PILOT PLANT STUDIES ON THE UTILIZATION ...shodhganga.inflibnet.ac.in/bitstream/10603/19010/8/08...by...

Transcript of PILOT PLANT STUDIES ON THE UTILIZATION ...shodhganga.inflibnet.ac.in/bitstream/10603/19010/8/08...by...

Chapter 4

UTILIZATION O? PETROLEUM REFINERY CAUSTIC WASH WASTE

FOR THE MANUFACTURE OF INDUSTRIAL BITUMEN

61

INTRODUCTION

Industrial bitumen of various grades aremanufactured by the air-blowing polymerization ofpaving bitumen in presence of additives like Phospherous pentoxide, Ferric chloride etc. Pavingbitumen is manufactured mainly by two differentprocesses (1) by the vacuum distillation processand (2) by the propane deasphalting process. Theadditives used for the bitumen air-blowing arecostly and hence the high cost of production ofindustrial bitumen. This necessitated the developmentof cheaper additives that will make the process aneconomic one.

IV(a).1 AIR-BLOWING or BITUMEN WITHOUT ANY ADDITIVE

EXPERIMENTAL

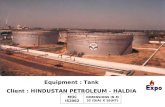

Paving bitumen (80/100 grade) obtained by thevacuum distillation process (Cochin Refinery) andby the propane deasphalting process (Haldia Refinery)were used as the raw materials.

The raw material is heated 10 around IZSCC,

made homogenous by stirring with a glass rod, andone Kg of the material is transferred to the reactoras described in Chapter II. By means of electricalheating the material in the reactor is heated to220°C and made to remain steady at that temperature

62

"Haul"!Inluuuunnllunfiuflnnuunugnufingflluul"Inna"“nnu."nfllulnuulnnlglnnnlunullN

S.oV 3.3 com A m N. 3 mmoé mS.oV 8.3 com A v a no So; m...3.oV 8.3 com A o NH 3. one.“ ..8.0V 3.? com A o 3. 3 «S; m8.oV 3.3 oonA 3 R. om mS.H N3.oV 3.8 oom A on ma 3 H84 H

.93 R ..._.3 x «no ucmnnmm E0 EE o.n\.n U Q UobNI@ onus onocflmon 5 .33 0 undo hu.n>m..uo |3o.nn Nno anon uunsaom numfi 3.33050 coaumuuocom mnacoumom oflaoonm coauous

"" unnnuuannnnuunnnun‘n"nnu"“uIuu“ul"nn.n"l"'mnnnU.'-.'ufl'."'un"'llufi'u'.'Iu'“Inn".

Mflgm .0M Mmnm ZHZ .H M UZHHQ H84“ 30..H.mlmH¢ WEB

A

UOONN H4 m>HBHQQ< Nzd .H.DO.._.HH3.. zzoqmumuc. .Z.1u.2_D..HHm uzH>.am ZHEUOU

63

"n "H"En"n”nn"n"n..n""'.u“"nnnn.""l"'.uuuuuInll”nnnunlnlunnllufl'n"Iu"'.I"ulfl'I“I!

8.0 V 23% com A o 0 22 08; m8.0V 3.3 oom A o o «S So; mé3.oV 8.? com A .o o Q: «No; v8.oV mm.mm oom A m m 8 So; mHo.oV 3.2.. oom A u S S floé N8.0V 3.3 oom A 3 on om . ~34 H

-- M. - - as - - - Ma- - - -5“. - - .. - - - - - - - W?--.“h_,.__.v

ocflmon 5 >93” o«\u . 00 ucaon hu.n>muo ...3oHn

so 33 ...B3om nnmfi aufiflusa aoauouuuaom onucoumom .ufl«uonm coflau"II. lnnuunnnunUnnnuuunflnfluIlnunlnnfllIInnlnunIlI"l.u'I'u".l."nI."_'Il'IIl'IIIUIl"llI'.I.nu“Inn

WAQEW oOM Nmmnu ZHZ .H W UZHHQ W.H.<d 30..H.mlMH4. ME

.3”

UOO¢N H4 m>HHHQQ< N24 HDOIBH3 Z3OAmImH< ZEDBHQ 0ZH>4m ZHEUOU

flflfllfllllflflUHfllflflflfllnunuuuflfllnufllnuflflflfllnulln.-ulln-hufllfllnulflflflflllflnuflflflflnullflfllfllflflnllfllllflflflll-uln

85 V 3.3 8... A o o .2: mac; m8.0V .233 oonA o o mfl So; mé8.oV Exam oonA o o 92 mac; «S.oV 8.3 oomA o o 03 «mo; n.3.oV 3.3 oomA H m om So; NS.oV no.3 oomA o 3 on . Zoé H

-- -- - -- - -wo...~-@.%-.r.;

mcflmmn 3. M0,: umwo h .5 EE o.n\H W 00 u:....om hvdfiwuo 463

co 33 u33om 5 E uflflusa coflmuuocmm mfiqouuom .ufl3oomm aoflflNH"NH"flflnufl"nnflnuflfl"flflflflnflflflnuflflflnufl.flfl.Inu.Mn—flI.n..II.lIfl-uflnunllln-InInnnulllnuflflnuulflfllnuluflnunullllfllflflflfln

mqaém OM mum ZHZ A m ozHmm N95 30...__.mlmH4 mme

H.

000mm .H.< m>H.__..HQQ4 H24 HDOIBH3 Z3OAmImH< zmzpanm 0ZH><m ZHEUOU

Ho.ouv ~».am oonAm .m m cm ono.H oHo.ouv m>.mm oomAm m m mu omo.H mHo.ouv mo.ma oomAm 5” ma um m~o.H ¢Ho.ouv >m.mm oomAm a pa an H~o.fi nHo.ouv om.mo oonAm va .H~ ¢m mHo.H uHo.ouv ¢m.mm oonAm afi mm aw . ado.“ H

mwwnmmwn . uwax u coma EU .5: 3} ... oo venom h%.au:h:m..u% ..Lua..m.H~n_co mmoq uansaom numam auaaauusn coaumuuuamm onauouuom _u«maoonm uofiuoh

uAmz<m .0M mam 22 A m ozmm WH<M 3OQhImH< NIB

.3‘

OOONN B4 m>HHHQQ¢ N24 BDOEBHB zzoamumnd ZHZDHHQ 0ZH><m 4HQA<I

66

" nnflunnnllnu!

