Valeextportal.vale.com/PMO/Mines PMO Safety Meetings/2017/May...• Vale owns the IM and the IM...

Transcript of Valeextportal.vale.com/PMO/Mines PMO Safety Meetings/2017/May...• Vale owns the IM and the IM...

Date

Time

Location

Chair

Attendees:

1 Emergency Preparedness by Chris LePera 1 Min

2 Introductions by Chris LePera 2 Min

3 Stop & Correct/Safety Share/ High Potential Review by BluMetric Environmental 10 Min

4 SAP IM ‐ Reporting and Investigation Toolkit rollout by Nancy Carrier‐Adams 60 min

5 Safety Stats/Stop&Correct Program Review ‐ Monthly Trends by Chris LePera 10 Min

6 Update on the PMO Extranet Site & New Vale Standards /Hazard Alerts by Chris LePera 10 Min

Update to SAF‐ SPI‐01 Eye Protection

Update to SAF‐SPI‐35 Eye Wear Fit System

Update to SAF‐SPI‐06 Fall Protection

Reflective Striping for Hardhats (O.Reg 854, Section 263 (2) & SPI 23

7 Open Discussion by Chris LePera 5 Min

8 Closing Remarks by Dave Pisaric 5 Min

113 Total

Time

Next Meeting

Date

Time

Location

PMO Extranet

Site

Sudbury PMO Portal (formerly the PMO Extranet site)http://extportal.vale.com/

Monthly Vale MINES PMO Contractor Safety Meeting

May 10th, 2017

8:00AM‐ 9:30AM

CC Club ‐ Invac & Outvac locations, emergency procedures.

Continuous alarm: OUTVAC ‐ Proceed to Assembly area in the Parking lot

Intermittent alarm: INVAC ‐ The Main Hall is the Invac Area

Please Stand Up when introducing yourselves (Name, Company, Position)

This will be done every meeting so we all get familiar with everyone.

DM#

Contracting Party: Safety Coordinators, Management, Supervisors (as available)

Vale Personnel: GSO Safety, Vale Management, PMO Project Managers, PMO Supervisor of Services, Guest Speakers

Chris LePera

Copper Cliff Club

Agenda

Wednesday June 14th, 2017

8:00amMPDG Conf Rm #4 (1st Floor Mezzanine)

DM# 1110480 v 5 Page 1 of 1

Agen

da

1. Emergency Preparedness

2. Introductions ( Please Stand, Speak loud enough so others can hear you)

3. Safety Share/High Potential Review

4. SAP IM Toolkit rollout

5. Safety Stats/Stop&Correct Monthly Trend

6. Updates/Standards/Hazard Alerts

7. Open Floor

8. Closing Remarks

Environmental PMO Contractor Safety Meeting May 10th, 2017

•Emergency Preparedness

•Introductions

Safety Meeting Workshop Results

Q1.What is the Purpose of the meeting? Sharing of Information

Q2. What do you hope to achieve? Growth and Knowledge

Q3. What do Contractors expect from Vale? Sharing of Vale Information & Systems

Q4. What do you think Vale’s expectation is of Contractors for this meeting?

Contractor Participation

•Safety Share/Stop & Correct (BluMetric)

www.blumetric.ca

Environmental Tailings Safety

Meeting

Stop and Correct

May 10, 2017

www.blumetric.ca

www.blumetric.ca

Situation Details

• Supervisor inspection being conducted on March 8, 2017

• H&S Supervisor observed a delivery driver backing down a hill

• A “spotter” was being used, but was directly behind the truck. – Poor line of sight to driver

– Very little space available for escape

• Risk: spotter could be hit if breaks fail or driver fails to see him

www.blumetric.ca

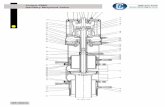

= Truck location = Spotter location

www.blumetric.ca

Corrective Action

• H&S Supervisor stopped the driver and asked if he

could see the spotter

– Driver responded that he could not

• Spotter was asked where he would go if he was in

danger of being struck by the truck

• H&S Supervisor explained the risk to the spotter in

this situation and factors that should be considered

• Driver and spotter agreed it was an unsafe

condition. Backing up must be done in a manner

where driver and spotter can see each other

www.blumetric.ca

Future Action

• Situation was discussed at BLM morning line-up

• Staff are completing a refresher on safe

reversing procedures

• Sub-contractors will undergo refresher on

reversing procedures and instructed that they

must be adhered to

• Reinforcement is occurring via site inspections

and by on-site Supervisors observing reversing

activities

www.blumetric.ca

Questions?

•SAP IM – Reporting and Investigation Toolkit Rollout

IM Investigation Expectations for PMO • Vale owns the IM and the IM Process

• Contractor owns the incident & investigation

• Vale to rollout Investigation Training for Vale/Seconded employees

• It is recommended that Contractors obtain 3rd Party Investigation Training

• Contractor in conjunction with PMO Rep to complete the investigation

(unless the contractor is the “Constructor”. )

• PMO Rep and Contractor to complete the Toolkit cooperatively

• PMO Rep and Contractor to complete High Potential Notification and Investigation Templates cooperatively

• PMO Rep to supply Contractor with a final SAP-IM Toolkit complete with signatures

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 1

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

INCIDENT MANAGEMENT REPORTING and INVESTIGATION TOOLKIT

HOW TO USE THIS TOOLKIT

INSTRUCTION: The purpose of this toolkit is to guide you in your investigation. The Toolkit is organized such that each STEP outlines the required investigation actions as well as the information that must be recorded in SAP-IM.

Time management tips are provided to help you meet the expected timelines.

Note: All standard investigations must be completed with the use of this Toolkit.

REPORT THE IM Timeline

STEP 1: Reporting an IM Before end of shift

Supervisor registers the IM in SAP before the end of the shift. All of the information in STEP 1 is required.

