Perform Achieve and Trade (PAT)- Methodology- Baseline Normalization, Energy Performance Indicators,...

-

Upload

laureen-cole -

Category

Documents

-

view

217 -

download

0

Transcript of Perform Achieve and Trade (PAT)- Methodology- Baseline Normalization, Energy Performance Indicators,...

Perform Achieve and Trade (PAT)- Methodology- Baseline Normalization,

Energy Performance Indicators, Targets and M&V

4th July,2012

K . K. ChakarvartiBureau of Energy Efficiency

New Delhi

NATIONAL MISSION FOR ENHANCED ENERGY EFFICIENCY (NMEEE)

• The National Action Plan on Climate Change was released by Prime Minister of India in June 2008

• The Action Plan Outlines 8 Missions including National Mission for Enhanced Energy Efficiency (NMEEE)

• The basic objective of the NMEEE mission is to ensure a sustainable growth by an approximate mix of 4 E’s, namely-Energy, Efficiency, Equity and Environment

NMEEE – Four New Initiatives

• Perform Achieve and Trade (PAT): A market based mechanism to enhance cost effec tiveness of improvements in energy efficiency in energy-intensive large industries and facilities, through certification of energy savings that could be traded.

• Market Transformation for Energy Efficiency (MTEE): Accelerating the shift to energy efficient appliances in designated sectors through innovative measures to make the products more affordable

• Energy Efficiency Financing Platform (EEFP): Creation of mechanisms that would help finance demand side management programmes in all sectors by capturing future energy savings.

• Framework for Energy Efficient Economic Development (FEEED): Developing fiscal instruments to promote energy efficiency

Fiscal Instrument for EE

Partial Risk Guarantee FundVenture Capital Fund

Public Procurement

Stimulate Funding for ESCOs

Energy Efficient AppliancesSuper Energy Efficient Program

Energy Intensive Industries

Targets for Mandatory Energy Saving

PAT EEFP

FEEEDMTEE

NMEEE – Four New Initiatives

NMEEE

Provisions in the Energy Conservation Act

• As per Section 14(g) of EC Act, 2001

“[Establish and prescribe such energy consumption norms and standards for designated consumers as it may be considered necessary: provided that the central government may prescribe different norms and standards for different designated consumers having regard to such factors as may be prescribed] the central government can stipulate energy usage norms for designated consumers.

The Energy Conservation (Amendment) Act , 2010

Main Amendments

• The Central Government may issue the energy savings certificate to the designated consumer whose energy consumption is less than the prescribed norms and standards in accordance with the procedure as may be prescribed.

• The designated consumer whose energy consumption is more

than the prescribed norms and standards shall be entitled to purchase the energy savings certificate to comply with the prescribed norms and standards.

• The Central Government may, in consultation with the Bureau,

prescribe the value of per metric ton of oil equivalent of energy consumed.

Perform, Achieve & Trade (PAT) Mechanism

The key goal of the PAT scheme is to mandate specific energy efficiency improvements for the most energy intensive industries.

The scheme builds on the large variation in energy intensities of different units in almost every sector, ranging from amongst the best in the world, to extremely inefficient units as well.

The energy intensity reduction target mandated for each unit is dependent on its current efficiency : the reduction target is less for those who are more efficient, and is higher for the currently less-efficient units.

The design of PAT is the result of extensive consultations over the last two years (2010-11 and 2011-12), which have contributed to its robustness and simplicity.

The energy usage pattern varies widely in industries of a particular sector due to various diversities like- Scale of Production (Installed Capacities) - Use of Raw Material- Process Technology- Vintage - O & M Practices- Type of Product Output etc.

