Plant Layout Cpmpressor

-

Upload

souparna-dutta -

Category

Documents

-

view

230 -

download

1

Transcript of Plant Layout Cpmpressor

-

7/28/2019 Plant Layout Cpmpressor

1/18

Plant Layout - Compressors

Table of Contents

1. Introduction

2. Reciprocating Compressors3. Centrifugal Compressors4. Drives

http://www.red-bag.com/cms/#introductionhttp://www.red-bag.com/cms/#reciprocatingcompressorshttp://www.red-bag.com/cms/#reciprocatingcompressorshttp://www.red-bag.com/cms/#centrifugalcompressorshttp://www.red-bag.com/cms/#drivershttp://www.red-bag.com/cms/#introductionhttp://www.red-bag.com/cms/#reciprocatingcompressorshttp://www.red-bag.com/cms/#centrifugalcompressorshttp://www.red-bag.com/cms/#drivers -

7/28/2019 Plant Layout Cpmpressor

2/18

1. Introduction

Compressors are the mechanical means to increase vapor pressure,

as pumps are used to increase liquid pressure .There are two basic types of compressors, reciprocating andcentrifugal. Each has one specific duty to intake vapor at lowpressure, compress it and discharge it at a higher pressure. Thequantity of vapor to be moved and discharge pressure it usually thedeciding factor in the type selected .

1.1 Reciprocating compressors

Reciprocating compression is the force converted to pressure by the movement of the

piston in a cylinder. These machine are generally specified for lower volumes than

centrifugal compressors. If several stages of compression are employed, extremely highpressures may be developed. Because of their reciprocating action these machines cause

piping, if not properly designed and supported, to pulsate, vibrate and generate fatigue .

1.2 Centrifugal Compressors

Centrifugal compression is the force converted to pressure when a gas is ejected by an

impeller at increasing velocity. Centrifugal compressors are specified for large quantitiesof vapor. Pressure differential may be small or large. These machines are not subject to

pulsation and therefore do not produce vibrational effects .

1.3 Compressor Drives

Drivers fall into three categories, i.e. electric, steam and gas.Electrical drivers range from small flameproof motors to large motors,2000 HP or more, requiring their own cooling systems . Steam driversare comprised of single or multistage turbines, either fully condensingof backpressure . Gas drivers cover gas turbines or gas engines.

2. Reciprocating Compressors2.1 Types of Machines

Reciprocating compressors can be obtained in a variety of patternsfrom a simple single cylinder to multi cylinder multistage machines.See figure 1,2,3 for the most widely used patterns.

-

7/28/2019 Plant Layout Cpmpressor

3/18

Figure 1 below is a single cylinder machine. It will operate at lowspeed, may be single or double acting.Figure 2 is a balanced horizontally opposed multi cylinder machine. Itwill operate at low speed, may be single or double acting, it can alsobe multi stage .

Figure 3 is a gas fuelled angle - type engine. The compressioncylinders are all on one side of the frame, cylinder diameters andlengths vary according to the composition, pressure and volume ofgas to be compressed. Dimensions from frame center line to cylindernozzles will vary with compression forces.

2.2 Types of Cylinders

Figure 3. Gas engine driven machine (note: gas engine may take 'V'form)Figures 4,5 for details of cylinder arrangements.

Figure 4: single acting cylinder, having one suction, compression anddischarge area per cylinder.Figure 5 : double acting cylinder, having two suction, compression anddischarge areas per cylinder.Multicompression stages : number of times the vapor is compressedby going through a series of compression cylinders to increasepressure.Gas compression raises temperature. In a reciprocating machine,compression is violent and heat rise is great. Inlet temperatures of 40oC may be raised to over 100 oC by the act of compression. Thecylinder gets hot and depending on the vapor being compressed, willneed some form of cooling. This will usually be in the form of coolingwater, but for low heat increases a glycol - filled jacket may suffice .

2.3 Compressor Foundation, Cylinder andSnubber Supports

The foundation for LP reciprocating compressors must beindependent from all other foundations. It must support thecompressor and all its auxiliary equipment.Cylinder supports are supplied by the vendor if they are required.They must be attached to the foundation concrete. Likewise thesnubber supports must be attached to the foundation concrete,springs will be used locally to support the snubbers .

