Petro Refinery Basics

Transcript of Petro Refinery Basics

Petroleum Refinery

Basics

• Crude Oil components

• Refinery Flowchart

• Other refinery units

• Unit Opns & Unit Proces in refining

• Physical and process Hazards

Thanks to

• John Kulluk Ph.D.

• Torrance Fire Department

• &

• Robert Distaso PE – 714/573-6253

• Orange County Fire Authority

Petroleum is extracted from underground reserves;

then it is cracked or “refined” into end products for

various uses. The petroleum industry thus has two

parts: an oil exploration and production industry

upstream and a refinery industry downstream.

Most oil producers also own refineries. But the

reverse is not true; a high proportion of oil is sold

to refinery companies that do not produce crude

oil.

Refining Means. . .

1. To reduce to a pure state, to remove

impurities

2. To improve or perfect

Salable products are made from crude.

What is Crude Oil?

• Mixture of organic

carbon chain

molecules

• Impurities include

sulfur and nitrogen

compounds

• Some metals and

salts too

Components such as . . .

• Straight-Chain

Hydrocarbons

• Olefins

• Cyclic H/C

• Aromatics

(Benzene, toluene,

xylenes)

• Mercaptans

• Hydrogen Sulfide

(H2S)

• Greases

• Propane

• LPG

Other Hazardous Materials

• Sulfur

• Hydrofluoric Acid (HF)

• Sulfuric Acid (H2SO4)

• Ammonia (NH3)

• Sodium Hypochlorite

• Radioactive Materials

• Chlorine

• Amines

• MEK

• Sulfur Dioxide (SO2)

• Heavy Metal Catalysts

• Sour Water

• Caustic (fresh/spent)

• Alcohol

• Asbestos

Heat & Mass Transfer Opns

The reactor effluent is then cooled via heat

exchange with unit feedstocks, fractionated into

the desired product streams via distillation,

which are then further cooled via heat exchange

with unit feedstocks. Individual refinery

processes are described subsequently,

simplified process flow diagrams will be

provided to illustrate the specific process flow

sequence for the applicable process.

Heat & Mass Transfer Opns

In fractionation or distillation the feedstock is

distilled into various cuts of target boiling ranges or

even separated into individual hydrocarbon

compounds. Distillation is accomplished by

imposing a temperature profile across the tower

enabling differences in the equilibrium

compositions of the vapor and liquid phases to

change the compositions throughout the distillation

tower.

Heat is added to the hydrocarbons at the bottom

of the tower through heat exchange in a reboiler

which vaporizes a portion of the tower bottoms

liquid for recirculation to the bottom of the tower.

Heat is removed from the top of the tower through

heat exchange in an overhead condenser and

then returning a portion of the condensed

hydrocarbons back to the tower as .reflux..

This heat addition at the bottom and heat

removal from the top of the tower establishes the

temperature profile across the tower. In some

applications, additional heat is removed by heat

exchange with circulating liquid „pump-around‟

streams which are withdrawn and returned at

intermediate levels of the tower. Perforated tray

decks or packed bed sections allow intimate

contacting of the liquid and vapor phases

followed by separation.

• Petroleum crude oils are : numerous hydrocarbons.

• Hydrocarbons are chemical compounds made up of

predominantly carbon and hydrogen.

• Hydrocarbons found in crude oils generally also

contain the elements sulfur and nitrogen. Many crude

oils also contain absorbed levels of the toxic gas

hydrogen sulfide (H2S).

Composition of crude oil

• Crude oils may contain trace amounts of metals

such as nickel and vanadium, as well as salts.

• Most of the nonhydrogen, non-carbon elements

found in crude oils are undesirable and are

removed from the hydrocarbons in total or in part

during refinery processing.

Components_ To be removed

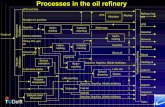

Refinery Process Flow Chart

Dis

tilling

Flasher

Visbreaker

CCU

Alky

Sp

litter

Hydrotreating

Hydrotreating

Isom

Reformer

Gas Plant

Sulfur

Fuel Gas

Gasoline

Jet Fuel

Distillate Fuel

Residual

Fuel Leffler, 1985

The principal products, with their

approximate boiling points, are petroleum

gas (20ºC), naphtha (40ºC), petrol (70ºC),

kerosene and jet fuel (120ºC), diesel (200ºC),

lubricant (300ºC), and furnace oil (370ºC);

solid petroleum coke collects at the bottom

after the liquid fractions are removed.

FLUID CATALYTIC CRACKING

HYDRO TREATING

Many fuels products are treated as a finishing

step prior to being shipped as .finished. products.

Treating removes impurities which cause

objectionable odors, unwanted colors or

corrosion of the product. Hydrogen sulfide (H2S)

and other sulfur compounds such as mercaptans

are examples of such impurities.

Amine contacting using aqueous amine solutions such as

monoethanolamine (MEA), diethanolamine (DEA), or

methyldiethanol amine (MDEA) are commonly used to

remove H2S from light ends streams prior to

disposition as fuel gas or propane (i.e., Liquefied

Petroleum Gas or .LPG.) product. The amine solution is

then regenerated in a still in which the application

of heat drives off the H2S. The H2S-rich stream produced

from the still (called acid gas.) is then routed to the Sulfur

Conversion process.

Other Refinery Units • Steam Generation

• Wastewater Treatment

• Hydrogen Generation

• Power Generation (e.g., cogen)

• Air Separation Plant

• Loading/Unloading - Railcar, Trucks, etc.

• Storage (high pressure hydrocarbon, crude oil, intermediates)

Floating-Roof Tanks - 150„ diameter is common

Spherical Tanks - 50„ are common

Horton Spheroid (refrigerated)

Steam-Heated Tanks for “Heavier” Products

• Self-Contained Firewater Supply

• Firewater Pumps

What’s All this Stuff?

What Goes on at a Refinery. . .?

• Separation of components by distillation, e.g.:

Atmospheric

Vacuum

Hydrotreating (uses excess hydrogen)

• Breaking apart molecules to make smaller ones, e.g.:

catalytic cracking

hydrocracking

• Joining molecules to make bigger ones, e.g.:

Reforming - alkylation that lengthens the hydrocarbon chain

Reforming - cyclic that generates hydrogen

Physical Hazards

• High Pressure/Temperature Steam

• Oil/Gas-Fired Furnaces

• Acoustic

• High Voltage (4160V, 480V, 13.2 kV)

• Falling Hazards

• Confined Space Hazards

• Cranes/Lifting Hazards

• Hot Work Hazards

• Acid Exposure

• Toxic Vapors

• Radiation

• Flammability Hazards

Common PPE Requirements

• Hardhat

• Hardsoled / Hardtoe Shoes

• Safety Glasses with Side

Protection

• Safety Goggles or Faceshield

• Fire-Resistant Clothing

Process Hazards

• Emergency Flare

• Atmospheric Pressure Relief

• High Temperature (up to 2000oF)

• Low Temperature (e.g., Brittle Fracture)

• High Pressure (up to 3000 psig)

• Low Pressure (e.g., vacuum)

Some petrochemicals are produced in large enough bulk to

take a significant proportion of refinery products: the

world consumed 345 million tons of hydrocarbons in 2004

to make 310 million tons of petrochemicals.

Most of the hydrocarbons are first turned into one of three

intermediates - ethylene, propylene and aromatics – before

being converted to other products. Of the latter, plastics

accounted for 225 million tons, and fibres for 38 million

tons; solvents, detergents and synthetic rubber accounted

for most of the rest.