Factors of Diversity Most Affected Sectorsa) Raw Material Input Pulp & Paper, Fertilizer, Power Plant, Textilea) Quality of Raw Material / Fuel All sectorsa) Process & Technology Aluminium, Iron & steel, Chlor-Alkali, Papera) Final Product output Textile, Iron & Steel, Aluminiuma) Vintage All Sectorsa) Capacity Utililization All sectors

Reasons for Large Energy Usage Bandwidth

Number of Designated Consumers (DCs) as notified under Indian Energy Conservation Act

Industry Sector Annual Energy Consumption Norm to be

DC (toe)

No. of Identified DCs

Aluminum 7500 10

Cement 30000 85

Chlor-Alkali 12000 22

Fertilizer 30000 29

Pulp & Paper 30000 31

Thermal Power 30000 144

Iron & Steel 30000 67

Textiles 3000 90

PAT - METHODOLOGY

PAT Scheme : Background & Scope

Covers 478 designated consumers in 8 sectors

All DCs consume about 165 million toe energy

Targets would be given to all DCs to achieve the same within a time frame

-Achievement > Target E-Scerts

-Achievement < Target Purchase E-Scerts / Penalty

The Energy Savings Certificates (ESCerts) so issued will be tradable on special trading platforms to be created in the two power exchanges (Indian Energy Exchange and Power Exchange India).

National Target = 6.686 million toe at the end of 1st PAT Cycle ( by 2014-15)

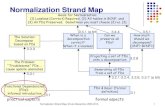

PAT Scheme : Approach Towards Target Setting

Establishment of Baseline : – As per reported data of 3 years (2007-08 to 2009-10)– Normalization Factors – Average of last 3 years value

Targets to be statistically calculated based on relative SEC approach after grouping the DCs suitably

The target reviewed by an expert committee before notification

Estimation of Energy Savings

Base:– Baseline Year : 2009-10– Baseline Production (Pbase) : Avg. of 2007-8, 2008-9 & 2009-

10– Baseline SEC (SECbase) : Avg. of 2007-8, 2008-9 & 2009-10

– Target SEC (SECtarget) : SEC as estimated in 2014-15

– Target : % reduction from SECbase

Estimation of Energy Saving (TOE) :P base ( SEC base – SEC target )

National Energy Saving Targets under PAT (%)(2012-15)

SavingTarget

Baseline SEC

Target SEC

Achieved SEC

Scenario 1 Scenario 2

Compliance

Issued Escerts

Purchase Escerts

Penalty

Concept of Target, Compliance, ESCerts & Penalty

Example Specific Energy Consumption (SEC) in Baseline year:

10 TOE/unit of production Baseline Production: 10000 units Target: 4% reduction in SEC SEC in the target year: 9.6 TOE/unit production For ESCerts or Penalty:– Reduction requirement: 4000 TOE– Scenario 1 (Achieved SEC = 9.4): +2000 TOE(ESCerts)– Scenario 2 (Achieved SEC = 9.8): -2000 TOE (Penalty)

Market Design

• ESCerts are issued– When energy efficiency improvements surpass

targets – With 1 toe = 1 ESCert– Banking of ESCerts allowed during each cycle

• 1st cycle ESCerts to 2nd cycle• 2nd cycle ESCerts to 3rd cycle

Advanced ESCerts

• Baseline, SEC(b) = 10 toe/t • Target, SEC (t) = 7 toe/t• Achieved after year 1, SEC (a) = 8.5 toe/t• Production = 10000 tons

• AFTER YEAR 1• ESCerts =[(SEC(b) – (SEC (b)– SEC (t))/3) – SEC(a)] x 80% x prod = ((10 – (10-7)/3) – 8.5)) x 0.8 x 10000 = (9-8.5) x 8000 = 4000 ESCerts

Revised Target = SEC(t) – (ESCerts/Prod) = 7 – (4000/10000) = 6.6 toe/t

Perform, Achieve & Trade (PAT) - Summary

Administrator

• Set target and compliance period

Designated Consumers

• 8 sectors Thermal Power Plant, Steel, Cement, Fertilizer, Pulp & Paper, Textile, Aluminium, Chlor-alkali

Auditing Agencies

• Independent• Monitor, verify and

certify

Market Place

• Transaction of energy efficiency instrument

Reward over achiever

Penalize under performer

Sta

keh

old

ers

Set Targets

• Setting targets on the basis of baseline specific energy consumption

• Set compliance period

Monitoring & verification of targets by Designated Energy

Auditors (DENA)

•Check if designated consumer has achieved targets

•Underachievement: Obligations to buy ESCerts or pay penalty

•Overachievement: Issuance of ESCerts for banking for later use or trade

Trading of ESCerts

• Participation by Designated consumers on platform provided by Power Exchanges

• Symmetrical flow of information

Pro

cess

es

Invo

lved

Market Based Mechanism

PAT for Cement Sector-A Case Example

Indian Cement Industry

India is the second largest cement market in the world, accounting for about 6% of the world’s cement production

The cement industry uses coal and electricity as the main sources of fuel.

