Pipe Cutoff Methods

-

Upload

kevin-steinbach -

Category

Documents

-

view

38 -

download

4

description

Transcript of Pipe Cutoff Methods

Pipe Cutoff Methods

• Explosive or Jet cutters

• Linear explosive charge cutter

• Chemical cutter

• Radial Cutting Torch

• Erosive/Abrasive cutter

• Mechanical cutter

• Collider (rarely used in interventions)

• Electrical arc tools

8/25/2015 1 George E. King Engineering

GEKEngineering.com

Pipe Cutoff Targets

• Pipe, usually tubing, when pulling a packer

• Tailpipe (below a packer)

• Special Targets

– Multiple strings

– Casing recovery

8/25/2015 2 George E. King Engineering

GEKEngineering.com

Explosive Cutters

• Continuous or segmented cutters

• A variation of linear shaped charge

• Needs to approach pipe ID: use a cutter with 80% of pipe ID for best performance.

• The charge behavior is similar to how a perforating shaped charge works.

8/25/2015 3 George E. King Engineering

GEKEngineering.com

Shaped Charge or Explosive Cutter – note the flare remaining. The flare is a result of yielding the pipe when cut. The flared end may have to be milled away to allow the pipe to be pulled.

8/25/2015 4 George E. King Engineering

GEKEngineering.com

Minimum flare from a well designed explosive cutter – still requires dressing to fish with an overshot.

8/25/2015 5 George E. King Engineering

GEKEngineering.com

Cutter Problems

• Large diameter cutter deployment is difficult die to restrictions in the string.

• Obtaining complete pipe separation

• Excessive flare at cut

• Outer pipe damage

8/25/2015 6 George E. King Engineering

GEKEngineering.com

Chemical Cutters

• A focused spray of bromine trifluoride that corrodes the tubular wall. BrF3 reacts violently on contact with water to evolve oxygen.

• Application expertise is critical to success of a chemical cutter. • Field data - 75% reliable (first cut) above packer, 25% reliable

below packer • Less reliability at depths beyond 10,000 ft and high alloy pipe

may be more difficult to cut • Usually cuts about 95% of pipe wall – have to pull apart. Typical

overpulls to part the pipe are > 30,000 lb. • Steel wool in mixing cavity believed to increase cutting efficiency. • The performance of chemical cutters is adversely affected by

liquid crossflows from uneven liquid heads or pressures in the tubing and annulus.

8/25/2015 7 George E. King Engineering

GEKEngineering.com

A Near Perfect Chemical Cut. 50k overpull, dropped off immediately when cutter fired. One joint in string above cut found backed off 4-1/2 turns on pulling tubing.

8/25/2015 8 George E. King Engineering

GEKEngineering.com

Note the nozzle spray pattern in this 3-1/2” S135 drill pipe. The nozzles must be of optimum size and at optimum distance from the inside wall of the target pipe for best performance. Small amounts of the wall may not be cut under even the best conditions and overpulls of over 50,000 lbs have been applied in some cases before the pipe finally separates.

Chemical Cutter Guidelines

• Avoid cuts in jewelry (profiles, collars, subs, mandrels and other heavy body or irregular shaped components), also avoid heavier wall and higher alloy pipe when possible

• The minimum restriction in a tubing string above the cut is the number 1 consideration when determining if a chemical cutter can be used. Efficiency is dramatically reduced if the cutter is used in tubing with a larger I.D. than recommended.

8/25/2015 9 George E. King Engineering

GEKEngineering.com

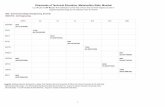

93% to 99% 75% to 92% 25% to 75%

6 to 8d max 9 to 15d max 16 to 24 d max

d

Nozzle Power Falls Rapidly With Increasing Standoff – The Jet is diffused with distance from the nozzle.

Note: this is for a fluid jet without particles.

8/25/2015 10 George E. King Engineering

GEKEngineering.com

Impact energy remaining at distances away from the nozzle. The spreading of the jet reduces the amount of chemical reacting with the cutting zone where pipe separation is needed.

Chemical cutter deployment – critical pieces are max tool diameter, centralization, anchoring and tool and casing preparation. Pulling pipe tension is often necessary.

8/25/2015 11 George E. King Engineering

GEKEngineering.com

Source unknown

Differential pressure effects

• Chemical tool performance can be severely reduced if a pressure differential exists between inside the tubing and the annulus.

• Typically, a small hole is created near the zone to be cut with a puncher charge and the pressures are allow to equalize before the pipe cut is attempted.

8/25/2015 George E. King Engineering

GEKEngineering.com 12

Tubing showing incomplete chemical cut The remaining steel in this example could not be yielded by overpull. Failures are due to many problems including small tool diameter, moving well fluids, deposits

inside the tubing, pressure, temperature, depth and pipe grade.

