PET for PAT? Process Evaluation Tools for Process Analytical Technologies in Manufacture of...

-

Upload

brittney-atkins -

Category

Documents

-

view

223 -

download

4

Transcript of PET for PAT? Process Evaluation Tools for Process Analytical Technologies in Manufacture of...

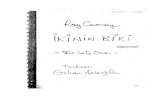

PET for PAT?Process Evaluation Tools for Process

Analytical Technologies in Manufacture of Biological Products

Charles L. CooneyDepartment of Chemical

EngineeringMIT, Cambridge, MA 02139

Advisory Committee for Pharmaceutical Science April 13, 2004

SOME ISSUES

• What does the pipeline for new biological products look like?

• What will be the path for Follow-on Biologics?• How does the biological product respond to

physical process change?• Do we have adequate analytics to address the

uncertainties in the biological products industry?• How can we assure robustness to design and

operation of biological products manufacture?

Where are we going?• Products

– Antibodies and Replacement proteins– Vaccines– Cellular therapies– Gene therapies

• Processes– Recombinant protein production– Tissue engineering - tissue repair– Transgenic plants & animals

• Challenges– Rapid and cost effective development &

scale-up– Continuous improvement & process

change– Follow-on biologics– Complex biologicals – cellular therapies

and tissue engineering

Multiple processes for the same or similar products

Complex processes for complex products

There is tension between the safety and economic agenda; where is the proper balance?

Process for BiologicalProducts

Raw Materials

EnvironmentalConditions

Product

Parameter Control

Information Flow

How does the biological process respond to physical change?

THE OXYGEN DILEMMA

•Required for efficient growth and recombinant protein expression•Potential in vivo or in vitro protein oxidation e.g. Met, Cys•Oxygen induced stress response

O2 Gradients in Large-Scale Fermentors

10,000 L

DO

10%

40%

100 mL

Homogeneous

10 L

Homogeneous

• How do O2 gradients affect cell ?

• How does cell respond?• Effects on recombinant

protein production?

100l

Homogeneous

Heterogeneous

Model System: 1-Antitrypsin• Elastase inhibitor (44 kDa) 10 met and 1 unpaired cys

• Activity lost with oxidation of active site MET358 Oxidation of met358 --> partial loss of neutrophil elastase activity & complete loss of porcine pancreatic elastase

• Use in protein replacement therapy• Cytoplasmic expression in E. coli BL21

methionine

methioninesulfoxide

H2N-C-H

COOH

CH2

CH2

CH3

S

H2N-C-H

COOH

CH2

CH2

CH3

S O

oxidation

M358

M351

• Recombinant 1-antitrypsin (soluble at 30C) – Degraded in E. coli– Proteolysis is oxygen-dependent

• What is the connection between O2 and proteolysis?

Observed Problem in Synthesis

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2

Norm

alize

d a

1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2N

orm

alized

a1A

T

Time (min)

WT ClpP-

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2

Norm

alize

d a

1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2N

orm

alized

a1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2

Norm

alize

d a

1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2N

orm

alized

a1A

T

Time (min)

WT ClpP-BL21

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2

Norm

alize

d a

1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2N

orm

alized

a1A

T

Time (min)

WT ClpP-

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2

Norm

alize

d a

1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2N

orm

alized

a1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2

Norm

alize

d a

1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2N

orm

alized

a1A

T

Time (min)

WT ClpP-BL21

Pulse-Chase Data (Laska, 2000)

WHERE IS THE PROBLEM?

AND SOLUTION?

• Proteolysis in E. coli– Majority requires ATP– ~70% by Lon and ClpP/AX– Current Strain BL21 is Lon-

• ClpP– Protease subunit of ClpP/AX

complex– Heat shock protein

• ClpP- strain (SG1146A)– E. coli BL21 ClpP-

Figure (Wickner & Maurizi, PNAS 1999)

Protease ClpP

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2

No

rmal

ized

a1A

T

Time (min)

0

0.2

0.4

0.6

0.8

1

1.2

0 10 20 30 40 50 60

N2AIRO2N

orm

aliz

ed

a1A

T

Time (min)

Wild Type SG1146A (ClpP-)

Some background degradation (~18%) remains• Other protease responsible

O2-Enhanced Degradation is Eliminated in ClpP- Strain

Do we have the analytical techniques to probe a cell’s

global response to its physical environment?

DNA Microarray Experiments

• 3,812 Genes representing 89% of E. coli genome

• Multi-Gene Groups– 167 protein complexes– 190 pathways– 333 transcription units

Hyperoxic Stress Responses

• Increasing N2 → Air → O2

• Sustained Response

• Increasing Air → O2

• Short-Term Response

OxyR Regulon - ahpC /ahpF /dps /grxA /katG

-1.5

-1

-0.5

0

0.5

1

1.5

2

0 30 60 90Post-Induction Time (min)

RelativeExpression(Average

Log Ratio)

O2AIR

SoxRS Regulon - fur /nfo /sodA /soxS

-5-4-3-2-101234

0 30 60 90Post-Induction Time (min)

RelativeExpression(Average

Log Ratio)

O2AIRN2

O2 Dependent Genes• SoxRS Response

– soxS, fur, sodA, nfo

• Iron Uptake– fur, sodA, fepB

• Fe-S Proteins– bioB, ilvD, leuB, mutY, fdx,

yfhI

• Fe-S Cluster Assembly– b2530 (iscS), b2531, hscA, fdx

What is the right next step?

When we introduce a process to make a biotherapeutic product do we know the “optimum” conditions

for quality and quantity?

During routine manufacture, do we improve the quality and

quantity of product?

SELF ASSESSMENT

What is the way forward?•Is there a better way than incremental adjustment to optimize and scale a biological process?•We live with variance; have we taken adequate opportunity to observe it and learn?•Can we explore experimental space more effectively?•How do we embrace risk and manage it?•How do we assure ourselves that we have a robust process?

PROCESS EVALUATION TOOLS

• Leverage analytical technology on process and product

• Look at the global system response• Explore how biological and parameter variance

propagate through the process?• Interrogate the cell at the molecular scale• Multi-scale analysis – scale down to scale up• Understand the interdependencies in experimental

space• Understand the connection between molecular

processes, process performance & product quality