Pipeline Failures in the USSR

Click here to load reader

Transcript of Pipeline Failures in the USSR

machine safety, pressure vessels. constructionproducts, and so on.

It has to be said. however, that much of this

information is at a 'macro' level. covering allmanufacturing industry, and certainly valve andactuator companies see the need for detailedguidance relevant to their sector. In this respect,BV AMA has acted on behalf of the industry andhas produced guidance notes on, for example,product-liability legislation specifically in relationto practical questions raised by manufacturers.Other regulations are being studied in the sameway.

Another area for representation IS standardization. and the importance of productstandards for the valve and actuator industrycannot be over-emphasized, certainly with EC

directives, where working to harmonized standardsis one way of meeting essential safety requirements.Considerable progress has been made withEuropean Standards for valves and actuatorsthrough the UK national body, BSI. and into theEuropean Standards Organization, CEN. BVAMAmembers represent the industry on 12 CENcommittees and working groups, covering allproduct and application areas.

The British Valve and Actuator Manufacturers'

Association is based in Birmingham, UK an can becontacted by phone on 021 643 3331, or by fax on021 643 5064. Among its publications of interest toreaders of Pipes & PI/ielines International will beValves and actuators from Britain, the Valve andactuator manual, Codes of practice and guidance notes,and the BVAMA members and products list.

t,

Causes and frequency of failures on gasmains in the USSR

by S I Levin and V V KharionovskyAll Russian Scientific/Research Institute for Natural Gas and Gas Technology (VNIIGAS), Moscow, Russia

ANII.YSI5; o( tht' caust's o(.f{ll"lure in gas pipt'lines .flml1S a basis .flJl' enhancing their rt'liabilit)" and providingsolutions to the problems o(protccting the environment. In/wrticlI/m: the ana(rsis offai/urt's in 1I11denmter gaspi/wlines is gaining in importance becallst' these relJairs requirc considerable time and /abol/l: n,is paper dcscrihes

the causes andf;H/lIen(r o{jiti/lIres ofg(/S nwinsf()/' the pcriod /98/-/990. and of IIndcl1l'ater gas pipelincsfor the/wrioc! /970-/990.

Gas-main failures during 1981-1990

The total length of gas mains in the former SovietUnion (FSU) increased by ~3'<)OOkm during theperiod 19RI-1990. and reached 20H100km by early1990. During this decade. the biggest gas pipelines.of 1.420mm (56in) diameter. were constructed and

put into service. linking the gasfields of WestSioeria to the European industrial regions. Theaverage annual growth rate was XJOOkm.

Statistical data have oeen used for the analysis ofI'ailures as a function of length of gas main. and arcgiven in Table I. The f(JIlowing causes of failurewere analysed:

material defects:construction and weld defects:external and internal corrosion and erosion:external intedcrence:

violation of operating codes:others.

The total numoer of failures \vhich occurred

during this period due to the aoove causes was 752.One of the main reasons for 1~lilure was defects in

pipe material. For the period under consideration

PIPES & PIPELINES INTERNATIONAL July -- August 1993

there were IOR cases. which accounted for 13.3% ofthe total number of failures. The most

unfavourable year was 19R5. when there were 16failures. compared to an annual average of 10 cases.

Defects in equipment material caused 17 failures(2.3%), including five cases in 19~9. However.external corrosion (24R cases out of the totalnumoer of 752) was the main cause (33%) of failure

for gas pipelines.Internal corrosion and erosion led to 52 failures

(6.9%). Unfortunately. erosion-induced failureswere not identified in this number, and it was

therefore impossible to cletermine an exact numberof failures which took place due to internalcorrosIOn.

Construction defects (dents. scores, etc.) were thecause of R.6% of failures: weld defects accounted for10.8%. hence, 19.4% of the total numbers of failuresoccurred due to insufficient control of construction.

External interference resulted in 127 failures. of

which 26 occurred in 19X7. Similarly. violation of

operating codes led to 22 failures (2.9%). Otherreasons accounted for 40 cases (5.3%).

9

...o

"0-"0

t"'l[fJ

$<:0

"0

:;t"'lr-Zt"'l[fJ

Z-lt"'l'='Z~oz;0r-""c:«"

I;0c:

IJQc::!!.