"UHI“U...""HunununuluunuflahlnflllflnuflIlflflflfllnflfllnulllfluunulflulflnIflnluflflflflnfllflnnuufl Inna.“

8.oV Show oomA o .o mm mmoé m8.oV 253 com A N v 3 mac.” ..S.o V ¢m.mm oomA v m S wmoé mS.oV 8.3 oomfl. o S 3 ~84 m.m8.oV 3.3 oomA m 3 mm o~o.a n3.oV 3.3 oomA 3 S 3 So.” H

II..uIII...I...lNIIlIW...IIIIIIIIIIIII4IIII I @..om.u:u

93 R 93 x nu ma .5 EE 3} , 0 vc._..o.m Dorm

onflmwn 5 mafia NH: huaaavoso aoaumuuocmm mmacovmom . hvfrmuo Izoan

co mmoq -338 oamdoonm coupe...

mqmz¢m .0H mmm 22 A m OZHMQ ma<m 3OAhIMH< HEB

HI

ooo¢~ B4 M>HBHQQ4 Mzd BDOEBHS z3oqmumH¢ ZBEDBHM 0ZH>¢m ¢HQA<I

flu"In-uflnuflfln-flflluuufluulnnulflfliu-nHlflflflnlfllnuflllinulununullfl-IIfllunlnuflflflHHUNIUNHIHIIHIIIIIullfllluulllfll

Ho.onv mo.mm oomAA o o NNH o¢o.H mHo.ouv ~n.mm oonAm o o om mmo.H vHo.ouv o>.mm oomAm o H mm >~o.H n

Ho.ouv Hm.mm oomAm N ,m or ewe.“ m.~Ho.ouv mm.mm oonAn o ofl om -o.H NHo.onv ~m.mm oomAm a pa vm mHo.H H

e,§Mw 3% s 2 0° ¥__w _m._tco mmoq uunsaom nmmam auaaauosn coaumuumcmm onacovmom .o«m«ommm cofiuau"" nunuunnnnnflununnunl"nun"nnuflung"unn"'in'nnnulun"‘nu.l."nnIn'nllnfiI='u'ul“"fin"

mqmvfim BUM mmm ZHZ A m OZHQQ mukm 3OA.mlmH< NIB

T

ooomm Ed m>H.HHQQ< Wzfl BDOIBH3 Z30.Hml~Z.< ZMZDHHQ 0ZH>¢m <HQ..H¢I

on

2.5 zo_.2mEzmE

8 . o—

w>_..Ea< >z< c,

....I . .)v.. . .:L> .415 r.>>3JD-2.1

on

2.2 law- zo_»<E.mzm._

2

98m #4 .0Poem ._.< .mooouu ._.< .<

n_>_ _ =._D( > Z1

9.8om

by means of a rneostat. Air is then blown into thematerial by means of an air-blowing tube and adjustedthe rate of flow of air to be 51 per min. per kg.sample with the help of the regulator provided on theair-flow meter. Samples are drawn at definite intervalsof time and tested. The process was repeated at 240°Cand 260°C also.

RESULTS AND DISCUSSION

The results are given in Tables 1 to 6. Theeffect of temperature on the softening-point penetrationrelationship are given in Figs.1 & 2.

From tables 1 to 6 it is clear that the polymerization process is very slow and hence not economical.Another observation is that the rate of conversion-ofHaldia bitumen is poor compared to that of Cochin bitumenHence Haldia bitumen requires a longer air-blowing timecompared to Cochin bitumen. It is of course possible toincrease the rate of conversion by raising the tanpera—ture of the process. But it has a drawback that it resulin products of poor softening point—penetration relationship as it is evident from Fig.1 &,2. According tothe IS 702-1961 there are different grades ofindustrial bitumen depending upon the softening pointpenetration relationship. They are mainlyr 75/30.85/25, 85/40, 90/15, 105/25, 115/15, 135/10 and 155/6.

the second one penetration. A grade 75/30 shouldhave the softening point between 70 to 80 and penetration between 25 to 35). From Figs. 1 & 2 it isclear that the manufacture of the different grades ofindustrial bitumen by air-blowing without any additiveis impossible.

IV(a).2 AIR-BLOWING OF BITUMEN IN PRESENCE OF PETROLEUM

REFINERY CAUSTIC WASH wAs1'§

In Petroleum Refineries. hydrogen sulphidepresent in liquified petroleum gas and naphtha fractionsis removed by the caustic washing process. An aqueoussolution of sodium hydroxide of strength 10 to 20% isused for this purpose. Hydrogen sulphide reacts withcaustic soda resulting in the formation of sodium sulphide

below 50°C

2 Na OH + H28 —————9 Nazs + 21-120<:_——above 50°C

Caustic wash is then discharged to the wastewater treatment sytem and then disposed to the inlandwaters. It was thought worthwhile to examine whetherthe sodium sulphide present in the caustic wash wastecould function as an additive in the industrial bitumenmanufacture.

Hflnl nullnnlu I. I I I.

N UUHHI"fllnuInunufllllu-nIlflnnufllflilfllllnluflflllfl-ununnuln-InnH.flnuflfllflfllflflllnunlflflflfllflflnunln-IInHo.ouv mm.mm oomAm ma on mofl sac.“ o._Ho.ouv mm.mm oomAA «N am No fine.” m:

Ho.ouv H>.mm oomAm «m on om u~o.fi o.“Ho.owv n>.mm oomAn mm m¢ on m~o.H m.4Ho.ouv ~m.mm oonAm um om aw omo.H o.4Ho.ouv mm.mm oomAA or mm mm . >Ho.H m..093 WM 00.3 .3 NW0 @ Om“: M

UCHHMUS CH Wu CHOQ :5 EE .., U0 HCHOQ 00 I

so mmoq uansaom nmmam muaaauusa cofiumuuucmm mnanoumom .u»w«wmmm cmmwmmuni.""nu"nunuunflnun“uunnnunn“nnnunmunnn'iu'mnnI'Inan“auulnnnlnlnnnufiuuuuunln"nun

mqmzdm .0M mum ZH2 A m ozamm mama zoqmnmac HEB

H‘

UOONN @ mammnpm ZDHQOW .x.o.~ EH3 Z30..HmlmH4 ZWZDBHQ UZH>¢m ZHEUOU

P I HQNCB

73

flu-u'Hl"""-HunII“-ufllnuluInufllnflllflflflfllnulfillllnflunlunnllfllnlflunflflfluflllnuflnuflllnnl-nlIlflnufllufllfluu-uflHo.ouv mm.mo oomAn m.o H «ma o¢o.H m.mHo.ouv o¢.mm oomAm ¢ m mma ~¢o.H o.mHo.oV» ¢m.mm oomAn m Ha mflfi omo.H m.~Ho.ouv oo.mm oomAn NH ma om one.” o.mHo.ouv o>.mm oomAn ma on an ewe.” m.HHo.ouv Hm.mm oomAm om pm we H~o.~ o.HHo.ouv mm.mm oomAm ow mm mm . mHo.H m.onu .93 x .u:wx «mo umwwm u E EE oaxfi ; o as on ucnn @ 1 .mun n

mnaummn ca mafia numam auuaauuso noaumuumnom mm«uou%om . a»«>muu uaoan

:0 .mmoA uunsaom uamdommm coauau"nunuflnunWnununufllnnIunulnuunflnnnunnnlnlnununnllliinulnuulllillnllIIIIUHIIIHIIUIIIIUIIEUHUlflnfln

mamzam o0M mmm ZHZ A m ozamm ma<m 3OAhlmH< HEB

HI:

ooovm B< NDHZQADW ZDHQOM Xbom IHH3 Z3OAmlmH< zmzpemm OZH><m ZHEUOU

7

Hflnlflnflnuufl"nununnuflflflunufl-ufllnnulfl-uflnnlnullnununlnnnfluflfluflflflflflfluflflflnuuflflflnnflflfllflflllflfllluflnuflau-IInnS.o\/. 3.3 oomA o o mi So; o._S.oV 3.3 oomA o o 2: So; mg3.0V 3.8 oomA m o m: «mo; o.“3.oV $.mm oomA m 3 3 So; mt8.oV 2.3 8mA 3 S 2. ~84 o..8.oV 8.8 oo...A 3 mm mm . So; m...

