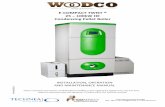

Pellet boiler

Transcript of Pellet boiler

pelletelegancePellet boiler

Wood gasification technology

acco

rding to

guarantee

pass

yearsyears

Guarantee

Guarantee

Guarantee

Guarantee

PREMIUM PREMIUMup toup to

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:28 Seite 1

© w

ww

.foto

lia.c

om

2

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 2

Heating comfort is living comfort!

With its compact design the pelletelegance is a realspace saver. It can be installed flush with the wall on twosides.

The pelletelegance comes ready to plug in - ready cabled,assembled, tested and preset, thereby saving additional costs.In tight spaces, the pelletelegance can also be delivered to theinstallation site as individual assemblies.

The technology

l Compact structurel Integrated return flow boost

(can also be used as loading control for buffer tank)l Two heating circuit pump sets can be integrated (optional) l Touchscreen control with possibility for visualisation on

smartphones, tablets and PCs.

Your benefit

l Technologies that set new standardsl The intuitive control helps you to save fuel costs

without loss of comfortl Independence from fossil fuels like oil and gas

3

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 3

Intelligent controlEverything under control with ecomanager-touch

4

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 4

09:11:31

°C

°C

M

°C

°C

0 %

24618

12

Heating circuit 1

31 Forw. temperature

37 Temperature

Mixer position

No request to Boiler 1

Heating circuit in heating mode

Heating circuit 13:37:37

5

Boiler 1 64

ecomanager-touch

helps you to measure and control!

Changing outdoor temperatures have to be taken intoconsideration as precisely as very personal livinghabits. If the boiler is used in combination with a solarenergy system, the burner only starts when the requi-red heating energy cannot be fully provided by thesolar energy system. This prevents any uneconomicalboiler starts.The ecomanager-touch is very easy to use. It enablesindividual settings and ensures a perfectly tailoredheating system.

44 °C

44 °C

320 l/h

32 °C

25°C27°C32°C

0 %

max.

50 °C

min.

22 °C

45 °C 29 °C

-15 °C 0 °C +15 °C

23 °C

10 °C

Act. priority:Tank 1

Solar module 1

Cal. flow temperature 22 °C

Solar circuit switched off

Flow temperature °C

Reduction

The core of your heating systemthe intelligent controlecomanager-touch

To meet your daily comfort requirements, the controlleris particularly important. The user determines whenthe heating comes on and how warm it should be.

l 7” VGA colour touch display: Guarantees simple,logical operation. Powerful microprocessorwith power-saving standby mode.

l 1 weather-controlled heating circuit3-point heating circuit curve, up to 8 modules arepossible (option).

l 1 DHW tank charging circuit, up to 4 modules arepossible (option).

l Fresh water module controllable with or withoutrecirculation pump (option).

l 2 x three-circuit or 4 x two-circuit solar controllerspossible (option). Also suitable for high-efficiencypumps.

l mySOLARFOCUS app: App for smartphone(Android and Apple) with attractive design for intuiti-ve operation of the main heating parameters, suchas room and flow temperature incl. heating times.Possibility to visualise the solar yield with installedheat quantity meter and control via ecomanager-

touch.l Weatherman function: Takes the weather forecast

for the system’s location into consideration. In conjunction with a solar-thermal system, prevents uneconomical start of the boiler when the weather forecast is good.

Weather-depending control+ mySOLARFOCUS app

makes you independent

5

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 5

6

2

1

5

76

8

4

14

lTE

CH

NO

LOG

Yl

BE

NE

FIT

Intermediate container for pellets (1)with suction turbine (2)l The pelletelegance has a generous intermediate contai-

ner. The suction turbine (2) enables filling of theintermediate container within pre-set times in a closedcircuit.

l The boiler room and pellet storage room do not haveto be directly adjacent to each other. The suction turbineis directly mounted onto the intermediate containerfor pellets.

Auger feeder (3) with single axis rotary valve (4)l The pellets are transported from the intermediate

container by the feed auger into the single axis rotaryvalve. The single axis rotary valve hermeticallyseals-off the combustion chamber from the intermediatecontainer. Six -chamber system - in one axis to the insertscrew with a directly flanged, maintenance-free gearmotor (5) .

l 100% backburn-proof even if there is a power failure.Minimum power consumption. No chains or gearwheels - low noise and maintenance free.

Stainless steel grate (6) l The pellets fall from above through the single axis

rotary valve onto the stainless steel combustion grate.l The fire is not disturbed as the pellets feed from

ABOVE on the fire-bed, with no mixing of ash andembers with the pellets = best efficiency!