2.4 Compressor Layout

-

7/28/2019 Plant Layout Cpmpressor

4/18

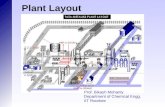

Effective compressor layout results in cost savings on process andutility piping, good maintenance accessibility and possibly reducedpulsation in suction and discharge piping. Poor layout does theopossite.See below figure; TYPICAL LAYOUT OF COMPRESSOR HOUSE &

SUCTION KNOCK OUT DRUMFor angle type compressors, locate the crankshaft parallel to thesuction and discharge headers. For balanced horizontally opposedcompressors, the crankshaft should run at right angles to the suctionand discharge headers. Compressor houses containing more than onemachine, particularly if they are long, will probably be equipped with atravelling gantry crane which will be manually or electrically operated.This feature can influence the overall dimensions of the house, as inaddition to the necessary building and maintenance clearances, thevertical reactions of the loaded crane will increase foundation size.Since these must not be connected to the machine foundations, the

building size will be affected. It is usual for compressor vendors toindicate the overall foundation dimensions on their layout drawings.(These should be requested as early as possible).The compressor building must be sized very early in the layout stagewhen only preliminary dimensions are available. It may be known thatthe overall length of the machine is 6 meters and the width is 4meters. To these dimensions must be added adequate clearance formaintenance plus possible control valve stations, lube oil equipment,local control panel, etc. Allow 2 meters all around the originaldimensions. In practice this 2 meter allowance will provide a walkwayof only 1200 - 1500 mm due to other items occupying floor space.

With two or more machines, allow 2 meters between compressioncylinders to allow for adequate piston removal. All dimensions mustbe confirmed from certified vendor drawings.Allow a maintenance area at one end of the building. A 6 meter bayshould be sufficient . Pits, trenches and similar gas traps should beavoided in gas compressor houses . Large reciprocating gascompressors will usually be elevated abovegrade with mezzanine floorlevel with the top of the foundation for operation and maintenance.The height of the mezzanine floor abovegrade will be kept to aminimum consistent with the adequacy of space for piping and access,especially to valves and drains .

2.5 Piping Layout

The piping layout will follow the plow diagrams as issued for the job. Ifthey conflict with any of the following notes, the flow diagrams willalways take precedence. It is usual for the suction piping to be routedto the top of the cylinder and discharge piping from the bottom.

-

7/28/2019 Plant Layout Cpmpressor

5/18

Liquids must be prevented from entering the compressors. Asliquids do not compress, extensive precautions must be taken toensure that absolutely no liquid enters the compressor cylinder ; asmall quantity would do extensive damage.If there is any doubt that the vapor is near its dew point, the suction

line must be steam traced between the suction drum and thecompressor inlet or local to the compressor inlet. Process Departmentwill advise the extent and it will be shown on the flow diagram.Suction and discharge headers will be located at grade level onsleepers up to the first piece of connecting equipment, e.g. suction KOdrum or aftercooler. Branch connections to the compressor from thesuction header will be taken from the top of the header . Suction anddischarge piping will be kept as straight as possible between thecompressors and headers. The use of short radius bends or tees andsimilar installations giving opposed flow shall not be permitted .Piping shall not be less than compressor nozzle size. Piping local to

cylinders shall clear the cylinder by sufficient distance to permitproper maintenance on the cylinder valves. When compressors areelevated with a mezzanine floor, piping and valves will normally rununder the floor.When more than one compressor is employed on the same service, allpiping to and from the compressors will be valved so that anycompressor may be shutdown and taken out of service. Spectacleblindes will be installed at the compressor side of the isolating valves.Startup bypasses are to be installed between suction and dischargepipes of compressors and will be located between the compressor andthe line block valve. When not furnished by the manufacturer, a relief

valve will take be installed between the compressor discharge andblock valve. This relief valve will discharge into the suction linedownstream of the block valve. The relief valve will be provided with abypass for hand venting.Distance piece and packing vent piping will be manifolded intosystems as indicated on the flow diagrams. These systems are eithervented to atmosphere outside the compressor house or connected toa collection system.Utility piping will comprise cooling water supply and return to lube oilcooler also to cylinder jackets. The minimum line size used will be3/4 . Sufficient vents and drains will be provided so that water lines

and jackets may be completely drained at shutdown. A steam orelectrical supply may be required if lube oil heaters are provided foreither the compressor or gear box oil. This system is used prior tostartup.Check for lines that have to be chemically and ensure drawingsindicate this requirement .

-

7/28/2019 Plant Layout Cpmpressor

6/18

3. Centrifugal Compressors

3.1 Types of Machine

Centrifugal compressors can be obtained in a variety of patterns. Seefigure 8. Centrifugal Radial CompressorCentrifugal radial compressors ( figure 8) : the compression process iseffected by rotating impellers of radial flow design ( figure 9 RadialImpellor) in fixed guide elements.Centrifugal axial compressors ( figure 10) : the force is converted intopressure by rotating vanes between fixed guide vanes; the flow isaxial .

