Poster-1 · Title: Microsoft Word - Poster-1.doc Author: Nonoshik Created Date: 7/13/2017 1:47:44...

Transcript of Poster-1 · Title: Microsoft Word - Poster-1.doc Author: Nonoshik Created Date: 7/13/2017 1:47:44...

Introduction Materials combining high electrical conductivity and optical transparency are vital for modern optoelectronics, especially for the realization of electro-optical control in liquid crystal (LC) devices, where they are use as transparent conductive layers. These electrodes are usually provided by a thin transparent layer of metal (e.g. Au, Ag) or metal oxide (e.g. indium tin oxide, ITO). Currently, there are several issues associated with the use of these thin films. For example, in the case of thin metallic layers, an antireflection coating [1] is required which complicates the fabrication process. In the case of many metal oxides, thin films often exhibit a non-uniform absorption across the visible spectrum [2] and chemical instability [3]. Hence alternative transparent conducting materials are currently being explored. A number of technologies have been developed to address this task, many of which are based on nano-materials. Among various competing technologies graphene films are showing great promise, due to their high conductivity, optical transparency, chemical resistance and mechanical flexibility [4]. These properties seem to make this material an excellent candidate for applications in various photonic devices that require conducting and transparent thin film electrodes. A large number of studies have been conducted on the application of graphene electrodes for light-emitting devices and touch screens with much promise for an ITO replacement. However, fundamental studies on their application as transparent electrodes for LC devices are yet to be explored properly. In this work we present the results of investigation of electro-optical and dynamic characteristics of LC cells with graphene electrodes compared with the characteristics of LC cells containing conventional ITO electrodes.

Conclusion Hybrid graphene-ITO nematic LC device have been investigated to characterize graphene’s electronic properties. The optical switching time characteristics of LC cells with graphene are slightly worse than of cells with ITO. But compared to the traditional ITO, graphene has a number of advantages: mechanical strength, chemical resistance and the possibility of transfer onto any surface including flexible as well as making multilayer LC structures possible. These outstanding properties of graphene make it suitable for successful use as a transparent conductive layer in LC devices.

This work was supported by State Committee Science MES RA, in frame of the research project № SCS 15T-1C157. References

1. Granqvist, C. G. Sol. Energy Mater. Sol. Cells. 2007, 91, 1529-1598. 2. Phillips, J. M., et al. Appl. Phys. Lett. 1994, 65, 115. 3. Schlatmann, A. R., et al. Appl. Phys. Lett. 1996, 69, 1764. 4. Zurutuza, A; Marinelli, C. Nat. Nanotechnol. 2014, 10, 730–734. 5. Kidambi, P. R;. Bayer, B. C.; Blume, R.; Wang, Z. J.; Baehtz, C.; Weatherup, R. S.; Willinger, M. G.; Schloegl, R. and Hofmann, S. Nano Lett. 2013, 13(10), 4769–4778. 6. Kidambi, P. R.; Ducati, C.; Dlubak, B.; Gardiner, D.; Weatherup, R. S.; Martin, M. B.; Seneor, P.; Coles, H. and Hofmann, S. J. Phys. Chem. C. 2012, 22492–22501.. 7. Qasim, M. M.; Khan, A. A.; Kostanyan, A.; Kidambi, P. R.; Cabrero-Vilatela, A.; Braeuninger-Weimer, P.; Gardiner, D. J.; Hofmann, S.; Wilkinson, T. D. Nanoscale., 2015, 7, 14114-14120. 8. Margaryan, H.L.; Hakobyan, N.H.; Hovhannisyan, D. L.; Abrahamyan, V. K.; Pokhsraryan, D. K.; Manucharyan, S. R. Molecular Crystals and Liquid Crystals. 2012, 561, 170–176.