Energy cost accounts for about 40% of the total manufacturing cost in some of the cement plants and coal accounts for 15%–20% of the total production costs.

The specific thermal energy consumption and electrical energy consumption for state-of-the-art cement plants are as low as 658 kcal/kg of clinker and 65 kWh/ton of cement, respectively.

Indian Cement Industry (contd.)

The specific energy consumption patterns of most of the plants very, having wide band variation.

This happens mainly because of plants having different product mix based on addition of Pozzolona, Slag and Fly Ash and different blending percentage.

The pure cement being Ordinary Portland Cement (OPC) and no dilution by additives, consumes the highest energy per ton.

The blending with additives to manufacture other varieties reduces the Specific Energy Consumption per ton.

Indian Cement Industry (contd.)

Because of these complexities, it becomes extremely difficult to come to a common model to arrive at standardized SEC per ton.

Considering all these situations, the conversion factors and best possible combination and categorization have been worked out so that no Designated Consumer may have any grievance on the targets set out

While setting targets , units best in the group as reference and then worked out targets for others.

Normalization of Product Mix

*CF (Conversion Factor)= Clinker used for x grade/Cement Production of x grade**Conversion of exported clinker to equivalent major grade cement = Clinker exported/CF of major grade cement

Raw MaterialCement Plant

Clinkering Unit(Clinker Production)

Grinding UnitClinker + Gypsum+ additives* =

Cement (OPC/PPC/PSC/any other Variety)

*(fly ash/Slag/any other unit)

Clinker Imported from Other Unit

Clinker Exported to Other Unit

Cement Dispatched

Conversion of Cement Equivalent to Major grade = (Cement production of a particular grade) X (CF* of Same grade)/(CF of Major grade)

Total Cement Production Equivalent to major grade =Production of all grades of cement equivalent major grade + (exported clinker equivalent to major grade Cement)**

Coal (Indian) (1,03,339 Tons/yr ,GCV 3438 kcal/kg)

Coal1 (Imported)(6246 Tons/yr, GCV 5454 kcal/kg)

Pet Coke(3316 Tons/yr, GCV 8400 kcal/kg)

Furnace Oil(669 Tons/yr, GCV 10000 kcal/kg)

HSD (570 Tons/yr , GCV 8600 kcal/litre)

Grid Electricity (53.08 Lakh KWh)

Crushed Limestone

Iron Ore, Bauxite,Gypsum

Clinker (0.06 Lakh Tons/yr)

CPP(Heat Rate

3135 kcal/kWh)

GRID (Exported)(19.35 LAKH kWh/YR)

Coal2 (Imported) 124746 Tons/yr, GCV 6192 kcal/kg)

EXAMPLE- INPUT & OUTPUT FOR A TYPICAL CEMENT PLANT

PPC (14.92LAKHTONNE/YR)

PSC /OTHER (2.30 LAKH TONNE/YR)

OPC (0.08 LAKH TONNE/YR)

DG SET(Heat Rate

2212 kcal/kWh) 2.09 Lakh kWh

Clinkerization(Raw Material Processing &

Pyro-processing)

Grinding(VRM and RP &BM)

Flyash, Slag, Etc

3148 lakh KWh

Colony, (5.1 Lakh kWh)

Crushing and Mining

(Exported)(25.12 LAKH kWh/YR)

Note: All values presented in the above diagram are average of annual energy consumption of 2007-08, 2008-09, 2009-10

Methodology for Baseline and EPIs (Summary)

For each plant, different types of cement products and exported clinker are converted in to equivalent major product produced by that plant with the help of conversion factor, reported by the concerned plant.

Thermal Energy Input is arrived at by taking all type of fuels into account.

Electricity Purchased is converted in to equivalent thermal energy by multiplying it with 860. Whereas the electricity exported to grid is calculated similarly by multiplying it with 2717 (national avg. heat rate).

Notional energy is also imposed on imported power Notional Equivalent Thermal Energy for Imported

Power= Electricity purchased from Grid x (Weighted avg. heat rate of CPP of Cement plants-860).

