Perdido Spar Installation.pdf

-

Upload

xadsfrfd-fgbh-hyjytjyjwq -

Category

Documents

-

view

215 -

download

11

description

Transcript of Perdido Spar Installation.pdf

DOT presentation03 Oct 2008

Perdido Installation program- Transport & Installation -

Perdido Project

2

AGENDA

IntroductionPerdido field specificsResourcesProgram / scheduleExecution

- Mooring pile installation- Flowline installation- Hull transportation & Installation- SCR installation.

3

Perdido Subsea Project overview

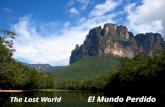

Perdido site

Alaminos Canyon, block 857

Company / Operator: Shell Exploration & ProductionPartners: BP/ Chevron

Location:Alaminos Canyon block 857Water depth: ~7,850 - 9,800 feet Truss Spar Subsea development

4

Far away offshore

Corpus Christi – 150 milesGalveston – 180 miles

Approx. 1.5 - 2 hours by helicopterNearest platform – 80 miles

Perdido site

Alaminos Canyon, block 857

5

Perdido field detailsWater Depths:

• N mooring cluster 2,460 m

• DVA site 2,380 m

• Tobago 2,950 m ! RECORD

• SE mooring cluster 2,630 m ! RECORD

• SW mooring cluster 2,330 m

DVA = Direct Vertical Access

6

Perdido Records

7

SPAR waterdepth development

8

• Mooring piles• SPAR• Topsides• Production Flowlines• Water Injection system• Export Steel Catenary Risers• Manifold piles & manifolds• Electrical SubmersiblePump (ESP) caissons &inlet assemblies

Heerema Scope

9

The offshore program

Jun Jul Aug Sep Oct

2008

1 Perdido Mooring piles

2 Perdido Flowlines

3 Perdido HOST hook-on

4 Perdido SCR’s

5 Perdido topsides (2009)

10

The resources

DCV Balder

SSCV Thialf

Support vessel Union Manta

Transport Barges etc.

400 ft.

300 ft.

250 ft.

Spar tugs

Fixed ballast

11

The people

12

Geneva

Delft, Zwijndrecht, Vlissingen, Leiden.

Houston

Lagos

Perth

Heerema Group Worldwide

Hartepool, Surrey

Mexico City, Villahermosa

Luanda

Heerema Group - worldwide

Bangalore

• subsea

• Moorings / hull• subsea

analysis support

13

Balder Work Area split

• Dedicated pipelay

• Storage

• Material handling

• Dedicated mooring

Accommodation for 350 persons

14

Upgrades for the deep

Greater waterdepth than before. Equipment upgrades required:A&R wire 4,000 m, 5.5 inch diameterL&P wire 4,000 m, 4.5 inch diameterCrane wires 2 * 19km, tuned constructionPositioning equipment more sensitive equipmentROV frame & winch capacity.

Type 8023Type 8023More DirectionalMore Directional

beam shape beam shape below transceiver facebelow transceiver face

15

9 leg taut mooring system in three clusters

Perdido Regional Host Installation- Spar mooring configuration

Lines 1, 2, 4, 5, 7 & 8 Lines 3, 6 & 9

Platform chain:Max. 345m of 135mm studless chainPolyester rope: 229mm diameter1830m + 1830m + 37m insertGround chain:54m of 135mm studless chain

Platform chain:Max. 345m of 135mm studless chainPolyester rope: 229mm diameter1220m + 1220m + 137m insertGround chain:67m of 135mm studless chain

1616

The 9 piles are transported on 2 barges each 260ft long

Phase 1 - Pile installation

Mooring Pile components:Suction piles: 5.5m dia. – 31m long, 250 tons

Pile shackle Between pile and pile chainPile chain: 75’ of 5.3” (134mm) studless chainMooring connector: BSW Ballgrab female connector + shackle