. . . N o . .. .

oqfimwg 2.33% “mm” bzgmoa cofimmhmm wmzwmmm mmfi -H,Hr__

C0 WWOR l._..n...5..om

.u.«m«ooQm coauauH"HUN".HUN“alhnunflflflnununununuflflflflflflflnuuuUnnuuulflfllfluufllunfluaIfllluunnullflluflflnlflnlnulfllnllnnuflH-uuunun

mqmz<m o0M mmm 22 A m wzamm ma¢m 3OAmlmH4 MEB

HI

OOOON Ed moummapm EDHQOm xo.~ EHHB Z3OAmImH< zm:paHm oz>¢m ZEUOU

"unI"u""""un"flan"flnnnuuulnflnnnnuunl'n.u'u"nn'flnuun"IIh'n"n"-nu"ulna"-unnulnunnuullanannnunS.oV 3.3 oomA m.o H 93 So; o;Ho.ouv ¢m.mm oomAn m.m ma «Ha mmo.H mgHo.oHv ~o.mm oomAn m.mH Nm Hog >mo.H o.4Ho.ouv mo.mm oonAm mm mm om ~mo.H o:Ho.ouv o>.mm oomAm mm mv no >mo.H o:

Ho.ouv Hm.mm oomAm we mm ¢m . m~o.H o.

. . . N u z .

mafia”; fifw “mm.” sinus gofimwfimm mmzwmmm hwnmuw -.fin.nco mmoq u33om .oHm._..UoQm cofiuou

m..Ez<m .oM mmm ZHE .H m OZHMM ..m..._...<d. 30..H.ml.mH< MIR.

.3‘

umoww a< mnHmmqpm z:Hoom xo.~ maH3 z2oqmumH4 zmzpamm ozH><m ¢Hoq<:

76

"nU.“uflnufluflnun-uflflnunuununnufllnfl-ulflnflnflnulluulflunflnfl-lnfllflflflununuuflflHflnuflflnuuuflflflflflflflnu-unl-nlflflflunnlnununS.oV 3.3 oom.A o o ofl 35; m;S.oV 3.3 oomA m.~ m m3 954 o._3.0V 3.3 oomA m S oi So; mg8.0V 3.8 oomA m 3 mm mmoé o._S.oV 3.3 oomA 3 on 2. 284 oz8.oV Exam oonA om 3 mm . omoé o..-- a, W - - my - - - “B- - - ._..M_ an - - é @ _ocaumwn 5. huaa nmmfim huaauuosa coaumuumcwm mmacwumom hu«>m.um lsoan

co mmoq Idnsaom oflaoonm co3a._HHflflflflflflflflflflflflnflflnunflunnuuflflflnuflfllnufl-"WNW.UNIHIIIINIUHUHIIIIIHHHIIIIHUHINIflllfllun-Ifllliuufllflnuflfl.

22 A m ozHmm ma<m 2OAmlmH¢ HEB

H

mqmz<m .OM mum

77

HflnulnflrllnufluflnflUnunflflflfllnuflflflunflfluuflflflflnunullflluluufllllflflflflnuflI-nun"flflfluflflnuflflfllflnnlnfllInn."-"nu-ulnun3.0V 3.3 oomA o o m3 mvoé o..8.0V 3.3 oomA oé N mi mmoé o:3.0V 3.3 oomA mi. m 2: mmoé mg8.oV Exam oomA m 3 mm ~84 o:S.oV 23$ oomA ow om S . So; atJ: x J3 x «mu ucwwm .5 .EE 3} 0 us on oohm @ .. Jun H

oaflmwn ma 33 sum? muflflunn aofimuuocmm mmacohom . .$«>muo 1.63

uuumnmwa-unfluwflmmanEH........n._..i...-.,....In....nu.:..-.%B..-.£u...u.HHHmmIMMHM

mamz¢m .0K mmm ZH2 A m OZHHQ ma<m zoqmumH< may

HI

uooom Bfi monmmnbm EDHQOW xo.~ mHH3 zzoqmnmad ZMZDHHQ oz>¢m ¢HQA4m

78

:2: zbwl zo:<mEzmE

om S on om or To

ooomu 5 .0oooeu .r< .mocouw ._.< .<

4

9..8oN—

of

OoJ.NlOd 9N|N3i:lOS

79

F_...: sows zoF<EmzmE

ocowu ._.< .0ocean H< .mocouu ._.< .<

B0

EXPERINTBTAL

The raw materials are air—blown with

Petroleum refinery caustic wash waste containing 2.0%sodium sulphide at varying temperatures, the air flowrate being 5L/min/kg sample.

RESULTS AND DISCUSSION

The results are given in Tables 7 to 12.The softening point penetration relationship of theblown bitumen are given in Fig. 3 & 4.

From Tables 7 to 12 it is evident that thereis a considerable increase in the rate of conversion.Air blowing in presence of 2% sodium sulphide at 220°Creduces the air-blowing time by about 60% as comparedto that without any additive. Another observation isthat, Cochin bitumen requires lesser air blowing timethan Haldia bitumen. A comparative study of Figs. 1 to4 makes it clear that there is considerable improvementin the softening point penetration relationship comparedto the air blown product without any additive. In thiscase also with rise in temperature the softening pointpenetration relationship of the air-blown product deteriorates. This is attributed to the blowing losses of oilthat become considerable as the temperature increases.This is also in agreement with the observations already112 113made by Lockwood and Hoiberg . But by suitablyselecting the temperature of air blowing it is easily

possible to make all the ten different grades ofindustrial bitumen. Another observation is thatcompared to the air-blown products from Haldia bitumenthe Cochin bitumen possesses better softening pointpenetration relationship.

Iv(a).3 AIR-BLOWING OF BITUMEN IN PRESENCE OF

E_E3RIc CHLORIDE

Ferric chloride is a widely used additivefor the manufacture of Industrial Bitumen. So it wasthought worthwhile to compare the efficacy of sodiumsulphide with that of the conventional additive ferricchloride.

EXPERIMENTAL

One kg. of the raw material was heated to220°C added 0.75% ferric chloride and air-blown at the

rate of 51 /minute / kg of raw material. The air-blowingprocess was repeated at temperatures 240 and 260°C in asimilar manner.

RESULTS AFB DI5CU5S§9R

The results are presented in Tables 13 to 18.The softening point penetration relationship of theproducts are given in Figs. 5 and 6. From the resultsit is evident that sodium sulphide is equally effectiveas Ferric chloride in reducing the air blowing period.Figs. 3 to 6 show that Sodium sulphide is equally effective in improving the softening point-penetration

82

flnunIfluun“HUInllnunuflflnunnulnuullnlflfluunflfl.flIIfllIlnuIu"nu'lun-nunInI-uuflHflnunflnnflfllflnulfllllflfllnuflflnnullll"

Ho.owv

oomAm ma «N oaa

om.mm amo.H o.Ho.ouv ~o.mm oomAm - Hm mm mmo.H m.Ho.oHv mo.mm oomAm mm um om m~o.H o.Ho.ouv ou.mm oomAm mm pw mu mmo.H m.Ho.ouv Hm.ma oomAm or on mm -o.H o.Ho.omv mm.mm oomAm mu no «m o~o.H m.