(Z'l:>t;)

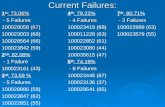

Number and frequency of failures (per 1000km year) on gas pipelines 1981-1990Failuresas a % of

1987

198819891981-total for

Year198119821983198419851986 1990

19901981-90

Length of gas pipelines148

160170177189196207operating at beginning of 124129138 1638

year (OOOkm)Causes of failure: 14

610916107910910013.3

Metal defect(0.113)

(0.047)(0.072)(0.061)(0.100)(0.059)(0.04D>(0.048)(0.051)(0.043)(0.061)

1

1 322251172.3Equipment defect

--(0.019)(0.012)(0.011)(0.011)(0.026)(0.005)(0.008) (0.008) (0.010)

11

5797106442658.6

Construction defect(0.089)

(0.039)(0.051)(0.061)(0.044)(0.059)(0.034)(0.021)(0.020)(0.010)(0.040)

7

53131381241068110.8

Weld defect(0.057)

(0.039)(0.022)(0.088)(0.088)(0.047)(0.068)(0.021)(0.051)(0.030)(0.049)

Internal corrosion and

33412510942 526.9

-erosion (0.024)(0.023)(0.029)(0.081)(0.031)(0.059)(0.051)(0.021)(0.010) (0.032)

36

22392834212217111824833.0

External corrosion(0.290)

(0.171)(0.283)(0.189)(0.215)(0.124)(0.124)(0.090)(0.056)(0.087>(0.151)

·15

989141626717612716.9

External interference(0.121)

(0.700)(0.058)(0.061)(0.088)(0.094)(0.147>(0.037)(0.086)(0.030)(0.078)

1

3224334222.9

Violation of codes --(0.007)(0.020)(0.013)(0.012)(0.023)(0.016)(0.015)(0.020)(0.013)

Other

144423545840

5.3(0.008)(0.031)(0.029)(0.027>(0.013)(0.018)(0.028)(0.021)(0.026)(0.039)(0.074)

88

557687968293546754752100.0

Total number of failures(0.71)

(0.43)(0.55)(0.59)(0.60)(0.48)(0.53)(0.28)(0.34)(0.26)(0.46)

Table 1. Causes and frequency of failures on gas pipelines 1981-1990.

Failure frequ~cy for sep'lnl te j"earsdue to all causes

'"::et::~I...

-=...,...l~Zo~z~I,..;f-~[fJ"'-l

~~Cl.

g:o(l[fJ••••Cl.

g:

...,a-~

::

mu:

>~c"~Cl"

~".2'n;u.

oa>

~0;a>

,,;",~

a;"-

'Q.~roCl>

.E

Cl

w

:rl'-<

140

13) .,

150 •.•.o

120

""

'""0.

l'

«•...

If)

""

><

-Cl0 7

180:r

l'-<w

:;J

en

er

'.w

170

er.

«•...

-"1

100tf)

'"

«:0

(0

..:l

ooo

&;0'>-<

ffi(]>

0>to,0>......

ffi0\

ffi(J\.....•

fO(]\.....•

CB(]\.....•

~•...

~<Xl0>.....•

(]I;0>....

M<Xl0>.....•

~.....•

Cl.!

ffi•...

.....•

$...•

I20

';I80z

::>

o:z:

8

Q

ril...:l

<:s

In

<~

z

:I:8<:>

""

o

Table I illustrates the failure frequency for eachcause in turn, along with an average failurefrequency (0.46/LOOOkm/yr) on gas pipelines for allcauses during the period 1981-1990.

During the first five years (1981-85), the averagefailure frequency was 0.57: for the last six years itwas 0.38. It should be noted that there was anincrease in failure due to external interference

within recent years (1986-90). The same applies tofailures due to violation of operating codes, whichincreased from six during 1981-85 to 16 during1986-90.

The number of failures induced by materialdefects in the first five-year period was equal to thatin the following five years.

The numbers of failures caused by weld defectswere also equal for both periods, and had notdecreased by the end of the period underconsideration. Failures caused by construction

defects decreased slightly during the second fiveyear period compared with the first.

A drop in the frequency of failures from 0.71 in1981 to 0.46 in 1990 is explained primarily by adecrease in the number of failures caused by pipecorrosion. A decrease in the rate of corrosion itself

is attributed to the construction of large-diameterpipelines (I,220-1,420mm) with an increased wallthickness. The same trend was observed in the

USA[II·

The graph in Fig.1 illustrates the change infrequency of failure for each cause: the failure

frequency for all causes is given by the envelopecurve of the figure.

USA/FSU comparison

A comparison of failures in the USA and theFSU is of particular interest. At the present time,about 400,OOOkm of gas mains are operated in theUSA[I]. Frequency of failure increases with anincrease in their'service life. and corrosion-inducedfailures sharply increase in gas pipelinesconstructed before 1950.

External interference is the main reason for the

largest number of failures in the USA. According to

statistics, poor quality of metal together withcorrosion amounted to 15-20% of total failures.

External interference and corrosion combined

therefore amounted to 85% of total failures in theUSA.

Failure frequency declines with an increase inpipe diameter. For gas pipelines of a diameter ofover 508mm, the failure frequency is within a rangeof O.I-0.6 failure per l.OOOkm/yr, with an averageannual frequency of 0.3.

These data are comparable with those for theUSSR (see Table I), where the average annualfailure frequency during the period 1981-1990 was0.46.

12

The principal reasons for a lower failure

frequency on large-diameter gas pipelines in theUSA are as follows:

increase in wall thickness:

improved construction and control quality:shorter service life.

