Polycarbonate

-

Upload

quantaprima -

Category

Documents

-

view

54 -

download

0

Transcript of Polycarbonate

PolycarbonateFrom Wikipedia, the free encyclopediaPolycarbonate

Repeating chemical structure unit ofPolycarbonatemade frombisphenol A

Physical Properties

Density ()1.201.22 g/cm3

Abbe number (V)34.0

Refractive index (n)1.5841.586

FlammabilityV0-V2

Limitingoxygenindex2527%

Water absorptionEquilibrium(ASTM)0.160.35%

Water absorption over 24 hours0.1%

Radiation resistanceFair

Ultraviolet (1-380nm)resistanceFair

Mechanical Properties

Young's modulus (E)2.02.4GPa

Tensile strength (t)5575MPa

Compressive strength (c)>80 MPa

Elongation ()@break80150%

Poisson's ratio ()0.37

HardnessRockwellM70

Izod impact strength600850J/m

Notch test2035kJ/m2

Abrasive resistance ASTMD10441015mg/1000cycles

Coefficient of friction ()0.31

Speed of sound2270m/s

Thermal Properties

Melting temperature (Tm)155 C

Glass transition temperature(Tg)147 C

Heat deflection temperature 10 kN(Vicat B)[citation needed]145 C

Heat deflection temperature 0.45 MPa140 C

Heat deflection temperature 1.8 MPa128138 C

Upper working temperature115130 C

Lower working temperature40 C[1]

Linear thermal expansion coefficient ()6570 106/K

Specific heat capacity (c)1.21.3 kJ/(kgK)

Thermal conductivity (k)@ 23 C0.190.22W/(mK)

Thermal diffusivity (a)@ 25 C0.144mm/s[2]

Electrical Properties

Dielectric constant (r)@ 1 MHz2.9

Permittivity ()@ 1MHz2.568 1011F/m

Relative permeability (r)@ 1MHz0.866(2)

Permeability ()@ 1MHz1.089(2)N/A2

Dielectric strength1567kV/mm

Dissipation factor@ 1MHz0.01

Surfaceresistivity1015/sq

Volumeresistivity ()10121014m

Near to Short-waveInfraredTransmittanceSpectrum

IR transmittance of polycarbonate. Also, polycarbonate is almost completely transparent throughout the entire visible region until 400 nm, blocking UV light.

Chemical Resistance

AcidsconcentratedPoor

AcidsdiluteGood

AlcoholsGood

AlkalisGood-Poor

Aromatic hydrocarbonsPoor

Greases&OilsGood-fair

Halogenated HydrocarbonsGood-poor

HalogensPoor

KetonesPoor

Gaspermeation@ 20 C

Nitrogen10 25cm3mm/(m2dayBar)

Oxygen70 130cm3mm/(m2dayBar)

Carbon dioxide400 800cm3mm/(m2dayBar)

Water vapour12grammm/(m2day) @ 85%0%RHgradient

Economic Properties

Price2.6 2.8/kg[3]

Polycarbonates(PC), known by the trademarked namesLexan, Makrolon,Makroclearand others, are a particular group ofthermoplasticpolymers. They are easily worked,molded, andthermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a uniqueresin identification codeand are identified as Other, 7.Contents[hide] 1Structure 2Production 3Properties and processing 4Applications 4.1Electronic components 4.2Construction materials 4.3Data storage 4.4Automotive, aircraft, and security components 4.5Niche applications 4.5.1Medical applications 5Manufacturers and brands 6History 7Potential hazards in food contact applications 8See also 9References

Structure[edit]Polycarbonates received their name because they arepolymerscontainingcarbonate groups(O(C=O)O). Most polycarbonates of commercial interest are derived from rigidmonomers. A balance of useful features including temperature resistance, impact resistance and optical properties position polycarbonates betweencommodity plasticsandengineering plastics.Production[edit]The main polycarbonate material is produced by the reaction ofbisphenol A(BPA) andphosgeneCOCl2. The overall reaction can be written as follows:

The first step of the synthesis involves treatment of bisphenol A withsodium hydroxide, which deprotonates thehydroxyl groupsof the bisphenol A.[4](HOC6H4)2CMe2+ 2 NaOH (NaOC6H4)2CMe2+ 2 H2OThe diphenoxide((NaOC6H4)2CMe2) reacts with phosgene to give achloroformate, which subsequently is attacked by another phenoxide. The net reaction from the diphenoxide is:(NaOC6H4)2CMe2+ COCl2 1/n [OC(OC6H4)2CMe2]n+ 2 NaClIn this way, approximately one billion kilograms of polycarbonate is produced annually. Many otherdiolshave been tested in place of bisphenol A, e.g. 1,1-bis(4-hydroxyphenyl)cyclohexane anddihydroxybenzophenone. The cyclohexane is used as a comonomer to suppress crystallisation tendency of the BPA-derived product.Tetrabromobisphenol Ais used to enhance fire resistance.Tetramethylcyclobutanediolhas been developed as a replacement for BPA.[4]An alternative route to polycarbonates entailstransesterificationfrom BPA anddiphenyl carbonate:(HOC6H4)2CMe2+ (C6H5O)2CO 1/n [OC(OC6H4)2CMe2]n+ 2 C6H5OHThe diphenyl carbonate was derived in part fromcarbon monoxide, this route being greener than the phosgene method.[4]Properties and processing[edit]Polycarbonate is a durable material. Although it has high impact-resistance, it has low scratch-resistance and so a hard coating is applied to polycarbonateeyewearlensesand polycarbonate exterior automotive components. The characteristics of polycarbonate are quite like those ofpolymethyl methacrylate(PMMA, acrylic), but polycarbonate is stronger and usable over a greater temperature range. Polycarbonate is highlytransparenttovisible light, with better light transmission than many kinds of glass.Polycarbonate has aglass transition temperatureof about147 C(297F),[5]so it softens gradually above this point and flows above about155 C(311F).[6]Tools must be held at high temperatures, generally above80 C(176F)to make strain- and stress-free products. Lowmolecular massgrades are easier to mold than higher grades, but their strength is lower as a result. The toughest grades have the highest molecular mass, but are much more difficult to process.Unlike most thermoplastics, polycarbonate can undergo large plastic deformations without cracking or breaking. As a result, it can be processed and formed at room temperature usingsheet metaltechniques, such as bending on abrake. Even for sharp angle bends with a tight radius, heating may not be necessary. This makes it valuable in prototyping applications where transparent or electrically non-conductive parts are needed, which cannot be made from sheet metal. Note thatPMMA/Plexiglas, which is similar in appearance to polycarbonate, is brittle and cannot be bent at room temperature.Main transformation techniques for polycarbonate resins: extrusioninto tubes, rods and other profiles including multiwall extrusion with cylinders (calenders) into sheets (0.520mm (0.0200.79in)) and films (below 1mm (0.039in)), which can be used directly or manufactured into other shapes usingthermoformingor secondaryfabricationtechniques, such as bending, drilling, routing, laser cutting etc. injection moldinginto ready articles

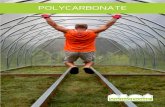

A bottle made from polycarbonateApplications[edit]Electronic components[edit]Polycarbonate is mainly used for electronic applications that capitalize on its collective safety features. Being a good electrical insulator and having heat resistant and flame retardant properties, it is used in various products associated with electrical and telecommunications hardware. It can also serve asdielectricin high stabilitycapacitors.[4]However, commercial manufacture of polycarbonate capacitors has mostly ceased following the decision of Bayer AG to discontinue production of capacitor-grade polycarbonate film at the end of 2000.[7]Construction materials[edit]

Polycarbonate sheeting in a greenhouseThe second largest consumer of polycarbonates is the construction industry, e.g. for domelights, flat or curved glazing, andsound walls.Data storage[edit]

CDs and DVDsA major application of polycarbonate is the production ofCompact Discs,DVDs, andBlu-ray Discs. These discs are produced by injection molding polycarbonate into a mold cavity that has on one side a metal stamper containing a negative image of the disc data, while the other mold side is a mirrored surface. Typical products of sheet/film production include applications in advertisement (signs, displays, poster protection).[4]Automotive, aircraft, and security components[edit]In the automotive industry, injection-molded polycarbonate can produce very smooth surfaces that make it well-suited for direct (without the need for a basecoat) metalised parts such as decorative bezels and optical reflectors. Its uniform mold shrinkage results in parts with greater accuracy than those made ofpolypropylene. However, due to its susceptibility toenvironmental stress cracking, its use is limited to low-stress applications. It can be laminated to makebullet-proof "glass", although "bullet-resistant" is more accurate for the thinner windows, such as are used in bullet-resistant windows in automobiles. The thicker barriers of transparent plastic used in teller's windows and barriers in banks are also polycarbonate.So-called "theft-proof" large plastic packaging for smaller items, which cannot be opened by hand, is uniformly made from polycarbonate.