.u.,§mw 2? 5 .____ Os U0 m%.w 3”co mmoq Iannaom numfim muwaauufln QOHHMHHUGMN mcacmumom .u«m.nooQm :o._U.a...""nnnflnnnnuunauunununnunnnnuu'n”uluuun'“'u'n"u'nn“lu"."un‘fll"nu:l“nlufl.nl'Iuun"nan"

mqmz<m .0M mam ZH2 Q m OZHHQ macm zoqmumac M28

H

UOONN B< HQHKOAEU UHMMMM xm>.o ZBHZ zzoqmsma¢ zm:paHm 0ZH>¢m ZHEUOU

B3

3..oV 3.3 oomA ..._.o H 1.: ..#o.a o;8.oV mm.mm oomA m.m 3 mug mmoé m.~Ho.oV no.3 oomfl 93 cm o3 mmoé o.”Ho.oV §.mm oomA on 3 ea mmoé m._3.oV. 8.3 oonA 3 mm am «no; o._3.0V 3.3 oomA mm mm mm H34 mg2...: R .93 .x «no ucmmn E0 E5 3} . U vcaom Dorm ® .. .m.un n

ucaumm: ca Mada T o mu._u>wuo I393

co mmoq ..33om nmmfim muflauuso aofiauuoamm maacuumom dflaoonm coflfl""nunuflnnn“nnnannuunln“"nunnnnfllnuulln'in'uln"IuI."'I"."II'Il'InI_l"""ullllnfl

HA&2<m .OM mum ZHZ A m OZHHQ ma4m 30AhlmH< HIE

H“ HUDO¢N H4 MQHMOAIO UHMZWM xm>.o EBH3 Z2OAmlmH< ZEDBHM OZH>¢m ZHSUOU

84

nun"IH-unflflnflflflluflflflnulnnu-nu.‘-nlnuflflflnflfllIfllflnnuluflfllnfllflflnufllflnflflflflnnfl-IN“flflllflnlflfllllflfllllnufln8.0V mmzmm oomA H N mm: So; mg3.oV 8.3 oomA m 5 o3 «mo; o.m8.0V 3.3 oomA E «N 3 omoé mg8.0V 5.3 oomA ma 2 S. mmoé o._S.oV 3.? oomA 3 2 mm «mod mgunuunununumnnuunouunun....nn..uu..n«..un..us.......unun..33 R .u3 x mo 0 Dorm © .n..:._ n

unflumwn 5. Mafia .~..~mu~%m..w hu._...mH_..U«o:Q :oH_”_«_m.nuV...%%.Humm Mm :nmmm%mm .au.n>m.uo Izoan

CO mmoa l.nD§._..Om .n damaoomm GOHUNH

""u"""""u"I..II”“nnn"unnun

mqm:<m .0M mam ZHE A m ozHmm me<m zoqmumH< WEB

HI

oooom H4 mDHmd§mw uHmmmm xm>.o EBH3 zzoqmnmH¢ zmz:eHm 0ZH><m ZHEUOU

85

fluHIHIflflflnunull."Iflunuuflnulflnnfluuu-uflflnnflnullflnullnnufllnlnuflflflfllnuuflUflflfluflflnflHnunnlnflllflflllflflfllufllllflflHo.ouv om.mm oomAm o.~ ¢ omfi wee.” m.mHo.owv o¢.mm oomAn Ha on mfiu o¢o.H o._Ho.ouv mm.mm oomAn pd ow um mmo.H m.,Ho.owv mo.mm oomAm mm mm mm mmo.H o..Ho.ouv ¢>.mm oomAm om ~¢ or ~mo.H o.“Ho.ouv Hm.mm oomAm ¢w mm mm m~o.H o.4uwfimmn .e.w.x.._mw ucwmn .5 as S} % Uo ufiom amwwmuw “firmco mmoq uunsaom numam muaaauosn aoauauumcmm oaacoumom .o«m«oonm coauau

mqmz<m .0M mmm ZHZ A m ozHmm ma<m 3OQmlMH¢ HEB

HI

UDONN B< HQHKOAEU OHMMMM xmn.o EBHB z3oamnmH< zmzbanm OZH><m 4HQA<I

86

fluInflnuunnnanuunlnuuninlnnnnn'nI.u"'flnl'In'uunnnnnnu“nun.”“"'"lnu"nfln"un“naII'fl

Ho.owvHo.owvHo.owv«o.owvHo.ouvHo.ouv

.u3 x «noca muaauansaom

O”; X

uaaummzco mmoa

vv.mmme.mmmm.mm¢o.mmmo.mmFromm

oomAm o.m v mma ¢vo.H o.voomAm o.m oa owe H¢o.H m.moonAm o.> ma mofl mmo.H o.moomAm ma mm mm mmo.H m.~oomAm ufl an up mmo.H o.~oomAm no we mm m~o.H o.Hucwwm E EE oa\u . oo ucwom aoonm m mmu: nnumam auaaauosn aoauauuuamm mcacwvmom _u«w«wmmm cmmmmmNHnuflflflflflflflflflflnulflflnuflflllflflnunuflflll-uflfll-um.flIIIIIIInuIn-InullIIIIIIIIIIIIIIIIIHIIIIIIIIIIIIIIIIflfln

mqm:<m .0¥ mum ZS A m OZHWQ ma<m ?OAmlmH< MIR

%'

OOOVN H4 MQHMOAEU uammmm xm>.o IBH3 Z3OAmlmH€ ZM2DHHm OZH><m <HQJ<E

67

Hflulfluflnuflfluflfllflflflnu-unnllfllnu-flnunu.uflflfl-unulIuulnnunhunfllnunuflflHun.-uuflflflnflflnnunnflflfllflnn-Ifl.hIlflnfl-"III-uflfl3.oV «Tom oomA o o E; 954 oé8.0V 2.3 oomfl o o mi m...o.... m.mS.oV mm.mm oomA o; m mfi So; o.m8.0V 3.8 oomA m.~ 3 N3 >84 m.~8.oV 8.3 oomA m.m 2 mo mmoé o.~S.oV 3.3 oomA o.fl 2.. no omoé o.Hnl‘ an ' '0.K.3'x'xmU' I ' .l I. Fl I. nl ‘EH I .I nl Iv In. .I .I i

ucjmwn 5 .au.:.. 34.” an Sauna :0 amino wfi. mo undo hu«>m..uu I3oHn

co mmoq uansaom £ an H A m cacwumom .uHmHUomm coauouH"n-"H"Hflflnflnrdnunflnnnnllflflflu“NIIunununulflmunllflllfillnnlunllnulllnnlullllnl-unlflflflnulluuuIflllnflu-uufllu-uh

mamzam OM mmm ZHZ A m OZHMQ ma<m ZOAmlmH¢ HEB

H

UOOON Ed NQHMOAEU oHmmmm xm>.o IBHB Z3OAmImH< ZMZDHHQ wzH><m ¢HQA¢E

88

EE iowz zo:<mEzwn_

om 3 om 8 S o

0

98w 2 .oocoa E .mocofi E .<

m

<

, mo_mo._:o oEmmn_I.._>> mmmsimmasmfi wz_>m<> ._.< z>>o._m-m_< zmsstm

z_:ooo n._0 n__:mzoE3mm zoF<mEzm._-+z_oa oz_zmEom not

_.T

owom

. om?8.com

OoJ_N|Od 9NIN3l:!OS

Eé zo:<mEzmn_

on 8 S

n L :14

89

8 8

ocowu ._.< .0053 ._.< .mocomu H< .<

mo_mo._:o o_mmmEI._.:S mmm3<mmE_>_.nF wz:E<> ._.< z>>o._m-m_< zmsstm<_D._<I n_O n__:mzoE3mm zoF<E.mzmn_#z_on_ wz_zm_Eom

ed: .

ow8ow8oom

90

vation is that in the case of ferric chloride alsothere is deterioration in softening point-penetrationrelationship with rise in temperature. But by suitablyselecting the temperature of the process a-l the tendifferent grades of industrial bitumen could be manufactured.