It is likely that the same reasons resulted indeclining failures in gas pipelines in the USSR in1988-1990. Over this period. the average I~lilurefrequency dropped to 0.26-0.34 (Table I).T.Anderson and A.Misundfl] point out that mostcorrosion failures in the USA occurred on field

coated pipes. This phenomenon indicates thehigher quality of factory-coated pipes.

Underwater gas-pipeline failures during 1961-1990

The first investigations into accidents on

underwater gas pipelines. and an analyticalcomparison of causes of failures in both the USAand USSR (at that time). were performed in theearly I960s. A total of 42 accidents on USApipelines and 26 accidents on USSR pipelines wereanalysedI2].

Gas pipelines which cross rivers over 30m inwidth, and which. according to previous codes andstandards. required a mandatory emergency string.were included in the study for subsequent years.

To summarize, 40 accidents which occurred in

underwater gas pipelines were studied. Causes of

failures were the same as for above-ground

pipelines, except for pipeline-span vibrationresulting in fatigue stresses and. finally. in completepipe rupture (see Table 2).

A span occurrence was usually due to insufficientdepth of trench or insufficient weighting. Four suchaccidents took place in the period 1971-1975.However, after the adoption of codes on mandatorydeepening of trenches beneath the level of the riverbed. possible pipeline deformation or flotation.there has only been one accident during the last 15years (1975-1990). The failure occurred on a 273mm gas pipeline with 8mm wall thickness at acrossing of the Alagir river in 1984.

One of the mai n reasons 101' underwater gas

pipeline failure on river flood plains was externalcorrosion (22.5% of total accidents). The maincause, however, was construction and weld defects

(27.5%), while violation of codes and standardscaused three accidents over the last five years (17%).

Precise definition of failure frequency forunderwater gas pipelines has been hampered bythe fact that there was no data on the true length ofthese pipelines. In order to estimate failurefrequency, therefore. the length of underwater gaspipelines was taken as 2% of the total length of gasmains constructed in the USSR Such an estimate

allows calculation of a general trend in failurefrequency for separate periods of construction, and

PIPES & PIPELINES INTERNATIONAL July - August 1993

Number and frequency (per 1000km year) ofFailures

failures on underwater gas pipelines 1971-1990

asa%of total

Remarks1971-

1976-1981-1986-1971-forYear 197519801985199019901971-90

Length of underwater

Assumed as 2%gas pipelines 1.352.072.483.40 of total pipeline

operating at start of lengthperiod (OOOkm)

Causes of failure: 4

1512.5

InsufficientVibration of pipe spans

--(0.11) burial of pipeline(0.59) (0.08)

2

32717.5Factory defect (0.30)

-(0.24)(0.12)(0.15)

3

2512.5

Weld defect --(0.24)(0.12)(0.11)

1

23615.0

Construction defect -(0.10)(0.16)(0.17)(0.13)

2

34922.5On flOQdplainExternal corrosion -(0.19)(0.24)(0.24)(0.19)

1

1137.5

TransportationInternal corrosion (0.15)

-(0.08)(0.06)(0.06) of untreated gas

1

3410.0

Violation of codes --(0.08)(0.17)(0.08)

1

12.5Other ---(0.06)(0.02)

Total number of

73141640100.0failures

(1.04)(0.29)(1.12)(0.94)(0.85)

"

Table 2. Causl.'s and frl.'qul.'ncy of failurl.'s on underwater gas pipdines, 1971-1990.

demonstrates that si nce 1971 the failure frequencyhad dropped to 0.29 in 1976-1980. increasing to0.94-1.12 by 1990.

The initial decline in accidents was the result of

newly-developed. stringent. codes and standardsfor underwater crossings. The increase in accidents.which began in 1981. is explained by metal defects(five accidents). weld and construction defects (10accidents) and corrosion (nine accidents).

including \0 gas pipelines which had been underservice for 15-20 years.

Conclusions

Based on the analysis of gas-pipeline failures, thefollowing recommendations may be used toprovide guidelines for gas-pipeline designers andoperators:

I. The application of pigging for monitoringcorrosion. wear and position of pipelines[3].

2. The use of factory-coated pipes. especially forflood plains, water obstacles and otherdangerous areas.

PIPES & PIPELINES INTERNATIONAL July - August 1993

3. Stringent control of pipe quality. especiallyfor underwater pipelines.

4. Stringent control of weld and constructionworks. Control must be entrusted to an

independent body.5. The current design and construction norms

and codes for gas mains must be correctedand improved according to new, morestringent. requirements for enhancing gaspipeli ne reliability and protecting theenvironment.

References

I. T.Andersen and AMisund. 1982. Pipeline reliability - someremarks offailure rate and characteristics. Veriras. 105.16-19.

2. S.I.Levin. 1963. Prevention of failures and repair of

underwater pipelines. Gosloplekhizdal. 1'.184.3. R.W.Shannon and R.Enol!. 1985. On-line inspection:

development and operation experience. Froc. 17th AnnualOffshore Technology Conference. Houston. Texas. 2. 259272.

13