INVESTIGATION WORKFLOW Required for all Incident and Near miss as well as Unsafe Conditions being investigated

STEP 2: Gathering Evidence Immediately & during the investigation

STEP 3: Sequence of Events 7 days

STEP 4 Root Cause Analysis 14 days

STEP 5: Recommended Actions 14 days Transfer the cause number(s) from STEP 4 to your Action plan. Using the Hierarchy of Controls indicate the required actions. Actions should be SMART. Select the appropriate Protection Goal. Assign actions to authorized individuals with due dates.

FINALIZE AND CLOSE THE INVESTIGATION

STEP 6: Superintendent Quality Check and Approval 21 days

Review your investigation with your Superintendent. Your Superintendent is required to: (A) Review/update and approve Root Cause Analysis (STEP 4) (B) Approve/update and approve Action plan. Initializing in the Superintendent approval column (STEP 5) (C) Estimate the likelihood of the Actual and Potential occurrence below. (D) With recommended controls, estimate the likelihood and severity of this occurrence occurring in the future. This will generate a

residual risk. If risk is still High or Very High return to STEP 4(E) (E) Identify Lessons Learned. What is important to share with your crew, with your plant or with the organization? (F) Superintendent approval and signature:

AREAS WITH FLA/ADMIN SUPPORT: Return your completed Investigation Toolkit (STEPS 1 TO STEPS 6) to your FLA/Admin. FLA/Admin will enter the necessary information into SAP IM, upload your Toolkit and generate the IM Summary Report. AREAS WITHOUT FLA/ADMIN SUPPORT: Data enter your information to your SAP IM, upload your toolkit to the Reports/Documents tab and generate the IM Summary Report

STEP 7: Investigation Signoff for 7A: VALE Events or 7B: CONTRACTOR Events 28 days Supervisor dates and signs the form Supervisor meets with the Originator and JHSC member to review the investigation. Complete the Signoff form.

AREAS WITH FLA/ADMIN SUPPORT: Return the completed Signoff form to FLA/Admin support. FLA/Admin will upload the form to your IM and close the investigation. AREAS WITHOUT FLA/ADMIN SUPPORT Upload your completed Sign-Off form to the Reports & Documents tab in your IM and close the investigation.

IMPLEMENT ACTION PLAN

STEP 8: Implement Actions. IM remains open until all Actions are implemented and closed in SAP IM. 42 days AREAS WITH FLA/ADMIN SUPPORT: Provide evidence to the FLA/Admin of completed actions. The FLA/Admin will upload your evidence and close the Actions in IM. AREAS WITHOUT FLA/ADMIN SUPPORT: As you complete your Actions, upload your evidence to your IM and close your actions.

FINALIZE AND CLOSE THE IM

STEP 9: Manager’s Final Approval and IM Closure 45 days AREAS WITH FLA/ADMIN SUPPORT: Once all STEPS are complete, the FLA/Admin will initiate IM closure in SAP IM by sending the final approval. Given that all stakeholders have signed off already, only the manager’s signature is required for final approval and IM closure. AREAS WITHOUT FLA/ADMIN SUPPORT: Set the status of your SAP IM to Closed and send the final approval to your manager.

MONITOR THE EFFECTIVENESS OF NEW CONTROLS

STEP 10: Through planned inspections and audits, continue to monitor the effectiveness of new controls Ongoing

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 2

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 1: REPORTING the Incident, Near Miss or Unsafe Condition Before end of shift

INSTRUCTION: Use this form to collect the initial information required for SAP IM data entry and notification. Record the occurrence in IM before the end of your shift, ensuring to record all of the information in STEP 1.

This form was completed by (print name): __CONTRACTOR Representative____________________________ Tel #: _705-222-1234________________ Are you reporting an: Incident: An occurrence that caused harm to people, to assets or to the environment

Near Miss: An occurrence that did not cause harm, but had the potential to cause harm

Unsafe Condition: A condition with the potential to result in a harmful occurrence.

When did it happen? Date (YYYY/MM/DD): _2017/02/10__________ Time (24-hr clock): ___08:30______ Where did it happen? Plant: __Creighton Mine ________________ Location: __L2400 access way______ What happened and what immediate actions have been carried out? OrgUnit (Supervisor) responsible to manage the incident or condition: _50087583 (VALE Representative)______________________________________

Who was injured (print): _n/a________________________________ Employee Contractor - include NORCAT # ______________________ For contractor occurrences Contractor company name: __Contractor ABC_____________________ Project/Work Order # _XYZ789_______________

Vale contact person: _VALE Representative____________________________

Witness (print): _Contractor name ___________________ Employee Contractor - include NORCAT # _ABC1234____________________

JHSC member involved (where applicable): __Vale JHSC Name / Contractor JHSC Name_______________________________________________________________

Classify the Severity of the event. For high potential events, follow the HPI protocol. Incident: Classify Actual and Potential Severity Near Miss: Classify Potential Severity

ACTUAL POTENTIAL SEVERITY CLASSIFICATION CRITERIA

SEVERITY How bad was it?

SEVERITY How bad could it have

been?

A MINOR

B MODERATE

C SERIOUS

D CRITICAL

E CATASTROPHIC

Safety (injury)

N/A CRITICAL

Incidents requiring only first aid only

Incidents without absence (requiring work restriction, medical treatment

Incidents with absence. Permanent disabling incidents or 1 (one) fatality.

Incident resulting in multiple fatalities.

Occ.

Health (illness)

N/A N/A

Low concern reversible effects or without known adverse effect

Reversible effects causing harm

Severe reversible effects

Irreversible effects Life-threatening or disabling diseases

Financial (asset)

MODERATE SERIOUS < US $10,000 US$ 10,000 -

US$ 100,000 US$ 100,000 - US$ 1,000,000

US$ 1,000,000 - US$ 10,000,000

> US$ 10,000,000

For an Environment related incident or near miss, contact the Environment department for direction on how to classify. Contact Environment-On Call outside of normal working hours (if urgent).