Nune Hakobyan1*, Hakob Margaryan1, Valeri Abrahamyan1, David Hovhannisyan1, Vladimir Aroutiounian1, Arpi Dilanchian Gharghani1, Amalya Kostanyan2, Timothy Wilkinson2, Nelson Tabirian3

1Yerevan State University, Armenia

2 University of Cambridge, UK 3Beam Engineering for Advanced Measurements Co., USA

Yerevan state university

Synthesis of graphene films The graphene was obtained by a chemical vapor deposition (CVD) process. Details of synthesis and extensive characterization of the CVD graphene can be found in prior works [5, 6]. The mono-layer graphene film was then transferred from the Cu foil to a pre-cleaned glass substrate by using a polymer support layer of polystyrene (PS, Mw 35k, 2% w/w in toluene) and an etchant acid (FeCl3 aq, 0.5 M) to remove the Cu, as described elsewhere [7]. This was followed by a wash in a warm ethyl acetate bath to dissolve the supporting polymer layer.

Device fabrication

c b a

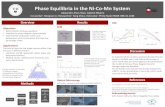

Fig.2. Images of the graphene-ITO hybrid LC cell between crossed polarizers: voltage not applied (a), 40 pp Volt applied to LC cell

with graphene electrodes (b), and l with ITO electrodes (c).

To insure the same processing conditions, the same thickness of LC layer, as well as the same orientation boundary conditions, two structures were made side by side in one device, each using different transparent conductive layers. Commercially available 15-20 ohm/sq ITO coated glass substrates with 0.7 mm thickness was used as a base of the structure, which was patterned to develop two divisions in each device. The left side of the device was developed to create a graphene-graphene structure along with the right side an ITO-ITO structure, as shown in Fig. 1. To avoid inhomogeneity caused by the mechanical treatment of the substrates (rubbing), the orientation of LC molecules was realized optically (photo-orientation) by irradiation of a photo-orienting polymer with linearly polarized radiation from a He-Cd laser at a wavelength of 325 nm. 6CHBT nematic LC ( n = 0.15) was filled by capillary action, the thickness of LC layer (20 μm) was set by spacers, the orientation is planar. Images of the fabricated cell, obtained between crossed polarizers when voltage is applied to different areas, are shown in Fig.2. Fig.1. A schematic of the

graphene-ITO hybrid LC cell.

A liquid crystal cell working as a light valve can operate in two modes: fast switching (high-voltage, V>>Vth) and slow switching (the voltages close to the threshold, V<5Vth).

During the fast switching mode, the reorientation times for LC cells with ITO and graphene conducting layers are 0,66 ms and 0,88 ms respectively, and relaxation times are 2,2 ms (ITO) and 2,1 ms (graphene). In the slow switching mode the switching times for LC cell with graphene conducting layer (23.2 ms – reorientation, 12.4 ms -relaxation) are a little more than for LC cell with ITO (18.6 ms – reorientation, 11.7 ms - relaxation).

In the slow switching mode reorientation occurs in the bulk of the LC. In this case, operation time is essentially much larger due to its dependency on only the rotational viscosity and elasticity of the LC. However, it is possible to achieve higher performance by applying a control voltage with a TNE based special shape, when a step change in voltage leads to the switching between the quasi-steady states of the LC.

a b

0 50 100 150 200 250

0,0

0,2

0,4

0,6

0,8

1,0

ITO electrods

Time, ms

Ligh

t Int

enci

ty, a

.u.

18.6ms 11.7ms

0

10

20

30

40

50

60

70

pp voltage, V

0 50 100 150 200 250

0,0

0,2

0,4

0,6

0,8

1,0

12.4ms

Graphene electrods

Time, ms

Ligh

t Int

enci

ty, a

.u.

23.2ms

0

10

20

30

40

50

60

70

pp voltage, V

Fig.8. Time characteristic of LC cells with ITO (a) and graphene (b) transparent conductive layers operating as a light valve in the slow switching mode.