Methodology for Baseline and EPIs (Summary)

Total GtG Energy Consumption is calculated by adding the thermal inputs through all type of fuels, electricity purchased and subtracting the power exported to grid.

Notional Energy (equivalent thermal energy) for Exported and Imported clinker are calculated based on thermal and electrical SEC reported by the concerned plant, wherein the Electrical kWh is converted into thermal kCal by multiplying the weighted average heat rate of the all form of electricity used in plant

The notional energy required for exported/imported clinker is added to the total thermal and electrical energy consumed by the plant only to arrive at the Gate to Gate Sp. Energy Consumption.

Perform, Achieve and Trade (PAT) Scheme

Normalization Factors (DRAFT) The following normalization factors have been considered in consultation with the Sectoral Expert Committee and various plants in the cement sector: a. Equivalent major grade of cement production The various product mixes are converted in to equivalent major grade of cement product by the plant by using the following formulae:

i. Conversion of Ordinary Portland Cement (OPC) production equivalent to major product

oductPrMajorofFactorConversionOPCoffactorConversion)TonMillion(oducedPrOPC

oductPrMajorEquivalent

[Million Ton]

ii. Conversion of Portland Pozolona (PPC) Production equivalent to major product

oductPrMajorofFactorConversionPPCoffactorConversion)TonMillion(oducedPrPPC

oductPrMajorEquivalent

[Million Ton] iii. Conversion of Portland Slag Cement (PSC)/any other variety of Cement

Production equivalent to major product

oductPrMajorofFactorConversionCementietyvarotheranyorPSC

offactorConversion)TonMillion(oducedPrCementietyvarotheranyorPSC

oductPrMajorEquivalent

[Million Ton]

iv. Conversion of Total Exported clinker to major product

oductPrMajorofFactorConversion)TonMillion(kerClinExportedTotal

oductPrMajorEquivalent [Million Ton]

where: Total Exported clinker= [Clinker Exported to other plants + clinker exported to clinker stock over and above the opening stock,]

v. Conversion of Total Imported clinker to major product

oductPrMajorofFactorConversion)TonMillion(kerclinportedImTotal

oductPrMajorEquivalent [Million Ton]

where: Total Imported clinker= [Clinker Imported from other plants + clinker Imported from clinker stock, equivalent to the quantity by which the clinker opening stock gets reduced] vi. Total Equivalent major product of Cement

It can be arrived at by summing up all the different grades of cements equivalent to major product calculated above:

Total Equivalent major product of Cement = a(i) +a( ii) +a(iii) + a( iv) [Million Ton]

Note: S.No. a(v) is already accounted in major product

a. Calculation for Gate to Gate Specific Energy Consumption (SEC) i. Total Thermal Energy Consumption (Kiln + power Generation)

Total Thermal Energy Consumptions to be calculated as:- Total Thermal Energy Consumption= [{Fuel consumed (kiln+ power generation) (Million Ton) X Gross calorific value of respective fuel (kcal/kg) X 1000}-{Electricity exported to grid (Million kWh) X 2717 (kcal/kWh)}]

[Million kcal] where: - 2717 kcal/kWh is the National Average Gross Heat Rate of Thermal Power Stations in the country in 2007. Note: - 1.With reference of definition of Energy as defined in the EC-ACT 2001, if biomass is used in the Kiln (in case of a cement plant), it does not form a part of energy and its energy value is not to be accounted. But, if the same biomass is used in a captive power plant, which is connected to the grid (whether exporting electricity or not), the same biomass gets covered as energy and its energy value is to be considered. 2. Clinker opening and closing stock has now been incorporated in the form-1, which automatically generates the summary sheet once the data is filled in Form1. The surplus closing clinker stock in 2009-10, with respect to clinker opening stock in base year (2007-08), has been considered for normalization as exported clinker. Similarly, the reduction in stock from the baseline has been considered as imported clinker and accordingly, it has been normalized as per the approved methodology.

ii. Energy forImported Electricity Consumption Total energy for imported Electricity Consumption is to be calculated as:- Total energy for Imported Electricity=[{(Total Imported Electricity from grid (Million kWh) X 860(kcal/kWh)}]