8/25/2015 13 George E. King Engineering

GEKEngineering.com Courtesy BP

Debris in pipe cut and pulled from a well. Debris, including pipe dope, mill scale, paraffin, scale, wireline grease, plastic coatings, etc., can be barriers to chemical cutters.

8/25/2015 14 George E. King Engineering

GEKEngineering.com

Chemical cutter head (Beryllium Bronze) with nozzles. Nozzles wear with use – critical wells and cuts at the limit of the tool may warrant use of a new nozzle body.

8/25/2015 15 George E. King Engineering

GEKEngineering.com

Chemical Cutter, tool cut 3.5”, 13.3 lb/ft, S-135 DP – no residual (uncut) steel was left – this was an unusually good cut. 8/25/2015 16

George E. King Engineering GEKEngineering.com

An experiment to measure the outside casing damage when cutting DP - <1” clearance from 7” casing to 3.5” drill pipe

8/25/2015 17 George E. King Engineering

GEKEngineering.com

Outer casing damage by chemical cutter when DP was touching casing Wall. Depression was about 0.15” deep. 8/25/2015 18

George E. King Engineering GEKEngineering.com

Test of Chemical Cutter on 13.5 ppf DP - 5% metal retaining.

The small uncut area, about 5% of pipe body, would require overpull to complete the pipe separation in the well. 8/25/2015 19

George E. King Engineering GEKEngineering.com

Chemical cut end of drill pipe, showing small uncut area broken by hand after the test.

8/25/2015 20 George E. King Engineering

GEKEngineering.com

Chemical cut on a recovered pipe – note the nozzle impact areas and the areas that had to be pulled apart by overpull.

8/25/2015 21 George E. King Engineering

GEKEngineering.com

Split Shot or Linear Explosive Shaped Charge

• Breaks the strength of the coupling. Usually requires only minor overpull to separate unless the connection uses hook-wall threads.

8/25/2015 22 George E. King Engineering

GEKEngineering.com

A SplitShot charge in a coupling – the effects vary but a high success is typical.

Problems:

Depth control

Hookwall threads

8/25/2015 23 George E. King Engineering

GEKEngineering.com Courtesy Owen Tool

Radial Torch Cutter

• Thermite plasma – extreme high temperatures (~5000oF).

• Nozzle cutter tool.

• Outer string damage potential controllable in most cases.

8/25/2015 24 George E. King Engineering

GEKEngineering.com

Troika Data

• TBG - 4-1/2" 13.5# 13Cr85

– 1st attempt w/chem cutter failed. Tool OD 3-

1/8" - Over Pull 25K

– 2nd attempt w/same tool failed- Over Pull 55K

– 3rd attempt w/radial cutting torch Tool OD 2-

15/16" - Over Pull 25 – pipe parted

8/25/2015 25

George E. King Engineering GEKEngineering.com

Radial Torch Cut, 13Cr 85 ksi pipe. Note the nozzle patterns and the melted steel.

8/25/2015 26 George E. King Engineering

GEKEngineering.com

Courtesy BP

String Shot Techniques

• Aid in backoff and jump-out of coupling.

• Stringshot – 1 to 4 strings of 90 grain (nominal wt) detonation

cord, 3 to 4 ft long, suspended with E-line, across a coupling.

– Initiated high order

– Tension already pulled into pipe (25k+ overpull) or torque when doing a back-off

– May not damage coupling or pin.

8/25/2015 27 George E. King Engineering

GEKEngineering.com

Abrasive Cutting

• Abrasives such as sand or pellets of carbonate carried at high velocity by water or oil can easily cut steel.

• Multiple layer cuts are possible.

• Control of the cut may be difficult.

• Back pressure in deeper wells slows the cutting performance.

• Nozzle performance less affected by standoff when using abrasives.

8/25/2015 28 George E. King Engineering

GEKEngineering.com

Cut End of 3.5” DP, after Abrasive Cutoff

8/25/2015 29 George E. King Engineering

GEKEngineering.com

Washout in drill pipe caused by stall during abrasive jetting with a rotating tool

8/25/2015 30 George E. King Engineering

GEKEngineering.com

Groove and washout in outer casing caused by abrasive tool

8/25/2015 31 George E. King Engineering

GEKEngineering.com

Surface Cutoff Test of Abrasive Cutter in 2-3/8” tubing cemented in 4-1/2” . Cut required less than 20 minutes using frac sand and a rotating head nozzle tool.

8/25/2015 32 George E. King Engineering

GEKEngineering.com

Courtesy Charlie Hailey

Company

Mechanical Cutters

• Best choice for pipe where no tension can be pulled.

• Minimize the number of cutter arms to insure good load application of cutter

• Must be anchored

• Slowest form of cutting – typically 1 to 10 hours to get a cut.

• Very experience dependent.

8/25/2015 33 George E. King Engineering

GEKEngineering.com

Two bladed mechanical cutter – blades pump out with pressure – must be held out and rotated by a motor powered by the same flow.

8/25/2015 34 George E. King Engineering

GEKEngineering.com