PLEATED BELT FILTER SYSTEM - MikroPul · 2011-10-20 · MikroPul Pleated Belt Filter System...

Transcript of PLEATED BELT FILTER SYSTEM - MikroPul · 2011-10-20 · MikroPul Pleated Belt Filter System...

®

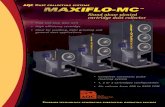

PLEATED BELT FILTER SYSTEM

DRY FILTRATIONWET SCRUBBERS

CYCLONESWET ELECTROSTATIC

PRECIPITATORS

Traditional surfaceloading filters

High efficiencyfiltration

Low efficiencybackflush mediacleaning pushes dustback into air stream

Large size

Examples: Bag filtersusing dense felt media,pleated cartridge filters,HEPA, membrane filters

Mat building filters

High efficiencyfiltration, once fibermat is built up

High capacity for filtersize

High efficiency suctionmedia cleaning

Allows particles topass through just-cleaned areas

Often requires aprefilter

Examples: Condensers,rotary drums, paper roll-ups, rotary discs, “V”cell type filters

PBF: combinesadvantages of both

High efficiencyfiltration

Very high capacity forfilter size

High efficiency off-linesuction cleaning

Pulse Jet3–196 x 10' (3 m) bag units

45,225 CFM(77,000 m3/hr)

Condenser/Rotary Drum

8' dia. x 20' drum(2.4 m dia. x 6 m drum)

50,000 CFM(85,000 m3/hr)

PBF8 x 10' (3 m) cells

50,000 CFM(85,000 m3/hr)

Space Comparison

The diagram above represents spacerequirements (front and top viewsshown) of different filter types forfiltering approximately 50,000 CFM(85,000 m3/hr). As you can see, thespace savings can be dramatic, whichcan save construction costs.

MIKROPUL PLEATED BELT FILTERHow the PBF ComparesA Breakthrough In Filtration

Technology

The MikroPul Pleated Belt Filter(PBF) is a patented, revolutionarydesign that combines high capacitypleated media with high efficiencysuction cleaning. The result is a highefficiency self-cleaning filter offeringmore capacity for its size than anyfilter on the market.

Unlike filters that rely on building afiber mat to retain small dust parti-cles, the PBF does not. And unlikefelt bag or cartridge filters, it doesn’tblow or pulse dust back into the airstream.

For the first time, thorough automaticcleaning of agglomerated fibers anddust out of dense pleated highefficiency filter media is possible.

Features and Benefits

• High filtration efficiency. Themedia is optimized for fibrous dustfiltration.

• High media cleaning efficiency.Fiber and dust are suctioned awayout of the air stream (off-linecleaning).

• Compact size—a 50,000 CFM(85,000 m3/hr) filter is 10' high x11.3' wide x 6.3' deep (3 m high x3.5 m wide x 1.9 m deep).

• Saves money—In many cases, thePBF does the work of tandemfilters. Also, cleaner air requiresless air turnover and improves airconditioning system efficiency.

• Installation is simple, quick, andeconomical—The PBF is pre-assembled on a steel base andprewired, including controls. Itdoes not require a smooth floor orelaborate leveling.

• The PBF is mechanically very sim-ple, each filter cell being basicallya conveyor. No moving parts (ex-cept for the media itself) are on thedirty side of the filter.

• The cleaning mechanism nevertouches the media—no nozzles toadjust and wear out or rub holes inthe media.

• Long lasting media—in normal op-eration, the PBF requires little orno attention for about two years,on average.

How The PBF Works

The PBF consists of a number offilter cells. Each cell is comprised ofan endless pleated media belt loopedbetween two pulleys.

Unfiltered air enters the unit parallelto the filter cells and passes throughthe straight sections of the belt loop.Larger fibers collect on the outeredges of the pleat and smallerparticles build up on the mediasurfaces between pleats. The cleanedair flows between the two sides of thecell into a plenum in back of the filterand then exits.

Pressure drop across the media isconstantly monitored by a dualsetpoint pressure gauge. When thehigh point is reached for a given cell,that cell’s belt begins rotating aroundthe pulleys. At the same time, astationary suction plenum underneaththe cell is activated and air jetslocated in the floor and lower pulley’shollow shaft are pulsed with lowpressure compressed air. As the beltmoves around the lower pulley, thepleats open up and air flow throughthe media is blocked, allowing thepleats to be easily vacuumed andpulsed clean.

Applications

The PBF provides outstandingfiltration performance for any airstream containing fiber and dust.Applications include:

• Textiles• Non-wovens• Pulp and paper• Wood products

To determine if the PBF is suitablefor your application, MikroPulmaintains a full scale test facility atour plant in Charlotte. Contact yourMikroPul representative for aperformance test on your dust.

