PLUMBER - CURRICULUM OUTLINE - 1-64...

Transcript of PLUMBER - CURRICULUM OUTLINE - 1-64...

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 1

Contents

Page

01. Foreword 2

02. Introduction 3

03. Contributions for the Development of is Curriculum 4-6

04. Occupational Outlook 7

05. Competency Profile 8-10

06. Programme Structure 11-12

Module Numbers and Modules

07. M-01 Lay Non-metal Pipelines 13-17

08. M-02 Fix Valves and Other Fittings 18-22

09. M-03 Lay Hot Water Pipelines and Fix Fittings 23-26

10. M-04 Fix Rain Water System 27-30

11. M-05 Lay Soil and Drainage Pipes 31-36

12. M-06 Fix Common Sanitary Fittings 37-41

13. M-07 Fix Sanitary and Drainage Fittings 42-46

14. M-08 Prepare Metal Pipelines 47-48

15. M-09 Lay Metal Pipelines and Fix Fittings 49-52

16. M-10 Fix Water Pump System 53-56

17. M-11 Techniques of Cleaning Sewerage and Drainage Systems 57-58

18. M-12 Repair Sewerage and Drainage Systems 59-61

19. M-13 Prepare Estimates 62-63

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 2

Foreword

Skills Development Project, funded by the Asian Development Bank aims atestablishing a competency based system within the Technical and VocationalTraining Sector.

One of the vital integral components in the competency based system is thecurriculum designed for a Competency Based Training (CBT).

A curriculum, in fact, is a plan for training and a competency based curriculum inparticular is a training plan aimed at developing a highly skilled work force toaddress the specific manpower requirements of the industry.

This curriculum developed for the occupation Plumber consists of 3 docu-ments, namely,

• Curriculum Outline• Learner’s Guide and• Trainer’s Guide

As competency based training approach is basically trainee-centered, theinstructional design of this curriculum is enriched with creations of activities thatfacilitate and enhance the learning process.

The curriculum, however, will have to be continuously reviewed and amendedas the technological developments provide significant changes in skills,knowledge and other requirements of the occupation.

The project wishes to express its sincere appreciation and gratitude to all thoseresource persons who have actively contributed to this exercise and also to theCBT Development Unit of the project for producing this valuable curricularmaterial.

Hector HemachandraProject DirectorSkills Development ProjectMinistry of Tertiary Education & Training10 - Nov - 2003

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 3

Introduction

This is the steering document prepared for competency based training ofPlumbers. The main purpose of this is to give an overview of the content of thecurricula.

In addition to this document, there are two other documents; Trainer’s Guideand Learner’s Guide for the complete Competency Based Training Curricula.

The Learner’s Guide has been developed as a series of modules and the detailsof each module is also provided in one or more pages of this document.

The information given in respect of each module are:

• Tasks included in the module,

• Standards to be achieved in performing the tasks,

• Basic theoretical knowledge required to perform the tasks,

• Machinery, equipment, tools and the learning & teaching aids requiredto complete the module,

• Targeted time for completion of the module.

Further, this document would also provide an idea on the following:

• the number of modules prepared for the occupation,

• the total time duration of the training program, and

• whether it would be possible to conduct a competency based trainingprogram for this occupation in a particular centre.

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 4

Contributions for the Development of this Curriculum

Resource persons who provided occupational information

Mr. R. Dharmapala - Maga Engineering InstituteMr. W.N.C. Fernando - Sri Lanka Ports AuthorityMr. A.W. Perera - Sri Lanka Ports AuthorityMr. T.A. Raymond - Lanka Petroleum Corporation

(Fire and Security Branch)Mr. H.M.V. Silva - Lanka Petroleum CorporationMr. S.A.N. Suraweera - Lanka Petroleum CorporationMr. P.C. Perera - Olympic Engineering InstituteMr. L.S. Perera - Olympic Engineering InstituteMr. W.A. Nihal Perera - Ilukkumbura Industrial Automation

Company LtdMr. G.K.M. Jayawardana - Ilukkumbura Industrial Automation

Company LtdMr. R.R. Etigalla - Ilukkumbura Industrial Automation

Company LtdMr. B. Susantha M. Fernando - Ilukkumbura Industrial Automation

Company LtdMr. Chinthaka Perera - Nippon Air Technology Company LtdMr. W.P.A. Silva - State Engineering CorporationMr. U.P. Yasaratne - Bandaranaike Memorial Conference HallMr. P.K. Perera - Private ContractorMr. K.I. Priyadharshana - Private ContractorMr. M.A.C.T. Fernando - Private ContractorMr. M.S.M.S. Fernando - Private ContractorMr. M.K.D.T. Perera - Technicians Training InstituteMr. F.H. Sunil Silva - Apprenticeship Training InstituteMr. Upali Jayasuriya - Apprenticeship Training Institute

Conducting Workshops

Mr. T.P.K. Perera - Task Analyst, Conducted DACUMWorkshop

Mrs. W.A.W.C. Premaratne - Task AnalystMr. K.G.P. Randeniya - Conducting DACUM WorkshopsMr. T.S.P.A. Wickramasingha - Task Analyst

Curriculum Writers

Mr. B.M.P. Premawardena - Manager Training, National Water Supplyand Drainage Board

Mr. Upali Jayasuriya - Apprenticeship Training InstituteMr. A.D. Ariyasingha - Lanka Petroleum CorporationMr. B.D.M.T.B. Dissanayaka - Apprenticeship Training Institute

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 5

Coordination

Mrs. I.L.V.L.R. Imbulana - National Apprenticeship and IndustrialTraining Authority

Consultancy and Direction for Curriculum Development

Mr. Karsten Houtmere - International Specialist Consultant forCompetency Based Training

Mr. M.S. Nanayakkara - Specialist Consultant, Competency BasedTraining

Mr. T.P.K. Perera - Process Specialist and Coordinator ofNational Apprenticeship and IndustrialTraining Authority

(Skills Development Project)

Editing

Mr. T. P. K. Perera - Lecturer, Technician Training Branch,National Apprenticeship and IndustrialTraining Authority

Pre-Print Editing

Mr. Gamini Amarasinghe - Specialist Consultant

(Skills Development Project)

Computer Assistance

Miss. H.K. Kumudu Nishanthi - National Apprenticeship and Industrial Training Authority

Miss. D.J.K.J. Kannangara - Skills Development ProjectMiss. L.N. Nayani Malkanthi - Skills Development ProjectMr. P.A.D. Gayan Siriwardena - Skills Development ProjectMrs. P.A. Pavithra Manohari - Skills Development Project

Overall Supervision

Mr. Gamini Bambaradeniya - Project Manager,(Curriculum Development and StaffDevelopment)

Skills Development Project

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 6

Overall Direction

Mr. Hector Hemachandra - Project Director,(Curriculum Development and StaffDevelopment)Skills Development Project

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 7

Occupational Outlook

A plumber should be able to perform the following tasks with special competency.