1717

Transfer from barge to Balder deck

Phase 1 - Pile installation

1818

Pile and mooring component assembly on Balder deck

Phase 1 - Pile installation

1919

Phase 1 - Pile installationUpend pile above deck using two cranes

Slew overboard and lower

2020

Phase 1 - Pile installation

Lower pile to seabedPositionApply suction with pump mounted on ROV

21

Phase 2 - Flowline phase work

Production flowlines2 no.’s 8.625” OD * 18.1 mm 3 no.’s 10.75” OD * 22.2 mmcoated with Glass sphere polyurethane (GSPU)

Water Injection flowline1 no.’s 10.75” OD * 22.2 mmOutside & inside coated with fusion bonded epoxy (FBE)

All with Pipeline end terminations (PLET’s) on both ends

22

PLET transfer

Phase 2 - Flowline phase work

23

Start-up PLET upending

Phase 2 - Flowline phase work

24

Phase 2 - Flowline phase work

Pipe layOn deck: 2 double Joints + 1 collar Joint = 1 Hex Joint

Hex Joints in tower

25

End PLET in tower

Phase 2 - Flowline phase work

2626

Phase 3a - Mooring line pre-deployment

The mooring components are transported on 2 barges, 300ft & 400ft long

3 Mooring line pre-deployed :Hurricane contingencyDecrease of critical spar exposure timeLearning curve for assembling components

2727

Phase 3a - Mooring line pre-deployment

The mooring components are transferred to Balder deck for assembly

2828

The polyester ropes are spooled from their transport reel on to Balder’s Mooring Line Deployment Winch

Phase 3a - Mooring line pre-deployment

Assemble mooring components on Balder deck

2929

Phase 3a - Mooring line pre-deployment

Connect ground chain to bottom polyester Overboard connection

Hang-off bottom polyester rope Spool on next polyester rope

3030

Phase 3a - Mooring line pre-deployment

Assemble mooring components on Balder deck

Connect bottom polyester rope with top rope…

Overboard connection and spool off top polyester rope

Connect & overboard buoy

3131

Inshore tow-out route

Phase 3b - Wet tow & Spar upending

Perdido site

Alaminos Canyon, block 857

3232

Phase 3b - Wet tow & Spar upending

Connect ballast hoses to spar

3333

Phase 3b - Wet tow & Spar upending

3434

Prepare Layout top of Spar

Install pull-in equipment

Make safe

Phase 3c - Mooring line hook-up

3535

Hand over polyester to tug to keep polyester off seabedSpool off top segment of poly rope

Phase 3c - Mooring line hook-up

3737

Install and deploy platform and messenger chainTug holds Poly wire from seabed

Phase 3c - Mooring line hook-up

3838

Lower chain clamp to transfer the load to the sparDisconnect using ROV

Phase 3c - Mooring line hook-up

3939

Slurry suspension to be pumped to soft tank

Phase 3d - Fixed ballast installation

Fixed ballast material: magnetite (iron ore), 13,533 mtontransported with hopper barge Peggy Palmer and push boat Naida Ramil, moored along Balder

4040

Install piping on Balder deckInstall ballast boom

Phase 3d - Fixed ballast installation

Install piping on spar deck

Connect piping to the soft tank filling points on top of spar

4141

Mix magnetite with seawater using front loaders and water from BalderPump slurry into spar

Phase 3d - Fixed ballast installation

42

Haul in 3 * 750’

(440 links)

Step 2

Pay out 2 * 750’(440 links)

Cluster 1 tension at stoppers ~1260 kips

Further increase tension of line 1 (~1860 kips). This will be above stall capacity (=1600 kips)

Step 1

Phase 3e – Mooring line stretching

43

Phase 4 SCR installation

Pick-up pre-laid pipe

Install final VIV strakes

flex joint welded

1 no.’s of 10.75” OD * 22.2 mm WT Water Injection SCR (ID coated)2 no.’s of 16” OD * 25.4 mm WT export SCR

44

Transfer headFlexjoint

3½″ SCR pull-in wire pre-installed on spar.

Socket

Phase 4 SCR installation

45

Phase 4 SCR installation

46

QUESTIONS ?