F-22 cockpitThe cockpit canopy of theF-22 Raptorjet fighter is made from a piece of high optical quality polycarbonate, and is the largest piece of its type formed in the world.[8][9]South African security companies have launched the 'transparent burglar bar' under a variety of retail names, made from polycarbonate.[10]Niche applications[edit]Polycarbonate, being a versatile material with attractive processing and physical properties, has attracted myriad smaller applications. The use of injection molded drinking bottles, glasses and food containers is common, but the use of BPA in the manufacture of polycarbonate has stirred serious controversy (seePotential hazards in food contact applications), leading to development and use of "BPA-free" plastics in various formulations.

Laboratory safety gogglesPolycarbonate is commonly used in eye protection, as well as in other projectile-resistant viewing and lighting applications that would normally indicate the use ofglass, but require much higher impact-resistance. Many kinds of lenses are manufactured from polycarbonate, including automotive headlamp lenses, lighting lenses,sunglass/eyeglasslenses, swimming and SCUBA goggles, and safety glasses/goggles/visors including visors in sporting helmets/masks and policeriot gear. Windscreens in small motorized vehicles are commonly made of polycarbonate, such as for motorcycles, ATVs, golf carts, and small planes and helicopters.The light weight of polycarbonate as opposed to glass has led to development of electronic display screens that replace glass with polycarbonate, for use in mobile and portable devices. Such displays include newere-inkand some LCD screens, though CRT, plasma screen and other LCD technologies generally still require glass for its higher melting temperature and its ability to be etched in finer detail.As more and more governments are restricting the use of glass in pubs and clubs[11]due to the increased incidence ofglassings, polycarbonate glasses[12]are becoming popular for serving alcohol because of their strength, durability, and glass-like feel.Other miscellaneous items include durable, lightweight luggage,MP3/digital audio player cases,ocarinas, computer cases,riot shields, instrument panels, tealight candle containers and blender jars. Many toys and hobby items are made from polycarbonate parts, e.g. fins, gyro mounts, and flybar locks for use withradio-controlled helicopters.[13]For use in applications exposed to weathering or UV-radiation, a special surface treatment is needed. This either can be a coating (e.g. for improved abrasion resistance), or acoextrusionfor enhanced weathering resistance.Polycarbonate is also used as a printing substrate fornameplateand other forms of industrial grade under printed products. The polycarbonate provides a barrier to wear, the elements, and fading.Medical applications[edit]Many polycarbonate grades are used in medical applications and comply with both ISO 10993-1 and USP Class VI standards (occasionally referred to as PC-ISO). Class VI is the most stringent of the six USP ratings. These grades can be sterilized using steam at 120 C,gamma radiation, or by theethylene oxide(EtO) method.[14]However, scientific research indicates possible problems withbiocompatibility. Dow Chemical strictly limits all its plastics with regard to medical applications.[15][16]Manufacturers and brands[edit]ManufacturerBrandManufacturerBrand

SabicLEXANBayerMAKROLON

TeijinPANLITEStyronCALIBRE

MitsubishiIUPILONIdemitsuTARFLON

Chi MeiWONDERLITEHonamHOPELEX

CheilINFINOLGLUPOY

SamyangTRIREXKazanorgsintezMAPKA

PCCI (KZPC)UnigelDURALON

History[edit]The polycarbonate derived from BPA was discovered atBayerbyDr. Herman Schnellin 1953 and soon atGeneral ElectricbyDaniel Fox. It was first introduced to the market in 1958 by Bayer Mobay, and General Electric.[4]Potential hazards in food contact applications[edit]Main articles:Bisphenol AandEndocrine disruptorThe use of polycarbonate containers for the purpose of food storage is controversial. The basis of this controversy is their hydrolysis (degradation by water, often referred to as leaching) occurring at high temperature, releasesbisphenol A:1/n [OC(OC6H4)2CMe2]n+ H2O (HOC6H4)2CMe2+ CO2More than 100 studies have explored the bioactivity of bisphenol A derived from polycarbonates. Bisphenol A appeared to be released from polycarbonate animal cages into water at room temperature and it may have been responsible for enlargement of the reproductive organs of female mice.[17]However, the animal cages used in the research were fabricated from industrial grade polycarbonate, rather than FDA food grade polycarbonate.An analysis of the literature on bisphenol A leachate low-dose effects by vom Saal and Hughes published in August 2005 seems to have found a suggestive correlation between the source of funding and the conclusion drawn. Industry funded studies tend to find no significant effects whereas government funded studies tend to find significant effects.[18]Sodium hypochlorite bleach and other alkali cleaners catalyze the release of the bisphenol A from polycarbonate containers.[19][20]Achemical compatibility chartshows that polycarbonate is incompatible with ammonia and acetone because it dissolves in their presence.[21]Alcoholis one recommendedorganic solventfor cleaning grease and oils from polycarbonate.See also[edit]