IV(b) CHARACTERISATION OF THE AIR BLOWN BITUMEN

Iv(b).1 INFRA-RED ANALYSIS

Figs. 7 and 8 show the infrared spectra ofthe air-blown Cochin and Haldia bitumen. An increase

in the intensity of the absorption band at 8.7 micronsand 9.4 microns are observed. The absorption at 8.7nicrons is attributed to the formation of disulphidesand that at 9.4 microns is due to the formation ofthiophenic compounds. Tucker114 after a number of studiesnave confirmed that the absorption band at 8.7 microns is

115flue to the disulphides ,Hartough confirmed the absorption band at 9.4 microns as due to the thiopheniccompounds.

There is the possibility for the formation ofthree types of bonds in this process, the Sulphur-carbonoonds, Carbon-Carbon bonds and Sulphur-hydrogen bonds.

Sulphur is known to react with hydro-carbons in bitumento form polysulphides at asout 125OC.135 A study ofliterature concerning the sulphurization of bitumenreveals that a chemical reaction takes place between

M Avzuv Emzaz m><>>

82 com. 8.: 89 com. Sow Bmmo

_ . u T J» .r L J.

<,Z«€J./> i<f%< \,»«(7n-/

xfiifi om

33? 3?

%;,§%:a?mE%f,;7§.60

L m5_mo._Iu uimmi IC>> - U

mainzam zaaom T:._>> .m am

.m>:._QQ< >Z< HDOI:>> - <

.wP:Im.%4 glueAaafimEa2admmw.3m.«$zflfl.

» L _ .u; .1 -_-- U u. 15]-!!! S3

or o.® OLD. 0.N. 9.0 02050:). 6.0 O

9.23 $5232 “>42,

w 82 oome ooi 88 com; ooom 8mm

_

??§i3i

/<<1,\L>1 gm

\ 277/)??? m 21)

4/K,

/52:: J/ 1% U

moaofu UEEE ::3-u rm

mQ_In_._Dm znaom ::>>-m_

m>Ega< >z< .5o::>>-<

& .mS<:am< <._9<I 2:932 no 225%.? Sq <Ez_ éoi

.8.

Or 0.90 .. 04% OH 540 mzomuzz 0mm 0.

EFFECT OF ASPHALTENE CONTENT AND ITS MOLECULAR WEIGHT ON

TABLE I 19

SOFTENING POINT - PENETRATION RELATIONSHIP

93

==========—"=====:7====-=======2===-‘==========='=:=€=========$$Q===

Soften- Penetra- Asphal- Molecular wt.Bitumen Air-O ing 0 tion tene of asghaltenesblown @ 220 C point C 1/10 mm content MW Mn(% wt)

withoutany 95 4 26.0 20200 9900additive

fi withI sodium8 sulphide 95 29 33.4 17100 87000

withferricchloride 95 32 34.6 16500 8450Withoutany 95 1 27.2 22400 12100additives

S5 withsodium 95 26 34.4 19000 10450sulphide

withferric 95 29 35.8 18400 10150chloride

=='==F========== i=====-'=—"========== ======1=%=====i=========N

Gaunumawlinolinalau

me 9.GEL PERMEATION CHROMATOGPAPH5 OFTHE ASPHALTENE FRACTIONS OF THEcomm AIR-BLOWN ASPHALTS.

_, 4.. _.. -4,_

9113“

WITHOUT ANY ADDITIVE.1

17.00“

9.03‘

WITH SODIUM SULPHIDE.

17.00"

9.00

WITH FERRIC CHLORIDE.

I

17TCfi

CONCENTRATION

(SEllnN|_|N)3Wl.L N0|J.N3.l.3l:l

mono. GEL PERMEATION CHROMATOGRAPHS OFTHE ASPHALTENE FRACTIONS or THEHALUIA AIR-BLOWN ASPHALTS.

9.00

WITHOUT ANY ADDITIVE

17.00

9.00

WITH SODIUM SULPHIDE

17.00‘

9.oo—{

WITH FERRIC CHLOREDE

CONCEN'I.‘RATION

96

sulphur and different hydrocarbons constituents ofbitumen Q about 200°C. The reaction proceeds by a freeradical mechanism initiated by the formation of sulphurfree radicals at high temperatures136.

The increase in the intensity of the bands at8.7 microns and 9.4 microns is due to the formation ofdisulphides anithiophenic compounds respectively duringthe air-blowing polymerization in presence of sodiumsulphide.

IV(b).2 MOLECULAR WEIGHT DETERMINATION BY GEL PERMEATIONCHROMATOGRAPHY.

During the bitumen air blowing processNaphthene aromatic fraction present in the bitumen isconverted to polar aromatics which then polymerize tofonn aspha1tenes134. So it was thought worthwhile tofind out the asphaltene contents and their molecularweights in the air-blown bitumen. The results aregiven in Table 19. The gel permeation chromatographsare presented in Figs. 9 and 10.

From Table 19 it can be observed that whenthe air-blown bitumen products possess high asphaltenecontents of low molecular weights (softer asphaltenes),the softening point-penetration relationship will bebetter. It is in agreement with the observations alreadymade by Dark116.

97

IV(b).3 EFFECT OF THE RAW MATERIAL ON SOFTENINGPOINT—PENETRATION RELATIONSHIP

From Table 19 it can be observed that Cochin air

blown bitumen possess better softening point-penetrationrelationship as compared to those of Haldia air blownbitumen. An attempt was made to distinguish theirbehaviour by studying the physical properties of theraw materials. Their physical properties are as givenbelow:

—-.—_—._.__.__.._—_..__..__._._._.__.:—.__—.__..__—_..__.__._.—.—.__..——.—.__.—-——-——————-———-—__.._-—_.._.—_.—_.._——_.._—_.._———_——.......___._._._.._—_.-.._.._—_-_.—._-._—._.—_—.—_.— __

1. Softening point °c 46 442. Penetration 1/10 mm 85 823. Flash point °c 330 3324. Ductility cms. :>10o j>1oo5. Specific gravity 1.007 1.019

As the above physical properties don't give anyclue to the solution of the problem, the chemical composition analyses of the raw materials were carried out bycolumn chromatography (Adsorpticn - elution chromatography)

the results of which are as follows in terms of percentage composition.

98

===-'====:======:=:=:=======::===========:======:====::====Cochin paving Haldia pavingFraction bitumen bitumen

1. saturates 8.9 5.02. Naphthene aromatics 46.6 43.93. Polar aromatics 34.8 38.04. Asphaltenes 9.7 13.1

The inferior softening point-penetration relationship of the air—blown products from Haldia bitumen may beattributed to the presence of lower content of saturates.During the air blowing process the saturates are not affected but the Naphthene-aromatics are transformed to polararomatics which further get polymerised to high molecularweight asphaltenes.