• Plan domestic water supply lines and preparation of required raw ma-terial according to plan

• Knowledge about valves, common sanitation fittings, bathroom fit-tings and drainage fittings

• Proper laying of domestic pipelines and drainage pipeline systemsaccording to plan and proper fixing of fittings

• Laying metal and non-metal pipelines• Knowledge about fixing water pumps and pumping systems

Demand for this occupation

Today there is a great demand for this occupation both locally and abroad inthe field of construction. Plumbers who have reached a competency level havea very important role to play in the construction field. Hence qualified plumbershave immense job opportunities abroad. In future there will be a special demandfor plumbers who get qualified in competency based training.

S

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

P

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

8

COMPETENCY PROFILEPLUMBER

COMPETENCY AREA COMPETENCIES

6. Calculatetransportcharges

6. Fix gatevalves

16. Fixconcealedshowervalve

6. Fixheatingmixer

6. Fix gulleygratings

16. Fix venttaper

7. Calcu-late lossesand wasta-ge

7. Lay PVC& CPVCpipes inwalls

17. Fixflexiblehose

7. Lay pol-ypropylenepipes usingheat mac-hine

7. Fix Strap

17. Fixinterceptedgulleys

8. Calculategrossamount

8. Lay PVC& CPVCpipes onwalls

18. Fixgarden, bib,push swantype taps

8. Lay poly-butylenepipes withcliplinkmethod

8. Fix P trap

18. Fix levelinverter

1. Inspectsite

1. Fix airrelief valve

11. Fixflange typeexpansioncoupling

1. Fixgeyser

1. Set soilanddrainageline

11. Fixsweepjunction

2. Drawreconnais-sance plan

2. Fix Y &Tee brassstrainers

12. BendPVC pipes

2. Fixinstantgeyser

2. LayABS/PVCpipes

12. Fixwatersyphons

3. Listmaterialsrequired

3. Fixpressurereducingvalve

13. Fix fau-cet valvesockets, fa-ucet elbowsand caps

3. Fix solarpoweredgeyser

3. Fix doorelbows andTees

13. Fixvikingjonsoncoupling

4. Calculatemachineequipmentcost

4. Fix watertank

14. Layundergrou-nd PVC &CPVC pipes

4. Fix polyp-ropyleneTee usingheat mac-hine

4. Fix Yjunctions

14. Fix pushfit typeexpansioncoupling

5. Calcu-late labourcost

5. Fix ballvalves

15. Fix pipelines tomassageshowers

5. Insulatehot waterpipelines

5. Fix flushvalves

15. Fixvent box

LAY HOT WATER

PIPELINESC

LAY SOIL AND

DRAINAGE PIPESD

LAY DOMESTIC

WATER SUPPLY

LINES

B

PREPARE

ESTIMATESA

9. Fix bend-s, elbows,plain socke-ts, reducingsockets &bushing

19. Fix rainbird valve

9. Cutthread ofCPVC pipes

9. Fix pud-dler collarto pipes

19. Fixclean out

10. Fix PVC& CPVC Teejoints

20. Conductpressuretest for pipeline system

10. Fix nutring typepolybutyle-ne Tee

10. Fix crossjunction

20. Conductsmoke test

S

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

P

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

9

COMPETENCY PROFILEPLUMBER

COMPETENCY AREA COMPETENCIES

6. Fix urinalbowls

16. Fixautomaticcistern

26. Fixbathroommirrors

6. Fixvacuumgauge

6. Fixrunninghead

7. Fix washbasin

17. Fix pipelines toSPA bath

27. Fixlinencupboards

7. Fix non-returnvalve

7. Fix metalflashings

8. Fix topcountervanity basin

18. Fixshowercurtains

8. Fix footvalve guard

8. Fix endcaps

1. Fixsquattingpan

11. Fixshowertrays

21. Fixstainlesssteelkitchensink

1. Fixcentrifugalpump

11. Fixflexiblebellow

1. Erectscaffoldings

2. Fix highlevelcistern

12. Fixbath tub

22. Fix insinkaerator(disposablemotor)

2. Fix deepwell kits

2. Fix rainwatergutters

3. Fix lowlevelcistern

13. Fixmain headshower

23. Fixceramickitchenbasin

3. Fixsubmersiblepumps

3. Fixgutterjoiner

4. Fix handbidet

14. Fixtelephoneshower

24. Fixwaterclosets

4. Fix footvalve

4. Fix downspout

5. Fixpedestalbidet

15. Fixwatermixing taps

25. Fixwash basinwithsupports

5. Fixpressurepump

5. Fix downpipes

9. Fixpedestaltype washbasin

19. Fix wallmountbathroomaccessories

9. Fixseweragepumps

9. Fix mitrejoint

FIX SANITARY

FITTINGSE

FIX WATER

PUMPSF

FIX RAIN WATER

SYSTEMG

10. Fix bot-tle traps

20. Fixsinking typebathroomaccessories

10. Fix union/ taperjoints

10. Fixmetal chainsto downpipe

S

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

P

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

10

COMPETENCY PROFILEPLUMBER

COMPETENCY AREA COMPETENCIES

6. Fix castiron &stainlesssteel pipeswith ‘O’rings

16. Fixcopperpipes withferrule

6. Cleandrains usingcleaningrods

16. Repairflush valves

7. Laycopperpipes

17. Fixbarrelnipples

7. Cleanpipelineswith ridgemachine

17. Repaircisterns

8. Fix G.I.,B.I., S.S. &brassthreadedTees

18. Fix capand plug

8. Cleandrain withdraincleaningacid

18. Repairball valves

1. Cutthread ofC.I. pipes

11. Fix C.I.pipes usingred lead

21. Bendgalvanizedpipes

1. Cleanbottle traps

11. Fixemergencycoupling

21. Repairfire hydrant(breachinginlet)

2. Cutthread ofG.I. andblack ironpipes

12. Laypush fittypeductile ironpipes

22. Bracecopperpipe joints

2. Clean‘P’ and ‘S’traps

12. Fixrepairclamps

22.Maintaintools &equipment

3. Fixcopper &stainlesssteel pipesby push fitmethod

13. Fixcopperpipes bypush fitmethod

3. Clearblocks withplunger

13. Repairasbestospipes

4. Layflange typecast ironpipes

14. Fix male& femalesockets

4. Clearblocks withpressuregun

14. Repairearthenware& stonewareclaypipelines

5. Joinflange typecast ironpipes

15. Fixcopperpipes withflaring

5. Clean Ystrainer

15. Repairautomaticflushingcistern

9. Lay G.I.,B.I. & S.S.pipes

19. Fix G.I.,B.I., S.S.and brassunion

9. Fix PVCrepairsocketusingadhesive

19. Repairstop taps

10. Soldercopper pipejoints

20. Bendcopper pipes

10. Fix PVCrepairsocket usingrubber ring

20. Repairbib taps

PERFORM

MAINTENANCE

WORK

I

LAY METAL

PIPESH

S

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

P

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

11

Lay Non-metal Pipelines

Fix Valves and Other Fittings

Lay Hot Water Pipelines and Fix Fittings

Fix Rain Water System

Lay Soil and Drainage Pipes

Fix Common Sanitary Fittings

