Crystal Growth and Wafer FabCrystal Growth and wafer fabricationrication

Photovoltaic Silicon Wafer _ SUMCO CORPORATION

-

Upload

lawrenceyuen3 -

Category

Documents

-

view

41 -

download

1

Transcript of Photovoltaic Silicon Wafer _ SUMCO CORPORATION

Photovoltaic Silicon Wafer

Photovoltaic Silicon Wafer | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/index.html

1 of 3 6/21/2012 4:38 PM

SUMCO CORPORATION is an EPIA MemberEuropean Photovoltaic Industry Association (EPIA) is the world's largest

Photovoltaic (PV) is one of the promising solutions to environmental and energy resource

problems that have become more serious each year.

A solar cell is a type of semiconductor that directly converts sunlight into electricity by the

photovoltaic effect.

Solar cells consist of many types depending on the materials and structures and are used in

different ways depending on the characteristics.

The manufacturing methods and general structures of multi-crystalline silicon solar cells will be

introduced.

SUMCO mass-produces high quality silicon wafers using a new proprietary technology known as

the “Electromagnetic Casting Method”.

SUMCO wishes to contribute to human living and our environment through photovoltaic silicon

wafers.

Photovoltaic Silicon Wafer | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/index.html

2 of 3 6/21/2012 4:38 PM

Photovoltaic Silicon Wafer

The enormous number of automobiles and the number of electrical appliances in households and

offices are increasing energy consumption. A large part of energy depends on fossil fuels, such as

petroleum and coal, which generate CO2 (carbon dioxide) during combustion. The problem of global

warming from CO2 emissions makes people to pay attention to the utilization of renewable energy,

such as photovoltaic energy.

The photovoltaic energy is acquired by a power generation system that directly converts sunlight into

electricity using solar cells.

Fossil fuels, such as petroleum and coal, have the problems of the emission of CO2 and the

depletion of the natural resource. On the other hand, photovoltaic energy using the inexhaustible

energy of sunlight is one of the promising solutions for environmental and energy resource problems

that are becoming more serious every year. The advantages are the complete lack of CO2

emissions, which is believed to cause global warming, and cleanliness and friendliness to the earth.

The photovoltaic energy system is a power generation system where demand is expected to increase

most rapidly.

Fig.1 : Trends in total CO2 emissions and CO2 emissions per person in Japan

In 2005, total CO2 emissions were 1,291 million tons, and CO2 emissions per person were

10.1 tons. These values show that total CO2 emissions increased by about 13% and CO2

emissions per person by about 9% in comparison with data from 1990. In order to protect

our environment, the reduction of CO2 emissions may be the most urgent task.

Source: National Institute for Environmental Studies

Why PV is attracting attention now ? | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/why.html

1 of 3 6/21/2012 4:38 PM

Fig.2 : Total supply of primary energy in

FY2007 in Japan

It is said that the CO2 emitted during the

combustion of fossil fuels such as petroleum is

one of the causes of global warming. Our life is

highly dependent on fossil fuels, which occupy

about 85% of the total energy supply. Since

resources such as petroleum are not limitless,

we are concerned about the lack of such

resources in the future. It is believed to be

necessary to promote the introduction of renewable energy, such as photovoltaic energy, to

decrease the degree of dependence on fossil fuels.

Source: Agency for Natural Resources and Energy

Japan's land area is about 380,000 km² and occupies about 0.3% of the world's land area. If we

were to pave all of the land area of Japan with solar cells, they would cover about 30% of the total

power consumption in the world.

Why PV is attracting attention now ? | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/why.html

2 of 3 6/21/2012 4:38 PM

Copyright © 2010 SUMCO CORPORATION All Rights Reserved.

Why PV is attracting attention now ? | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/why.html

3 of 3 6/21/2012 4:38 PM

Photovoltaic Silicon Wafer

A solar cell is a type of semiconductor that directly converts sunlight into electricity. Almost all

semiconductors use single-crystalline silicon as the raw material, and many current solar cells now

use crystalline silicon.

SUMCO supplies silicon wafers for solar cells along with silicon wafers for semiconductors all over

the world.

The most popular solar cells at present use silicon, which is also used for semiconductors.

Exposure of silicon to light generates holes with an electrically positive property and electrons with a

negative property. This is called the photovoltaic effect. However, simply generating electrons and

holes does not allow taking out electricity, and they also disappear immediately.