3.2 Size and Position of NozzlesCentrifugal compressor manufacturers have basic case designs; theychange the rotor blade design to meet volume and pressurerequirements. For this reason suction nozzles are sometimes muchlarger or smaller than the line size for hydrocarbon processapplications. For example, a 30 suction nozzle may have a 20 or 24suction line. It will be necessary to increase the suction line diameterlocally at the compressor nozzle. Do not use a reducing flange as thiswill introduce full velocity to the rotor blades at a turbulent condition.Use 30 flange and a concentric reducer as a minimum. It is better if a

pipe length of 3 dias of 30 pipe can also be accommodated .Suction and discharge nozzles are either on the underside or the topof the compressor. On multistage compressors two or more inletnozzles may be provided ; the suction lines are connected to suctiondrums controlled to maintain the various inlet pressures .

3.3 Compressor Foundations

(See fig.10 Centrigfugal axial compressors)The foundation of each machine will be combined with its directcoupled drives but must be independent from all other foundations,including the lube console .

3.4 Compressor Layout

(See fig. 11,12,13 below)Centrifugal compressors are usually large capacity machines. They aredriven by electric motors, steam or gas turbine, the drive may be via a

-

7/28/2019 Plant Layout Cpmpressor

7/18

gearbox. It is usual to mount such machines on a tabletop about 4meters high with elevated access all around. The lube and seal oilconsoles for both the compressor and turbine, if used, will be locatedat grade. The suction and discharge connections of the compressorwill most likely be on the underside; these lines can be anchored at

grade. Should these connections be on the top of a horizontally splitcase compressor, see fig 13 for details of removable spools.A typical compressor house layout is shown in figures 11 and 12. Herean electrical motor and a condensing type turbine has been used.Note the withdrawal and maintenance areas, also the acoustic hoods.Determine the type of travelling gantry crane, and ensure that piping,etc. is clear of it. Note the lube oil header tanks, these must beelevated above the machines, if the vendor has not stated a minimumelevation use 10 meters above the center line of the machines.Their purpose is for emergency lubrication, and are tripped - in shouldthe normal lubrication supply system fail. They supply oil to the

bearings until the machine comes to a standstill .The lube and seal oil consoles are comprised of the following items :oil storage tank, filters, pumps, oil cooler, sometimes an oil heater forstartup, control instruments.Interconnecting piping must be in accordance with the flow diagram,all return lines must be free - draining from the machines to theconsole.Suction and discharge piping must be supported so that the nozzlesare not overloaded, use reducers not reducing flange local to suctionand discharge nozzles. Make provision for removal of strainers in theinlet line. Silencers may be required in both the suction and discharge

piping.Acoustic hoods may be required for both the compressor and turbine ;ensure that the tabletop is large enough to accommodate them. Theymay be of sectional construction. The travelling gantry crane will beused to dismantle them; this must be taken into consideration whendetermining the elevation of the crane hook.Maintenance area must be large enough to accommodate the acoustichood, turbine and compressor half casing rotors, etc.

4. Drives4.1 Electrical Motors

Flameproof motors will be employed for small to medium HPmachines.

-

7/28/2019 Plant Layout Cpmpressor

8/18

Ensure that the cables can be routed to the terminations, also thatthere is space behind the motor to remove the rotor .Large HP machines their own cooling systems ; these fall into twocategories : CACW (close - air - circuit water cooled machine ) or CACA( closed - air - circuit air cooled machine ) . These types of machines

may require an area of 7 m x 7 m and, therefore, determine the sizeof the compressor house.CACW machines (see fig. 14) : may be mounted on a tabletop with thecooler located under, in a sealed room. The cooling air circulatingaround the motor is itself cooled by water cooled heat exchanger.Provision must be made for removal and service of the exchanger.It is possible to obtain motors with the cooler mounted above or toone side of the motor.CACA machine consideration must be given regarding the safelocation of the air intake, which will be outside the compressor house.If a filter is required in the intake system, provide access for

replacement or cleaning .

4.2 Steam Turbines

Two types of steam turbines must be considered, condensing andnoncondensing. The noncondensing type uses high pressure steamand exhausts lower pressure steam to a stream header. Thecondensing turbine exhausts to a surface condenser (which is usuallya large exchanger with hot well attached, but may take the form of anair fan ) to recover condensate. Surface condensers are often grade-mounted directly below the compressors turbine. This arrangementemploys a turbine with outlet nozzle directly connected via anexpansion joint to the surface condenser. (See fig.16 ) . The surfacecondenser may be mounted at grade alongside a grade-mountedturbine. With arrangement very little NPSH is available.If an air fan is used as a surface condenser it will usually be locatedabove the turbine, either on the compressor house roof or over a piperack. If the condenser is the shell and tube type, it will most likely beof the fixed tube plate design and will require access for rodding thetubes. The cooling water lines associated with the condenser are largebore and some consideration must be given to the piping arrangementand placing of valves to give good operation and utilization of plotspace.The steam supply to the turbine will be taken from the top of thesteam header, a bellow may be required local to the turbine and atemporary strainer will be used for startup.The turbine will required a similar lube oil console to that provided forthe compressor. Do not pocket the return drains. An elevated lube oilheader tank also be required.

