PLASTIC FURNITURE MANUFACTURING PROCESS · 2016-08-07 · Process Plastics used Marks left Tooling...

Transcript of PLASTIC FURNITURE MANUFACTURING PROCESS · 2016-08-07 · Process Plastics used Marks left Tooling...

I N T D 3 0 1 F U R N I T U R E AN D F I T T I N G S

PLASTIC FURNITURE

MANUFACTURING PROCESS

COMMON MANUFACTURING METHODS FOR PLASTIC FURNITURE

1. MOLDING 1. Extrusion molding

2. Injection molding

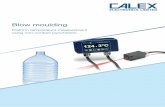

3. Blow molding

4. Rotational molding

2. FORMING 1. Thermo forming

2. Vacuum Forming

3. CASTING

4. FOAMING

INJECTION MOLDING

• Injection molding process is used for making single work piece without joints.

• With injection molding, parts with very complex shapes can be molded very easily.

INJECTION MOLDING

• Molten polymer is first forced into a mold cavity where it cools and hardens to take the shape of the final product.

• Sometimes automated rams are used to push the molten material into the cavity.

• http://www.technologystudent.com/equip1/inject1

.htm

• http://www.technologystudent.com/rmflsh1/alevq2

.html

THERMO FORMING

• In this process, a thermoplastic sheet is heated to become softer, and is pressed against a mold and allowed to cool until it retains the shape of the mold.

• Applications of thermoforming are spas, bathtubs, sinks, swimming pools, furniture and housewares, point-of-purchase displays, amusement park rides, automotive components, signs, aircraft components, molds, lighting fixtures etc

The process involves heating a plastic sheet until

soft. The softened sheet is draped over a

mould. A vacuum sucks the sheet into / onto

the mould. The newly shaped sheet is taken off the mould.

VACUM FORMING

• http://www.technologystudent.com/gprep07/vac3

.html

FOAMING

• Foaming process is used for making foams or cellular plastics.

• Eg: thermocol, styrofoam cups,

packaging materials, insulating materials etc.

FOAMING

• Foaming processes cause tiny bubbles to form within the plastic, solidifies the bubbles, or at least the holes created by the bubbles, remain.

• The solidified bubble-containing material can be thought of as a cellular structure.

Process Plastics used Marks left Tooling

cost

Production

Volume

Uses

Blow Moulding High density polythene

Line along the join of mould parts

High High Hollow products with smaller openings than the body

Extrusion high density polythene; polystyrene and polyvinyl chloride

none moderate high but restricted to minimum order lengths

anything with a constant cross section: curtain rails or window frames

Foaming polystyrene, polyurethane, polyvinyl chloride

none

Medium High packaging; sponges; soles of shoes; steering wheels; vending cups, insulat ion; foam furniture

Injection moulding

all thermoplast ics

the plast ic enters the mould through what is known as a gate which leaves a 'sprue' which is then

broken off but leaves a slight ly rough, often circular area; there are sometimes also smooth

circular marks left by the ejector pins used to help release the warm moulding from the mould

High

High

precision technique capable of complicated shapes: e.g. medical components; Airfix kits; cheap products

produced in very large numbers: Lego; plast ic cutlery; machine housings; washing-up bowls

Process Plastics used Marks left Tooling

cost

Production

Volume

Uses

Rotational moulding

low or medium density polythene

Same as Injection moulding

Relat ively low

Medium only for products with uniform wall thickness and where the inner surface of the product can be

inferior to its outer surface which replicates the surface of the mould. Usually large simple forms: storage

tanks; t raffic bollards

Thermoforming most sheet thermoplast ic materials

None Low suitable for low quantit ies or even one offs, but can be

mechanised to speed up process

shallow forms: baths and boat hulls, bowls, margarine and yogurt pots

FINISHING OF PLASTIC FURNITURE

• After the plastics are molded or cast to their desired shape, they require additional finishing before they are in their final use form.

• Common finishing operations are as follows; 1. Flash removal

2. Shaping (postmold forming) (used if the molded part is at an intermediate shape)

3. Mechanical joining and assembly (by using rivets, metal screws, or designing snap joints and internal hinges)

• Adhesive bonding (with adherents and adhesives)

• Non-adhesive bonding (i.e. fusion bonding, ultrasonic welding, Radio frequency welding, friction welding, and induction welding)

4. Coating and decorating (painting, printing, metallizing, etc.)

WOODWORKING FLOWCHART

Purchase of Timber

Wood cutting

Seasoning in

factory

Furniture Design in

CAD

Shaper machine to

shape

Molding machine

Carving

Assembly

Polishing

• Wood cutting automated saw

• Wood bending

• Wood bending is one of the technique in furniture manufacturing process.

• This adds the value of the product.

• Wood with good grain conditions (little loose grains), highly ductile and free of defects can be used for bending.

• Wood carving- manual or

automated: CNC machine

METALS • Joining of metals can be done precisely by

screwing, riveting, bolting or welding.