Ltd ABN 66 010 831 722 Australian Credit Licence 229882 (“Suncorp Bank”) to approved applicants only. Terms, conditions, fees and charges apply and are available upon request. BSUN8504

David Charge

Area Manager, Agribusiness Vic, Tas, SA

0457 567 285 [email protected]

Ben Gierisch

District Manager, South Australia

0428 104 265 [email protected]

Paul Griffin

District Manager, Gippsland & South-East Victoria

0428 102 608 [email protected]

James Ryssenbeek

Agribusiness Manager Melbourne, Central & South-West Victoria

0417 542 339 [email protected]

The biggest success stories

start with a little chat.

In an industry that’s constantly innovating and adapting to get better results,

you need a bank that’s agile enough to help you to stay ahead of the game.

With the ups and downs of farming, the relationship between farmer and

bank is critical to your success. That’s why our Agribusiness Specialists

strive to build long term relationships with customers.

They’re from the land too, so they’ve got what it takes to understand your

plans and make them happen. We’ll even come to you, wherever you are.

To write the next chapter of your own success story, talk to your Suncorp Bank Agribusiness team today.

the genuine alternative

Banking products are issued by Suncorp-Metway Ltd ABN 66 010 831 722 Australian Credit Licence 229882 (“Suncorp Bank”) to approved applicants only. Terms, conditions, fees and charges apply and are available upon request. BSUN8504

David Charge

Area Manager, Agribusiness Vic, Tas, SA

0457 567 285 [email protected]

Ben Gierisch

District Manager, South Australia

0428 104 265 [email protected]

Paul Griffin

District Manager, Gippsland & South-East Victoria

0428 102 608 [email protected]

James Ryssenbeek

Agribusiness Manager Melbourne, Central & South-West Victoria

0417 542 339 [email protected]

14

NEWSMarket update: Low rates effect your businessThe Reserve Bank of Australia (RBA) decided to leave the overnight cash rate at 2.25% at their most recent March and April meetings after somewhat surprising the markets back in February with its first move in the cash rate for more than a year, cutting from 2.50%. As the market was already pricing in a 100% chance of a cut by May we only saw around a 0.10% dip in the three and five year swap rates (as swap rates are forward looking and are based on market expectations). Marker speculation indicates a 70% chance of a cut to 2.00% at the May meeting.

Other key points as to why the RBA eased monetary policy in February are:

Deflation fears across many economies, especially in Europe which has embarked on its own Quantitative Easing program, similar to the US. Essentially, the European Central Bank (ECB) is purchasing longer dated assets (such as bonds) to help push longer term rates lower and provide incentive for firms to borrow and invest.

Central banks across the globe cutting rates in order to align with lower GDP growth. 25 central banks globally have eased their cash rates this year.

Australian inflation remaining in the lower end of the 2-3% target band.

Plummeting commodity prices resulting in a falling terms of trade (a barometer of a country’s wealth) and disincentives to invest in mining activities. The fall in commodity prices has also had a major impact on the Federal Government budget. The falling oil price will also potentially affect future LNG sale contracts.

Low wage growth Rising unemployment as more

mining projects complete construction and move into production, it takes less labour to run a mine than construct one.

Political uncertainty (both domestically and abroad e.g. Greece).

A lower cash rate has a number of implications for the Australian economy. Lower rates lead to asset price appreciation (the main aim of loose monetary policy), which may result in overheating of the housing and equity markets. It’s worth noting that capital city property prices have risen sharply in Sydney and Melbourne while other capital cities have only experienced subdued growth of around 3%.

The RBA also mentioned it believes risks in commercial property are

beginning to build. Despite vacancy rates remaining high and weaker leasing conditions, commercial property prices have increased. This appreciation in price is due to ‘yield compression’ where, in the hunt for higher returns, investors are purchasing commercial property and accepting lower capitalisation rates.

A lower cash rate assists in the devaluation of the Australian Dollar, something that the RBA has been pining for to assist the Aussie economy transition away from mining and into services, construction, and agriculture. While the AUD was buying around 98 US cents for much of last year, it has fallen back to about ~78. The RBA has noted in its February minutes that the AUD still “remained above most estimates of its fundamental value, particularly given the declines in key commodity prices”.

Most market commentators and economists are predicting a further devaluation in the AUD against the USD. Some of this leg work will be assisted by the US Federal Reserve, which is currently deliberating on when to lift the Federal Funds Rate. Once the Fed starts lifting its cash rate, it’s expected that the AUD will continue lower. Some market commentators are calling a AUD/USD in the 60s by the end of 2015.

Interest Rate Risk ManagementInterest rate risk, like any market risk

(foreign exchange, commodity price) or business risk (counterparty risk, management risk, business continuity risks, staffing risks), requires constant management to ensure your business is protected from adverse events.

The two extremes of an interest rate exposure are being:

100% variable – 100% exposed to rising interest rates; or

100% fixed – 100% exposed to falling interest rates (an economic cost).

In order to take a risk neutral position, a starting point may be to consider hedging half your exposure. That way you have the same amount of exposure to rising and falling interest rates. Other considerations include where current rates are positioned in the interest rate cycle, your borrowing time frame, how much risk you are prepared to take, choice of hedging instrument and how your business is leveraged to the economic cycle.

For example if interest rates are at historical lows this may be incentive (depending on an individual’s personal circumstances) to fix a larger proportion of your debt for a longer time frame.

Borrowers will often take the view of staying 100% variable. This has been a good strategy over the past six years (post GFC) as we’ve seen the Reserve Bank cut rates to record lows. However, as we near what is potentially the bottom of the interest rate cycle, interest rate risk management is something all borrowers should be putting at the top of their to do list (again, depending on their individual circumstances).

Fixed rates are forward looking and are a reflection of market expectations of the variable rate for that specific period. Short term rates (one-two year) currently remain reasonably anchored close to and below the current variable rate as the market is pricing in the possibility of one or two further rate cuts in the near future. In the medium term (three-five years) fixed rates are trading at very low premiums to the current variable rate which we believe presents good value and therefore an opportunity to consider some interest rate risk management strategies.

Are you already locked into a fixed rate? For borrowers that are already fixed, the current “flatness in the yield curve” presents opportunities to restructure your current fixed rate into a lower fixed rate for a set period, via an interest rate swap product. This can be done by building the cost of breaking an existing fixed rate into a new fixed rate for a longer term, effectively spreading the cost over the period. As this cost is worn through the interest rate this may not impact your Loan to Valuation ratios or your cash balance and result in lower financing costs for you today.