Fix Sanitary and Drainage Fittings

Prepare Metal Pipelines

Lay Metal Pipelines and Fix Fittings

B-7 B-8 B-9 B-10 B-11 B-12 B-13 B-14B-15 B-17 B-20

B-1 B-2 B-3 B-4 B-5 B-6 B-16 B-18B-19

C-1 C-2 C-3 C-4 C-5 C-6 C-7 C-8C-9 C-10

G-1 G-2 G-3 G-4 G-5 G-6 G-7 G-8G-9 G-10

D-1 D-2 D-3 D-4 D-5 D-6 D-7 D-8D-9 D-10 D-11 D-12 D-13 D-14 D-15 D-16D-17 D-18 D-19 D-20

E-1 E-2 E-3 E-4 E-5 E-6 E-7 E-8E-9 E-10 E-11 E-12 E-13 E-14

E-15 E-16 E-17 E-18 E-19 E-20 E-21 E-22E-23 E-24 E-25 E-26 E-27

H-1 H-2 H-20 H-21 H-22

H-3 H-4 H-5 H-6 H-7 H-8 H-9 H-10H-11 H-12 H-13 H-14 H-15 H-16 H-17 H-18H-19

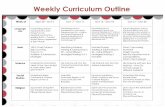

COMPETENCY AREA MODULE MODULE TITLE COMPETENCIES TIME (Hours)

These tasks will be performed by the Trainees as “ Major Learning activities”. Hence these tasks are notdetailed out in Learner’s Guide.

M - 01

M - 02

M - 03

M - 04

M - 05

M - 06

M - 07

M - 08

M - 09

Programme StructurePLUMBER

LAY DOMESTIC WATER SUPPLYLINES

LAY HOT WATER PIPELINESYSTEM

FIX RAIN WATER SYSTEM

LAY SOIL AND DRAINAGE PIPES

FIX SANITARY FITTINGS

LAY METAL PIPELINES

B

C

G

D

E

H

35

105

175

35

105

245

280

140

70

S

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

Sk

ills D

evelopm

ent P

rojectS

kills

Develop

ment

Project

P

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

Plum

ber -

Curriculum

O

utlineP

lumber

- C

urriculum

Outline

12

Fix Water Pump System

Techniques of Cleaning Sewerage and DrainageSystems

Repair Sewerage and Drainage Systems

Prepare Estimates

F-1 F-2 F-3 F-4 F-5 F-6 F-7 F-8F-9 F-10 F-11

I-1 I-2 I-3 I-4 I-5 I-6 I-7 I-8

I-9 I-10 I-11 I-12 I-13 I-14 I-15 I-16I-17 I-18 I-19 I-20 I-21 I-22

A-1 A-2 A-3 A-4 A-5 A-6 A-7 A-8

COMPETENCY AREA MODULE MODULE TITLE COMPETENCIES TIME (Hours)

M - 10

M - 11

M - 12

M - 13

Programme StructurePLUMBER

FIX PUMPS

PERFORM MAINTENANCE WORK

PREPARE ESTIMATES

70

70

210

30

F

I

A

These tasks will be performed by the Trainees as “ Major Learning activities”. Hence these tasks are notdetailed out in Learner’s Guide.

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 13

Module No. : M - 01

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Lay Domestic Water Supply Lines

Module Title : Lay Non-metal Pipelines

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

B-07

B-08

B-09

• Lay PVC & CPVCpipes in walls

• Lay PVC & CPVCpipes on walls

• Fix bends, elbows,plain sockets,reducing sockets &bushing

At the end of task B-07,

• Measurements and suitability ofpipelines in accordance with theplan and without defects

• Pipelines laid according to plan

• Pipelines fixed inside walls toprevent jutting out

• No seepage in the pipeline system

At the end of task B-08,

• Measurements and suitability ofpipelines in accordance with theplan and without defects

• Pipelines laid according to plan

• No seepage in the pipeline system

• Fixed pipelines inside the wall firmlyso that they would not get unfixed

At the end of task B-09,

• Measurements and suitability ofpipelines in accordance with theplan and without defects,

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 14

Task No. Task Performance Standards

• Pipelines laid according to plan

• Pipelines fixed inside walls toprevent jutting out

• No seepage in the pipeline system

• The coupling of the PVC pipes fixedfirmly to prevent getting unfixed

At the end of task B-10,

• Measurements and suitability ofpipelines in accordance with theplan and without defects

• Pipelines laid according to plan

• Pipelines fixed inside walls toprevent jutting out

• No seepage in the pipeline system

• The coupling of the PVC pipes fixedfirmly to prevent getting unfixed

At the end of task B-11,

• The measurements of expansioncouplings and pipelines in accorda-nce with plan and without defects

• No seepage in the pipeline system

• Fittings fixed at places in accordan-ce with the plan

At the end of task B-12,

• Pipelines bent to the required shape

• No damage to pipes when bendingand no reductions in cross section

At the end of task B-13,

• In accordance with the sizes andmeasurements, mentioned in theplan, fittings selected with no defe-cts and fitted as required accordingto the relevant / specified direction

• Fix PVC & CPVC Teejoints

• Fix flange typeexpansion coupling

• Bend PVC pipes

• Fix faucet valvesockets, faucetelbows and caps

B-10

B-11

B-12

B-13

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 15

Task No. Task Performance Standards

• Pipes inserted into the fittingsmentioned here up to the mark itcould be inserted

• No seepage of water from thepoints where they are fixed

At the end of task B-14,

• The pipelines in accordance withmeasurements and data given inthe plan, and with no defects

• Pipelines laid in deep ditchesaccording to plan

• No seepage of water from thepipeline system laid

At the end of task B-15,

• Massage shower fixed according tothe instructions of themanufacturer

• Water supply connected to theshower according to theinstructions of the manufacturer

• Shower could be operated asmentioned by the manufacturer

• Water draining tray of the showerfixed at specified slope to enableflow of water

• No seepage of water from thepoints where shower was fixed

At the end of task B-17,

• Pipe suitable for the given pipelinesystem and with no defects

• No seepage of water from points offixing

B-14

B-15

B-17

• Lay undergroundPVC & CPVCpipelines

• Fix pipelines tomassage showers

• Fix flexible hose

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 16

Task No. Task Performance Standards

B-20 • Conduct pressuretest for pipelinesystem

At the end of task B-20,

• Decided whether the pipelines testedcould withstand pressure accordingto the given instructions

• Decided on seepage / non-seepageof water from the system

• No seepage of water from thesystems fixed for consumption

Knowledge required for the module

• Applications of PVC and CPVC pipes and the characteristic featureswhich distinguish them