Thus it can be concluded that eventhough thephysical properties of the two different raw materials arepractically the same there is significant difference intheir chemical composition especially as far as the saturatecontents are concerned. This is because they are manufactured by two different processes, Cochin bitumen by thevacuum distillation process and Haldia bitumen by thepropane deasphalting process. However, our studies showthat by suitably adjusting the temperature of the airblowing process it is possible to manufacture all theten different grades of industrial bitumen as per IS 702-1961from both the raw materials.

99

g5;<4o;>o

IV(C) KINETIC STUDIES ON BITUMEN AIR—BLOWING

Iv(c) .1 METHOD OF CALCU..ATION or RATE COlISTA;I'I‘S

It is already reported that asphalt air blowingbehaves kinetically as a first order reaction with respectto the hydrocarbon reactants in bitumen 117. The datausually available to the designer and to the operatoras a measure of reaction completion is only the rise insoftening point of the asphaltlle. Thus the designerand operator need a simpler type of analysis using softening point as the variable.

The simplest type of reaction that fits batchair blowing is an irreversible, first order reaction.The differential equation for such a reaction can bewritten as

where C is the concentration of the reactantsin bitumen. Since the concentration of the reactantmaterials is inversely proportional to the softening

point of the asphalt, C = %, where S is the softeningpoint. Substituting this in the differential equationand integrating, the equation becomes,

_ A S_tk — t in so 'where SO is the initial softening point and St is thesoftening point at any time t. The next step is tocheck out this equation with the actual test data andsee how well it fits.

100

TABLE - 20

CCCHIN PAVING BITUHEN AIR—BLOWN WITH DIFFERENT

FLOW RATES or AIR AT 220°C

=========================================================

iiirzefigw ofD1hJ3.-25:3‘; in ggffiinigg rgtiésgozgigxitL/MIN/Km _ _ _hf_>ufS _ _ _ _ _ _ _ _ _ _ _ _ _ _hc_>u§_ _ _

1 51 0.102 57 0.114 3 64 0.114 72 0.115 31 0.111 53 0.142 60 0.143 69 0.14

5 4 77 0.135 as 0.141 54 0.152 62 0.156 3 72 0.154 33 0.155 95 0.15

=============-_-====—“_—===============-_= ======= ===-_.=:=====:-_=

101

TABLE - 21

HALDIA PAVING BITUMEN AIR—BLOWN WITH

DIFFERENT FLOW RATES OF AIR AT 220°C

================ _____ _=== ______ _================aa.=======

ALE f}§‘i'n§f2§e of §‘i‘§31°i3“1n gggggigg raiiriiniidafiisample hours hour‘1 _" ' ' ' ' ' ' ' ' ' 'Z"""Ze"""ofo§"2 53 0.094 3 58 0.094 64 0.095 70 0.091 49 0.112 54 0.105 3 61 0.114 67 0.115 76 0.111 50 0.132 56 0.123 63 0.126 4 70 0.125 79 0.12

102

IflflflflflflflflflflnnflflflfluuuflflflflflflflflHflflufllflflflflflfl-nun""HUNHfl"H"HflflflflnflulflflflflflnnfllflflflflflflflflflflflflflflflflHnufluufluufl

>~.o ¢bH om.o nna ¢H.o Ha m

>~.o mma om.o NHH ¢H.o mm m.¢

>~.o mmfi o~.o HOH mH.o up ¢m~.o won H~.o mm ¢H.o mm mm~.o om om.o mo ¢H.o on N>~.o om om.o om ¢H.o mm HI 3 I 3 I 3 o

unumucmumcoo U u:._..oQ mac: mucmumcoo uoucuom Hm; mucmumcou ooufiom

an oumu o 05" a mumu 9: ouwu m5 .mu: 9.:Hmouo umufim Icwumom umuuo umufim Icmumom ummruo umuam Inuumom. 350.3 mo

oooom © Uoovm © ooomm @

H" flnnnnnflflnfluuuflnflflnnuufluulnufllnufl-uflnfluuuflunuuflflnlunuununnfllnlnflunluunlflflflunulnuunflflfllnllflflnflflflflflnuflunnu

mAmz¢m «WM .ZH2 A m ozHmm ma<m 3OAmlmH¢ HEB .mmm=e<mmmzma

H‘

0ZH%m<> B4 m>HBHQD< wz< BDOEBHZ Z3OAmlmH¢ ZMZDHHM 0ZH>4m ZH$UOU

NN I nqm<a

103

o~.o «NH mH.o mm HH.o on mom.o mm mH.o Hm HH.o he ¢H~.o mm mH.o mo aH.o Hm mo~.o om mH.o mm oH.o ¢m No~.o ¢m mH.o Hm HH.o av HI vw I we I ¢¢ o

H: uucouncou o uuaon Hmson Bcmuncoo ooucaom mg. mucauncoo o ucaom

HI oumu o and suck and H ouuu o and .uu: ucwuoouo REE ncmuuom umuno umufim ncouuom umuno umuum Iuouwom Izoan mo. coauuuao

oooo~ © Uoovm ® uoomm ©

mqmzdm .mMHIZH2 A m ozamm ma<m 3OJhlmH¢ HIE .mmm:a<mmm:ma

0ZHMm¢> B4 m>HHHQD4 wz< HDOIHH3 z2oamumH< Zm2bBHm 0ZH>dm (H0442

nu I nanca

104

F|G.11 BITUMEN AIR-BLOWN AT 220°C WITH VARYING AIR-FLOWRATES.

0.20 4

A

0.15A BT

1:‘

v 0.10 ‘_Ad

L(D

‘ULO

.2"LL.

0.05 ._

A. COCHIN BITUMENB. HALDIA BITUMEN

0) up4 5AIR FLOW RATE (L/MIN/KG)

105

TABLE — 24

COCHIN PAVING BITUMEN AIR—BLOWN WITH VARYING

CONCENTRATIONS or SODIUM SULPHIDE AT 220°C

===========================.===========.============.=====

°°2§e§§§i:i.°“ J§“£i‘Zii2g ggfggnggg raiiriéniéfifiisulphzi.-de % hours hour-11.0 57 0.211.5 64 0.221° % 2.0 70 0.212.5 77 0.213.0 86 0.211.0 61 0.291.5 70 0.282.0% 2.0 80 0.282.5 92 0.283.0 105 0.281.0 62 0.301.5 72 0.30

2 5 2.0 83 0.30. % 2.5 97 9.303.0 112 0.30

106

TABLE - 35

HALDIA PAVING BITUMEN I ~ '

CONCENTRATIONS OF SODIUM SULPHIDE AT 220°C

=========================================================

°°2§e§§§i§i°“ o'§“§"i‘§$i3g Sgfiggiag riiisioiiiiitsulphide % hours hor-11.0 52 0.162.0 61 0.151.5% 3.0 71 0.164.0 32 0.164.5 89 0.16

. . _ . _ _ _ _ . . . _ . _ _ _ . _ _ . _ . _ . - _ , - 1.0 54 0.212.0 67 0.212 , 0% 3 . o 82 0 . 2 14.0 101 0.214.5 112 0.21