Separate to a standard Fixed Rate Loan there are many strategies and tools available to assist borrowers in managing their interest rate risk.

“Every borrower’s situation is different and the best way to find a solution that fits your particular situation is to get in touch with your Suncorp Bank Manager or Treasury Representative and have a discussion regarding your current position,” said Ben Gierisch, District Manager – Agribusiness.

CONTINUED ON PAGE 40 w

LEADING SUPPLIERS OF CAGE FREE POULTRY EQUIPMENT

www.potterspoultry.com

Long life, strong and stable Flexible design - maximises stocking density

Australasian Agricultural Services,18 Lennox Street, Redlands Business Park,

Redland Bay, Queensland, 4165

Office phone number: 07 3829 3242Office facsimile: 07 3829 1906

MULTI-TIER AVIARYFOR FREE RANGE AND BARN SYSTEMS

NESTING SYSTEMSFOR BREEDERS AND LAYERS

SLATS SINGLE AND TWO TIER NESTSFOR LAYERS

Rack & Pinion lifting floor with original AstroturfProbably the strongest and most stable available

18

Third time lucky visiting solar saver

By PETER BEDWELL

Today hand decorated Kombi vans from that era are still a feature in the region.

Backpackers and other tourists from around the globe appreciate the lush countryside and fabulous beaches.

The location of Ken and Jane’s farm however, stands out.

The fast flowing Byron Creek forms a natural moat around the 60-acre farm with just 200 metres of road frontage. So not only is it picturesque, it ensures good biosecurity for the broiler farm that was once a pig farm, a Charolais stud, then modified for horse agistment and rider training and is now an Inghams RSPCA broiler code operation.

The three sheds, built about 20 years ago, house 75,000 birds and though of older curtain sided design they are tunnel ventilated: an ideal set up for an RSPCA operation.

Ken Wake’s career is an interesting one – an airline pilot for first Air New Guinea, then Singapore Airlines, he ended his long aviation career in Hong Kong in a pilot training role for Cathay Pacific.

Fifteen years ago he acquired the Binna Burra farm as an investment that was run by a farm manager and his family.

Then four years ago he and Jane w

Ken and Jane Wake on their property at Binna Burra.

A couple of months ago Waverly Phillipson, Commercial Manager for the national renewable energy company the Modern Group, called Poultry Digest to discuss the potential for solar power in saving the poultry industry from energy costs.

Waverly told us about Ken Wake’s broiler farm at Binna Burra near Byron Bay in NSW and how he had dramatically reduced his power bills by going solar.

We agreed that Poultry Digest should visit the farm and talk to Ken about his experience in saving with sunshine.

That proved to be the easy bit as the storms that have lashed SE Queensland

and Northern NSW recently caused two cancelled trips but on the third attempt we made it.

The weather in SE Queensland on May 8 was perfect as Poultry Digest and Waverly drove from Coolangatta Airport to Ken and Jane’s property at Binna Burra.

Normally we don’t mind a bit of overcast weather, particularly in the middle of the day, as harsh sunlight can make on-farm photography as much, or more of a challenge, than grey skies.

However seeing as his story was about solar energy we were glad to enjoy a prime component of the story – sunshine!

Waverly did point out that a good quality solar set up like the one installed by Ken, would still perform in overcast conditions given Australia’s high levels of UV.

“Anyway many of the advances in solar equipment design have taken place in Northern Europe where grey skies are more prevalent than the brilliant sunshine we enjoy in south east Australia,” Waverly said.

Much has been said about the beauty of the Bangalow area of Northern NSW as young city dwellers flocked there in the 1970s to establish hippie colonies.

Highly effective againstAvian Influenza including H7

w

returned to Australia after Ken retired and gradually took over the running of his farm.

After a period, while enjoying the farming life, he didn’t appreciate the ever rising power bills, or the prospect of them being even more out of control in the future.

So when Ken returned to his farm a few years ago and saw how power bills were spiralling out of reasonable control, and likely to get worse as state governments rushed to sell of the ‘poles and wires’, he took considered action and invested in a solar alternative.

So has the Wakes’ strategy worked?

“Well we’re just over two years in and close to a complete return (in another one and a half years) on the investment. In selecting the equipment we opted for high quality German designed and developed products that have a guaranteed long life span, and we just happened to install the solar when the Australian dollar was at an all time high, which turned out to be a bonus,” Ken said.

In short Ken didn’t opt for a ‘least cost’ option.

“Also that calculation is based on historic energy costs and not what energy providers, possibly privatised, might charge in the future,” he added.

Waverly points to the fact that the Tier 1 solar panels they installed are regarded as ‘state of the art’ and engineered for both longevity and performance.

“The panels use specially developed glass and solar cells that are warranted for 25 years of efficient production.

“Similarly the three power input inverters are regarded as being of the best quality and most efficient standard,” Waverly stated.

“Conversion to solar is an ideal way to reduce a chicken farmer’s dependence on grid electricity supply and rising costs of production.

“An analysis of Ken’s first quarter electricity invoice showed a saving of $2,202.00. In total, his energy costs have reduced by around 47%,” Waverly said.

“I had a staggering saving of $4,400.00 over six months. I haven’t had an invoice that low in many years,” said Ken.

Prior to walking over to the sheds we discussed the farm’s move to RSPCA protocols.

“I can see that consumers approve of RSPCA having an overview of our production methods and how retailers can use that to their advantage.

“The aim of the protocols is to improve bird welfare and that has definitely been achieved, and will continue to improve in the future.

20

v

1. Climate controlled sheds rely on long proven technology. 2. Top quality Schneider PV panels guaranteed for 25 years. 3. One of three Aurora Italian inverters. 4. Trusty generator always ready and properly serviced. 5. Grillo walk behind rotavator performs many duties on the farm.

1

2

3

4

5

FREEWEBBOX* Limited

Offer

Monitor your Solar productionand energy consumptionfrom your computer with a

COMMERCIALAustralia’s Trusted Renewable Energy Company

IT’S TIME TO GO SOLARREDUCE ENERGY COSTSINCREASE PROFIT!

Australian owned business for over 35 years

Fully accredited national company

Over 22,000 solar installations

Energy Audit and site inspection/evaluation.

Premium quality system and components

25 year warranty on panels

PERFORMA

NC

E

LO

N

GEVITY AND

GOLD

STANDARD

H

H

Modern PV Solutions. Purpose Designed to Achieve OptimumReturn on Investment for the Poultry Industry.

