Poster international conference on engineering failure analysis 2008

-

Upload

fundacio-ctm-centre-tecnologic -

Category

Business

-

view

452 -

download

1

Transcript of Poster international conference on engineering failure analysis 2008

EXPERIMENTAL PROCEDURE

D. Casellas, I. Picas, J. Caro, I. Valls1, B. Casas1

Materials Technology Area, CTM Centre Tecnològic Av. Bases de Manresa 1, 08242 Manresa (Spain)

1 ROVALMA S.A., Apol.lo 51, Terrassa, Spain

FRACTURE MECHANISM

INTRODUCTION

FRACTURE OF COLD WORK TOOLS DURING HIGH STRENGTH STEELS FORMING

New Materials Requirements in Automobile Industry

≤ 140 MPa

180 - 240 MPa

260 - 300 MPa

320 - 420 MPa

≥1000 MPa

High yield stress of high strength steels

High forming pressures on tools

Accelerates wear

Premature fractures

AIM: To evaluate the effect of the tool steels microstructure on the fracture behaviour of tools during high strength steels sheet forming

Sheet steel:B steel 1500 MPa

Tool steel:DIN 1.3202 (AISI T15) 62 HRCHWS (ROVALMA) 60 HRC

Hot stamping of B steels

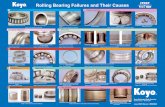

FRACTROGRAPHY

Fractures and wear at the cutting edge

Broken carbides near the cutting edge

Broken carbides

M6C carbide

Element Weight%

V 3.4

Cr 2.7

Fe 24.8

W 66.7

MC carbide

Element Weight%

V 40.8

Cr 4.3

Fe 18.4

W 36.5

lc

a a

l

a

(a) (b) (c)

lc

a a

l

alc

a a

lc

a a

l

a

(a) (b) (c)

Fracture toughness of carbides

“Fracture toughness of carbides in tool steels evaluated by nanoindentation” D. Casellas et al., Acta Materialia 55 (2007)

2/3

3/22/1

C c

P

H

E

l

a016.0K

=

DIN 1.3202

HWS

M7C3 carbide

Element Weight%

V 9.6

Cr 32.1

Fe 33.9

W 1.9

14 16 18 20 22 24 26 28 300

1

2

3

4

5

1,3202 HWS 1,2379MC M7C3 M7C3

M6C MC

Kc(M

Pa

m1/

2 )

H (GPa)

MC carbide

Element Weight%

V 55.8

Cr 8.5

Fe 4.3

W 10.5

CONCLUSIONSThe need for high performance forming tools implies that microstructure of tool steels must be tailored, containing hard and tough carbides. Nanoindentation can be used for characterizing carbides in tool steels