[Million kcal]

iii. Notional/ Normalization energy for Imported electricity from Grid Notional Energy for imported electricity= [{Imported Electricity (Million kWh) x (3208 - 860) (kcal/kWh)}]

[Million kcal] where: 3208 kcal/kWh is the weighted average heat rate of captive power plants in all DCs in cement sector.

iv. Notional/ Normalization energy for grinding of exported Clinker

It is calculated by using following formula:

Notional Energy =[{Total Exported clinker to major product (Million ton) X Electrical SEC of cement grinding (kWh/ton of cement)

X Weighted Average Heat Rate (kcal/kWh)}] [Million kcal]

where: -Weighted Average Heat rate (kcal/kWh) = [{Imported Electricity (Million kWh) X 3208 (kcal/kWh)} + {DG generation (Million kWh) x DG heat rate (kcal/kWh)} + {Captive Power Plant Generation (Million kWh) x Captive Power plant heat rate(kcal/kWh)}] / [Imported Electricity (Million kWh) +DG generation (Million kWh)+Captive power plant generation (Million kWh)] v. Notional/ Normalization energy for clinkerization of imported Clinker

It is calculated by using following formula: Notional Energy = Total Clinker imported (Million ton) x [(Thermal SEC of Clinkerization, kcal/kg clinker x 1000) +{Electrical SEC of Clinkerization (kWh/ton of clinker) x Weighted Average Heat Rate (kcal/kWh)}]

[Million kcal]

vi. Gate to Gate (GtG) Energy Consumption

GtG Energy Consumption =b(i) +b(ii) +b(iii) +b(iv)+b(v) [Million kcal]

vii. Gate to Gate (GtG) Specific Energy Consumption Gate to Gate (GtG) Energy Consumption (Million kcal)

GtG SEC = Total Equivalent of Major Product of Cement (Million ton) X 1000

[ kcal/kg of equivalent cement]

Estimation of Gate to Gate (GtG) SEC

GtG SEC (kcal/kg major product cement)

Total GtG Energy Consumption with normalisation (kcal)

= --------------------------------------------- Production of Equivalent Major Grade of Cement (kg)

Grouping of DCs

CEMENT PLANTS(85 DCs)

PPC (55) OPC(16) PSC (7) White OPC(2)+

Grinding(2)+

Only clinker(1)

Based on Major Product

Wet Plant(2)

National Target of Energy Saving among all Sectors

S.NO. SectorNo. of

Identified DCs

Annual Energy

Consumption (Million toe)

Share Consumption

(%)

Apportioned Energy

Reduction For PAT Cycle-1

(Million toe)

1 Power (Thermal) 144 104.56 63.38% 3.211

2 Iron & Steel 67 25.32 15.35% 1.4863 Cement 85 15.01 9.10% 0.8154 Aluminium 10 7.71 4.67% 0.4565 Fertilizer 29 8.20 4.97% 0.4786 Paper & Pulp 31 2.09 1.27% 0.1197 Textile 90 1.20 0.73% 0.0668 Chlor- Alkali 22 0.88 0.53% 0.054

Total 478 164.97 100.00% 6.686

DRAFT ENERGY CONSUMPTION RANGE IN INDIAN CEMENT PLANTS (85 DC’s) (2007-10)

Products/Process (No. of Plants)

Thermal Energy Consumption

(kcal/kg of clinker)

Electric Energy Consumption (kWh/Tonne

equivalent cement)

Normalized Energy Consumption gtg

(kcal/kg equivalent cement)

Total Energy Consumption of Sub-Sector

% Share of Sub- Sector

(Major Product)

Minimum Maximum Minimum Maximum Minimum Maximum (toe)

(%)

PPC (55 Plants)

658 1074.02 64.18 110.24 712.31 1227.1 10292843.975 68.57%

OPC (16 Plants)

727.33 1000.94 75.67 143.48 964.66 1368.43 3295349.387 21.95%

PSC (7 Plants)

701.02 1207.71 71.03 119.69 700.39 968.17 932008.497 6.21%

White Cement (2 Plants)

1093.72 1279.66 108.93 119.81 1452.23 1484.65 105566.281 0.70%

Wet Cement Plants (2 Plants)

1026.67 1415.07 79.75 113.86 1241.4 1244.56 152403.633 1.02%

Grinding Units (2 Plants)