· PV Solar· Battery Hybrid. On and Off-grid

· Peak Load Shaving· Power Factor Correction

· Lease Finance from 4.9%#

1300 558 067Call today for a customised energy evaluation

www.moderncommercial.com.au#Terms, conditions, fees, charges & lending criteria apply.

Finance available for approved applicants. Modern NSW LIC. No. 86266C. Modern WA Painter’s Reg No 3315,Modern QLD QBSA LIC. No. 79335, Modern SA 40806, Modern VIC BLD. LIC. No. DB-L25602.

*Conditions apply. One FREE WEBBOX per installation.

Ken & JaneWake Poultry FarmNSW

COMMERCIAL

22

“I am keen to comply in running our farm to the required standards as long as I know exactly what they are and how we are expected to achieve that compliance in the medium and long term,” Ken said.

“If it helps our industry and my integrator in particular, to build consumer confidence I’m all for it.”

Ken in two extended careers, has proved to be a master of adaption both on the flight deck of a 747-400 and today running a broiler farm.

He has a forensic eye for detail. He spots a curtain that is not quite fitting flush with the shed wall and later a leaking O ring on one shed’s water filtration system.

“We may need to improve air flow in the sheds and I’m looking at how we can achieve that,” he said.

In answer to the question over litter re-use Ken explains that with a good and reliable source of wood shavings, he cleans out after each batch, but is prepared to consider options should circumstances change.

A shiny new Italian Grillo walk behind rotivator is probably his Plan B on that issue but he does say that “it is a versatile and very useful piece of equipment around the farm”.

With the sun well across the yardarm we toast Ken and Jane’s efforts and their enviable lifestyle.

Jane has plenty of ideas about how to develop their farm and situation in one of the world’s premier tourist and lifestyle locations.

With the challenge of energy costs

The commercial Modern Groups Commercial solar plant installed on Ken and Jane Wake’s farm was specifically designed to reduce electricity consumption from the grid during periods when it is most expensive.

“Key components are Tier 1 ET Solar Photo Voltaic panels that are recognised as being the ‘gold standard’ in solar power for both performance and longevity.

“The panels are manufactured using the best quality solar cells, low iron, high impact glass and components mean that they will perform well beyond the 25 year performance warranty,” Waverly Phillipson said.

“They can generate over 156kWh of electricity per day dependent upon weather conditions but will perform in both full sunlight and overcast conditions.

“Once installed, tested and

Ken Wake’s ‘Modern’ Solar Power equipmentcommissioned the system requires little maintenance other than a clean from time to time and an annual health check.

“The 3 10kW inverters turn the DC power generated by the PV panels into 240volt AC current that can be utilised by the sheds electrically powered equipment.

“The inverters we use are state of the art and extremely efficient with minimal losses during conversion.

“While Ken’s system is not designed to supply surplus power back to the grid, he does end up selling quite a bit during the low load periods particularly when the sheds are empty.

“The system can in the future be expanded to generate more power or even using advances in battery technology to further reduce dependence of the grid.

“The original concept of significantly reducing energy costs

1

2

1. Ken and Jane Wake maintain an immaculate property – Ken has a keen eye for detail. 2. Enclosed cool pad section reduces disease risk and helps to extend cool pad life.

both now and in the future for Ken’s broiler operation has been achieved.

“Since Ken’s installation has been in operation there are now even more cost effective energy saving options available to farmers and specifically to those in the Poultry industry.

“The recent Federal Budget offer of tax exemption on a spend of up to $20,000 for capital equipment, and renewable energy subsidies when combined with the increasing requirement to reduce energy costs, will provide a further incentive for broiler farmers to ‘go solar’” Waverly said.

The panels used on the Wake farm are highly rated under the Bloomberg New Energy Evaluation Scheme coming in at number three in a field of more than 180 products.

“As the number two product is not available in Australia, number three is not a bad place to be,” Waverly concluded.

under control they have achieved a smooth transition to the RSPCA broiler protocols and thus remain a viable

business in an ever changing industry and still growing market for safe and healthy protein.

24

The Poultry CRC has teamed up with the NSW Department of Education & Communities (DEC) to produce a number of videos outlining the fundamentals of keeping chickens in schools.

A series of nine videos (ranging from three minutes to seven minutes) has been made available online via LearningNSWDET and Poultry Hub’s YouTube channels. This will also soon be made available on Scootle (the National Curriculum online database).

The films are targeted at schools that are new to keeping chickens, providing information and useful insights from a school already using poultry in their classrooms, with some expertise from Poultry CRC researchers and veterinarians. The titles of the films are:• Choosing your birds• Housing requirements• Feeding and watering• Poultry behaviour• Routine management and holding a. Bird health and external parasites

NEWSVideo resources for schools

b. Bird health and internal parasites c. Bird health and disease• Show bird preparation

“With the number of schools that are keeping poultry on the rise, we saw a need for good quality teaching resources for schools that are new to poultry” said Poultry CRC Education Coordinator Liz Roan.

“With the inclusion of Sustainability as a key curriculum area across all subjects, and Food and Fibre Production now included in the National Technology Curriculum, more schools are looking into keeping poultry at school and teachers are looking for good resources.

“The addition of short, informative films which can be referenced via the updated Animals in Schools website will be an invaluable tool in helping teachers make a good start,” she said.

Investment in school education is a long term proposition which will generate future support for industry in terms of public understanding as well as future personnel.

Correct information must be provided to schools so they can easily comply with animal welfare legislation. Videos such as these reduce the chances of negative outcomes for the birds and engage students with the science behind the practices.

The advantage of producing materials for schools and educating school students is that it is possible to educate young people before they acquire negative or incorrect knowledge. This can only be to the industry’s long term benefit.

Additionally, the development of this resource gives the CRC reach beyond our lifespan, where we are no longer able to post out physical resources to schools.

“It complements the work we have already done in the production of the chick embryo development animation.

“The quality, visual appeal and availability of these videos will no doubt have an ongoing impact in schools across Australia (and hopefully across the world),” said Liz.

Tyson Foods strives to eliminate human antibiotics from broiler chicken flocks by 2017Tyson Foods, Inc said recently it is striving to eliminate the use of human antibiotics from its United States broiler chicken flocks by the end of September 2017.

The company will report annually on its progress, beginning with its fiscal 2015 Sustainability Report.