• Aspects to be considered in laying PVC and CPVC pipelines insidewalls, to what extent they should be embedded in walls

• Information about bends, elbows, types of sockets, expansioncoupling, faucet valves, socket caps and Tee junctions used forPVC and CPVC pipes

• The kinds of adhesives used in joining PVC pipes, methods ofjoining CPVC pipes and the aspects to be considered

• Aspects to be considered in fixing fittings in PVC and CPVC pipes• Bending PVC pipes to specific shapes at particular points• Aspects to be considered in laying PVC and CPVC pipelines

underground and the special techniques used• Hints in deciding seepage from a system as against pressure

values

Prerequisites

• Making grooves along walls according to the plan to fit in thepiping system

• Digging trenches according to measurements in the ground plan,and preparation of measurements according to the bending planof pipes

List of tools, equipment and teaching and learning material required

Tools and equipment:

• Hacksaws, pipe cutter, measuring tape, screw drivers, spanners,2" pipe wrench, blow lamp reamer

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 17

Teaching and learning material and equipment:

• Models, handouts, manual pressure machine

Target time : 35 hours

Note: Tasks B-12, B-13 and B-20 will be performed by the trainees asmajor learning activities

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 18

Module No. : M - 02

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Lay Domestic Water Supply Lines

Module Title : Fix Valves and Other Fittings

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

B-01

B-02

• Fix air relief valve

• Fix Y and Tee brassstrainers

At the end of task B-01,

• Air retained inside the pipelinessystem released

• Fittings for pipelines selectedaccording to plan and with nodefects

• When fixing the valve on a basesteps taken to prevent it gettingrusted

• Air relief valves functioned asmentioned by manufacturer

• Valve fixed on the relevant side inaccordance with the plan

• No seepage of water from thepoints where the valve was fixed

At the end of task B-02,

• No impurities in water after goingthrough strainers

• Water flowed through strainers freefrom obstructions

• Measurements of selected pipesand fittings found suitable with nodefects

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 19

Task No. Task Performance Standards

B-03

B-04

• Fix pressurereducing valve

• Fix water tank

• The functioning of Y - Tee strainersas mentioned by the manufacturer

• The material applied uniformly tocover the whole surface

• No seepage of water

At the end of task B-03,

• When the pressure inside the pipelinesystem is more than the pressurefixed, pressure automaticallyreleased from the valve

• Pipeline fittings selected according toplan and with no defects

• When fixing the valve on a basesteps taken to prevent the basegetting rusted

• The pressure reducing valvefunctioned as was mentioned by themanufacturer

• Valve fixed on the relevant sideaccording to the plan

• No seepage of water from the pointswhere the valve was fixed

• No water flowed through the valvewhen it was closed

At the end of task B-04,

• Water tank located according to plan

• No damages to water tank whenfixing

• Supply pipelines, distribution pipelinesand flushing pipelines fixed to thewater tank as given in the plan

• No seepage of water from the pointswhere tank was fixed

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 20

Task No. Task Performance Standards

B-05

B-06

B-16

• Fix ball valves

• Fix gate valves

• Fix concealedshower valve

At the end of task B-05,

• Ball valve functioned as mentioned by the manufacturer

• Ball valve moved down the verticalpipe

• The pipe inserted into the socket upto the mark shown on the pipe andcemented

• Ball valve selected according to theplan with no defects in it

• Fixed on to the relevant side ac-cording to plan

• No seepage of water from the pointswhere the valve was fixed

• No water flow across the ball jointwhen it was at the fixed water level

At the end of task B-06,

• Gate valve taken to suit thediameter of the pipe and functionedwithout defects

• Pipe fittings selected according toplan and with no defects

• Gate valve functioned according tomanufacturer

• Tap pointed to the side whichenables easy manipulation and fixed

• No seepage of water from the pointswhere the valve was fixed

At the end of task B-16,

• Concealed shower fixed according toinstructions of manufacturer

• Water supply provided to showeraccording to manufacturer’sinstructions

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 21

Task No. Task Performance Standards

B-18

B-19

• Fix garden, bib,push swan typetaps

• Fix rain bird valve

• Shower functioned as mentioned bythe manufacturer

• No seepage of water from thepoints of water supply connectionsto shower

• When a concealed shower has to befixed

At the end of task B-18,

• Kinds of taps and fittings selectedaccording to plan and with nodefects

• Taps functioned as mentioned bythe manufacturer

• Taps fixed pointing to the side whichenable easy manipulation

• No seepage of water from pointswhere taps were fixed

At the end of task B-19,

• Rain bird valve fixed according toinstructions of manufacturer

• Fittings for rain bird valve selectedaccording to plan and with nodefects

• Rain bird valves functioned asmentioned by the manufacturer

• No seepage of water from thepoints where the valve was fixed

Knowledge required for the module

• Aspects to be considered in fixing air relief valves, Y and Teestrainers, pressure reducing valves, water tanks, ball valves,gate valves, concealed shower valves, garden taps, bib taps,push swan tap and rain bird valves ; the application of thesevalves and their functioning

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 22

Prerequisites

• Previous knowledge about the types of valves, knowledge aboutvarious products, measurements about construction of watercolumns, drainage capacity of water, relevant pipelines

List of tools, equipment and teaching and learning material required

Tools and equipment:

• 8" pipe wrench, shifter, spirit level, screw drivers, reamer, wheel pipecutter, hammer drill, hacksaw

Teaching and learning material and equipment:

• Types of valves, models, handouts

Target time : 105 hours

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 23

Module No. : M - 03

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Lay Hot Water Pipeline Systems

Module Title : Lay Hot Water Pipelines and Fix Fittings

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

C-01

C-02

C-03

• Fix geyser

• Fix instant geyser

• Fix solar poweredgeyser

At the end of task C-01,

• Geyser fixed according to plan orinstructions without waterseepage and in a methodical orderaccording to instructions ofmanufacturer

At the end of task C-02,

• Water kept heated within theadjusted 2 oC temperaturelimit

• Hot water made available atrelevant capacity according toinstructions of manufacturer

• No seepage of water from thepoints where pipes are fixed tothe instant geyser

At the end of task C-03,

• Solar powered geyser fixed on theroof where sunlight prevails overthe maximum period as instructedby the manufacturer

• Geyser fixed oriented to thedirection given by themanufacturer

+

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 24

Task No. Task Performance Standards

• Water supply and distributionpipelines connected to the geyzerpreventing any seepage

• Hot water obtained within thetemperature range at times whensunlight prevails as mentioned bythe manufacturer

At the end of task C-04,

• Polypropylene Tee jointsuitable for the pipeline systemselected as shown in the plan andwith no defects

• No seepage of water at the Teejunction

At the end of task C-05,

• Hot water pipelines insulated usingrelevant insulating materialaccording to given instructions