38.78 40.38 138.73 201.05 88211.169 0.59%

Only Clinkerization (1 Plant)

869.33 87.47 1257.22 143790.367 0.96%

Total 15010173.309 100.00%

Apportionment of Sub-Sector Target of Energy Saving in Cement Sector(Data pertains to 85 plants as DC)

S.No. Sub Sector NO. OF DCsAvg. Energy Consumption

Target Energy Reduction for PAT Cycle-1

Mkcal Million toe % Million toe toe

1 PPC 55 102928440 10.293 68.57% 0.559 558865.489

2 OPC 16 32953494 3.295 21.95% 0.179 178925.965

3 PSC 7 9320085 0.932 6.21% 0.051 50604.807

4 White 2 1055663 0.106 0.70% 0.006 5731.880

5 Wet 2 1524036 0.152 1.02% 0.008 8274.985

6 Grinding 2 882112 0.088 0.59% 0.005 4789.558

7 Clinkerization 1 1437904 0.144 0.96% 0.008 7807.315

Total 85 150101733 15.010 100.00% 0.815 815000.000

Summary Sheet of Designated Consumer Cement PlantDetails of information regarding Gate to Gate SEC, Target SEC and Target Energy saving for PAT Cycle -1

1 Name of the Unit ABC Plant

2 The Sector to which unit falls Cement Sector

3 Complete Postal address of Plant India

4 Details of Production Basis/Calculation Unit Average of Period (2007-10)a Total Clinker Production Annual Production Lakh Tonne 11.02

bTotal Combined Cement

Production Annual Production Lakh Tonne 13.64c Production of OPC Annual Production Lakh Tonne 2.65d Production of PPC Annual Production Lakh Tonne 10.99e Production of PSC Annual Production Lakh Tonne 0.00f Clinker Exported Annual Lakh Tonne 0.33g Clinker Imported Annual Lakh Tonne 0.09h Clinker Stock (Closing Clinker stock in 2010- Opening Clinker Stock in 2007)/3 Lakh Tonne 0.19i Total Clinker Exported (Clinker Exported + Clinker exported to clinker stock) Lakh Tonne 0.52j Total Clinker Imported (Clinker imported + Clinker Imported from clinker stock) Lakh Tonne 0.09

5 Conversion Factors (CF) for Clinker to various Cement grades unit a Clinker to OPC Clinker used for OPC Production/OPC Produced Fraction 0.97b Clinker to PPC Clinker used for PPC Production/PPC Produced Fraction 0.73c Clinker to PSC Clinker used for PSC Production/PSC Produced Fraction 0.00

6Total Thermal Energy

Consumption[Fuel Consumed (Lakh Tonne) X CGV of Fuel (Kcal/Kg)] X 100

Million kcal 1523498.01

7Total Electricity consumed within

the plant

{(Electricity Generated through CPP+Electricity generation through DG Set + Electricity generation through WHR+ Electricity Purchased from Grid) -

Electricity exported to Grid} Lakh kWh 1278.73

8 Electricity Purchased from Grid Average of year 2007-08, 2008-09 and 2009-10 Lakh kWh 183.709 Electricity Exported to Grid Average of year 2007-08, 2008-09 and 2009-10 Lakh kWh 59.46

10Total Energy Consumed

(Thermal+Electrical)

[Total Thermal Energy (Million kcal)+{(Total Electricity purchased from grid (Lakh kWh) X 860)-Electricity exported (Lakh kWh) X National Heat

Rate 2717 kcal/kWh}/10] Million kcal 1523140.4111 Equivalent major grade cement Production unit Average of Period (2007-10)

aOPC Production equivalent to

major product(OPC Produced X CF Of OPC)/CF of Major Product

Lakh Tonne 3.52

bPPC Production equivalent to

major product(PPC Produced X CF Of PPC)/CF of Major Product

Lakh Tonne 10.99

c

PSC/any other verity Cement Production equivalent to major

product (PSC Produced X CF Of PSC)/CF of Major Product

Lakh Tonne 0.00

dTotal Exported clinker to major

productTotal Exported Clinker/CF of Major Product

Lakh Tonne 0.71

eTotal Imported Clinker to major

productTotal Imported Clinker/CF of Major Product

Lakh Tonne 0.12

fTotal Equivalent major product of

Cement (11a)+(11b)+(11c)+(11d) Lakh Tonne 15.2212 Performance Indicators unit Average of Period (2007-10)a Thermal SEC Annual kCal/kg Clinker 952.33