Tyson Foods has already stopped using all antibiotics in its 35 broiler hatcheries, requires a veterinary prescription for antibiotics used on broiler farms and has reduced human antibiotics used to treat broiler chickens by more than 80% since 2011.

“Antibiotic resistant infections are a global health concern,” said Donnie Smith, President and CEO of Tyson Foods.

“We’re confident our meat and poultry products are safe, but want to do our part to responsibly reduce human antibiotics on the farm so these medicines can continue working when they’re needed to treat illness.”

“Given the progress we’ve already made reducing antibiotics in our

broilers, we believe it’s realistic to shoot for zero by the end of our 2017 fiscal year.

“But we won’t jeopardise animal well-being just to get there. We’ll use the best available treatments to keep our chickens healthy, under veterinary supervision,” Mr Smith said.

Tyson Foods is also forming working groups with independent farmers and others in the company’s beef, pork and turkey supply chains to discuss ways to reduce the use of human antibiotics on cattle, hog and turkey farms.

Those groups will begin meeting this summer.

Tyson Foods’ international business is committed to taking similar measures on antibiotic use in its global chicken operations but has not set a timeframe.

Tyson Foods plans to work with food industry, government, veterinary, public health and academic communities, and provide funding, to accelerate research into disease prevention and antibiotic alternatives on the farm.

The company is also getting input from its Animal Well-Being Advisory Panel, which is made up of independent advisors.

“One of our core values is to serve as responsible stewards of animals – we will not let sick animals suffer,” Mr Smith said.

“We believe it’s our responsibility to help drive action towards sustainable solutions to this challenge by working with our chicken, turkey, beef and pork supply chains.”

Mr Smith said this recent announcement will not materially affect the company’s financial performance.

26

NEWSIntensive ag must reduce costs says Nuffield scholarManaging costs is important to all businesses, but in the intensive world of meat chicken production, it’s critical.

For New South Wales farmer Guy Hebblewhite, keeping expenses under control on his Tamworth chicken farm is getting more and more difficult.

“Our costs are increasing at a great rate – electricity and gas costs on our farm are going through the roof and so to achieve some sustainable long-term growth prospects we need to actually keep a lid on those expenses,” he explained.

Guy decided there was a real opportunity to reduce his gas and electricity costs by using the manure produced on the property to create biogas, which is produced by the breakdown of organic material through anaerobic digestion.

Further capitalising on that, Guy wanted to utilise heat from the process to create a renewable energy source, and so in 2013 he embarked on a Nuffield Scholarship to study how businesses around the world were tackling the same problem

Starting in Canada after the Nuffield Contemporary Scholars Conference in 2013, which brings together all scholars studying in a particular year, Guy then also went to the USA, before then completing his individual studies in the UK, the Netherlands and Germany in June 2014.

“I went all over the place, it was absolutely fantastic learning from farmers who had actually adopted the anaerobic digestion and biomass technology in whichever industry they were in, whether that be a dairy, turkey farm, or just be a stand-alone unit built to utilise biogas and biomass opportunities,” he explained.

In terms of costs of the technology, Guy saw the good and the bad, with a considerable financial outlay for large operators using a biogas system.

“That technology was costing into the one or two million euros at that stage overseas, but the equivalent systems in Australia are up around the two million dollar mark, so they are very heavy capital investment options.

The good ones were operating very well, however I did actually see a couple of these units in Germany that had gone into receivership due to high ingredient input prices,” Guy recalls.

However, despite the high capital

costs, the benefits of generating electricity and heat from the units cannot be ignored.

“The banks in Holland now will not fund these projects without the heat being utilised in some way, so they’ve actually said, great that the electricity is produced, and we can generate that electricity very happily, but the heat must be used in some form,” Guy explained.

So what can Guy implement on his northern NSW property, and recommend more broadly to his industry, as a result of his Nuffield learnings?

He believes it all starts with thinking outside the square about the technologies available and, most importantly, seeing beyond the short term cost to the long-term benefits.

“We’re very happy to keep on paying our bills every month to the electricity and gas companies, but rather than doing that we could actually look at utilising a model I think that could actually pay off these investments a lot quicker, potentially over a four to seven year period and then actually be operating on free energy.

So we just need to think outside the square, it’ll certainly be an investment model that needs to join with the theory of how to actually get these sites established, but it can be something that is actually very exciting for the industry into the future,” Guy said.

Guy’s scholarship was supported by the RIRDC Chicken Meat Program.

You can watch Guy presenting his findings at the Nuffield Australia conference in Launceston here https://vimeo.com/108885983 and follow him on Twitter here @GuyHebblewhite.

Nuffield Australia provides opportunities to Australian primary

producers and managers between the ages of 28 and 40 to travel the globe investigating a research topic important to them and Australian agriculture.

The organisation is currently taking applications through to the June 30, 2015 for the 2016 scholarship program. A $30,000 bursary is provided to successful applicants to carry out their study over a two-year period.

To keep up with the latest from our organisation, please connect with us at www.nuffield.com.au, on twitter @nuffieldaust and #nuffieldag, and on Nuffield Australia’s Facebook page.

To advertise in Poultry Digest contact Pete Bedwell on 02 9797 2406 or

0419 235 288. Please not our address is now

250 Hawthorne Parade, Haberfield NSW 2045

Email: [email protected]

NSW farmer, Guy Hebblewhite

DOL 539 Free-Range Climate and Production Computer

• Large graphic touch screen - navigation via icons on the screen• Special free-range functions

• Automatic change between free-range ventilation and normal ventilation• CO2 control, also in free-range mode• Basic and broiler production facilities

• Pop-holes to be opened automatically or manually (sensor on doors if manually)• Automatic ventilation turned off in free-range mode• Automatic change of alarm for high/low temperature

• CO2 ventilation active in free-range mode (will start ventilation if CO2 is too high)• Pressure alarm

• Fans only operate if needed (too high temperature or too high CO2)• When pop-hole door closes, the program changes back to “Normal ventilation”

All the required functions for ensuring optimum production under any climatic conditions.

Features

SKOV Free-Range Ventilation

30

HEALTH FEATURETesting the efficacy of Vaxsafe ST vaccine

Vaxsafe ST (Bioproperties Pty Ltd) is an aroA deletion mutant vaccine for the control of Salmonella Typhimurium in chickens. It is registered for spray and drinking water applications and has been shown to aid in the control of Salmonella in short lived birds (such as broilers).

The main objective of this study was to test efficacy of Vaxsafe ST with a new vaccination program aimed at lengthening the duration of immunity for the full productive life of layers.