Title: Forklift dropped pallet of drums

Description of occurrence or condition: Note: For contractor related IMs, include project number or work order number:

Contractor was moving a pallet of drums using Forklift #234 from the storage bay at L2400 to the maintenance garage at L2400.

The forks titled downwards and the pallet of drums shifted and fell to the ground. No reported injury.

Immediate actions (corrective measures) taken to address the occurrence or condition:

VALE and CONTRACTOR Representative were contacted and attended the area. Area is roped off pending investigation. Environment department was contacted to assist with the spill.

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 3

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 2: Gathering Evidence Immediately & during investigation INSTRUCTION: As the supervisor you are likely the first on the scene, giving you valuable insight. Start collecting pertinent information immediately and record it on this form. This will be valuable information during your investigation. This completed form must be attached to the SAP IM for all incidents and near misses. Attach additional information as required (i.e.: photos; maps; etc). This form was completed by (print name): _CONRACTOR Representative___________ Tel #: _705-222-1234_____________

PART A - EQUIPMENT & AREA LAYOUT (add photographs or drawings as required) 1 Scene layout and positioning of equipment (re-enactment or as located after event). The first rule of capturing the site layout is to take photographs of the scene.

Accurate recording of the scene layout is especially important if photographs cannot record everything as is. This should include a sketch of openings of floor layouts as well as where any equipment was located after the event, and if possible, where it came from. Record all equipment numbers.

TAKE PHOTOS. THIS AREA IS PROVIDED TO DRAW A SKETCH OF THE SCENE.

2

Tools, process, material equipment (what is required, what is missing, and what was involved in the occurrence?)

Forklift#123 is usually used to move materials in this area. Forklift was changed to #234 a few days prior to the task. Forklift #234 met load restriction but it wider than #123.

If hand tools or other non-mobile process equipment or material are involved, record what it is and the condition.

3

Safety devices (what is required, what is missing, and what was involved in the occurrence?)

Pre-use check was completed. Equipment appeared to be fully operational. Hydraulic controls are different from unit #123.

Check the operation of all safety devices (if possible) such as automatic or manual shutoffs; warning devices or conversely if missing safety devices such as lock tags/mechanical stops, etc…

4

Personal protective devices (what is required, what is missing, and what was involved in the occurrence?)

n/a

Check the use of and condition of all personal protective equipment (if possible) such as face shields, harnesses or conversely, if personal protection devices should have been present and are missing such as lifeline, etc…

5 Control panel, signaling and alarm layout.

n/a

Where relevant, check the layout of the control panels and mechanism used for process control and signaling and abnormal operating conditions. Provide a description of any contributing factors that may have been involved and provide photographs or sketches to support the description.

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 4

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

PART B - CONDITIONS OF WORK

6 Prevailing climate / temperature / humidity

n/a

It is important to record what the climate conditions were, especially if they are contributing factor to the occurrence. Is the area excessively cold or hot or wet? Record what part the prevailing workplace climate may have had to play in the occurrence.

7

General workplace conditions (road or surface conditions / ventilation / structural integrity)

Road surface was a bit wet. Mud had accumulated on shoulders. Sanding and grading was not scheduled until next week.

The physical condition of the workplace can contribute to an occurrence. If conditions are a contributing factor, record the physical issues. Consider the entire workspace from what is underfoot, overhead and around.

8 Visibility and lighting Adequate

Prevailing lighting conditions that can affect visibility need to be recorded if this is deemed a contributing factor. (This could include whether the area is foggy for example which is possible in some workplaces.)

9 Vibration / noise / radiation n/a

Was there noise, vibration or radiation that may have contributed to the occurrence? Document the conditions.

10 Housekeeping

Area appears well maintained.

Housekeeping is usually a good indicator of the prevailing level of acceptance of workplace standards. The level of housekeeping in the area must be specifically documented with areas of concern well detailed.

11 Hazardous conditions (chemical/biological) / oxygen deficiency

n/a

Are there hazardous conditions contributing to the occurrence

12 Ease of access to workspace (restrictions, obstructions, tight corners, etc…)

Tight area especially around the storage bay corner to the access way. Pallets were in a difficult area to reach with that particular forklift.

Where this may be a contributing factor, record the ease of access to the workspace. Is it a highly congested, high traffic area or is the access impeded by other obstructions?

13 Physical / ergonomic constraints (cramped, over-stretching, repetitive, etc…)

n/a

Look for ergonomic factors contributing directly or indirectly to the occurrence especially where the risk of injury may be due to an over-reaching or cramped type of condition.

PART C - PERSONAL FACTORS

14 Knowledge and skill

Operator is a certified forklift operator. He was new to the L2400 level. Has worked 2 shifts on this level. Operator had never used Forklift #234 and was not familiar with the different hydraulic system.

Knowledge and skill/experience requirement to safely perform the work. Are these requirements met? What is missing?

15 Physical/Physiological Condition (medical restrictions or disability / physical fatigue / restricted range of motion / etc…)

n/a

Where this may be a contributing factor, chronic or acute conditions that do not allow full capacity to perform the task as currently designed. Remember to respect the confidentiality and integrity of all involved.

16 Mental/Psychological Condition (mental fatigue / distraction / conflicting demands / repetitive or monotonous work)

n/a

Where this may be a contributing factor, identify situations that require deep concentration, complex decision making, repetitive and monotonous work, leading to error.

17 Motivation/Conduct (rush / internal pressures / overconfidence / attempt to safe time or effort)

Task was prioritized to be done by 8:30 am before the Access way would close for ventilation work. There were 4 pallets to be moved in a period of less than 1hr.

During the initial information gathering, identify any external pressures (real or perceived) that could have led to performing the work differently than expected and that may have led to the occurrence.