-

7/28/2019 Plant Layout Cpmpressor

9/18

Noncondensing turbine assemblies comprise a turbine, lube oilconsole and header tank. The low pressure steam discharge line willbe a large bore, a bellow will most likely be required in the line, whichmust join the top of the header. If the line has a low point, a steamtrap and drip pocket must be provided.

Maintenance access : provision must be made to dismantle theacoustic hood, and remove half of the turbine casing and the rotor .

4.3 Gas Turbines

When using a gas turbine to drive a compressor, a similararrangement to a steam turbine can be used; the lube oil console andheader tanks will be required. In addition, the exhaust system must beconsidered; this will be comprised of ducting to some heat recoverysystem, either a steam raising plant or process heaters.Combustion air to the turbine burner must be taken from a safe

location outside the compressor house. Inlet silencer and filter willmost likely be required. Provision for operation and maintenance to allmachinery must be provided .

4.4 Gas Engines

Gas engines are used to drive reciprocating compressors, eitherdirectly or through a gearbox. The machine may have bothcompression and drive cylinder attached to a common crankshaft.These types of engines may develop 2,000 HP or more. Ensure that

adequate space is allowed for removal of cylinder heads and pistons.The lube oil system may be integral with the engine that or in theform of a console. Should the latter be used, ensure that the engine isat suitable elevation to allow for free-draining oil return lines. (seefig.17)The engine and compressor will be mounted on a common foundationthat is independent of all other foundations. Due to the vibrationproduced by these machines, a large mass concrete foundation will beemployed.The general layout of the compressor house will enable the use of atravelling gantry crane for all maintenance, therefore when routing

piping this must be considered. It is not likely that a mezzanine floorwill be employed local to the machines, enabling most of the piping tobe kept low.Combustion air must be taken from a safe location outside thecompressor house. If an air filter will be required, arrange formaintenance access. Likewise, the exhaust must be dischargedoutside the building.

-

7/28/2019 Plant Layout Cpmpressor

10/18

-

7/28/2019 Plant Layout Cpmpressor

11/18

Figure 3. Gas engine driven machine (note: gas engine may take 'V'form)

Figure 4: single acting cylinder, having one suction, compression anddischarge area per cylinder.

Figure 5 : double acting cylinder, having two suction, compression anddischarge areas per cylinder.

-

7/28/2019 Plant Layout Cpmpressor

12/18

Figure 6: DETAIL OF FOUNDATION & SUPPORT FOR CYLINDER & SNUBBERS

Figure 7:TYPICAL LAYOUT OF COMPRESSOR HOUSE & SUCTION KNOCK OUT DRUM

-

7/28/2019 Plant Layout Cpmpressor

13/18

Figure 8: Centrifugal Radial Compressor

Figure 9: Radial Impellor

Figure 10: Centrigfugal axial compressors

-

7/28/2019 Plant Layout Cpmpressor

14/18

FIG. 11 TYPICAL LAYOUT FOR COMPRESSORS ONE TURBINE DRIVEN ONE ELECTRICMOTOR DRIVEN

fig. 12 TYPICAL SECTION THROUGH COMPRESSOR HOUSE

-

7/28/2019 Plant Layout Cpmpressor

15/18

FIG.13 THE NOZZLE ORIENTATION FOR HORIZONTALLY SPLITCOMPRESSOR CASING

-

7/28/2019 Plant Layout Cpmpressor

16/18

FIG.14 TYPICAL SECTION THROUGH A 'CLOSED-AIR-CIRCULATIONWATER-COOLED MACHINE'

FIG. 15 TYPICAL SECTION THROUGH A 'CLOSED-AIR-CIRCULATION AIR-COOLED MACHINE' NOTE: CLOSED-AIR-CIRCUIT AIR COOLED (CACA)ENCLOSURE A TOP MOUNTED AIR TO AIR HEAT EXCHANGER IS USED.tHE EXTERNAL AIR IS CIRCULATED BY MEANS OF A SHAFT MOUNTED

-

7/28/2019 Plant Layout Cpmpressor

17/18

FAN IN THE CASE OF CAGE MACHINES AND BY SEPARATE MOTOR/FANUNITS MOUNTED IN THE DUCTING FOR WOUND ROTOR MOTORS

FIG.16TYPICAL SECTION THROUGH A CONDENSING TURBINE SET

FIG. 17

-

7/28/2019 Plant Layout Cpmpressor

18/18

FIG. 18