The first dose was delivered by spray on chicks at one day of age followed by two doses administered orally at 2 and 6 weeks of age (woa) respectively, and a fourth dose administered by intramuscular (IM) injection at 10 woa.

All vaccination doses were administered at 107 cfu/dose.

For the fourth IM dose, the vaccine was delivered in two different formats, mixed in diluent or in a mixture with Nobilis EDS+ND vaccine (Intervet).

At 16, 30, 45 and 65 woa respectively (that is at 6, 20, 35 and 55 weeks post IM vaccination) a sample of the vaccinated birds, was transported to a research facility and challenged with wild type S. Typhimurium (ST) or S. Infantis (SI). Salmonella shedding of vaccinated birds were compared with a control unvaccinated (challenged) group in order to assess efficacy of the vaccine.

Vaxsafe ST delivered in either diluent or with Nobilis EDS+ND killed vaccine, provided protection against strong homologous (ST) and heterologous (SI) challenges compared to the unvaccinated birds.

IntroductionVaxsafe ST is a registered vaccine

produced by Bioproperties Pty Ltd. The statement of claims for this vaccine is as ‘An aid in the control of colonisation by S. Typhimurium’.

The vaccine has been shown to reduce the excretion of virulent S. Typhimurium and provide chickens with an aid in protection against challenge by this strain.

The registered method of administration is by spray on chickens at one day of age followed by an oral

administration at 2 woa. This regimen was designed to

protect short-lived birds (broilers) against S. Typhimurium challenge, but to date has not been widely adopted.

Recently it has been used by injection in broiler breeder Salmonella control programs in Australia, combined with killed vaccines with great success.

In order to extend the duration of immunity till the end of life for layers, a new vaccination program needs to be developed and tested.

Previous studies have shown that Vaxsafe ST when given with regimens including an intra-muscular injection can provide useful protection against S. Typhimurium challenge and heterologous challenge with S. Infantis, and to a lesser degree S. Virchow challenge (Sharp et al. 2012).

These experiments did not define the duration of this immunity and the cost of administration would be an impediment for general adoption in the layer industries.

In this study, the current vaccination program for Vaxsafe ST was modified to include a third dose delivered by drinking water at 6 woa followed by a fourth dose administered by intramuscular (IM) injection at 10 woa.

For the first three vaccinations, Vaxsafe ST was delivered at a dose of 107 cfu in water.

For the fourth vaccination, it was tested at a dose of 107 delivered in diluent, or mixed with Nobilis EDS+ND killed vaccine. Nobilis EDS+ND is a combined vaccine for the immunisation of chickens against Newcastle Disease and Egg Drop Syndrome ’76.

The Nobilis EDS+ND killed vaccine consists of an inactivated antigens prepared as a water in oil emulsion.

Methods A total of 26,000 Salmonella free

commercial Hy-Line layer birds were vaccinated at the hatchery by coarse spray at day of age.

The birds were transported to a commercial farm and reared in cages in shed A as per the normal farm management procedures. A group of 26,000 birds were left unvaccinated and transported separately to the same farm and reared in cages in shed B.

At 2 and 6 weeks of age all birds in shed A were vaccinated with Vaxsafe ST (107 cfu/dose) in drinking water as per manufactures instructions.

At 10 weeks of age, two groups of 125 birds were selected from shed A and vaccinated by IM injection (0.5mL/dose/bird) into the pectoral muscle with one of two Vaxsafe ST formulations (in Marek’s diluent or mixed with Nobilis ND/EDS killed vaccine).

A vial of freeze dried Vaxsafe ST vaccine (1000 doses/vial) was resuspended in 3 mL of Marek’s diluent and then added into 1000 doses of the killed vaccine and mixed by shaking.

Birds in shed B remained unvaccinated against Salmonella. At each of 6, 20, 35 and 55 weeks post IM vaccination, ten birds from each of the vaccinated groups and ten birds from shed B (control shed) were transported to a research facility, and placed into isolators.

At 48 and 24 hours before the administration of the challenge, all chickens from all groups received vancomycin (60 mg per bird per os in 0.6mL). (Modified from Marcq et al., 2011).

The challenged consisted of freshly cultured 109 cfu/dose of wild-type ST or SI. Chickens were monitored for clinical signs throughout the study and screened for Salmonella shedding with cloacal swabs being taken on days 0, 2, 7 and 14 post challenges.

The presence and concentration of live Salmonella in swabs was determined by titration in Rappaport-Vassiliadis (RV) media (after resuscitation in Peptone broth) and identity confirmation on XLD and SMID plates followed by specific wild-type ST or SI PCR based methods.

All data collected from the vaccinated and challenged birds were compared with those collected from the control groups in order to assess efficacy of the vaccine.

Results No clinical signs were observed

in any of the vaccinated groups immediately after vaccination, or throughout the study.

Prior to each challenge time-point, cloacal swabs were collected from chickens on the farm from both sheds A and B and screened to ensure that the birds were not infected with Salmonella.

Also just prior to challenge, cloacal swabs were collected from birds in all w

By Y. ABS EL-OSTA, S. MOHOTTI, F. CARTER, S. KUCHIPUDI, R. YOUIL, G. UNDERWOOD, P. C. SCOTT and C. J. MORROW

[email protected]/animal-nutrition

Cost per kg meat? Check! Feed needs support to live up the demand of modern animal production. CreAMINO® boosts natural creatine synthesis, reduces the need for arginine, and saves energy. To get performance up and costs down.

Evonik – Simply Effi cient™

w

32

groups. All these results were negative for Salmonella.

In the positive control groups, the infection profile for ST was quite different to that of SI in terms of the number of organisms shedding, as well as the duration of the infection.

Nonetheless, shedding from the positive control ST and SI groups was relatively high, indicating a good rate of challenge.

Shedding of S. Typhimurium and S. Infantis

There was a reduction in mean shedding of ST (see Figure 1. Panel a) in vaccinated chickens at most time points.

Chickens challenged at 6 weeks after the IM vaccination with Vaxsafe ST combined with Nobilis EDS+ND showed a significant reduction the amount of ST shedding by day 14 after challenge.

However, in chickens challenged at 20, 35 and 55 weeks after the IM vaccination, Vaxsafe ST delivered in either diluent or combined with Nobilis EDS+ND showed reduction the amount of ST shedding by day 14 after challenge.

There was a reduction in shedding of SI in all vaccinated groups over the 3 sampling time points (days 2, 7 and 14) when compared with the unvaccinated positive control group.