• Temperature drop of hot water perunit length kept within the givenlimits

At the end of task C-06,

• Warm and cool water mixedaccording to standards andinstructions given by the heatingmixer manufacturer

• Heating mixer complying to thegiven data of the hot watersystem or the plan selected andfixed preventing seepage of water

C-04

C-05

C-06

C-07

C-08

• Fix polypropyleneTee using heatmachine

• Insulate hot waterpipelines

• Fix heating mixer

• Lay polypropylenepipes using heatmachine

• Lay polybutylenepipes with cliplinkmethod

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 25

Task No. Task Performance Standards

C-09

C-10

• Cut thread ofCPVC pipes

• Fix nut ring typepolybutylene Tee

It is recommen-ded that tasksC-07, C-08,C-09 and C-10 bepractised in thefield of industries

Knowledge required for the module

• Functioning of a geyser, geyser types and aspects to be consideredin fixing them

• The functioning of an instant geyser, types, applications andcomponents

• The functioning of a solar-powered geyser• Aspects to be considered in fixing and using them and in utilizing

solar power• Properties of polypropylene pipes, methods of joining them and

aspects to be considered in their application• Methods used in insulating water pipes, types of insulators, and

aspects to be considered in insulating and their standards• Parts of a heater mixer, its functioning and aspects to be

considered in fixing

Prerequisites

• Knowledge about reading plans, finding mathematical values,testing domestic electricity supply

List of tools, equipment and teaching and learning material required

Tools and equipment:

• Wheel pipe cutter, reamer, bench vice, adjustable shifter, vernier caliper,power blower, square steel, measuring tape, hacksaw, fusion joint-ing tool

Teaching and learning material and equipment:

• Handouts, mixer taps, geyser

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 26

Target time : 175 hours

Note : Tasks under C-07, C-08, C-09, and C-10 should be performedby trainees as learning activities

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 27

Module No. : M - 04

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Fix Rain Water System

Module Title : Fix Rain Water System

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

G-01

G-02

G-03

• Erect scaffoldings

• Fix rain watergutters

• Fix gutter joiner

At the end of task G-01,

• Reinforcements and fastenersdone to maintain the stability ofthe scaffold

• Protective railings erected forsafety

• Scaffold constructed at a suitableheight for work

At the end of task G-02,

• Rain water gutters selectedaccording to plan

• Brackets fixed to supportgutters at intervals shown in theplan or at 600 mm interval

• Rain water gutters supported onbrackets at the given slope

• No water seepage through therain water gutters fixed

At the end of task G-03,

• Gutter joiners suitable for selectedgutters fixed

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 28

Task No. Task Performance Standards

G-04

G-05

G-06

• Fix down spout

• Fix downpipes

• Fix running head

• Rain water gutters joined withgutter joiners preventing waterseepage

At the end of task G-04,

• Down spout selected to suit thediameter / cross section of thegutter

• Down spout fixed at the relevantplace according to plan

• No seepage of water at the placewhere the down spout wasconnected

At the end of task G-05,

• Down pipe selected according toplan or instructions and fixed tothe running head or down spout

• Down pipes fixed pointingdownwards vertically from therelevant points as shown in theplan

• Down pipes fixed to the wall usingclips at relevant intervals asindicated in the plan orinstructions

• No seepage of water from thepoints where down pipes werefixed

• Down pipes fixed using relevantfittings

At the end of task G-06,

• No seepage of water from thepoints where running heads wereconnected to rain water gutters

• Running heads selected to suitrain water gutters and fixedaccording to instructions

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 29

Task No. Task Performance Standards

• Running heads joined to rainwater gutters at points given inplan

At the end of task G-07,

• Metal cut and bent properly

• Metal flashings that match thethickness mentioned in the planselected

• Metal flashings held in themanner given in the plan

At the end of task G-08,

• End caps suitable for rain watergutters selected and fixedaccording to instructions

• No seepage of water from pointswhere they were fixed

At the end of task G-09,

• Mitre joints that match the shapeof rain water gutters selected

• Selected left or right mitre jointaccording to the manner in whichit would be fixed

• No seepage of water from pointswhere mitre joint was connected

At the end of task G-10,

• Used metal chains that can resistrusting and are relevant toinstructions

• Number of chains requiredaccording to instructions fixed tothe socket of running head ordown spout

• Chains terminated at a height ofabout 450mm from ground levelor at the specified height

G-07

G-08

G-09

G-10

• Fix metal flashings

• Fix end caps

• Fix mitre joint

• Fix metal chains todownpipe

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 30

Knowledge required for the module

• Details about the various fittings used in fixing rain water gutters,situations where they are used and aspects to be considered inapplication

• Materials used in connecting rain water gutters and their properties

Prerequisites

• Scaffolding, water levelling

List of tools, equipment and teaching and learning material required

Tools and equipment:

• Handsaw, hammer, pliers, chisel, screw drivers, water level, try

square, 4 2

1 " rain water gutters, end covers left and right, gulley

head, rain water gutter joint, perpendicular joint, down spout head,gutter holds, downpipe holds, downpipe elbows, downpipe joint,downpipes, solvent cement

Teaching and learning material and equipment:

• Handouts, audio- visual instructional material (O.H.P)

Target time : 35 hours

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 31

Module No. : M - 05

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Lay Soil and Drainage Pipes

Module Title : Lay Soil and Drainage Pipes

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

D-01

D-02

D-03

• Set soil anddrainage line

• Lay ABS/PVCpipes

• Fix door elbowsand Tees

At the end of task D-01,

• Middle line of the pipeline markedaccording to directions given inthe plan

• Pipe laying levels given either atevery point of change or in termsof constant distances

At the end of task D-02,

• Pipe fittings suitable formeasurements given in plan andwith no defects

• Pipelines laid along the inclinationgiven in plan

• Necessary action taken tomaintain the inclination of pipelines

• Necessary action taken tosafeguard the pipe

• Pipelines laid causing no damageto them

At the end of task D-03,

• Measurements of fittings suitedfor pipes laid or to data given inplan and with no defects

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 32

Task No. Task Performance Standards

D-04

D-05

D-06

D-07

• Fix Y junctions

• Fix flush valves

• Fix gulley gratings

• Fix ‘S’ trap

• Fittings located at relevant pointsaccording to plan

• Fixed to the side which allows theopening of door

• No seepage of water from thepoints where they were fixed

At the end of task D-04,

According to given instructions andplan

• Measurements of pipe fittingscorrespond to plan and withoutdefects

• Fixing located according to plan

• Fixed cleaning eye on the outside

• No seepage of water at pointswhere they were joined

At the end of task D-05,

• A flush valve that is agreeable toinstructions and data selected

• No defects in fluid valve

• Fixed at the relevant pointaccording to plan

• Flush valve functioned asmentioned by manufacturer

• No seepage of water from jointsfixed

At the end of task D-06,

• Grating selected according toinstructions and fixed to gulley

At the end of task D-07,

• ‘S’ trap selected according to givenplan or instructions and fixed

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 33

Task No. Task Performance Standards

• No seepage of water from pointswhere ‘S’ trap was fixed

At the end of task D-08

• ‘P’ trap selected according to planand fixed

• No seepage of water from pointswhere ‘P’ trap was fixed

At the end of task D-09

• Puddler collar fixed to pipesaccording to given instructions

• No seepage of water from pointswhere puddler collar was fixed

At the end of task D-10

• Cross junctions selected to suitsoil pipeline system or accordingto plan and fixed