There are two types of silicon: p-type silicon in which holes gather and n-type silicon in which

electrons gather. A solar cell consists of piled p- and n-type silicon layers. Therefore the generated

holes is attracted by the p-type silicon layer, and the electrons is attracted by the n-type silicon layer.

Thus the condition is the same as that of the + and - sides of a battery.

Each surface of the p-type silicon and n-type silicon is provided with an electrode for taking out the

electricity generated by the solar cell. The connection of electrical wires to the electrodes enables

the use of electric energy. Although it may seem difficult to understand because of the unfamiliar

terms, the mechanism is extremely simple where exposure to light generates electricity.

Mechanisms of photovoltaic energy | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/structure.html

1 of 2 6/21/2012 4:39 PM

Copyright © 2010 SUMCO CORPORATION All Rights Reserved.

Mechanisms of photovoltaic energy | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/structure.html

2 of 2 6/21/2012 4:39 PM

Photovoltaic Silicon Wafer

Solar cells consist of many types in addition to those that use crystalline silicon, depending on the

materials and structures; solar cells are used in different ways depending on the characteristics.

The most popular solar cells at present are crystal-based silicon solar cells using mono-crystalline or

multi-crystalline silicon. Crystal-based silicon has been used in solar cells from the beginning. A

silicon ingot is sliced into wafers as thin as about 0.2 mm on which the solar cells are created.

Although mono-crystalline silicon has high conversion efficiency (efficiency to convert sunlight into

electrical energy), the disadvantage is the high production cost. On the other hand, multi-crystalline

silicon has the advantages that it is cheaper and suitable for mass production.

SUMCO manufactures multi-crystalline silicon wafers proven to have high quality and stability for a

long period of time.

Copyright © 2010 SUMCO CORPORATION All Rights Reserved.

Types and features of solar cells | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/characteristic.html

1 of 1 6/21/2012 4:40 PM

Photovoltaic Silicon Wafer

We will introduce methods for manufacturing multi-crystalline silicon solar cell.

How to manufacture silicon solar cells | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/process.html

1 of 4 6/21/2012 4:40 PM

How to manufacture silicon solar cells | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/process.html

2 of 4 6/21/2012 4:40 PM

Multi-crystalline silicon wafer Solar cell Photovoltaic module (Solar panel)

Solar cell:

Silicon wafer where solar cell functions are created.

Photovoltaic module (Solar panel):

Combined and arrayed solar cells protected by transparent resin and strengthened glass to

make it an integral body.

Also called a solar panel.

Photovoltaic array:

Combined and connected photovoltaic modules.

A photovoltaic energy system can be easily maintained and controlled because of the simple

function of receiving light to generate power. In addition, it emits no exhaust gas or noise, but it can

be installed only if the land receives a sufficient amount of sunlight. Further construction by

combining modules allows changing the system size depending on the installation area.

Inverter/Protector:

An inverter converts DC (direct current) from the solar cells to AC (alternative current). The

How to manufacture silicon solar cells | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/process.html

3 of 4 6/21/2012 4:40 PM

power company supplies AC power.

Distribution Panel:

Distributes power to the wiring in the house.

Watt-hour meter:

Measures power purchased from the power company and power sold to the power company.

Generally, two meters are required for these cases.

Copyright © 2010 SUMCO CORPORATION All Rights Reserved.

How to manufacture silicon solar cells | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/process.html

4 of 4 6/21/2012 4:40 PM

Photovoltaic Silicon Wafer

SUMCO has developed an electromagnetic casting method that enables stable manufacturing of

high quality multi-crystalline silicon ingots. It is a quite unique technology which we are proud of.

1. Raw silicon

“Eleven-nines”(purity 99.999999999%) silicon is used as a raw

material

2. Electromagnetic casting method

Raw silicon is molten from high frequency induction heating using induction coils. The high

frequency induction heating system allows an object to induce electric current using the same

principle as an IH heater. Since the electromagnetic force generated by the induction coil provides

molten silicon with the force directed toward the center, the liquid silicon can maintain high purity

without making contact with the crucible. By lowering the ingot slowly, the liquid silicon cools

gradually and crystallizes.

SUMCO's unique technologies | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/original.html

1 of 3 6/21/2012 4:42 PM

3. Square multi-crystalline silicon ingots

The ingot manufactured by the electromagnetic casting method

is the largest silicon crystal for solar cells in the world with a

length of 7,000 mm.