Shedding from the positive control remained high even at 14 days post challenge (see Figure 1. Panel b). Significant reduction (p<0.05) in SI shedding in vaccinated groups compared with the unvaccinated groups (positive control) was obtained when Vaxsafe ST was delivered in diluent for challenges at 6 and 20 weeks after vaccination.

Interestingly, a significant reduction (p<0.05) in SI shedding compared with the positive control groups was obtained for both injected presentations of Vaxsafe® ST (in diluent and mixed with Nobilis® EDS+ND) for the challenged at 35 and 55 weeks after vaccination.

Discussion This experiment lacked the power

to cope with the stochastic nature of the Salmonella challenge shedding data, but trends were consistent and the demonstration of significant effects at later time points (in the case of the heterologous SI challenge) would allow the reasonable conclusion that some protection existed at earlier points.

This problem may be overcome by Bayesian analysis of the data similar to a recent paper by Arnold et al (2014).

These trends were a decrease in excretion in day 2 swabs in ST challenge in vaccinated groups and then all groups had similar rates of

clearance. The SI challenge organism appears

to be able to colonise the hens with cloacal shedding results from day 7 and day 14 being similar while in vaccinated groups these usually appeared to be being cleared.

This suggests that the immunity from the Vaxsafe ST vaccine primes the hen and this broad immunity can be rapidly mobilised in the gut of the chicken to reduce excretion of heterologous serovars.

By day 14 the rates of shedding were similar in most cases whether the vaccine had been mixed with the killed NDV/EDS or just administered separately in diluent (Figure 1).

The vaccination regimen described illustrates potential for protection against ST egg contamination, and may provide a broad general Salmonella protection.

Large numbers of layer hens in the field have now been vaccinated with similar IM regimens and it is well

tolerated and rearing is reported as unaffected.

Transient depression after vaccination (Groves and Sharp 2012) has not been observed in this experiment and has not a problem in the field to date.

The Egg Layer industry should have the confidence from this work, previous work (Sharpe et al 2012), and positive experiences with similar vaccination regimens using Vaxsafe ST in the broiler breeder industry, to begin investigating the advantages of this technology.

Ackowledgements: This research was conducted within the Poultry CRC, established and supported under the Australian Government’s CRC Program. We would like to thank Cheryl Colson and the team at animal housing facility at the APCAH at the University of Melbourne. Thanks also to Dr Nilhan Fernando and Dr Arif Anwar from Scolexia Pty Ltd.References available on request.

Figure 1: Shedding of ST and SI in vaccinated and control groups challenged with wild type ST or SI at 6, 20, 35 and 55 weeks after IM vaccination with Vaxsafe ST delivered either in either diluent or mixed with Nobilis EDS+ND killed vaccine. Means with error bars (standard error). Sampling/Data points are a 2, 7 and 14 days after challenge.

v

AU

/NA

EV

/101

4/00

02 MSD Animal Health91-105 Harpin Street, Bendigo East VIC 3550 Free Call: 1800 033 461www.msd-animal-health.com.au

For product enquiries contact Robin Anderson Mobile: 0424 197 640 Email: [email protected]

For orders contact Customer Service Free Call: 1800 033 461 Free Fax: 1800 817 414 Email: [email protected]

THE SCIENCE OF HEALTHIER ANIMALS

Nobilis® AEVVaccine

Live vaccine for protection against Avian Encephalomyelitis Virus in chickens.

RR

A/M

SD

1614

6

34

welfare more broadly both nationally and internationally,” said Ms Eileen Thumpkin, President RSPCA Australia.

“In honour of the important role he has played the RSPCA has created a new award which will recognise future leaders in the space of animal welfare.

“RSPCA Australia is calling on individuals from all walks of life who can demonstrate their commitment to animal welfare and the philosophy and policies of the RSPCA, whether this is through their employment, study, research, personal interest or volunteer activities to apply now,” she said.

The Awardee will present the Hugh Wirth Animal Welfare Oration, an original speech that sets out their vision for improving animal welfare in Australia and providing animals with ‘a life worth living’ at the 2016 RSPCA Australia Animal Welfare Seminar.

For more information please visit: www.rspca.org.au/hugh-wirth-award

NEWS

RSPCA Australia has unveiled a prestigious new award which recognises the contribution, achievement and vision of a future leader in the field of animal welfare - The Hugh Wirth Future Leader in Animal Welfare Award.

Dr Hugh Wirth AM is one of Australia’s best known animal welfare advocates.

His commitment to the RSPCA spans more than five decades having played key roles within the organisation since the mid-1960s, including as a Board Director, President of RSPCA Victoria (a positon he still holds) and President of RSPCA Australia, a position he held for 26 years.

This award is in honour of the incredible contribution he has made to animal welfare throughout his lifetime.

“Dr Wirth has played an integral part in the history of the RSPCA here in Australia, he has helped shape the organisation along with animal

RSPCA calling future leaders in animal welfare to step forward

Dr Hugh Wirth AM.

2015 AgriBusiness Innovation of the Year AwardNext instruments has announced that the company was presented with the 2015 AgriBusiness of the Year Award at the Wimmera Field Days, held in Horsham, Victoria in March.

The award was for the CropScan 3000S On Silo Analyser that was launched at the event.

The CropScan 3000S is a unique system designed for measuring protein, moisture and oil in grans and oil seeds as they pass through an auger, along a conveyor belt or through a pnaumatic pipe.

The system consists of the CropScan 3000 Near Infrared Transmission spectrometer, a remote sampling head and a touch screen PC controller mounted onto a trolley for transporting the system around the yard or shed.

The analyser is part of an ongoing product development that started 15 years ago when NIR Technology Systems developed the portable NIR analyser for farmers. Since 2000, NIR Technology Systems and now Next Instruments have introduced a complete range of on-farm analyser technology that includes the CropScan

3000H On Combine Analyser, the 1000H On Farm Analyser, the 1000B Whole Grain Analyser and the CropNet Farm Data Management Software.

The CropScan 3000S allows farmers, grain traders and grain processors to measure the quality parameters of their grain in real-time. This enables the user to monitor the protein, moisture and oil content as the grain is being loaded into a container, a truck or ship.

It allows farmers to blend grain from two silos to ensure that they meet contract specifications. It allows grain processore like flour millers and stockfeed manufacturers to check the incoming loads of grain to ensure greater uniformity in feed stock.