Automatic ignition (7) l Ignition of the pellets is fully automatic via a highly

heat-resistant solid ceramic glow pencil.l The glow pencil only requires 260 W. The glow pencil

operates quietly and is maintenance-free.

Downfiring combustion technology/pellets gasification (8)l When using downfiring combustion technology (8)

(wood gasification technology) the released gas issucked through the grate and burned (residue-free) inthe combustion chamber (9) with a flame tip temperatureof approx. 1,200°C.

l Efficient fuel utilization, highest efficiencies.

Cross section pelletelegance

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 6

7

makes you indepentent

9

11

103

12

13

Diagrammatic view: pelletelegance

Stainless grate cleaning (9) l The downfiring combustion technology automatically

transports the ash downwards into the ash pan.l In underfeed and case stage systems, the ash has to

be removed mechanically via a complex mechanism(reversible stainless , tilting grate, grate, ...).

Induced draft fan (10) l The combustion air sucked in is regulated by the ID fan.l Efficient external rotor motor with stainless steel fan

vanes, low noise, maintenance free with speed monito-ring. The flue pipe connection can be rotated and theoutlet can either be at the top or at the rear. This meansthat the boiler can be installed flush with the wall on twosides.

Lambda sensor (11)l The Lambda technology enables uniform combustion

of the pellets in the pelletelegance. Lambda technology isessential to ensure maximum efficiency with differentload ranges.

l Guarantees environmentally-friendly, energy-savingcombustion in all load ranges. Decades of experienceusing Lambda technology since 1981.

Heat exchanger cleaning system (12)l Turbulators (12) clean the walls of the heat

exchanger (13) at regular preset intervals. Increasedexhaust gas temperature results in a loss of efficiency.Clean fuel exchangers save fuel!

l AUTOMATIC means AUTOMATIC!Uniform efficiency saves energy costs! Manualcleaning is not required. Maintenance free.

Automatic ash extraction (14)l The ash is automatically transported into a 14.5 litre ash

box.l Long emptying intervals make for a convenient heating.

On request your mobile phone notifies you via SMSwhen the ash box has to be emptied.

The energy-saving champion – Heating makes fun!

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 7

8

Innovative technical solutionsWood gasification technology

When using downfiring combustion technology (wood gasificationtechnology) the released gas is sucked through the grate andburned (residue-free) in the combustion chamber with a flame tiptemperature of approx. 1,200°C.

l Efficient fuel utilizationl Saves fuel

Single axis rotary valve

The auger feeder with single axis rotary valvetransports the pellets from the intermediate container.The single axis rotary valve hermetically seals-offthe combustion chamber from the intermediatecontainer. 100% backburn-proof even if there isa power failure. Six-chamber system - along anaxis to the feed auger with a direct flangedconnection,maintenance free drive motor.

l No chains and gearsl Maintenance free and simply structure

Lambda sensor

The lambda technology is essential to ensure maximum efficiencywith different load ranges. It is the core for a controlled andemission-free combustion.

l Many years of experience with lambda sensor since 1981l Clean combustion with minimal dust values

Automatically heat exchanger cleaning

The cleaning of the heat exchanger is crucial when it comes to ensuring aconsistently high level of efficiency. With the patented turbulators, cleaningtakes place via a rotating scraping edge. The turbulators clean the surfaceof the heat exchanger so well that no after-cleaning is needed. The flowoptimised guide plates ensure even better heat transfer of the flue gas and low flue gas temperatures.

l Consistently high efficiencyl Low flow gas temperatures

Rotating scraping edge

Flow-optimised guide plates

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 8

9

makes you independentYour advantagesIntegrated hydraulic

The return booster module with mixer motor for buffer/DHWtank charging is pre-integrated. If required, up to two additio-nal heating circuit pump sets with 3-way mixing valve andservomotor can be easily installed in the boiler.All connections exit at the top and the components are easilyaccessible.

l Return flow boost already integratedl Up to 2 heating circuits can be integrated in a boiler

Unit easily flush-mounted on two sides

With a just 0.54 m² footprint, the compact boiler is idealfor small boiler or installation rooms. In addition, the boiler canbe installed flush with the wall on two sides. All connectionsexit at the top. If required, the flue pipe connection can berotated, and the outlet can either be at the top or at the rear.

l Only 0.54 m² footprintl Flue pipe connection traversable (top / rear)

Automatic ash extraction

The ash is automatically transported into a 16.3 litre ash box.

l Long emptying intervals make for a convenient heating.l On request your mobile phone notifies you via SMS when the ash

box has to be emptied.