b Electrical SEC (up to

Clinkerization) Annual kWh/Tonne Clinker 67.04

c Electrical SEC (Cement Grinding) Annual kWh/Tonne Cement 32.33

13 Calculation for Gate to Gate SEC unit Average of Period (2007-10)

a

Notional Energy Required for grinding of exported Clinker

{Major Product of Cement of Total exported clinker (Lakh Tonne) x Electrical SEC of cement grinding (kWh/Tonne of cement) x Weighted

average Heat Rate (kcal/kWh)}/10Million kCal 9143.04

b

Notional Energy Required for clinkerization of imported

Clinker

[Total Clinker imported (Lakh Tonne) x {Thermal SEC of Clinkerization kCal/kg clinker) x 1000+electrical SEC of clinkerization (kWh/Tonne of clinker)x Weighted average Heat Rate (kcal/kWh)}/10]

Million kCal 10549.21

c

Notional Energy for Purchased Power

Purchesed Electricity (sr.no.8) X {Weighted average heat rate of all dcs in cement sector( 3208 kcal/kWh) - 860}/10

Million kCal 43133.82

d

Gate to Gate Energy Consumption

(10)+(13a)+(13b)+(13c)Million kCal 1585966.48

e

Gate to Gate Specific Energy Consumption

(13d)/{(11f)*100} kcal/kg equivalent major cement

product

1042.13

14 Target Estimation for PAT Cycle-1 unit PAT Cycle-1

a

Reduction Specific Energy Consumption (SEC) Target

From Summary Sheet of Cement Sector%

5.8378

b

Target Specfic Energy Consumption for PAT cycle-I

(13e) x {1- (14a)/100}kcal/kg equivalent

major cement product

981.29

c

Target Energy saving for PAT cycle-I

[{(13e) - (14b)} x (11f) x 10] metric ton of oil equivalent (toe)

9258.56

15

Note:- Weighted average heat rate of your plant

[{Imported Electricity (Lakh kWh) X 3208 (kcal/kWh)} + {DG generation (lakh kWh) x DG heat rate (kcal/kWh)} +{Captive Power Plant Generation (lakh kWh) x Captive Power plant heat rate (kcal/kWh)}] / [Imported Electricity (Lakh kWh) +DG generation (Lakh kWh)+Captive power plant generation (Lakh kWh)]

kcal/kWh 3988.72

16

Note:- Weighted average heat rate of all DCs in Cement Sector ∑{Captive power plant generation (Lakh kWh) X Captive power plant Heat

Rate (kcal/kWh)} / ∑ {Captive power plant generation (Lakh kWh)}kcal/kWh 3208

Summary of Energy Saving targets for Cement Sector

1) Total Energy Consumption :-15.01 Million toe2) No. of DC's as of date :- 853) Total reduction for cement sector:-0.815 Million toe 4) Reduction target for DC's varying from :-

i) 3.99% to 6.87% (for PPC as major Product) ii) 4.23% to 6.00% ( for OPC as major product) iii)3.71% to 5.13% ( for PSC as major product) iv) 5.01% to 5.12% (for white cement plants)v) 4.87% to 4.88% (for Wet Cement plants)vi) 4.10% to 5.94% ( for grinding plants)

CONCLUSION Introduction of Perform, Achieve and

Trade Scheme for Energy Intensive Industries improves energy efficiency and facilitates cost effectiveness by certifying energy saving that could be traded due to its market based mechanism.

The 478 designated consumer plants offer an energy saving potential of 6,686,000 ton of oil equivalent/year(6.686 million toe/year) at the end of first phase of PAT Cycle (2012- 2015).

CONCLUSION PAT is one of the most promising initiatives to

achieve the goal by implementing Best Available Practices and Technologies in the identified sectors through economical viable projects.

Broader implementation of sectoral crediting mechanisms could ensure that low carbon ‐technologies are also used more widely, which in turn would encourage Indian industries to invest in these technologies.

44