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 5

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

PART D - SYSTEMS

18 Communication

Forklift #234 is not an appropriate for this work area. Communication with the site Supervisor did not take place prior to this change out. Contractor was not aware of this change. Operator did not communicate with his supervisor when he identified that that the Forklift was different than the one he had used on his last shift.

Inadequate communication, programs, mechanisms or execution for effective transfer of information

19 Emergency Systems n/a

Lack or failure in emergency systems and/or response.

20 Leadership

Work was given to a new operator in this work area with limited time to complete the task. SLAM was not completed with the operator prior to starting the work.

Lack or failure in planning the work, matching individual qualifications to task requirements, availability of workforce,

21 Maintenance and inspection

Deteriorating road conditions. Increased water on access way this time of year. Mud on shoulder of the road.

Lack or failure in planning and /or execution of maintenance or inspection

22 Management of risk and change

Forklift used was too wide for the access way. Forklift #234 had different hydraulic system. Pallets to be moved were in an awkward area.

Failure to identify and assess risk; manage change; failure to implement controls or monitor effectiveness of controls

23 Operational control

Golden Rule #1: Only perform work that you are trained, qualified, authorized and fit to perform. Golden Rule #3: Always use mobile equipment and light vehicles for the purpose they were designed for and adhere to site pedestrian/vehicle traffic rules. Golden Rule #10: Always conduct a management of change assessment before implementing any temporary or permanent change (process, equipment or facility.

Lack or failure in planning and or execution of operational controls (Example: Golden Rules, Safety and Health programs and procedures; Fatality Prevention; Operational Processes; Work Permit; Critical Activities; etc…)

24 Projects and engineering

n/a

Lack or failure in design, commissioning, shutdown, project criteria and demands (Example: Drawings to identify / operate / isolate process equipment; Project plans for design and commissioning, etc…)

25 Purchasing and management of contractors

n/a

Lack or failure in specification of purchasing requirement; contractor management; materials management/storage.

26 Tools, equipment, machines and devices

Forklift was not appropriate for this work area.

Lack or failure in defining usage requirements; designed vs. installed capacity; availability

27 Training and orientation

Operator was a qualified forklift operator; however had never used Forklift #234. Operator was not sufficiently orientated to the location / area to know the issues with this access way. Operator knowledge of the area was limited to 2 prior shifts.

Lack or failure in adequately defining and/or executing on training or orientation requirements; performing safety toolbox meetings; evaluating employee knowledge; instruction qualification, visitor orientation, etc…

28 Work standards

Work standard for movement of this material in this location was not needs to better specify the appropriate equipment / forklift for the task.

Lack or failure in the development or review of standards including assessment or risk; legal requirements; permits; standards contradict the reality of the area.

PART E - OTHER COMMENTS 29 What else can help this

investigation? Attach separate sheets as necessary.

What other information might have not been captured here and would be useful to the investigation?

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 6

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 3: Sequence of Events 7 days

INSTRUCTION: The sequence of events is important to the ultimate goal of finding root causes. Once the sequence of events are

understood, you can start looking at the causes that resulted in each step leading up to the occurrence.

Completed by: _CONTRACTOR Representative_____________ Date: __February 12, 2017____________

# DATE TIME

EVENT

1 Feb 7/17 9:00 am Forklift #123 was removed for routine management and replaced with Forklift #234

2 Feb 10/17

7:00 am

Contractor line up meeting held by contractor supervisor to assign work for the day. Contractor tasked with moving 4 pallets of drums

from the storage bay at L2400 to the maintenance garage at L2400. Access bay will be closed after 8:30am for ventilation

maintenance.

3 Feb 10/17 7:20 am Operator performed his pre-inspection and noted that the hydraulic controls were a different configuration than Forklift #123

4 Feb 10/17 7:25 am Operator started the forklift engine and tested for controls.

5 Feb 10/17 7:30 am Forklift was used to pick up the first pallet of drums.

6 Feb 10/17 7:30 am Forklift operator pushed the hydraulic to lift the forks

7 Feb 10/17 7:30 am The forks tilted downwards and the pallet of drums shifted and fell to the ground.

8 Feb 10/17 7:35 am Operator turned of the forklift and contacted his supervisor

9 Feb 10/17 7:55 am CONTRACTOR Supervisor and VALE Supervisor attended the scene. Area roped off pending investigation. Environment department contacted to assist with the spill.

10

11

12

13

14

15

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 7

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 4: Root Cause Analysis (5-WHY worksheet) 14 days

INSTRUCTION: Use this worksheet to help you work through the

5-WHY to identify the cause-effect relationship in an occurrence. By repeatedly asking the question “why?” you peel away layers of issues and symptoms that can lead to the root cause. Start with a statement of the occurrence and ask why it occurred. Turn the answer to the first question into a second why question, etc… until you identify the root cause.

The forks tilted downwards and the pallet of drums

shifted and fell to the ground.

Why – 1a

Forks were not aligning with the pallet properly

Why – 1b

Area was too narrow for a direct alignment

Why – 1c

Forklift #234 too wide for this area. Forklift #123 usually used

Why – 1d

Forklift was replaced but communication did not include the Contractor

Why – 1E – ROOT CAUSE

There is not formalized process for communicating equipment changes with contractor Golden Rule #10

Why – 2a

Road was wet causing the front right tire to slide

Why – 2b

Increased water on the access way this time of year

Why – 2c

Road maintenance crew not aware of the condition

Why – 2d ROOT CAUSE

Road maintenance procedure not taking into consideration the need for increased maintenance this time of year

Why – 3a

Why – 3b

Why – 3c

Why – 3d ROOT CAUSE

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 8

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

INSTRUCTION: Circle the immediate, underlying and root cause(s) below that you identified in your 5-WHY Analysis. The causes

below align with SAP IM.

