Paul Stewart Marathon

-

Upload

jimmydenislaborelec -

Category

Documents

-

view

64 -

download

4

Transcript of Paul Stewart Marathon

Management of legacy control systems

Paul Stewart, Automation and Control for Energy Conference, May 2011

Marathon Integrated Oil and Gas Company overviewUpstream

Oil and Gas Exploration

Oil and Gas production

Oil sands mining

LNG

Shale gas

Downstream

2

Refining

Marketing

Transportation

Distribution

World wide operations

3

Brae area infrastructure

4

Brae Alpha - 1984

Photo

5

Brae Bravo - 1987

Photo

6

East Brae - 1993

Photo

7

Typical control systems on an Oil and Gas Installation

ESD

Safety Instrumented Function logic solvers

F&G

DCS

MCS

SCADA

Gas Turbine control systems

Machinery control, sequence logic

Machinery protection, vibration monitoring

Compressor Anti‐Surge protection

Flow Metering

8

legacy control systemLegacy – from the past

A system whose development is complete

A control system which is not a current product

9

Obsolete

A product or system is considered obsolescent when an end of life date has been announced

A product or system is considered obsolete once it is no longer available from the original manufacturer, even though parts or components may still bethe original manufacturer, even though parts or components may still be available in the supply chain

Obsolescence is inevitable and requires effective management to reduce the business impact

Ineffective obsolescence management can result in difficulty obtaining spares or support

10

Standards

IEC 62402:2007 (BS EN 62402) Obsolescence Management – Application guide

Gives guidance on establishing a framework for obsolescence management

Covers the following areas:‐

Design of new products

New technology insertion into existing products

Support and maintenance of legacy products

11

Reasons for keeping legacy systems

The system works satisfactorily and it is therefore difficult to justify replacement.

The costs of redesigning or replacing the system are prohibitive because it is large and/or complex.large and/or complex.

The system requires close to 100 percent availability, so it cannot be taken out of service without a significant impact on production.

The way that the system works is not well understood. This is common on legacy systems where it is likely that the original designers of the system have left the organisation and the system design has either not been fully documented or documentation has been lost.

12

Reasons for replacing a legacy control system

The system is unreliable.

The system is unsupportable either by the OEM or after market service providers.

h i ll i h i i lif hi h i ffi i l l k iThe installation has a remaining life which is sufficiently long to make it unlikely that obsolescence can be overcome without replacement of the system.

13

Obsolescence management process

Effective management of obsolescence is essential to ensure an optimum

balance between reliability, availability and cost‐efficiency.

Identify – Critical control systems are assessed to identify obsolescence issues

Mitigate – Select and implement the most appropriate obsolescence strategy for each system.

Monitor – Carryout periodic re‐assessments, monitor effectiveness of strategy

14

Identify

Control Systems are assessed to identify any obsolescence issues

Hardware, software, documentation, support contracts and competency shall be assessed with respect to obsolescence

A ll i i d f h b d li iAn overall assessment is carried out for each system based on a qualitative approach using a risk matrix and shall take in to account probability and severity of obsolescence. A risk category of low, med or high shall be assigned to each system

15

Risk Matrix

16

Mitigation strategies

A reactive or proactive obsolescence strategy shall be selected for each of the control systems

Unlikely that one solution will be applicable to all systems, likely to be a combination of solutions across an installation depending on risk to thecombination of solutions across an installation depending on risk to the business, cost, where the system is in it’s lifecycle. replacement, migration/upgrade and life extension

17

Reactive obsolescence strategy

Do nothing until the need arises

Suitable only where impact on safety, environment or business is low

This is a positive decision to do nothing

Recovery options:‐

Product search by contacting OEM, after market suppliers, contacts within the industry (other Oil and Gas Operators)

Repair by specialist electronic repairers

Cannibalisation from redundant equipment

18

Cannibalisation from redundant equipment

Proactive obsolescence strategies

Replacement

Migration

Upgrade – brought up to date by replacement of obsolete items.

Life extension of existing equipment

19

Monitor

The obsolescence assessments on critical instrumentation and control systems is repeated periodically

Active dialog with manufacturers and suppliers to establish end of life dates for systemsfor systems

Monitor obsolescence strategy for effectiveness

20

Life extension

The Service Life Extension Program (SLEP), was developed in the 1980s toThe Service Life Extension Program (SLEP), was developed in the 1980s to extend the service life of the US Navy’s aircraft carriers. The concept subsequently expanded to all of the US Navy’s life‐extension programs for ships, aircraft, and combat systems including the NASA Space Shuttle program

SLEP considers factors including safety, reliability, supportability, performance, and cost reduction

21

Life extension

Review each of the following areas to understand what is required to extend the

life of the system

Hardware

Software

Supplier management

Training

Technical support

documentation

22

Hardware

Lifetime buy from OEM

Aftermarket resellers

Repair

Reverse engineer

23

Software

Backups

Ability to modify software

Software emulator to overcome obsolete software or hardware

Well constructed and annotated code to enable reverse engineering

24

Spares Management

Clear spares management strategy

Accurate bill of materials

Onsite spares

Offsite spares

Periodic testing of stored spares to ensure they are serviceable

25

Competency

Suitably trained and experienced staff on site.

Mixture of formal training, mentoring and hands on experience to build up a skills set.

A i kf i h UK Oil I d kill i i iAgeing workforce in the UK Oil Industry, skills retention is important

26

Documentation

Up to date Operation and Training manuals

Maintenance manuals

As built drawings

May be an opportunity to obtain design info for end of life products from OEM

27

Supplier Management – Contract award and structure

Sole source or tender?

Good quality contract structure – CRINE, LOGIC standard contracts

Contracts must comply with corporate standards, EU procurement regulations, Oil d G UK l h i d f dOil and Gas UK supply chain code of conduct.

Market conditions – where does the balance of power rest?

28

Supplier Management – Managing Performance

Supplier and Purchaser feedback through FPAL process.

Use of KPI’s, metrics, penalty clauses and bonus structure

Hold periodic review meetings

Build an effective working relationship with key suppliers

29

Compressor Vibration and Temperature control upgrade

Original CML system

30

Compressor Vibration and Temperature control upgrade

Replacement Rockwell XM system with Panelview

31

LM5000 gas turbine control system

Replacement control system at FAT

32

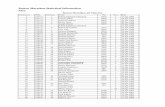

DCS migration

33

East Brae metering system

OEM migration path enabled replacement of flow stream microcomputers with new generation micros

34

East Brae metering system

35

Questions

36