The CropScan 3000S, like all of the CropScan range of NIR analysers, is linked to the CropNet software which can then post data in real-time to the web.

Farmers, buyers and traders can access the web using their smart phones, tablets of office PC to capture grain quality data along with tonnage, storage location, variety and other information relating to grain.

Call for a quote: Etienne Misfud on Mob: 0428 481 811 or 0417 481 811 Office: (02) 4774 8764

Fax: (02) 4774 8415 Email: [email protected]

R & E SHEDSBuilt to Last

• Over 20 years experience in building poultry and machinery sheds• All styles of sheds – conventional, free range and tunnel sheds• Well known reputation for fast and efficient erection time without

compromising good quality workmanship• As the owner of R&E Sheds, Etienne Misfud oversees the whole job from

start to finish• Repairs, extensions, insurance work to any existing sheds• All sheds can be customised to suit any clients’ needs• All structural steel work manufactured at R&E Sheds, so no delays on

completion of the project• No project too small or large• We travel to all areas of Australia and New Zealand• Fully licenced to build interstate or overseas

R & E SHEDS

Call for a quote: Etienne Mifsud on Mob: 0428 481 811or 0417 481 811 Office: (02) 4774 8764

Fax: (02) 4774 8415 Email: [email protected]

R & E SHEDSR & E SHEDSBuilt to Last

• Over 20 years experience in building poultry and machinery sheds• All styles of sheds – conventional, free range and tunnel sheds• Well known reputation for fast and efficient erection time without

compromising good quality workmanship• As the owner of R&E Sheds, Etienne Mifsud oversees the whole job from

start to finish• Repairs, extensions, insurance work to any existing sheds• All sheds can be customised to suit any client’s needs• All structural steel work manufactured at R&E Sheds, so no delays on

completion of the project• No project too small or large• We travel to all areas of Australia and New Zealand• Fully licenced to build interstate and overseas

Project5:R&E Shedsfinal 25/03/14 2:26 PM Page 1

36

NEWSTelling the whole story about agricultureAs owner of a free-range egg operation in the Great Southern of Western Australia, Kate Mason is passionate about connecting with consumers.

Kate had always thought the key to engagement lay in educating the consumer, but she had a reality check not long after departing her Kojonup farm on her 2013 Nuffield scholarship.

“In one of my first meetings during my individual studies, I was talking to an ag consultant in Canada and he said to me ‘forget about it, you’ll never educate the consumer, there are too many people with a vested interest in confusing them,” Kate recalls.

It was that meeting that made Kate actually analyse how agriculture goes about trying to educate consumers, and she quickly realised a different strategy was needed.

“Sometimes I think we are actually creating this fantasy bubble where we are creating our very own sensitive consumer.

“What I believe we need to do is to start telling the whole story about exactly what happens on farms, and we need to see things that go wrong as an opportunity to explain exactly what happens in agriculture,” Kate explained.

Through Kate’s individual Nuffield travel she was able to visit a US enterprise having a strong impact with consumers using exactly this approach.

“Fair Oaks Dairy Farm in Indiana has 37 thousand milking cows which are in housed barns and they want the visitors, who are of course also consumers, to see all 37 thousand of these cows and exactly what happens on that farm on a daily basis.

They’ve actually got a birthing barn and I asked them how they select the cows that they’re using in there to have calves so they don’t have any problems. He said “No, no, no, that’s not what we’re doing. We want to use those problems as opportunities to explain to the consumer exactly what is happening here”.

Interestingly, while Kate says animal activists are still targeting the high profile dairy operation, consumers are now standing up for the farm.

“Consumers are saying - well I’ve been there, I’ve taken my kids there, we’ve seen everything and we know what’s going on,” Kate said.

In the Netherlands, Kate experienced a similar transparency on farms with the Roundel system, a

housing system for chickens in which they are raised with an emphasis on animal welfare and the environment.

“It’s really amazing – they’re still using everything we’re using in commercial agriculture, but the thing is they’ve put a positive spin on it and they’re explaining it all to the consumer.

“It’s set up in a way that is very friendly for the consumer to come and have a look, and it actually gives them a positive feeling towards the product when they leave there,” Kate said.

In Australia, Kate would like to see a similarly transparent approach for engagement between farmers and consumers, however she believes it’s the first step that will be the hardest.

“I think people worry about what will come from opening their doors and showing all, but while it would be a big step for one person, after one successfully does it other people will follow and it may become a bit more the normality.

In fact, we’re looking at doing

this on our own farm with Katie Joy’s Free Range Eggs – we’d really love to be able to explain to the consumer everything that we do, why we do it and how we do it, because we know that our systems are great,” Kate concluded.

Kate’s scholarship was supported by the Australian Egg Corporation.

You can watch Kate presenting her findings at the Nuffield Australia conference in Launceston at: https://vimeo.com/110224565 and follow her on Twitter @katiejoyjoy.

Nuffield Australia is currently taking applications for the 2016 scholarship program through to the June 30, 2015, for travel in 2016. A $30,000 bursary is provided to successful applicants to carry out their study over a two-year period.

The organisation provides opportunities to Australian primary producers and managers between the ages of 28 and 40 to travel the globe investigating a research topic important to them and Australian agriculture.

Kate Mason, Nuffield Scholarship winner

* Shed Wash Service* Spray Sanitise & Fumigation

* Beetle Spray Service* Water Sanitisation

(Chlorine Dioxide/Chlorine)* Brood Paper Supplies

* Feed Caddy * Litter Management* Litter Amendment * Odor Control

* pH Correction * Chemical Supplies* Ammonia Meters & Testing Equipment

* Personal Protective Equipment (PPE) * Drum Pumps

Office: 4942 3334 | Lisa: 0427 886 866 | www.prowashpoultry.com.au

BATCH TO BATCH POULTRY SPECIALISTS

012

221

012221 Prowash Full Page Ad 02.indd 1 15/12/2014 12:05:42 PM

The most affordable litter management device on the market!

THE LITTER SAVER

PULVERIZES

AERATES

DRIES

LEVELSPerfect for • Eliminating any caked & wet litter• Multi-Batch Litter use • Wet Shavings and Bedding Materials • RSPCA Approved Farming Scheme

5 Pulverizes hard caked litter and allows moisture to evaporate

5 Will ride under litter without digging into the pad

5 Leaves a smooth, soft, well aerated surface

5 Low Maintenance, compact and easy to use

5 Available in two sizes with PTO driver or Bobcat options

GOOD LITTER MANAGEMENT IS TO KEY TO PERFORMANCE AND PROFITABILITY.