IMMEDIATE CAUSES

1. ACTS / DECISIONS (behaviour)

1A Deactivation of safety devices 1B Deviation from work standards (rules, standards, permits)

1C Failure to identify risk situation

1D Failure to lock/secure 1E Failure to warn/inform/ communicate 1F Inadequate elevation/lifting handling of load

1G Inadequate position for task 1H Inadequate use of PPE 1I Operation at inadequate speed

1J Operation of equipment without authorization or training

1K Performing repairs/service of equipment in operation

1L Restricted/unauthorized area access

1M Use of defective tools/ equipment/devices 1N Use of inadequate material 1O Use of tools/equipment/ devices in an inadequate or improvised manner

2. CONDITIONS

2A Adverse weather conditions 2B Adverse/inadequate road conditions 2C Congested/restricted space for action

2D Defective PPE 2E Inadequate/defective guards or barriers 2F Inadequate/defective tools/equipment/ devices

2G Deficient structural integrity 2H Excessive/insufficient lighting or visibility 2I Extreme temperatures (heat/ cold)

2J Favourable conditions for fire or explosion 2K Hazardous conditions (chemical or biological agents)

2L Inadequate instructions/procedures

2M Inadequate housekeeping 2N Inadequate material 2O Inadequate soil/surface conditions

2P Inadequate ventilation 2Q Inadequate or non-existent warning/alarm system 2R Noise level above OEL

2S Oxygen deficiency 2T Radiation level above OEL 2U Vibration level above OEL

UNDERLYING (INTERMEDIATE) CAUSES

3. PERSONAL

3A Knowledge/Skill (Example: Lack of awareness; Lack of experience or understanding of task requirements)

3B Physical/Physiological Condition (Chronic or acute physical condition, including fatigue that does not allow full capacity to perform the task as currently designed.)

3C Mental/Phsychological Condition/Stress (Situation that requires deep concentration, complex decision making, or, repetitive and monotonous work, that may lead to error.)

3D Physical/Physiological Capacity (Illness that impairs the normal execution of work.)

3E Motivation/Conduct (unintended or intended deviation from expected standards / practice based on the existing perceptions of an individual.)

ROOT (BASIC) CAUSES

4. SYSTEMS

4A Communication ( Inadequate communication, mechanisms, or execution for effective transfer of information)

4B Emergency systems (Lack or failure in emergency systems)

4C Leadership (Lack or failure in planning the work, matching individual qualifications to task requirements, availability of workforce)

4D Maintenance and Inspection (Unimplemented, incomplete or failure of maintenance program, equipment monitoring and/or inspection programs.)

4E Operational Control (Inadequate hazard controls, or lack of consistent application of existing controls. Example: Procedures; Rules; PPE; Golden Rules; Work Permit)

4F Project and Engineering (Lack or failure in design, commissioning, shutdown, project criteria and demands (Example: Drawings to identify / operate / isolate process equipment; Project plans for design and commissioning, etc…)

4G

Purchase and management of contractors (Lack or failure in specification of purchasing requirement; contractor management; materials management/storage)

4H Tools, equipment, machines and devices (Lack or failure in defining usage requirements; designed vs. installed capacity; availability)

4I Training/Orientation (Lack or failure in adequately defining and/or executing on training or orientation requirements; performing safety toolbox meetings; evaluating employee knowledge; instruction qualification, visitor orientation, etc…)

4J Work Standards (Lack or failure in the development or review of standards including assessment or risk; legal requirements; permits; standards contradict the reality of the area.)

4K Management or risk and change (Failure to identify and assess risk; manage change; identify and implement controls measures; monitor effectiveness of controls)

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 9

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 5: Recommended Actions 14 days

INSTRUCTION: Now that you have identified the causes, what actions are required to address them. Use the Hierarchy of Controls in making your decision. The goal of the action plan is to prevent a recurrence. Actions should be SMART. Avoid actions that are too broad or that focus on a punitive approach. Assign the actions to specific individuals with the appropriate authority to implement the actions. Assign a due date for the completion of actions.

Cause # from

STEP 3

Required Actions Hierarchy of Control #

Protection Goal #

Implementer (Responsible)

Due Date Supt. Approval

Date Completed

Sup ’r Initial

1

2B Road at L2400 being resurfaced and grated

3 2 Vale Rep. name

Feb 11/17

2

4H Review and formalize the requirement for forklift use for L2400

2 8 Vale Rep name

Feb 20/17

3

4D Revise Road Maintenance Standard to increase road inspection to 2x daily during the spring runoff season

2 2 Vale Rep. name

Feb 15/17

4

4K

Formalize Risk/Change Management Process to include prompt and appropriate communication with all work crews when equipment is changed out

2 9 Contractor Rep & VALE Rep

Feb 12/17

5

4C Contractor to formalize SLAM and job observation process .

2 8 Contractor Rep

Feb 15/17

PROTECTION GOAL: 1. Maintain / repair equipment 2. Maintain / repair property 3. Maintain compliance 4. Reduce / avoid ergonomic stressor 5. Reduce / avoid noise stressor 6. Reduce / avoid risk to the

environment 7. Reduce / avoid worker future illness 8. Reduce / avoid worker injuries 9. Reduce risk of negative outcome 10. Reduce risk of negative reputation

Actions should be SMART

- Specific - Measurable - Achievable - Relevant

- Time Bound

Note: You will give this Action plan to your FLA/Admin Support on two separate occasions.

1) After you have completed this package including STEP 6; and

2) After your actions are completed and you have dated and initialed the last two columns. Keep a copy of this Action plan close by for montioring of action completion.

If you are not supported by an FLA/Admin, input your data into SAP IM after STEP 6 is completed.

