Parts List - myHARDI

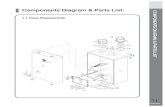

Transcript of Parts List - myHARDI

2 HARDI Parts List 2019

Hand Sprayers and Accessories

Part No

Hand Sprayers

The P series pressure sprayers are made from quality materials for long life and performance.The nozzle gives control over fine and coarse atomisation. The container is pressurised witha plunger pump and a trigger valve controls intermittent or continuous spraying.

P1.5 - pressure sprayer 1.5 litre - minimum 6 buy 84640300 P6 - pressure sprayer 6 litre 84640100 P8 - pressure sprayer 8 litre 84640200 P1.5 service kit 28094600 P6 & 8 service kit 28095000

Backpack Sprayers

The BP15 Backpack sprayers are made of quality materials for the home gardener, hobby farmer, small business and pest control operator. They have comfortable ergonomically adjustableshoulder straps and waist belt. A lever activated piston pump with pressure chamber requiringlow pumping frequency and is capable of high operating pressure. A trigger valve controls intermittent or continuous spraying

BP15 litre 846258 BP15 & 20 service kit 755735

Pressure & Backpack Accessories

Quality accessories expand the application possibilities of the pressure and backpack sprayers. Telescopic lances provide extra reach and the possibility to spray fruit trees. Fan and cone shieldcan be used when applying herbicides around desirable plants. 2, 3 and 4 nozzle booms can beused to spray large areas more precisely and faster.

0.37m Lance 720331000.5m Lance 720329001.0m Lance 7304410.5 -1.0m Telescopic Lance 7557550.75 -1.5m Telescopic Lance 7557411.0 - 2.0m Telescopic Lance 755742Constant flow valve 741651Double nozzle holder, inc nozzle 7557502 nozzle boom 7557463 nozzle boom 7557474 nozzle boom 755748Fan shield, including nozzle 741647Cone shield, including nozzle 741721Adjustable nozzle kit 371864Spray test paper 893211Aluminum lance upgrade kit 755834Nozzle kit to suit hand sprayers 741723Trigger & Lance assy. 0.37m 7417235911203

BPM 100 backpack mistblower

16 Litre with 5hp motor, recoil start, remote throttle and flow control5hp, 16 litre BPM100 84640000

3HARDI Parts List 2019

12 Volt Accessories

Part No

Flojet pumps

Flojet pumps are built to the highest standards for quality and performance. Flojet reliability will always outperform the imitators.

Model LF14-12-01 pump, 3.8 L/m 26120304Model 2130-132 pump, 6.5 L/m, high pressure 5911808Model 3000-501 pump, 7.6 L/m 5911817Model 4100-505 pump, 13 L/m 5911807Model 3521-500 pump, 13.6 L/m 5911818

Flojet spare Parts Kits

LF14 pump head 20908-005A2100 valve kit 20028-0872100 diaphragm kit 21010-0042100 pressure switch 02095-1004100 valve kit 20407-0203000-501 valve kit 20407-0333000-501 diaphragm kit 20419-0113521-500 valve kit 20407-0213521-500 diaphragm kit 20419-015Power Cable, 2.74m 26043804

Flojet pumps & filter kits

Model 3521-500 flojet pump, filter & controldelivers 13.6 L/m, 84603204

Weed Spray Kit & Lance

Model 3000-501 flojet demand pump, filter,control and lance delivers 7.6 L/m, 84603604

Weed Spray Kit & 60S Gun

Model 3521-500 flojet pump, filter, control,6m hose and 60S gun delivers 13.6 L/m, 84603504

Accessories for Flojet pump kits

HARDI Lance and trigger, 0.37m 5911203HARDI 60S gun 84319612mm or 1/2” pest weed hose (per/mtr) 591371112 volt relief valve and gauge kit 8410000460S Gun Gasket Repair Kit 750270