1.0 55 0.232.0 69 0.222.5% 3.0 87 0.234.0 109 0.234.5 122 0.23

103H

HHflfluflflflnuufluuflflflflflnfluflflflflflflflflflnnflnflflullnuHH"U"HuuunflflflnflnflnuflflflflflflflfluflflflflHnflflflnnflnflfluuflflu

m¢.o mpfl bmoo mna mm.o moa o.mmvoo owa >m.o mad m~.o mm m.~mvoo MHH nm.o om mm.o om o.~m¢.o aw mm.o mp mm.o or m.Hee.o an mm.o um mm.o no o.H

w¢.o mm om.o mm m~.o mm m.o

I mw I ow I ow o

Iuson nucmumcoo 0 ucdom use: muqmumcoo Uo uaaom Iuson mpcdumcou uo ucwom

ouwu 9: HI much 9: H much 9: . mu: ma.“uwuuo umufim Icmumom umcuo umuum Icmumom uovuo umufim ucmuuom. Isoan mo

oooom @ ooo.v~ © ooomm @ coaumusoH"flu"-u""nH'.nflIu'nunufl..""”fluflfluunnulunflnflflnnnnufllunuuflnnnflflnIuflnnunnuuflfluflnununnulfluflnnlnulluulnunuuu-nIflfllufl

mmmnaammmzma oz»m<> Ed HQHZQADM EDHDOW xo.~

EH3 mAm:<m .0M\ZHZ\.Hm mo mnkm zoq.mumH4 mma .5 zzoamumfia zmzB..Hm ozH><m zHmooo

on I mafia

108

HHI.-u-nfluHHun"H"HH""nunununun"NEH"Huflflflnnfluuuflnnnnfl-unnuudflflI"-uflfl-uufllununfllnhfl-uflnuflunflnflflfluflflnuflflflfl-uflfluufl

I I >m.o omfi Hmoo mad m.¢

mm.o mofl mm.o mmfl H~.o Hon vmm.o mfifi u~.o mm o~.o om mmm.o mm >~.o mp H~.o no Nmm.o Hm m~.o mm HN.o vm HI wv I ¢¢ I ¢v o

Hluson nucwumcou oo ucaom Iuson mucmumcoo 00 ucaom H50: muqmumcoo 00 ucaom

mumu and H oumu Una HI mama Una .mu£ OCHuovuo umuam Icouwow umwuo Umhfih Icmumom umouo umuam Icmuuom |3OHfl noI JV I II coaumuzo

UOOON @ U0 OVN ® UOONN @

"unfl-flnnnnunuuflnnflnuflnuflHflflnuunnunflnnnuHull“-unnluuufluuununflflnnnfllflnflflflu“nflufllnuluflflulfliflnnnflflfllflfllnunlflfluu

mmmB.rmmm:me OZH.._.rmd.> B4 moammqmm EDHQOW

.VaO.N IBH3 mqmzém. .0M.\ZH2\..Hm mo NEE 301.3 mH< H28 84 Z30..HmlmH< ZwED.HHm <HD1H¢I

on I nan<a

10$

FlG.12 BITUMEN AIR-BLOWN AT 220°C WITH VAFIYING CONCENTRATIONS or SOD_IUM SULPHIDE

0.35 -.

A030 ~

TH£0.25:4La% 0 BL:O4-!

.2LL.

0.20 ‘

A. COCHIN BITUMENB. HALDIA BITUMEN0.15 ¥ _ L

1.0 1.5 2_() 2.5CONCENTRATION or: somum SULPHIDE (% vvt)

110

IV(C).2 BITUMEN AIR—BLOWING WITHOUT ANY ADDITIVB

To find out the optimum rate of flow of airrequired for the process, asphalt is air blown withdifferent rates of flow of air at 220°C. The resultsare given in Tables 20 and 21. It can be observedthat the optimum air flow rate required for the processis 5L,/ min. per kg. sample.

EFFECT OF TEMPERATURE ON THE VELOCITY CONSTANTS

In order to determine the temperature coefficientsof the process, the process was carried out at varyingtemperatures. Using the mean velocity constants obtained,the Arrhenius plots are drawn as in Figs.14 and 15. Theactivation energies in Kcal per male for Cochin bitumenand Haldia bitumen are found to be 8.78 and 7.86 respectively.

Iv(c).3 BITUMEN AIR BLONN NII‘H SODIUM SULPI-IIDE

In order to find the optimum concentration ofsodium sulphide required for the process, the raw materialsare air blown at 5L/min per kg. sample at 220°C in presenceof varying concentrations of sodium sulphide. The resultsare given in Tables 24 and 25. It can be seen that theoptimum concentration of sodium sulphide required forthe process is 2.0%.

EFFECT OF TEMEERATURE OH THE VELQCITY CONSTXKTS

The process was carried out at varying temperatures. The results are presented in Tables 26 & 27.The Arrhenius plots are drawn using the mean velocityconstants. The activation energies in Kcal/mole for

111

Cochin bitumen and Haldia bitumen are found to be

6.50 and 6.04 respectively.

Based on the above experimental results thefollowing reaction mechanism is suggested.

(1)

(2)

(3)

R+

RH + 02

R + 02

Formation of free radicals

———>

———>

R00’ + H25 ———>0

HS + 02ROOH

0RH + HOO

H O22RH+6H

RH + S

RI-2+}-IS.

—>—?>———>

———>————>

?—>———>

Unsaturatedcompound

Ii R'H+R' ‘H

R R'H R"H

———e P? R'H R"I-I

R’ + H00’

R00’

noon + Hs

H00’ + ’s'

Rd -+ 5H

R7 + H20

2 6H

fi + H20fl + H§

£5 + H28

Polymerization by Chain reaction0 . 0RH ‘-——+RRH

disproportionation

Crosslinking reaction

X/(a) formation of disulphides

stable products

112ll19 1 C

R-S + R - s -———————> R-S-S-R

(b) Formation of thiophenic compounds.

Qt. I\‘- _____9 _+_1«12s

+ esgjjgfi

EOE}; UPSulphur is report:d to be fore powerful than oxygen

(Naphtheyiccompound}

~ostraction of hydrogen from hydrocarbozs inbitumen13 . The effect of sodium sulphide in the polyin the

\)

merization of bitumen is attributed to the formation ofsulphur free radicals.