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 10

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 6: Superintendent Quality Check and Approval 21 days

INSTRUCTION: Review your completed investigation and action plan with your Superintendent. This is an opportunity for your Superintendent to provide additional support in your investigation process and to ensure appropriate actions are

implemented to prevent a recurrence. Your Superintendent is required to: (A) Review/update and approve Root Cause Analysis (STEP 4) (B) Review/update and approve Action plan. Initializing in the Superintendent approval column (STEP 5) (C) Estimate the likelihood of the Actual and Potential occurrence below. (D) With recommended controls, estimate the likelihood and severity of this occurrence occurring in the

future. This will generate a residual risk. If risk is still High or Very High return to STEP 4

ESTIMATION OF LIKELIHOOD AND RESIDUAL RISK

ACTUAL POTENTIAL

RESIDUAL SEVERITY CLASSIFICATION CRITERIA LIKELIHOOD

SEVERITY (How bad was it?)

LIKELI-HOOD

SEVERITY (How bad

could it be?)

LIKELI-HOOD

SEVERITY How bad was it?

LIKELI-HOOD

A Minor

B Moderate

C Serious

D Critical

E Catastrophi

c

FREQUENT One or more a

month

Safety (Injury)

N/A LIKELY CRITICAL LIKELY CRITICAL OCCASIONAL

Incidents requiring only first aid only

Incidents without absence (requiring work restriction, medical treatment

Incidents with absence.

Permanent disabling incidents or 1 (one) fatality.

Incident resulting in multiple fatalities.

LIKELY Within one

year

Occ. Health (Illness)

N/A N/A N/A N/A N/A N/A

Low concern reversible effects or without known adverse effect

Reversible effects causing harm

Severe reversible effects

Irreversible effects

Life-threatening or disabling diseases

OCCASIONAL Within 1 and

10 years

Financial (asset) MODE3R

ATE LIKELY SERIOUS LIKELY SEROUS

OCCASIONAL

< US $10,000

US$ 10,000 - US$ 100,000

US$ 100,000 - US$ 1,000,000

US$ 1,000,000 - US$ 10,000,000

> US$ 10,000,000

UNLIKELY Every 10-100

years

For an Environment related incidents or near miss, contact the Environment department for direction on how to classify. Contact Environment-On Call (after hours if urgent).

RARE One per

lifetime of facility

(E) Identify Lessons Learned. What is important to share with your crew, with your plant or with the organization?

Lesson learned Who needs to know

Only Forklift #123 is appropriate for movement in restricted access way on L2400 All crews, contractors working in the area

PHR for contractors needs to include this important information PMO coordinators

Increased road maintenance in areas where access water is anticipated All plants and mine managers

(F) Superintendent approval and signature:

Superintendent Signature Vale Project Superintendent Date Feb 24, 2017

If the residual risk is High or Very High, return to STEP 4. Review

contributing factors and implement further actions to reduce the risk.

If a reduced risk cannot be achieved, escalate to Manager.

C C D

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 11

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 7A: Investigation Signoff Form for VALE event 28 days

INSTRUCTION: Every investigation must be reviewed with the Originator and the involved Joint Health and Safety Committee member prior to closing the investigation. The IM Summary Report is a useful tool to print and have on hand when completing this review. Once completed, return to the FLA/Admin support to be uploaded in your SAP-IM. This will initiate the closure of the investigation in SAP IM.

Supervisor

I approve the closure of this investigation.

Print name: _____________________________ Date: ____________________ Signature: _____________________________

Originator (i.e.: notifier / injured person) I have reviewed the investigation and I am satisfied with the corrective actions taken to address the contributing factors. Yes No If not satisfied, please identify why: ____________________________________________________________________________________________________________________________________________________________________________________ Print name: _____________________________ Date: ____________________ Signature: _____________________________

JHSC Member: I have reviewed the investigation and I am satisfied with the corrective actions taken to address the contributing factors. Yes No If not satisfied, please identify why: __________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________ Print name: _____________________________ Date: ____________________ Signature: _____________________________

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 12

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 7B: Investigation Signoff Form for CONTRACTOR event 28 days

INSTRUCTION: Every investigation must be reviewed with the Originator and the involved Joint Health and Safety Committee member(s) prior to closing the investigation. The IM Summary Report is a useful tool to print and have on hand when completing this review. The completed Investigation Signoff Form will initiate closure of the invetigation.

VALE Representative CONTRACTOR Representative

I approve the closure of this investigation. I approve the closure of this investigation.

Print name: __________________ Date: ________ Print name: __________________ Date: ________ Role: _____________________________________ Role: ______________________________________ Signature: ________________________________ Signature: _________________________________

Originator (i.e.: notifier / injured person)

I have reviewed the investigation and I am satisfied with the corrective actions taken to address the contributing factors.

Yes No If not satisfied, please identify why: ____________________________________________________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________ Print name: _____________________________ Date: ____________________

Signature: _____________________________

VALE JHSC Member CONTRACTOR JHSC Member (if applicable)

I have reviewed the investigation and I am satisfied I have reviewed the investigation and I am satisfied with the corrective actions taken to address the with the corrective actions taken to address the contributing factors. contributing factors. Yes No Yes No

If not satisfied, please identify why: If not satisfied, please identify why: ____________________________________________ __________________________________________ ____________________________________________ __________________________________________ ____________________________________________ __________________________________________ Print name: __________________ Date: _________ Print name: _________________ Date: _________

Role: ______________________________________ Role: _____________________________________

Signature: _________________________________ Signature: ________________________________

SHE, ON Operations Training Version: 17(c)-2017\03\18 No.: SHE-SAP-IM-INVESTIGATION TOOLKIT pg. 13

IM #: 123456

TITLE: Forklift dropped pallet of drums

OCCURRENCE DATE: February 10, 2017

STEP 8: Implement Actions 42 days

INSTRUCTION: The SAP IM will remain open until all assigned Actions are completed. Implement and monitor completion of actions. As the actions are completed, complete the final columns in STEP 4 Recommended Actions.