4 HARDI Parts List 2019

12 Volt Sprayers

Model Part No

Swift Compact Sprayer with lance 50 litre, demand - 7.6 L/m 84600204100 litre, demand - 7.6 L/m 84600404 Swift Compact Sprayer with 60S Gun 50 litre, demand - 7.6 L/m 84600704100 litre, demand - 7.6 L/m 84600804 Bike Sprayer with Lance 50 litre, demand - 7.6 L/m 8460000475 litre, demand - 7.6 L/m 84602504 Bike Sprayer with 60S Gun 50 litre, demand - 7.6 L/m 8460010475 litre, demand - 7.6 L/m 84601004 Bike Sprayer with 60S Gun, pressure regulation & gauge 75 litre, Control 3 - 7.6 L/m 84602404 Bike Boom 1.5 metre rigid 59081002 metre rigid 59081023 metre breakaway 59081044 metre breakaway 5908105 Professional Sprayer, 60S gun, 6 metre hose, pressure regulation & gauge 250 litre, control - 15.1 L/m 84601604250 litre, control & 20m reel - 15.1 L/m 84602304 12-Volt Accessories 1.0m Lance 7304410.5 -1.0m Telescopic Lance 7557550.75 -1.5m Telescopic Lance 7557411.0 - 2.0m Telescopic Lance 755742Double nozzle holder - with nozzles 755750Pressure control w/- gauge 8410000460S spray gun 84319612mm or 1/2” Hose (per/mtr) 5913711Hose reel, 20m hose, 60S gun 5904101Hose reel, 20m hose, NO GUN 5904102

SWIFT COMPACT SPRAYER - 100 LSWIFT COMPACT SPRAYER - 50 L

5HARDI Parts List 2019

Trailed UTV Sprayers tandem axle - Heavy duty trailer with flotation tyres, pressure regulation , 6m hose, 60S gun and boom 400L, 15.1 L/m, 6m SB boom 5911684400L, 15.1 L/m, 8m SB boom 5911685 Trailed UTV Sprayers tandem axle - Heavy duty trailer with directed coupled Honda engine, pressure regulation & bypass control, flotation tyres 400L, NO BOOM, Honda 4hp, 603 pump 31 l/m 5903419400L, 6m SB boom, Honda 4hp, 603 pump 31 l/m 5903420400L, 8m SB boom, Honda 4hp, 603 pump 31 l/m 5903421400L, 10m SB boom, Honda 4hp, 603 pump 31 l/m 5903422Optional Extras Trapeze suspension kit suit SB boom 727571End nozzle assembly manual - suit 1/2 boom tube (per side) 590820020m hose reel, 20m hose and 60S spray gun 5904101TFL 24 litre double-sided, with switchbox 5904210 Pump units direct coupled to Honda engine, pressure regulation & bypass control 4hp, 503 pump 16 L/M, brass control 59101634hp, 603 pump 31 L/M, brass control 59101655.5hp, 1203 pump 99 L/M, BK180 control 59101665.5hp, 321 pump 50 L/M, brass control 59101675.5hp, 1303 pump 114 L/M, BK180 control 59101719hp, electric start standard, 364 pump 194 L/M, BK180 control 5910172

12 Volt Trailers and Engine Drive Units

Model Part No

Estate Turf - Turf trailer with 1.5m boom, 6m hose & choice of lance or gun 120L, 7.6 l/m control, lance 84604004120L, 7.6 l/m control, 60S gun 84604104

Estate Professional & Estate turf trailer with 7.6 l/m, 2m boom, 6 metre hose & lance 120L, 7.6 l/m control 809056Optional add 60S gun, 6m hose and fittings 70026804 Trailed CADET Sprayers single axle - Heavy duty trailer with flotation tyres, pressure regulation, 6m hose, 60S gun and boom size 300L 15.1 control 6m hose reel & 60S gun 84604304300L 15.1 control with 20m hose reel 84604404300L 15.1 control with 3m ATV boom, 6m hose & 60S gun 84604504300L 15.1 control with 3m ATV boom & 20m hose reel 84604604300L 15.1 control with 4m ATV boom, 6m hose & 60S gun 84604704300L 15.1 control with 4m ATV boom & 20m hose reel 84604804300L 15.1 control with 6m SB boom, 6m hose & 60S gun 84604904300L 15.1 control with 6m SB boom & 20m hose reel 84605004

CADET 300L with 15.1 control with SB boom & 20 metre hose reel

6 HARDI Parts List 2019

Pick Up Units

Options Part No Ex GST Inc GST

Booms options - MUST ALSO SELECT BOOM MOUNT Boom Mount for SB Booms 72330104 6 Metre SB Boom with MD02 nozzles - MUST ALSO SELECT ABOVE BOOM MOUNT 72330504 8 Metre SB Boom with MD02 nozzles - MUST ALSO SELECT ABOVE BOOM MOUNT 7233060410 Metre SB Boom with MD02 nozzles - MUST ALSO SELECT ABOVE BOOM MOUNT - 72330704Hi mount transport bracket - STANDARD ON 10M SB BOOM - 70036204Trapeze centre kit 70034704 Hose reels mounted with 60 S handgun 20m hose reel and 60s gun 590410130m hose reel and 60s gun 8180040450m hose reel and 60s gun 72330904 Foam Marker and Hand wash tank 15 litre hand wash tank 72331204Double side foam marker 72331104