I\/(C) .4 BIT‘JI»I.'_’IZ3 .?:.IR E3-LOJLT '.-.'I 331 F__RI~1IC CI~ILC)ILZDE

In order to find the optimum concentration of

ferric chloride required for the process the raw materialswere air blown with sl/hdn per kg. at 220°C with varying

113

TABLE - 28

COCHIN BITUMEN.AIR-BLOWN WITH VARYING

CONCENTRATIONS OF FERRIC CHLORIDE AT 220°C

Concentration Duration Softening First orderof ferric of blowing Point °C rate constantchloride hours hour"11 j 1 Q 1 ; j 1 j 1 Z 1 1 1 1 1 Z 1 I I i I I I I ’ 1 1 1 11.0 58 0.231.5 63 0.210.5% 2.0 73 0.232.5 81 0.233.0 91 0.23

1.0 62 0.311.5 73 0.290.75% 2.0 86 0.312.5 99 0.313.0 116 0.31. . . . . . . . . _ _ . . . . _ . _ _ _ _ . . . - - , _ .. _1.0 64 0.331.5 77 0.341.0% 2.0 89 0.332.5 106 0.333.0 125 0.33-T-=-.'_'==== -‘J==Z-'=='=".=="—='=='=='=2:==='==_‘?_'=a=‘———.——"==2==r_.'_.___.""—*_§_.—"" '—._-—"====

114

TABLE - 39

HALDIA BITUMEN AIR-BLOWN WITH VARYING

CONCENTRATIONS OF FERRIC CHLORIDE AT 220°C

Concentration Duration Softening First orderof ferric of blowing Point °C rate const tchloride hours hour‘1.0 52 0.172.0 62 0.170.5% 3.0 74 0.173.5 79 0.174.0 87 0.171.0 56 0.232.0 70 0.230.75% 3.0 89 0.233.5 97 0.234.0 112 0.231.0 56 0.242.0 72 0.251.0% 3.0 92 0.253.5 105 0.254.0 118 0.25

_.___._,_._._—¢—_.._—_.__._.-.-_.¢——:-—_.__.—__-—_.._..—..._—._——._-—-—————.--—_.————-___.___—___._———.._—-.—.—.__-——.-__-_.——-—-——¢_—..—._-——._——¢_.._-.—g—_—._—-—_.—.—-_.—._.——

115

I I Ovoo ¢mH Hm.o OHH Oomm¢oO mmfi O¢oO ONH Hm.o vm m.mmv.o ONH mm.o OOH Hm.o mm OoNm¢oO #0 Ovoo ¢m mNoO Mb m.Hm¢oO mb H¢.o mo Hm.o NO OoHOmoo mm mm.o Om Nmoo fim m.o

I Ov I mw I ®¢ O

Iuson mucmumcoo Uoucaom uzoc mucmumcoo U ucaom uson mucmumcoo 00 ucaom

H wumu oca HI mumu o mca HI mumu mew .mu m:

umouo umuam Icmuwom umvuo umuam Icmuwom Hmnuo umuam Icmumom Izoun mm-----------mn..mm~ @u uoofi @ ..m..u.m- @ u coflmuso

mmm:e<mmmzma wzHwm<> H< HQHKOAEU oHmmmm xm>.o

IHH3 mqmz<m OM\ZHZ\J m mo ma<m ZOAM NH4 HEB B4 Z3OAmlmHd ZMEDBHQ DZH>¢m ZIUOU

on I mamas

116

mm.o mbfl mNoO mmfi ¢NoO mad o.¢mm.o mvd mNoO ONH mNcO hm m.mmm.o mNH ®NoO NOH mm.o mm Oommm.o mm m~.o FF mm.o Ob OoNmm.o Nw mNoO mm mNoO wm OoH

I vw I ¢v I flv 0

uses ucmumcou oo ucaom H50: munmumcou oo ucaom Iusos mucmumcoo oo UGHOQ

HI wumu 9: HI wuwu 9: .__ mum.» 9: .m.u£ madumnno umufim Icwumom umuuo um.u._...m Inmuuom uocuo umuam Icoumom Izoan weI oooom © ooowm @ ooomm @ nu coflmuso

“uflnnfluulauununnnnunnnunnlflnnuuununnnnnnfinnuunnnl"un"nnn"l"n'n'fl'n"nIu"NunU".nnm."".."n"uunununnuunu

mmmo94mmmzma oz»m<> B< MQHMOAEU oHmmmm xmn.o

EHH3 mamz4m o0M\2HZ\J m mo ma<m zoqm|mH¢ MIR B4 zzoqm|mH¢ zm::eHm ¢HQ£afl

3 I Sufi

117

F|G.13 BITUMEN AIR-BLOWN AT 220°C WITH VARYING CONCENTRATIONS OF FERRIC CHLORIDE ‘

0.35 -_

0.30

)-1

1_0.25

First order k( h

0.20

1 10.5 0.75

A. COCHIN BITUMENB. HALDIA BITUMEN

1.0

CONCENTRATION OF FERRIC CHLORIDE (vawt)

118

Concentrations of ferrichloride. The results aregiven in fables 28 and 2?.

EFFECT OF TEJPERADUR; ON THE VELOCITY CQNJTAITS

The process was carried out at varying temperatures. The mean velocity constants wer: used for makingthe Arrhenius plots. The activation energi;s in Kcal/molefor Lochin and Haldia bitumen are found to be 6.23 and

5.77 respectively.

Based on the above experimental results thefollowing reaction mechanism is suggested.

1. The formation of free radicals as a result of valencyconversions of iron.

0r1

FeCl3 + RH ._____;> R + Feclz + HCl

FeCl3 + I-I20 —~9 FeCl2 + HCl + OH2+ F 3+ 0 ._H_:sFeCl2 + 02 .__._;> Fe ..... O2.___g> e .... 2 ¢___3 0Fe + + H00

2. Increase in the probability of hydrocarbon raiicalscoming in contact with oxygen as a result of theincrease in their concentration in the startingperioi of oxidation.

n+o2?9RooR00’ + 1:3: *9 R00}! + '31

220011’ _% no + o:—:R1lH + 024 _9 R 11 + 2-120

1H + HOO —————€> R + H2 02

119

H202 ———> 2 OH.R1}! + on ——9 R1 + H20

Besides ordinary decomposition of hydropcroxide andperoxide radicals with the formation of aldehydes,ketones and alcohols, they interact with bivalentiron.PeCl2 ?> FeCl2OI-I + R0R00 + FeC12 —-——> ROO FeCl2

+ ROOH

Interaction of trivalent iron with the oxidationproducts having reducing properties with the

2+regeneration of Fe and with the separation of water.

FeCl2OH + RC1-IO —% Feclz + H O + RCO‘2

Acceleration of decomposition of peroxides withbivalent iron.

F-e2+ +H2O2 ———> Fe3+ + OH + 01:

Fe3+ + OH’ —% Fe2+ + OH

RH + OH —-——9 R + I-I20Polymerization

.R+ RIH ——————> R R1H(unsaturatedcompound)

1R R H + R11H ——> R R11-*1 R111-I

disproportionationR R113. R1121’ 9 stable products

1.60

1.50

1.40

2+logk

1.30

1.20

FIG.l4 ARRHENIUS PLOTS OF AIR-BLOWN COCHIN BITUMEN

120

A. WITHOUT ANY ADDITIVE

B. WITH SODIUM SULPHIDE

C. WITH FERRIC CHLORIDE1 .1.90 1-95

FIG.l5 ARRHENIUS PLOTS OF AIR-BLOWN HALDIA BITUMEN

1.50 _C

1.40 _ 81.30 _

XU32+(‘I

1020 "

1.10 _

A. WITHOUT ANY ADDITIVE

B. WITH SODIUM SULPHIDE \\0. WITH FERRIC CHLORIDE \\4 1- ! \C

1.90 3 1.95 2.00x 10

122

SUMMARY

Petroleum refinery caustic wash waste isfound to be an excellent additive for bitumen air

blowing. This additive in concentrations of theorder of 2.0% reduces the blowing time to the extentof about 6 % and is economically advantageous inindustrial bitumen manufacture. Since there is atremendous increase in the production of industrialbitumen in the recent years it is important to knowthe mechanism of air-blowing in detail. The presentstudy also gives the physico-chemical characteristicsof the reactions involved.

'k***-kir