Areas with FLA/Admin: Provide evidence of completed actions to your FLA/Admin of completed actions. The FLA/Admin will close the actions in SAP IM.

Areas without FLA/Admin: As actions are completed, complete the actions in your SAP IM Work Overview and attach evidence to the Report & Documents tab in your IM.

STEP 9: Manager’s Final Approval and Closure of IM 45 days

INSTRUCTION: When all actions are completed, the Manager’s provides a final review and approval in SAP IM. The Manager will complete this action through the SAP IM Work Overview tab.

Areas with FLA/Admin: The FLA/Admin will send the SAP IM to the Manager for Final Approval and Closure.

Areas without FLA/Admin: Change the IM status to closed. Remove all approvers except for the Manager.

STEP 10: Monitor Effectiveness of New Controls Ongoing

INSTRUCTION: Ensure to monitor the effectiveness of new controls through planned insepctions and audits.

Congratulations, you have successfully completed your investigation and SAP IM.

Ensure to attach to the SAP IM, any additional evidence to help support the completion of actions (Example: attendance sheet; completed work order; photos; etc…)

Given that all stakeholders have signed off in STEP 6 and STEP 7, only the Manager’s final signature is required to close the SAP IM.

Stakeholders will be notified that the IM is sent to the Manager for final approval.

•Safety Stats/Stop&Correct Program Review – Monthly Trends

PMO Mines Safety Stats May 10th, 2017

April High Potential Incidents 0 reported

Zero Harm Calendar

0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 0 0 0 0 0 0

0 -Zero Harm

F -First Aid Injury

M -Medical Aid Injury

R -Restricted Work Injury

L -Lost Time Injury

April

TRIF ANALYSIS

•

Mines PMO Injury Stats by Plant

April Plant Manhours FAI MAI RWI LTI TRI TRIf Coleman 21111 1 0 0 0 0 0 Creighton 31758 0 0 0 0 0 0 CCM 35637 0 0 0 0 0 0 Garson 2523 0 0 0 0 0 0 Stobie 2497 0 0 0 0 0 0 Totten 19495 0 0 0 0 0 0 Mill 8026 0 0 0 0 0 0 Environmental 33177 0 0 0 0 0 0 Total 154,224 1 0 0 0 0 0

Mines PMO Contractor Injury Stats

TRI= Total Recordable Injuries = MTI+RWI+LTI TRIf= Injury Frequency(per million hours) = (TRI)/(hours)x1,000,000

Contractor Injury Statistics - YTD 2017 Contractor Manhours FAI MAI RWI LTI TRI TRIf SCR 37,976 1 0 0 0 0 0 Dumas 20,707 0 0 0 0 0 0 Redpath 19,583 0 0 0 0 0 0 Anmar 6,803 0 0 0 0 0 0 Day 6,054 0 0 0 0 0 0 BluMetric 4,273 0 0 0 0 0 0 Cecchetto 3,438 0 0 0 0 0 0 Vallard 3,027 0 0 0 0 0 0 Technica 2,989 0 0 0 0 0 0 Lopes 2,246 0 0 0 0 0 0 Legend 1,816 0 0 0 0 0 0 CCM 1,594 0 0 0 0 0 0 Carman Construction 1,202 0 0 0 0 0 0 ECM Automation Networks 371 0 0 0 0 0 0 Moran 278 0 0 0 0 0 0 KCB 232 0 0 0 0 0 0 JL Richards 177 0 0 0 0 0 0

Patrick Mechanical 136 0 0 0 0 0 0 TES 69 0 0 0 0 0 0 Dorland Surveying 60 0 0 0 0 0 0 Pioneer 30 0 0 0 0 0 0 Metal Air 24 0 0 0 0 0 0 Northern Security 20 0 0 0 0 0 0 Aluma 6 0 0 0 0 0 0 Golder 5 0 0 0 0 0 0 GHD 3 0 0 0 0 0 0

2017 KPI’S 2017 ZERO HARM KPI'sAs of:

2017-May-02 Yearly Actuals

2013 2014 2015 20162017 OBJ

Monthly Limit Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

YTD TOTAL

CUMULATIVE YEARLY DISTRIBUTION of OBJECTIVE => 8.3% 16.7% 25.0% 33.3% 41.7% 50.0% 58.3% 66.7% 75.0% 83.3% 91.7% 100.0%

SAFETY & HEALTH -4 50% reduction from best year ever (rounded down)# LTI's (Vale Ont Ops emp's) 22 17 7 10 3 0.25 1 2 0 2 0 5

CUMULATIVE YEARLY PERCENT of OBJECTIVE => 33.3% 100.0% 100.0% 166.7% 166.7% 167%

-17 25% reduction from best year ever# MSD TRI’s (Vale Ont Ops emp's) 100 70 67 67 50 4.2 6 7 8 7 2 30

CUMULATIVE YEARLY PERCENT of OBJECTIVE => 12.0% 26.0% 42.0% 56.0% 60.0% 60%

-11% More thanZero Harm Days(Ontario Ops level) 53 70 85 99 110 9.2 10 3 9 5 0 27

CUMULATIVE YEARLY PERCENT of OBJECTIVE => 9.1% 11.8% 20.0% 24.5% 24.5% 25%

-337 50% reduction from 2016 actual

# MOL ORDERS 233 516 524 674 337 28.1 17 56 20 60 0 153CUMULATIVE YEARLY PERCENT of OBJECTIVE => 5.0% 21.7% 27.6% 45.4% 45.4% 45%

ENVIRONMENTAL 50% reduction from best year ever

Exceedances 13 13 4 10 2 0.2 1 0 3 0 0 4CUMULATIVE YEARLY PERCENT of OBJECTIVE => 50.0% 50.0% 200.0% 200.0% 200.0% 200%