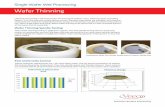

4. Multi-wire saw

A multi-wire saw capable of cutting four silicon blocks

simultaneously is used to ensure wafer quality and productivity

that is state-of-the-art for the industry

5. Cleaning

The sliced wafers are carefully washed in a two-step process consisting of an initial wash and a

finishing wash.

6. Inspection

To ensure that stringent customer standards are met, each wafer product is inspected by an

experienced inspector who is a specialist in the field.

SUMCO's unique technologies | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/original.html

2 of 3 6/21/2012 4:42 PM

The electromagnetic casting method is a process by which high frequency induction inside a cooling

crucible is conducted to melt raw silicon and use powerful electromagnetic energy to suspend the

molten silicon and form ingots continuously. This enables high quality silicon ingots to be

manufactured without the molten silicon ever coming in contact with the crucible.

Advantages of silicon wafer manufactured by the electromagnetic casting method

Continuous casting process improves uniformity and maintains quality.

Small variations in the conversion efficiency can provide stable performance and quality.

High resistance to breakage of the wafer enables a reduction in thickness, leading to the

saving of raw materials.

SUMCO's silicon wafers demonstrate these excellent features and are highly evaluated by the

customer as easy-to-use wafers.

Copyright © 2010 SUMCO CORPORATION All Rights Reserved.

SUMCO's unique technologies | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/original.html

3 of 3 6/21/2012 4:42 PM

Photovoltaic Silicon Wafer

Photovoltaic power generation uses an extremely clean, cheap power generation method and needs

no fossil fuels as required in thermal power generation and emits no waste gas such as CO2

emissions during power generation. In the past, since fossil fuel was mined in large quantities and

supplied at low cost, the relatively high cost of solar cells restricted the speed of growth. However,

possible depletion of fossil fuel resources and price increases as well as serious environmental

issues made people pay more attention to photovoltaic energy. The promotion of the expansion of

the solar cell market will contribute to a reduction in the cost of solar cells, leading to a significant

increase in demand.

Fig.3 : Shipments of solar cells by Japanese vendors

Source: Japan Photovoltaic Energy Association (JPEA)

Although environmental and energy resource issues are important, the problem with renewable

energy in the form of photovoltaic energy is that the cost of introduction is high. In order to promote

the use of photovoltaic energy, many countries are implementing a variety of support measures. The

primary measures promoting the use of renewable energy are as follows:

Expanding PV market | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/market.html

1 of 3 6/21/2012 4:43 PM

Cash subsidies or loans at low interest rates as support for the purchase and installation of

photovoltaic energy systems

Purchase of generated power at favorable prices

Cost of installation is tax deductable

Obligatory installation in public buildings and large facilities

Obligatory use of renewable energy such as photovoltaic energy

In the face of the severe recession in the world economy, many countries will implement a policy to

develop renewable energy and environmental technology in order to stimulate the economy and

increase employment because the growth of renewable energy-related industries is expected to

create jobs and have a positive effect on the economy.

Primary measures for the use of renewable energy and environmental policy

Measures for promoting the use of

photovoltaic energyEnvironmental policies

Japan

Cash subsidies for installation cost

(70,000 yen per kilowatt per house and

50% of the cost for public institutions)

along with an income tax deduction for

part of the installation cost. Surplus

photovoltaic power to be purchased at

about 24 yen per 1 kWh. Studying the

purchase of surplus power at a price

nearly twice the current amount.

Electric power suppliers are obliged to

use renewable energy-related electric

power at more than a specific ratio

corresponding to the sold electric

energy.

Cabinet council decided to implement

a low carbon society creation action

plan where the primary purpose is to

increase the number of photovoltaic

energy system installations to 40 times

the current number by 2030. In

addition, studying the promotion of

investment in the development and use

of energy-saving technologies and

products to restrict CO2 emissions as

well as the creation of targeted

employment for more than 800,000

people in the next five years through

the growth of environment-related

industries.

United

States

Deduction of 30% of the cost of

introduction of photovoltaic energy

system from income or corporate tax,

and cash subsidy for introduction in 38

states. Each state determines the

introduction target or provides support

and assistance measures.

Proposal for the investment of 150

billion dollars in the environment and

energy industries in the next 10 years

to create employment for 5 million

people.

GermanyPurchasing generated power at a

favorable price (feed-in tariff).