• Junction fixed at the relevantpoint according to plan

• No seepage of water from pointswhere cross junction was fixed

At the end of task D-11

• Sweep junction selected accordingto plan or to suit soil pipelinesystem

• Sweep junction fixed withoutallowing water seepage at therelevant point according to plan orinstructions

At the end of task D-12

• A water syphon selectedcomplying with the measureme-nts of the pipeline system or datagiven in plan and fixed on to thesoil pipelines according to theinstructions of its manufacturer

• Fix ‘P’ trap

• Fix puddler collarto pipes

• Fix cross junction

• Fix sweep junction

• Fix water syphons

D-08

D-09

D-10

D-11

D-12

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 34

Task No. Task Performance Standards

• No seepage of water from pointsfixed

• Syphoning processes occurringinside the syphon of soil pipelinesystem

At the end of task D-13

• Viking jonson coupling selectedaccording to given instructions orto the pipeline system

• Fixed at the relevant pointaccording to given instructions

• No seepage of water from pointswhere they were fixed

At the end of task D-14

• Expansion coupling fixed to suitthe pipeline system or data of thegiven plan

• No seepage of water from pointswhere expansion coupling wasfixed

At the end of task D-15

• Vent box selected to suit thepipeline system or the given plan

• Vent box fixed firmly at the levelindicated in the plan connectingvent pipes

At the end of task D-16

• Vent taper selected to suit thepipeline system or the data in thegiven plan

• Fixed at the relevant placeaccording to plan and instructions

D-13

D-14

D-15

D-16

• Fix viking jonsoncoupling

• Fix push fit typeexpansion coupling

• Fix vent box

• Fix vent taper

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 35

Task No. Task Performance Standards

At the end of task D-17

• Gulley selected to comply with thepipeline system or the data givenin the plan

• Intercepted gulley fixed torelevant pipeline system accordingto measurements and levelsmentioned in the plan

At the end of task D-18

• Level inverter selected to suit thepipeline system or the data givenin the plan

• Level inverter fixed at the placeaccording to levels mentioned inthe plan

• No seepage of water from thepoints where the level inverterwas fixed

• Fix interceptedgulleys

• Fix level inverter

• Fix clean out

• Conduct smoketest

It is recommended toperform the tasksD-19 and D-20 underlearning activities

D-17

D-18

D-19

D-20

Knowledge required for the module

• Aspects to be considered in setting soil and drainage pipes, themeasurements to be taken, hints in constructing the required angles

• Aspects to be considered in laying asbestos and PVC pipelines andthe materials used in joining these pipes

• Aspects to be considered in fixing door elbows and Tees, clean outand their applications

• Information about fixing Tee joints, flush valves and theircomponents, functions and applications

• The necessity for fixing gulley gratings, aspects to be considered inselecting them, types of grating and their applications

• ‘S’ and ‘P’ traps, puddler collar, cross junctions, sweep junctions,water syphons, viking jonson, coupling, vent box, vent buffer,intercepted gulley and spirit level and fittings

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 36

Prerequisites

• Work shop training, reading plans, finding mathematical values,identifying sanitary fittings and tools

List of tools, equipment and teaching and learning material required

Tools and equipment:

• 8’’ pipe wrench, measuring tape, E-hammer drill, chain vice,hacksaw, square steel, angle grinder, screw drivers, spanners,hammers, spirit level, tube cutting tool, scriber, files, center punch

Teaching and learning material and equipment:

• Soil pipes and fittings, sanitary tools and fittings

Target time : 105 hours

Note: Tasks D-19 and D-20 should be performed by trainees as learningactivities

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 37

Module No. : M - 06

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Fix Sanitary Fittings

Module Title : Fix Common Sanitary Fittings

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

E-01

E-02

• Fix squatting pan

• Fix high levelcistern

At the end of task E-01,

• Pan selected to the given size andtype in plan

• A ‘P’ or ‘Q’ type trap fixed tosquatting pan and connected tosoil pipeline

• The pan placed horizontally

• Flush pipes fixed to pan preventingseepage of water if their fixturewas necessary

• Pan put in place using theconcrete mixture given

• No seepage of water from thepoints where the pan was joined

At the end of task E-02

• High level cistern given in planselected

• Parts of cistern assembledaccording to instructions of cisternmanufacturer

• Flush pipes and supply pipes fixedafter setting cistern at relevantlevel according to instructions ofmanufacturer and the plan

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 38

Task No. Task Performance Standards

E-03

E-04

E-05

• Fix low level cistern

• Fix hand bidet

• Fix pedestal bidet

• When flushed, water flows into pansmoothly without leaks in between

• When cistern was filled up to theset level, water flow in to thecistern stopped at the valve

• When cistern was operated,flushingeffected as mentioned bymanufacturer

At the end of task E-03

• Low level cistern selectedaccording to plan / instructions

• Cistern assembled according toinstructions of manufacturer

• On manoeuvring the side handle ofthe cistern water made to flowinto commode without leaks

• Inlet and outlet water pipe systemconnected to cistern according toplan

At the end of task E-04

• Bidet fittings selected to complywith pipeline system or plan

• No leakage of water from thepoints after fixing bidet fitting

• Functioned as mentioned bymanufacturer

At the end of task E-05

• The type of pedestal bidetmentioned in plan selected

• Fixed firmly at the point shown inplan

• Warm, cool and soil pipelinerequired for the bidet joinedwithout leakage

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 39

Task No. Task Performance Standards

E-06

E-07

E-08

E-09

• Fix urinal bowls

• Fix wash basin

• Fix top countervanity basin

• Fix pedestal typewash basin

• Bidet functioned as mentioned bymanufacturer

At the end of task E-06

• Joined to the main pipeline system

• Types of urinals selected and fixedat points as mentioned in plan

• Urinal bowls fixed at the levelgiven in plan

• Water supply lines connected tourinals according to plan /instructions

• No leakage of water from thepipes connected to urinals

At the end of task E-07

• Type of wash basin and tapselected as given in plan

• Wash basin fixed at height given inplan

• Water supply and drainage pipetoo connected to basin withoutleaks according to plan

At the end of task E-08

• Basin and fittings selectedaccording to data given in planand basin fixed at relevant level