The patented media is a significantnew design that is central to thePBF achieving its uniquecapabilities. The pleats are tightlyspaced for filtration purposes andopen up around the lower pulley forcleaning purposes.

Operation and Maintenance

The PBF is automatically controlledand normally does not requireoperator intervention. In the unlikelyevent of a controller failure, a manualoverride mode allows operation byhand.

No tools are required for mediachangeouts. The filter cells are heldin place with toggle clamps and themedia is attached via velcro strips.

Controls are simple and user friendly

40,000 CFM (68,000 m3/hr)filter depicted

PBF SYSTEM DESIGN

MikroPul can provide all systemcomponents, including airlocks Stripped dust collector

Stripped Dust Collector

Dust stripped from the PBF’s mediais carried away in a relatively lowvolume air stream. Because of thelower air quantity, the dust can beefficiently collected in a speciallydesigned pulse-jet collector.

As shown in the drawing, dust ladenair enters the unit through atangential inlet. An inner cylinderinduces cyclonic flow, causing largerparticles to separate from the airstream and fall into the hopper. Theremaining fine particles collect on thefilter bags, which are cleaned throughperiodical back-pulses.

Plant air inlets

Cyclone or prefilter(if needed)

PBF

Return air fan

Stripped dust fanand collector

Typical Pleated BeltFilter System

Cleanair

Clean air

The PBF is the heart of a system thatprovides efficient removal of fibrousdust from plant air streams. AMikroPul Pleated Belt Filter Systemconsists of the following:

• The main PBF unit sized for the airvolume and dust loading required.

• A small collector to collect the duststripped from the PBF media.

• Appropriately sized fans for thePBF and small collector.

• If necessary, a prefilter or cycloneis used to remove larger fibersfrom the air stream.

MikroPul can engineer, supply, andinstall the complete system, includingairlocks and ductwork, from the plantair inlets to the clean air exhaust.

Self-cleaning Prefilter

Compact design features a rotatingdisk-shaped screen which capturescoarse dust and fiber. An oscillatingsuction arm cleans the screen,sending the dust to the stripped dustcollector. By reducing the load on theprimary filter, the prefilter increasesoverall system efficiency.

Final Filter

These sturdy filter elements areavailable in a wide range of filteringefficiencies, including two HEPAgrades. The glass fiber paper, mini-pleated into mats, provides highvolumetric airflow and low operatingpressure drop.

Modular Component System

The Pleated Belt Filter is onemember of MikroPul’s line ofmodular preassembled and prewiredair filtration components. Modulescan be bolted directly to one anotheras needed to suit your application.Each module is skidded to allow easyrelocation as needs change.

The illustration shows how thesemodules can be assembledto form a complete, verycompact filtrationsystem.

In the example shown, thesystem includes:

• Inlet plenum module• Rotary self-cleaning prefilter for

removing larger fibers from the airstream

• PBF module• Final filter module• Fan module

The entire system is only 24 ft (7.3m) in length. As shown, this systemcan filter up to 43,300 CFM (73,600m3/hr) and can be configured to filterup to 60,000 CFM (102,000 m3/hr).

MikroPul can also provide othermodules for air conditioning,including:

• Chilled water coils• Fogging manifold• Eliminator blades

Return AirFan

Final FilterElements (seebelow)

Self-cleaning Prefilter(see below)

PBF Filter Cells

Inlet Plenum

OPTIONSMikroPul offers a number of optionsfor the PBF and system componentsto tailor the system to meet yourrequirements.

• PTFE membrane media, providing99.97% efficiency, 0.5 micron andlarger (standard spun bond mediaprovides 95% efficiency).

• Weatherproof PBF housing foroutside installation.

• PLC-based controller forinterfacing with central monitoringstations.

• Controller with timer for timedcycle media cleaning.

• Various methods for handling dustat discharge points.

– The Pneumatically Sealed DrumCover provides a simple solutionto a common problem—leaks thatoccur when discharging intodrums. It features an inflatablebladder that creates an airtight sealeven with out-of-round or denteddrums.

– A Screw Compactor containing ahelical screw conveyor designed tocompact fibrous dust. This simple,effective device achieves about 5:1compaction and can handle about400 lb/hr (180 kg/hr) of strippeddust.

– Our Briquetter provides a simple,clean and efficient way to disposeof your dust. It compresses fibrousdust into compact, easy to handlebriquettes. They can be used orsold as fuel, and eliminate the needfor plastic bags or special disposalarrangements.

When inflated, the seal conformsto the inside surface of the drum.Pneumatically sealed drum cover.

The Screw Compactor reduces wastebulk by about 5:1.

The Briquetter will compact the pileof dust shown above into the high

density briquette in the foreground.