The number of employees working in

renewable energy-related industries,

Expanding PV market | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/market.html

2 of 3 6/21/2012 4:43 PM

Measures for promoting the use of

photovoltaic energyEnvironmental policies

Purchasing price is 35 to 47 euro cents

per 1 kWh depending on system size

and installers. Loan at low interest rate

and tax deduction are also available.

including photovoltaic energy, is

currently 250,000. Further reductions

in CO2 emissions, including the

obligation to use green electric power

to create employment for an additional

500,000 people.

* These information is correct as of March 2009

The amount of solar energy striking the earth is very large and

inexhaustible. It would be wonderful if human beings could

create electricity, which is very important for living comfortably,

from clean solar cells.

SUMCO wishes to contribute to human living and our

environment through photovoltaic silicon wafers.

Links

European Environment Agency (EEA) (New Window)

Agency for Natural Resources and Energy (ANRE) (New Window)

Greenhouse Gas Inventory Office of JAPAN (New Window)

New Energy and Industrial Technology Development Organization (NEDO) (New Window)

European Photovoltaic Industry Association (EPIA) (New Window)

Japan Photovoltaic Energy Association (JPEA) (New Window)

Copyright © 2010 SUMCO CORPORATION All Rights Reserved.

Expanding PV market | SUMCO CORPORATION http://www.sumcosi.com/english/products/solar/market.html

3 of 3 6/21/2012 4:43 PM

Product Lineup

SUMCO supplies all kinds of silicon products for the semiconductor industry, ranging from single

crystal silicon ingots to polished, epitaxial and SOI wafers. The high quality products meeting our

customers' needs are made from raw materials with ultra-high purity under attentive quality control.

Single Crystal Silicon Ingots

Polished Wafers (PW)

Annealed Wafers

Epitaxial Wafers (EW)

Junction Isolated Wafers (JIW)

Silicon-On-Insulator (SOI) Wafers

Reclaimed Polished Wafers (RPW)

Specifications of Silicon Wafers

Single Crystal Silicon Ingots

High quality silicon ingots are produced by the method of Czochralski

(CZ) or Magnetic field applied Czochralski (MCZ) up to 300 mm in

diameter.

Polished Wafers (PW)

Polished wafers have excellent flatness and cleanliness by polishing

chemically and mechanically the wafers sliced out of silicon ingot. The

external gettering layer could be produced on the back surface of the

polished wafers as option.

Annealed Wafers

The polished wafers annealed in hydrogen or argon atmosphere have the improved crystalline

perfection of surface.

Product Lineup | SUMCO CORPORATION http://www.sumcosi.com/english/products/lineup.html

1 of 3 6/21/2012 4:44 PM

Epitaxial Wafers (EW)

A thin single silicon crystal layer is deposited on the

polished wafer by chemical vapor deposition. Epitaxial

wafers have superior crystalline perfection.

Junction Isolated Wafers (JIW)

Junction Isolated Wafers are epitaxial wafers with

buried layers which are produced with the patterns of

IC meeting customers' designs by using

photolithography, ion-implantation, thermal diffusion

technology and so on.

Silicon-On-Insulator (SOI) Wafers

Silicon-On-Insulator (SOI) wafers are developed to

realize the new generation of semiconductor devices

which require larger scale integration (LSI) level, lower

power consumption, faster operating speed and/or

higher reliability. Three types of SOI wafers are

produced as follows.

Reclaimed Polished Wafers (RPW)

SUMCO has also reclaim-process for used wafers to return high-quality reclaimed wafers to

customers.

Specifications of Silicon Wafers

Type Polished Annealed Epitaxial Junction SOI Wafer

Product Lineup | SUMCO CORPORATION http://www.sumcosi.com/english/products/lineup.html

2 of 3 6/21/2012 4:44 PM

Wafer Wafer WaferIsolated

Wafer

Diameter (mm)

100

125

150

200

300

−

125

150

200

300

100

125

150

200

300

100

125

150

200

−

−

−

150

200

−

Direction of crystal <100> , <111> , <110>

Elements added for

type and resistivity

control

B (Boron), P (Phosphorus), Sb (Antimony), As (Arsenic)

Copyright © 2010 SUMCO CORPORATION All Rights Reserved.

Product Lineup | SUMCO CORPORATION http://www.sumcosi.com/english/products/lineup.html

3 of 3 6/21/2012 4:44 PM