• Supply and drainage pipes fixedpreventing any leakage

At the end of task E-09

• Wash basin, tap and fittingsselected complying to giveninformation and data

• Wash basin fixed at the level givenin plan

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 40

Task No. Task Performance Standards

E-10

E-11

E-12

E-13

E-14

• Fix bottle traps

• Fix shower trays

• Fix bath tub

• Fix main headshower

• Fix telephone

• Water supply pipes and drainagepipes connected preventingleakage of water to wash basin

• Selected mixer or tap fixedaccording to instructions

At the end of task E-10

• Bottle traps selected complying todata given in plans

• Bottle traps fixed at relevantplaces according to plan

• Bottle traps connected to drainagesystems according to instructionsof manufacturer

At the end of task E-11

• Shower tray fixed at place and atrelevant level given in plan

• Drainage pipes connected toshower tray without any leaks

At the end of task E-12

• Tub fixed as per the model givenby manufacturer and its fittingsfixed without any leaks accordingto instructions given bymanufacturer

• Tub fixed at the point given in plan

• Supply pipes and drainagepipelines connected to tub withoutany leaks

At the end of task E-13

• Shower fixed according to planand instructions given

• No seepage of water after showerwas fixed

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 41

Task No. Task Performance Standards

shower At the end of task E-14

• Telephone shower fixed according toplan and instructions given

• No leakage of water after fixingshower

Knowledge required for the module

• The functioning of fittings like squatting pan of sanitaryware, highlevel cistern, low level cistern, hand bidet, pedestal bidet, urinals,wash basins, vanity basins with top counter, pedestal wash basin,bottle trap, shower tray, bath tub, main shower, telephone shower;Aspects to be considered and safeguards to be adhered in fixing thecomponents of these fittings and their applications

List of tools, equipment and teaching and learning material required

Tools and equipment:

• Hacksaw, spirit level, hammers, file (flat, round), screw drivers, pli-ers, spanners, shifters, wrenches, bench vice, grip vice, chain vice,blow lamp, measuring tape

Teaching and learning material and equipment:

• Handouts, models, all sanitary fittings and tools

Target time : 245 hours

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 42

Module No. : M - 07

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Fix Sanitary Fittings

Module Title : Fix Sanitary and Drainage Fittings

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

E-15

E-16

• Fix water mixingtaps

• Fix automaticcistern

At the end of task E-15,

• Tap suited for given instructionsselected and fixed firmly at therelevant point using washers

• Hot and cool supply connected toleft and right in order

• No seepage of water from pointswhere pipes are connected

At the end of task E-16

• Cistern assembled according toinstructions given by automaticcistern manufacturer

• Fixed at the specific place at thelevel indicated in plan

• Flush pipe connected to relevantsystems according to plan

• No seepage of water at all pointsof connections

• Functioned to adjusted water levelor period and released water toflush pipe as mentioned bymanufacturer

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 43

Task No. Task Performance Standards

E-17

E-18

• Fix pipeline to SPAbath

• Fix shower curtains

• Measurements of materialscomplied and without defects

• Fixed at the correct alignment

• Appropriate rawlplugs and nailsused

• Brackets firm / strong

• Auto flush syphon functioned well

At the end of task E-17

• SPA bath located according to plan

• Water and air pipes connectedaccording to instructions andspecifications given by SPA bathmanufacturer

• No water or air leakage at pointsof connection

• To control air and water enteringthe system valves fixed accordingto plan

• Only the quantity of shampoorequired for SPA bath flowed asmentioned by manufacturer

• When the bath was filled withwater up to the adjusted levelwater supply stoppedautomatically

• Soap foam produced to requiredquantity through air bubbles asmentioned by manufacturer

At the end of task E-18

• Curtain fixed at relevant height atthe place indicated in plan

• Curtain fixed according toinstructions given by curtainmanufacturer and it could bemoved about

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 44

At the end of task E-19

• Accessories shown in plan fixed atrelevant levels

• Accessories selected complying todata given for accessories withregard to design, quantity andkind

• No cracks or defects inaccessories

At the end of task E-20

• Accessories relevant to placesgiven in plan fixed at relevantlevels

• Accessories selected complying todata given for accessories withregard to design, quantity andkind

• Without creaks or defects

At the end of task E-21

• Sink fixed at the place andrelevant level given in plan

• Relevant tap for the sink fixedfirmly as given in instructions

• Supply and drainage pipes of thesink fixed without any leakage ofwater

At the end of task E-22

• Aerator selected according tospecifications given in plan

• Fixed inside sink according toinstructions and specifications ofaerator manufacturer

• Aerator functioned as mentionedby manufacturer

Task No. Task Performance Standards

E-19

E-20

E-21

E-22

• Fix wall mountbathroomaccessories

• Fix sinking typebathroomaccessories

• Fix stainless steelkitchen sink

• Fix in sink aerator(disposable motor)

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 45

Task No. Task Performance Standards

• No leakage of water at pointswhere pipes are fixed to aerator

At the end of task E-23

• Basin constructed at the placeshown in plan at a level within

+ 12 mm limit

• A tap fixed to the sink from supplypipe system

• Drainage pipelines laid as outletpipes from sink

• No seepage of water from placeswhere pipes are connected

At the end of task E-24

• Closets fixed at given level anddirection as mentioned in plan

• Seat and seat cover fixed

• Cistern fixed at a lower level tothat of closet

• Cistern fixed

• Flushing pipeline system from thecistern fixed to closet withoutallowing any leaks

• Closet connected to soil pipelinewith sealing

At the end of task E-25

• Wash basin fixed at the relevantlevel and place given in plan

• Supply and drainage pipelinesystem fixed to wash basinwithout any leaks

• Taps fixed to wash basin accordingto instructions / specifications ofthe plan

• Fix ceramic kitchenbasin

• Fix water closets

• Fix wash basin withsupports

E-23

E-24

E-25

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 46

Task No. Task Performance Standards

E-26

E-27

• Fix bathroommirrors

• Fix linen cupboards

At the end of task E-26

• Mirror fixed to wall or relevantplace / using plumb line vertically

• If an edge of the mirror is straightmirror fixed with that edgehorizontally

At the end of task E-27

• Linen cupboard fixed at the relevantplace according to instructionsgiven in plan

• Cupboard fixed at level mentionedin plan

• The doors opened / closed withoutany difficulty

Knowledge required for the module

• Places where accessories like water mixing taps, automatic cistern,SPA bath tub, shower curtain, stainless steel kitchen sink, ceramickitchen sink and aerator are applied, their components, functioningand aspects to be considered in fixing them

• Accessories such as bathroom fittings fixed on walls and inside walls,air freshener holders and mirrors and aspects to be considered infixing them

• Aspects to be considered in fixing closets, wash basin on support,and linen cupboard, their applications and components

• Safety precautions to be adopted in fixing the above accessories

Prerequisites

• Drill bores on ceramic tiles and walls, standard slope of drainagepipes

List of tools, equipment and teaching and learning material required

Tools and equipment:

• Hammer drill, Vernier caliper, center punch, scriber hammers, tilecutter (professional), chain vice, spirit level, shifters, chisel, file, pipewrench, blow lamp

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 47

Teaching and learning material and equipment:

• Bathroom utensils / tools, sanitary utensils, handouts, audiovisuals (O.H.P)

Target time : 280 hours

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 48

Module No. : M - 08

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Lay Metal Pipelines

Module Title : Prepare Metal Pipeline

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

H-01

H-02

H-20

H-21

• Cut thread of C.I.pipes

• Cut thread of G.I.and black ironpipes

• Bend copper pipes

• Bend galvanizedpipes

At the end of task H-01

• Thread cut according to British orinternational thread standards

• Thread cut without irregularitiesand given a clean finish

• Thread cut to given length

At the end of task H-02

• Thread cut according to British orinternational standards

• Thread cut without irregularitiesand given a clean finish

• Thread cut to given length

At the end of task H-20

• Copper pipe bent to given shapeor the requirement

• No twisting or damages at thebent place and no reduction incross-sectional area

At the end of task H-21

• Pipe bent according to the givenangular shape and measurements

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 49

Task No. Task Performance Standards

H-22 • Brace copper pipejoints

• No irregularities or damages in thebent pipe and no reduction incross-sectional area in bending

At the end of task H-22

• According to given bracing methodcopper pipes connected to oneanother by bracing conforming tobracing standards

• Bracing done to give a uniformthickness

• A smooth finish given

• No harm done to copper pipes

Knowledge required for the module

• Distinguishing characteristics of GI, CI and BI pipes• Tools and equipment used in cutting outer thread of CI,

galvanized iron pipes and BI pipes, hints to be considered in use• Different kinds of thread and their applications, aspects to be

considered in cutting thread and safety precautions to be adopted• Benders to be used in bending GI, and copper pipes, steps to be

followed in using them and safety precautions to be taken• Aspects to be considered in bracing copper pipes to one another

and hints for preparing gas welding sets for it• Materials used in bracing

Prerequisites

• Bracing

List of tools, equipment and teaching and learning material required

Tools and equipment:

• Stock and die, pipe vice, bench vice, chain vice, reamer, wheel pipecutter, shifter, pipe wrench (adjustable), hammers, files (half round10’’, round 10” bastard, rough, smooth) pipe bending machine,hacksaw

Teaching and learning material and equipment:

• Types of metal pipes, handouts, thread-cut pipe models, pipebending equipment (by diameter)

Target time : 140 hours

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 50

Module No. : M - 09

Endorsement Date : 14 June 2005Revision Date : 14 June 2007

Occupation : Plumber

Competency Area : Lay Metal Pipelines

Module Title : Lay Metal Pipelines and Fix Fittings

Performance Objective : After successful completion of this module thetrainee will be able to perform each of the tasksaccording to the relevant standards andspecifications

Tasks to be Performed :

Task No. Task Performance Standards

H-03

H-04

• Fix copper andstainless steelpipes by push fitmethod

• Lay flange typecast iron pipes

At the end of task H-03

• Pipes and fittings selectedcomplying to data mentioned inplan and pipes joined to levelsmentioned at the relevant place

• No water or liquid seepage

At the end of task H-04

• Pipes and fittings selectedcomplying to data mentioned inplan

• Pipes fixed at relevant levels atplaces mentioned in plan

• No liquid or water leaks after fixing

• Specified measurements matchedaccordingly

• No obstructions to flanges

• Prepared according to given plan

• Standard rubber packs andbrackets used

• Pipes laid to direction and slopementioned in plan

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 51

Task No. Task Performance Standards

At the end of task H-05

• Flanges joined to one anotherusing bolts and packing to preventseepage of water

At the end of task H-06

• Cast iron or stainless steel pipesjoined using “O” rings according toinstructions preventing waterseepage

At the end of task H-07

• Water pipes laid at relevant levelat the required place according toplan

• No liquid seepages from pointswhere copper pipes were joined

At the end of task H-08

• Tee junctions appropriate forplaces mentioned in plan fixedpreventing liquid seepage

At the end of task H-09

• Pipes and fittings selectedcomplying to data in the givenplan and pipes laid at relevantplace and at relevant levelpreventing fluid seepage

At the end of task H-11

• Pipes laid according to given planand instructions

• Red lead used at places wherecast iron pipes were joinedpreventing leakage

At the end of task H-12

• Complied with plan and data

• Pipes and fittings complementarywithout defects

H-05

H-06

H-07

H-08

H-09

*H-10

H-11

H-12

• Join flange typecast iron pipes

• Fix cast iron &stainless steel pipeswith ‘O’ rings

• Lay copper pipes

• Fix G.I., B.I., S.S. &brass threadedTees

• Lay G.I., B.I. & S.S.pipes

• Solder copper pipejoints

• Fix C.I. pipes usingred lead

• Lay push fit typeductile iron pipes

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 52

Task No. Task Performance Standards

• Push fit pipes laid withoutseepage of liquid

At the end of task H-13

• Fittings without any defects fixedat relevant places according toplan and instructions

• Pipe inserted into the socket upto the mark made on the copperpipe

• No liquid leakages from fixedjoints

At the end of task H-15

• Pipe fittings without defectsselected according to plan andinstructions

• No defects in the copper pipeswith flarings

• No liquid seepage from placeswhere pipes were joined

At the end of task H-19

• Unions without defects andsuitable for the pipeline systemand the given plan selected

• Materials applied in pipe and insideunion

• Union fixed at relevant placesaccording to plan preventing anyleakage

• Fix copper pipes bypush fit method

• Fix male & femalesockets

• Fix copper pipeswith flaring

• Fix copper pipeswith ferrule

• Fix barrel nipples

• Fix cap and plug

• Fix G.I., B.I., S.S.and brass union

H-13

*H-14

H-15

*H-16

*H-17

*H-18

H-19

Skills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development ProjectSkills Development Project

Plumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum OutlinePlumber - Curriculum Outline 53

Knowledge required for the module

• Aspects to be considered in selecting metal pipes• Properties of G.I, B.I and S.S pipes and instructions to be adhered• Various methods of joining copper pipes and the fittings, equipment

used and aspects to be considered• Methods of joining various metal pipes• Methods of joining cast iron pipes• Accessories fixed for metal pipes and aspects to be considered in

selecting them• Aspects to be considered in laying various types of metal pipes• Aspect to be considered in activities like flaring copper pipes, by

fixing barrel nipples and fixing ferrule

List of tools, equipment and teaching and learning material required

Tools and equipment:

• Hacksaw, pipe wrench, jig saw, angle grinder, square steel, chainvice, pipe vice, spanners, screw drivers, shifters and hammers

Teaching and learning material and equipment:

• Types of pipes, bracing materials and sets

Target time : 140 hours

Note : *H-10, H-14, H-16, H-17 and H-18 will be performed by pupils as

learning activities