Flexibility

The pelletelegance is supplied ready cabled, assembled,tested and preset as standard, which saves costs and time.In tight spaces, the pelletelegance can also be deliveredto the installation site as individual assemblies, the heaviestof which weighs just 93 kg.

l Plug-deliveryl Modular design allows flexibility

Zonne-energiecircuit in werking

09:11:31Zonneregelaar

93 °C

65 °C

60 °C100 %

307 l/h40 °C

pelletelegance

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 9

10

Storage and feeding systems

pelletelegance with suction system withsuction heads manual or automatic

l Maximum hose length 20 mMaximum auger height 2.5 m

l Optimum utilisation of spaceMinimum installation effortFor damp storage areas/rooms

pelletelegance with vacuum system with extraction auger

l Maximum hose length 35 mMaximum auger height 5 m

l Maximum auger length 6 ml Complete storage room emptying

pelletelegance with pellet box 350 litre with suction head, manually fillableor pellet box with suction system

Extraction with augerl Maximum hose length 35 m

Maximum auger height 5 m

Extraction with suction headl Maximum hose length 20 m

Maximum auger height 2.5 m

Pellet box 350 litre with suction head manually filliable

pelletelegance with manual storage container

l Available for pelletelegance 10 andpelletelegance 15

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:29 Seite 10

Zonne-energiecircuit in werking

09:11:31Zonneregelaar

93 °C

65 °C

60 °C100 %

307 l/h40 °C

pelletelegance

FWM

auta

rk

Zonne-energiecircuit in werking

09:11:31Zonneregelaar

93 °C

65 °C

60 °C100 %

307 l/h40 °C

pelletelegance

Zonne-energiecircuit in werking

09:11:31Zonneregelaar

93 °C

65 °C

60 °C100 %

307 l/h40 °C

pelletelegance

FWMau

tark

11

Zonne-energiecircuit in werking

09:11:31Zonneregelaar

93 °C

65 °C

60 °C100 %

307 l/h40 °C

pelletelegance

Standard schemaspelletelegance with stratified buffer storage tank and fresh water module FWMautark

The grey-shaded area on the diagram,the return booster module with mixermotor for buffer/DHW tank charging isintegrated into the pelletelegance

(standard).

pelletelegance with HYKO storage tank and solar plant

pelletelegance with buffer storage tank, fresh water module FWMautark and solar plant

The yellow-shaded area on the diagram,heating circuit 1 and heating circuit 2 can bedirectly integrated into the pelletelegance

(optional, NOT included in scope of delivery).

pelletelegance with drinking water storage tank and solar plant

More hydraulic schemesare available - we can helpyou by plannning!

FRESH WATER SYSTEM

FRESH WATER SYSTEM

FRESH WATER SYSTEM

makes you independent

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:30 Seite 11

H90,5

D

11,5 45

60

A

ca. 7045

6 5 4 3 2 1

60

A92,5

6 5 4 3 2 1

22

Top flue pipe connection

Rear flue pipe connection

Room-sealed operation possible !

pelletelegance 10 15 20 24Power ratings [kW] 2.9 - 9.9 4.4 - 14.9 5.9 - 19.8 7.2 - 24Height incl. adjustable feet (without connection)* (H)[cm] 130 130 157 157DM flue pipe [cm] 10 10 13 13Height flue pipe centre* (D) [cm] 70 70 72 72Weight [kg] 198 198 250 250Water content [l] 25 25 36 36Pellet storage container [l] 48 48 88 88Ash box [l] 16.3 16.3 16.3 16.3A [cm] 44 44 47 47* Adjustable feet at maximum depth of thread1) Buffer storage tank return flow (Drinking water tank return flow), 2) Buffer storage tank flow (Drinking water tank flow), 3) Heating circuit 1 return flow, 4) Heating circuit 1 flow, 5) Heating circuit 2 return flow, 6) Heating circuit 2 flow. All connections 1“ flatsealing.

acco

rding to

guarantee

pass

yearsyears

Guarantee

Guarantee

Guarantee

Guarantee

PREMIUM

PREMIUM

up toup to

makes you independent

Dimensionsin cm

Everything from one supplierSolar systems − Biomass heating − Storage technology − Fresh water technology

Your specialised dealer

Subject to technical modifications, typesetting and printing errors. The images used are symbolic photos. All use is prohibited without the written consent of the copyright holder SOLARFOCUS.

© S

OLA

RFO

CU

S G

mbH

| 04

/201

6

EN 303-5CEN/TC 57

Tested leading-edge technology – EN ISO 9001 certified

SOLARFOCUS GmbH, Werkstrasse 1, A-4451 St. Ulrich/Steyre-mail: [email protected] Tel.: +43 (0) 7252 / 50 002 - 0web: www.solarfocus.com Fax: +43 (0) 7252 / 50 002 - 10

Technical data

pelletelegance_EN_04-2016_tedoc_Solar-technik_02_2005_Original.qxd 11.04.2016 14:30 Seite 12