Moderate, Serious Env Occurrences 11 4 7 2 5 0.4 0 1 1 0 0 2

CUMULATIVE YEARLY PERCENT of OBJECTIVE => 0.0% 20.0% 40.0% 40.0% 40.0% 40%

Critical, CatastrophicEnv Occurrences 0 0 0 0 0 0 0 0 0 0 0 0

2017 Monthly Actuals >

Stop & Correct Reporting Summary For PMO Mines

Plant Manhours Submitted Avg/month per worker

Coleman 21,111 165 1.30

Creighton 31,758 361 1.89

CCM 35,637 492 2.30

Garson 2,523 25 1.65

Stobie 2,497 1 0.07

Totten 19,495 902 7.71

Mill 8,026 48 1.00

Environmental 33,177 450 2.26

Total 154,224 2444

2017 From Jan 1st to Apr 28thPlant Manhours Submitted Avg/month per worker

Coleman 19,770 93 0.78

Creighton 48,803 216 0.74

CCM 62,871 128 0.34

Garson 5,708 6 0.18

Stobie 6,550 6 0.15

Totten 38,111 430 1.88

Mill 12,208 3 0.04

Environmental 16,164 212 2.19

Total 210,185 1094

2016 From Jan 1st to Apr 28th

Stop & Correct Reporting Summary For PMO Mines

Plant 2016 Avg/M 2017 Avg/M % Change

Coleman 93 165 77%

Creighton 216 361 67%

CCM 128 492 284%

Garson 6 25 317%

Stobie 6 1 -83%

Totten 430 902 110%

Mill 3 48 1500%

Environmental 212 450 112%

Total 1,094 2444 123%

Comparison

Stop & Correct Top 10 Trends Stop & Correct Trends Count

Rock/Debris on Ramp/Road 85 Housekeeping 50 Tools/Equipment 49 Slips/Trips/Falls 48

Mobile Equipment 41 Dust 34 Material Handling & Storage 33 Uneven Ground 30

Screen-Removal/Repair 23 Water Management 18

Working At Heights

Previous Count:

5 Last Month Count: 12

Safety Goals for 2017 GOAL 2016 2017

Goal YTD

Reduce Trif: (50% improvement from our best performance)

18.0 4.9 0

Zero Harm Months (2015 – May & Dec 0 injuries) 1 4 3

(Jan,Mar,Apr)

Stop&Correct’s: (20% increase by Plant) 1094 1313 2444

LTI’s 0 0 0 MOL Orders: 0 0 1 IM’s – Closed less than 45 days

Average was 70 Days 45 55.5

Safety Plan Compliance 100% 99.8%

•Updates/Standards/Hazard Alerts

Helmet Striping O.Reg 854 Section 263, (2),((b)) & (4)

(2) Subject to subsection (3), between sunset and sunrise, every worker on the surface shall wear, (b) retro-reflective material applied to the front, back and sides of head gear. O. Reg. 265/15, s. 19 (1). (4) All high visibility safety apparel and all retro-reflective material on head gear must be maintained in good condition so that they adequately visually identify a worker. O. Reg. 265/15, s. 19 (2).

Vale SPI-023 5.3: 5.3.1 Silver coloured retro-reflective Hot Dots for muffs 5.3.2 Silver coloured retro-reflective material applied to the front, back and both sides

Helmet Striping

Protective eyewear must be worn in: a) All underground operations b) All surface industrial operations

Non-prescription eyewear can be changed by the user but SAF-SPI-35 Eye Wear Fit System must be followed

Note: • Gap of 10mm or less is required

Note: • Selection of custom fit eyewear will be retained

Eye Injury Stats (Fitted Eyewear program implemented in 2014 for Vale Employees)

March 2017 Added

Added to section 3. references: - ANSI A92.5-2006 Boom-Supported Elevating Work Platforms - ANSI A92.6-2006 Self-Propelled Elevaring Work Platforms - VALE CED SPEC-20001 Standard Designs General Lifeline Attachment & Anchors

March 2017 Added

Added to section 4.8 Suitable Anchor Point: - If the anchor point is a permanent anchor point, then it requires be engineered. Both for fall arrest and travel restraint. - Temporary anchor points depend on the loads or forces they are subjected to but require to withstand a minimum amount of force. - Please reference the Construction Regs (26.7) , the Ontario Building Code, and also the CSA Standards for more specifics.

March 2017 Added

Added to Section 4.0 Definitions: 'Engineered Anchor Point: An anchor point that must be installed, inspected, and maintained in accordance with a Professional Engineer’s Design. Reference Vale CED SPEC-20001 Standard Designs- General- Lifeline Attachment & Anchors. In this standard, it refers to various acceptable lifeline bolting installations i.e. steel, concrete or rock.'

March 2017 Replaced

Replaced under Section 5. Fall Arrest System Requirement, f): 'While using equipment, such as mobile stagings, up-ups, etc., a Fall Arrest System shall be used at all times. A travel restraint system can be used but only after the completion of a formal risk assessment (see 'Section 13 Resources' for Risk Assessment tool).' with: 'While using elevated work platforms, i.e. scissor lifts, knuckle booms, etc., manufacturer recommendations in the owner’s manual on the recommended fall protection should be followed. If an owner’s manual only states “don fall protection”, then travel restraint is to be used.

March 2017 Replaced Replaced under Section 6. Fall Arrest System Equipment for Plants & Mines, C): 'method of support' with 'working platform'.

March 2017 Added Added to Section 9. Anchor Point Requirements' 9.1.1.: ' the vertical distance from the onset of a fall to the point where the fall-arrest system begins to apply force to arrest the fall is'

March 2017 Update Updated stock code numbers under Section 9.1.3 a)15628034 and b) 15580121 and c) 15677038

March 2017 Added Added to Section 10. The Requirements of the Anchoring Hitch are as follows: 'and not be knotted or allow to become knotted when used or worn.'

Revisions:

•Open Discussion

•Closing Remarks