0 10 20 30 40 50

0,0

0,2

0,4

0,6

0,8

1,0

Graphene electrods

Time, ms

Ligh

t Int

enci

ty, a

.u.

0.88ms 2.1ms

0

40

80

120

160

200

240

280

pp voltage, V

0 10 20 30 40 50

0,0

0,2

0,4

0,6

0,8

1,0

ITO e lectrods

Time, ms

Ligh

t Int

enci

ty, a

.u.

2.2ms0.66ms

0

40

80

120

160

200

240

280

pp voltage, V

a b Fig.7. Time characteristic of LC cells with ITO (a) and graphene (b) transparent conductive

layers operating as a light valve in the fast switching mode.

In the fast switching mode under the influence of a strong electric field, the bulk and boundary layers of LC are involved in the reorientation process. This reduces the relaxation time due to the binding energy of the LC molecules with the surface of the substrate. Despite the short response time there are undesirable backflows, making a device in such mode less attractive.

The transmission spectra of the both sections have measured in the visible range (Fig.3). The cell with ITO electrodes is more transparent for the 400-500 nm wavelengths, and the cell with graphene electrodes - for wavelengths exceeding 800 nm. The transparency is the same for the 550-800 nm wavelengths range.

400 500 600 700 800 9000

10

20

30

40

50

60

70

80

90

100

Graphene-Graphene cell

ITO-ITO cell

Tran

smis

sion

, %

Wavelength, nm

Fig.3. The transmission spectra of hybrid LC cell

with graphene and ITO sections.

The dynamic characteristics of the both sections are investigated. Measurements were carried out with a specially designed driver which allows the selection of the form of applied voltage, including the transient nematic effect (TNE [8]). When the He:Ne laser beam (632 nm) propagates through the LC cell, placed between crossed polarizers so that the direction of the polarization of the incident beam makes a 45◦ angle with the LC director (Fig.4), then the LC cell can operate as an electrically controlled light valve, where the intensity of the transmitted light is changed from minimum to maximum and vice versa with an associated π phase shift. In order to determine the voltage corresponding to the minimum of switching time, an experiment was carried out to obtain the dependence of the light intensity, transmitted through the cell located between crossed polarizers on a control voltage (Fig. 5). As presented the light intensity at the output is in the form of characteristic oscillations, with increasing voltage. It is important to note that both sides of the hybrid LC cell, with different conducting electrodes (i.e. graphene-graphene and ITO-ITO), show almost identical characteristics. A similar pattern was observed during the study of the reorientation and relaxation processes, under the influence of an external bipolar pulse voltage (Fig. 6).

Fig. 4. Schematic of the LC characterization experiment.

Fig.6. Time dependence of the intensity of light passing through the LC cells with graphene and ITO electrodes.

0 200 400 600 800 1000

0,0

0,2

0,4

0,6

0,8

1,0

Graphene ITO

Time, ms

Ligh

t Int

enci

ty, a

.u.

0

40

80

120

160

200

240

pp Voltage,V

Fig.5 Light Intensity vs. voltage applied, passing through the LC cells with ITO and graphene layers.

0 5 10 15 20 25 300,0

0,2

0,4

0,6

0,8

1,0

ITO Graphene

Ligh

t Int

enci

ty, a

.u.

pp Voltage, V

Measurements All measurements were carried out on both sides i.e. graphene-graphene, ITO-ITO of the hybrid LC cell.

![[XLS]... Read Document - Home – The National · Web view47 4 1 4 10 47 4 2 1 10 47 4 3 1 38 47 8 1 1 11 47 8 2 1 12 47 8 3 1 13 47 8 4 1 10 47 8 5 1 12 47 8 6 1 8 47 8 7 1 8 47 8](https://static.fdocuments.in/doc/165x107/5aa83cb97f8b9a81188b4e73/xls-read-document-home-the-national-view47-4-1-4-10-47-4-2-1-10-47-4.jpg)