Part No Tank L/Min Pump Engine Controls Steel Frame 5903204 300 38 603 4 HP Honda Brass Std 5903205 400 38 603 4 HP Honda Brass Std 5903206 600 38 603 4 HP Honda Brass Std 5903208 800 38 603 4 HP Honda Brass Std 5903234 300 50 321 5.5HP Honda Brass Std 5903235 400 50 321 5.5HP Honda Brass Std 5903236 600 50 321 5.5HP Honda Brass Std 5920563 - 99 1203 5.5HP Honda M70 Base In Lieu of Std 4HP engine and 600 Pump

Electric Controls in lieu of Standard Brass

SC-3 Electric distribution valve (8bar) 72330004 EVC-3 Electric distribution valves (15bar) 72367304

REFER TO EXTRANET FOR CONFIG AND FREIGHT PRICE

7HARDI Parts List 2019

Linkage price list

Reference No. Linkage 400 Lt

NK400-NB NK400 Lt, 603 31 l/m Pump, No Boom, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK400-6SB NK400 Lt, 603 31 l/m Pump, 6m Boom Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK400-8SB NK400 Lt, 603 31 l/m Pump, 8m Boom Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK400-10SB NK400 Lt, 603 31 l/m Pump, 10m Boom with Transport Bracket Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

Reference No. Linkage 600 Lt

NK600-NB NK600 Lt, 603 31 l/m Pump, No Boom, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK600-6SB NK600 Lt, 603 31 l/m Pump, 6m Boom Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK600-8SB NK600 Lt, 603 31 l/m Pump, 8m Boom Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK600-10SB NK600 Lt, 603 31 l/m Pump, 10m Boom with Transport Bracket Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

Reference No. Linkage 800 Lt

NK800-NB NK800 Lt, 603 31 l/m Pump, No Boom, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK800-6SB NK800 Lt, 603 31 l/m Pump, 6m Boom Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK800-8SB NK800 Lt, 603 31 l/m Pump, 8m Boom Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK800-10SB NK800 Lt, 603 31 l/m Pump, 10m Boom with Transport Bracket Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

NK800-12MB NK800 Lt, 603 31 l/m Pump, 12m Boom with Trapeze Suspension Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Top Down Drain, Top Link Extension, PTO Included

Reference No. Linkage 1000 Lt

NK1000-NB 1000 Lt, 1203 99 l/m Pump, No Boom, BK 180 3 Section Control, Top Suction, Quick Hitch, Agitation

NK1000-10SB 1000 Lt, 1203 99 l/m Pump, 10m SB Boom with Transport Bracket includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Quick Hitch, Agitation, PTO included

NK1000-12MB 1000 Lt, 1203 99 l/m Pump, 10m MB Boom with Trapeze Suspension includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Quick Hitch, Agitation, PTO included

NK1000-12HYS 1000 Lt, 1203 99 l/m Pump, 12m HYS Boom with Trapeze Suspension Includes Mini Drift Nozzles, BK 180 3 Section Control, Top Suction, Agitation, Quick Hitch, PTO Included

Versatile high/low hydro-pneumatic sprayer

ZEBRA

Cannon sprays out to 27 metres

Adaptable to any type of fruit culture

Spout with 3 nozzles

Canon

Spout with 3 atomizers

Spout with 2 atomizers

Spout with 4 atomizers

Spout with 5 nozzles

Low volume Pneumatic Systems produce droplets when the spray liquid is torn off a shear plate by high speed air. Droplet size is very fine and operating pressure is 1 to 4 Bar

Hydro-pneumatic solutions to suit your application

The convenience of a linkage sprayers with the power of a trailer sprayer

Starting from $12,000+GST

Hydraulic Nozzle droplets are formed when the liquid passes through the aperture. Droplet size is small to medium and operating pressure is 4 to 25 Bar.

• Lift mounted mistblowers available from 400, 600 and 1000 litres.

• A wide range of fan and turbine choices to provide optimum air generation for specific crop and working conditions.

• The air delivery systems ensures maximum air volume with the minimum power consumption.

• High quality air volume enables higher forward speeds while maximising penetration and efficiency of application.

• Chassis and tank profile provides low centre of gravity ideally suited to narrow and steep working plantations.

• Reliable, robust and easy to operate.

• Easy access for servicing.

• ZEBRA is designed for maximum drift control and minimum environmental impact.

