Placing Equipment Chapter 5. Chapter Topics Placing concrete directly from trick mixers Manual or...

-

Upload

eugene-burchill -

Category

Documents

-

view

214 -

download

0

Transcript of Placing Equipment Chapter 5. Chapter Topics Placing concrete directly from trick mixers Manual or...

Chapter Topics

• Placing concrete directly from trick mixers• Manual or motorized buggies• Crane and bucket• Concrete conveyors• Concrete pumps

Placing Directly from Truck Mixers

• Most economical placing method• Minimal handling; minimizes segregation• With chute extensions up to 20 ft• Deliver 8 to 10 cy and weigh up to 80,000 lbs• Avoid cracking sidewalks and driveways• Avoid open excavations or walls– If wall 6 ft deep, stay 6 feet away

• Take advantage of mixer-mounted conveyors

Manual or Motorized Buggies• Transport from mixer to deposit

• Walk-behind or riding

• Some can fit through 36 inch doorways

• Placing capacity ranges from 15 to 20 cy/hr

• Consider costs– Buggy may need temporary ramps– Can’t run over reinforcing

Crane and Bucket• Lift concrete bucket to desired location

• Typically for small placements: columns

• Two buckets increase production

• Buckets– Different sizes: 1/3 to 3 cy– Different attachments: rubber discharge chutes

Concrete Pumps

• Trailer pumps– General purpose: 20 to 35 cy/hr– Pump up to 250 ft vertically – Pump up to 1000 ft horizontally– 4 to 5 inch diameter pipelines– Labor intensive for pipeline placing and removal

Concrete Pumps

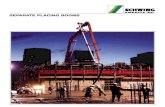

• Boom-mounted pumps– Most efficient method for large placements

• Consider these factors– Delivery output– Pump layout and boom length– Site conditions– Number of pumps needed