Air Flow

TECHNICAL DATA76"B

A

1,930 mm

Model Nom. Capacity A B Weight@ 12:1 A:M

Height (ft) x # cells CFM m3/hr in mm in mm lb kg

7 x 3 11,124 18,908 84 2,137 56 1,422 2,313 1,0497 x 4 14,832 25,210 84 2,137 72 1,829 2,759 1,2527 x 5 18,540 31,513 84 2,137 88 2,235 3,206 1,4547 x 6 22,248 37,815 84 2,137 104 2,642 3,630 1,6477 x 7 25,956 44,118 84 2,137 120 3,048 4,077 1,8497 x 8 29,664 50,420 84 2,137 136 3,454 4,524 2,0527 x 9 33,372 56,723 84 2,137 152 3,861 4,971 2,255

9 x 4 19,632 33,369 108 2,743 72 1,829 3,151 1,4299 x 5 24,540 41,711 108 2,743 88 2,235 3,660 1,6609 x 6 29,448 50,053 108 2,743 104 2,642 4,142 1,8799 x 7 34,356 58,395 108 2,743 120 3,048 4,656 2,1129 x 8 39,264 66,738 108 2,743 136 3,454 5,169 2,3459 x 9 44,172 75,080 108 2,743 152 3,861 5,656 2,567

10 x 5 29,520 50,176 120 3,048 88 2,235 3,782 1,71610 x 6 35,424 60,211 120 3,048 104 2,642 4,419 2,00510 x 7 41,328 70,246 120 3,048 120 3,048 4,965 2,25210 x 8 47,232 80,281 120 3,048 136 3,454 5,520 2,50410 x 9 53,136 90,316 120 3,048 152 3,861 6,029 2,735

11 x 6 43,200 73,428 132 3,353 104 2,642 4,742 2,15111 x 7 50,400 85,665 132 3,353 120 3,048 5,323 2,41511 x 8 57,600 97,904 132 3,353 136 3,454 5,905 2,67911 x 9 64,800 110,142 132 3,353 152 3,861 6,476 2,938

The PBF and its media areprotected by U.S., Canadian,Mexican, and EuropeanCommunity patents.

Electrical requirements: 380, 460 or575 VAC, 3 phase, 50 or 60 Hz

Compressed air requirements: 15 psig(1 bar)

MikroPul backs up our products andsystems with worldwide customersupport. Call us any time you needhelp.

Parts and Media

Because we know your equipment,MikroPul is your best resource forparts and media. We carry a full lineof replacement parts, and keepcritical items in stock for immediateshipment. We also offer a scheduledmaintenance media swap-outprogram, as well as spare filter cellsand filter belts.

Services

MikroPul has the unique capability toupdate your system to meet today’schanging operating conditions andperformance requirements. Ourservices include:

• Complete systems evaluations• Mechanical equipment review and

evaluation• Equipment refurbishing• Equipment rebuilding• Technical training• Maintenance training

Whether you need spare parts,equipment service, or completesystem rebuilds, we are here tosupport your requirements.

MIKROPUL SUPPORT

MikroPul Global Network

MikroPul LimitedChadwick HouseBirchwood ParkWarrington, Cheshire WA3 6AEUNITED KINGDOMTel: +44-01925-849220Fax: [email protected]

Asia/PacificMikroPul Australia Pty Ltd1 Toohey RoadWetherill Park, NSW 2164AUSTRALIATel: 61-2-9756-2933Fax: [email protected]

AfricaMikroPul (Pty.) LimitedEvapark Block BCnr DF Malan Dr. & Judges Ave.,Cresta, JohannesburgSOUTH AFRICATel: +27-(11)-478-0456Fax: +27-(11)[email protected]

MikroPul, S de RL de CVAv. Lomas Verdes No. 480-302BCol. Lomas VerdesCP 53120 NaucalpanEdo. de MexicoTel: 52-55-5343-8224Fax: [email protected]

EuropeMikroPul GmbH & Co. KGWelserstrasse 9-11D-51149 CologneGERMANYTel: +49-2203-9391-0Fax: [email protected]

MikroPul FranceParc Club du Moulin àVent33, Avenue Dr. Georges Lévy69693 Vénissieux CédexFRANCETel: +33 478 78 9005Fax: +33 478 01 [email protected]

AmericasMikroPul Headquarters4500 Chesapeake Dr.Charlotte, NC 28216, USATel: 704-998-2600Fax: [email protected]

MikroPul Pittsburgh2591 Wexford-Bayne Road, Suite 202Sewickley, PA 15143, USATel: 724-934-3910Fax: [email protected]

MikroPul Chatham17 Watchung AvenueChatham, NJ 07928, USATel: 973-635-1115Fax: [email protected]

MikroPul Canada, Inc.245 Matheson Blvd. E., Unit # 10Mississauga, Ontario L4Z 3C9CANADATel: 905-712-0722Fax: [email protected]

BIM515 5/01 5000A member of Beacon Industrial Group

www.mikropul.com