We stock the full range of Priefert Poultry Equipment including the Priefert Litter Blade for windrowing.

The only supplier of Chlorine Dioxide to the Poultry Industry with direct industry experience and understanding!

• Effective Fast Acting Sanitation

• Eliminates Biofilm & Prevents Biofilm Re-Growth

• Eradicates Microbial Contamination: bacteria, viruses, fungi, mould and odour

• Effective Over a Wide pH Range

• Cost Efficient & Easy to Use

• Automatic Dosing Provides Continuous Protection

38

NEW PRODUCTS

Energy saving poultry shed dimmable lightingSouth Australian based company zükt LED Lighting has developed and manufactured a robust IP65 poultry shed light that is energy saving and has the ability to smoothly dim to zero, accurately transitioning through dawn to dusk settings.

“The new luminaire needed to have the necessary light output, light characteristics, and control flexibility to exceed the current RSPCA Approved Farming Scheme Standards criteria,” said zükt Director Ned Wright.

“In addition, very low electricity consumption was required while maximising the growth and feed conversion potential required by the grower.

“The development process was initiated by contact with local growers who were looking for a solution to their new lighting requirements,” Ned said.

“The result was the production of the Big Bird, a dust and water proof integrated LED luminaire that produces 4,300 lumen from just 48 watts, and utilises a DC dimming driver which is able to dim smoothly from 100% to zero with no flickering.

“The dimming features a reduction in the electricity consumption that is linear with the dimming.

“Dimming to 50% of maximum light output results in correspondingly 50% less electricity used,” he said.

“The variation in lighting characteristics in different sites can be fine tuned by setting the maximum light level at the RSPCA standard, making the electricity consumption to achieve the light level as efficient as possible, and the dimming can be done up to, and down from this point.

“Growers will have to ability to fine tune their electricity consumption for lighting, and exactly meet the RSPCA Approved Farming Scheme standard.”

Until recently, zükt had concentrated its activities in the commercial areas of retail, manufacturing and warehousing.

“The company produces a range of LED lighting products suited to new construction as well as converting existing premises to the energy saving LED lighting technology,” Ned said.

“The benefits of our products in our established market revolve around significant electricity savings for the client.

“Local growers alerted us to their new lighting challenge, giving us the

opportunity to develop a product that provides much more than just the electricity savings.

“The zükt Big Bird provides the grower with the ability to fine tune their lighting requirements to suit their own specific requirements.

“Growers have stipulated the features of this luminaire, and we have

Above: zükt LED Lighting director Ned Wright in a modern poultry house with Big Bird luminaires installed.

given them exactly what they wanted. “In addition, the price is very good

due the cost savings achieved by our small company managing the design and manufacturing process ourselves.

“We could not be more hands on.“ We are now looking for partners

to help us distribute our product to Australian growers.”

2015 AVPA AND CPV ConferenceKey poultry industry issues will be addressed at the upcoming Australasian Veterinary Poultry Association (AVPA) and Commercial Poultry Veterinarians (CPV) joint conference to be held in Queenstown, NZ in October.

The conference is held every six years in New Zealand and offers delegates a valuable opportunity to meet and mix with industry professionals from Australia, New Zealand, USA and Asia.

The revitalised two-day event will feature top international speakers and cover topical industry areas such as antibiotics, welfare, food safety, emerging diseases of poultry and emerging technologies-apps for poultry.

There will also be opportunities for networking with other delegates and speakers during the conference.

Delegates will have two days of conferencing concluding with a Gala

Dinner on the final night at Walter Peak Station, a short cruise across the lake on vintage steamship the Earnslaw.

The conference is being held from October Monday 12 to Tuesday 13, 2015 at Skyline Conference Centre and delegates will be accommodated at one of Queenstown’s leading hotels, the 5-star Hotel St Moritz (Accor).

The conference is now open for registrations to industry professionals (not restricted to veterinarians).

The cost for members (including conference registration, conferencing – with morning and afternoon tea and lunch daily and gala dinner on the final night) is NZD$300. Accommodation is additional and delegates must cover their own transport costs

For more information visit http://www.avpa.asn.au or contact: Kerry Mulqueen, email [email protected] or phone 649 520 4300

zükt | 08 8382 8216 | [email protected] | www.zukt.com.au

RSPCA Approved Farming Standard CompliantMASSIVE ELECTRICITY SAVINGS & DIMS TO ZERO

LED Lighting

Providing brighter more energy efficient lighting, including graded dimming to simulate dusk and dawn

•Massive electricity savings - improved lighting.•100% Australian owned company.•Rated to last 50,000 Hours.•Minimal to no maintenance.•IP65 - Waterproof and dust proof.•0-10V dimming.•100% - 0% smooth dimming with no flickering.•Compatible with most 0-10V controllers.•Super bright, efficient and with linear drop in power consumption with dimming.

•50% less electricity than fluorescent to achieve the same light level.

•Complies with AUS/NZ safety standards.•No mercury or harmful chemicals.•SAA Approved.

Your LED poultry shed lighting solution

TM

40

World Veterinary Poultry Association and Merial announce new vaccination award

NEWS

The World Veterinary Poultry Association (WVPA) and Merial have recently jointly announced the creation of the WVPA-Merial Innovation in Vaccination Award which will be presented to a veterinarian or poultry health scientist for an outstanding contribution to the field of innovation in poultry vaccination.

The first award will be presented during the Opening Ceremony at the forthcoming WVPA Congress that will be held in Cape Town, South Africa on September 7 to 11, 2015 (www.wvpac2015.com ).

It is envisaged that nominations for the award will come from the pure and applied research fields as well as from those involved in the application or monitoring of vaccination and that nominations will come from the research, academic and practitioner

sectors. The winner will receive €5,000 to

help fund his/her on-going professional development or training, as well as a suitable memento of the occasion.

“We see vaccination as a key facet of modern poultry production that is important in all regions of the world”, says WVPA’s vice president, Nigel Horrox, “and we really appreciate Merial’s involvement and support for this award which will give well-deserved recognition to those involved in this key activity, maintaining high standards in poultry health and productivity”.

In sharing Nigel’s views, Dr Stéphane Lemière, Merial Global Avian Technical Services Director, added “Merial plays a significant role throughout the world with innovative products, services and technical advice in poultry vaccination and

looks forward to working with WVPA on this new award which we see as an excellent way of recognising the importance played by individuals in this critical aspect of health management in modern poultry production.