• V-Deflector directs upper air to the target

• Adjustable bottom deflectors ideal for large trees

MISTBLOWERS for growers who want the convenience of a linkage sprayer with the power

of a trailer sprayer

Air Sheer pneumatic low volume application

V-Deflector

MEC

URY

COVA

MAX

FROM

$58

,000

+GST

9HARDI Parts List 2019

Chemical Pumps / Vac N Mix

Part No

Chemical transfer pumpsScienco PH6 6 piston chemical transfer pump kit 28304704Scienco PH6 6 piston chemical transfer pumpwith SEM 10 Flowmeter 5912228Scienco SEM 10 Flowmeter 5912224Sotera 850 Flowmeter 28004604

Chemical transfer hoppersTurboFiller 25L w/- valve & fixed bracket 72601100TurboFiller 35L w/- valve & fixed bracket 72539900Turbo Filler swing down bracket for 35lt only 72540100

Vac N Mix 60L w/- valve & drop-down bracket 842253Vacuum suction kit for Vac N Mix 5912190

BANJO hydro-motor drive transfer pump2” Banjo pump with hydro-motor drive (650 L/m) 59052263” Banjo pump hydro-motor drive (800 L/m) 5905225

Foam markersEconomy TFL single-sided, No In-cab control 5904217TFL 24 litre single-sided, with switchbox 5904212TFL 24 litre double-sided, with switchbox 5904210

Versatile high/low hydro-pneumatic sprayer

Air Sheer pneumatic low volume application

10 HARDI Parts List 2019

Diaphragm Pumps

Part No

Diaphragm Pumps

A robust design of high nickel and cast iron construction. With greased bearing dry sump design, can run dry without harm to moving parts. Features low power consumption, self priming and easy maintenance.

Model 503

540rpm 16 L/M with Direct PTO coupling & chain (no feet base) 8216161000 rpm 16 L/M with foot base for engine drive 821618540 rpm (25bar) 16 L/M with foot basefor engine drive 821026540 rpm 16 L/M with foot base forlinkage or trailer mounting 821617

Model 603

540 rpm 31 L/M with PTO coupling and chains 821623540 rpm 31 L/M with foot base 8216241000 rpm 31 L/M with foot base 821625

Model 321 540 rpm HP 25bar 51 L/M withfoot base 821557540 rpm HP 25bar 51 L/M throughshaft 30mm cylindrical/taper with foot base 821560540 rpm 73 L/M through shaft 6 spline with foot base 821607540 rpm 73 L/M 6-splined shaftwith foot base 821614

1200 Series Model 1203 540 rpm 99 L/M with foot base 821630Model 1203 1000 rpm with 108 L/M foot base 821629

1300 Series Model 1303 540 rpm 114 L/M with foot base 821635Model 1303 1000 rpm 136 L/M with foot base 821634

11HARDI Parts List 2019

Diaphragm Pumps

Part No

Model 364 - Suction 1 1/2” - Delivery 1 1/4”

540 rpm 140 L/M 6 spline through shaft 82169900540 rpm 194 L/M 6 spline shaft 82170000540 rpm 194 L/M 6 splined through shaft 821703001000 rpm 201 L/M 21 spline shaft (Suction Pressure Side) 821697001000 rpm 201 L/M 21 spline shaft (Suction Crank Side) 82169500Suction Fitting S93 1 1/2" 32242300Suction Fitting O-Ring 242225Outlet Fitting S67 1 1/4" 32242200Outlet Fitting O-Ring 24266600

Model 464 - Suction 2” - Delivery 1 1/4" - with foot base

1000 rpm 305 L/M 21 spline through shaft 821681001000 rpm 305 L/M 21 spline shaft 82168000540 rpm 276 L/M 6 spline shaft 82168200540 rpm 276 L/M 6 spline through shaft 82168300540 rpm 322 L/M 6 spline shaft 82168500Suction Fitting S93 2" 32242400Suction Fitting O-Ring 24266800Outlet Fitting S67 1 1/4" 32242200Outlet Fitting O-Ring 24266600

Model 464 - Suction 2” - Delivery 1 1/4" - no foot base

540 rpm 322 L/M 6 spline shaft 72993500540 rpm 322 L/M 6 spline through shaft 72993900540 rpm 276 L/M 6 spline shaft - suit flex cap. only 729938001000 rpm 322 L/M 21 spline shaft 729936001000 rpm 322 L/M 21 spline through shaft 72993700

Pump pulsator kits

Pulsator kit for 503/603/321pump 727864Pulsator kit for 1203/1303 pump 727861Pressure Pulsator, complete 845014Suction Pulsator, complete 703032

Pump kit with pulsators for mounting directly to the tractor PTO shaft

Model 503 540 rpm 16 L/M with Pulsator kit,PTO coupling and chains 5905200Model 603 540 rpm 31 L/M with Pulsator kit,PTO coupling and chains 5905201

Pump diaphragm and valve repair kits

500 series diaphragm and valve kit 75073000600 series diaphragm and valve kit 750732001200 series diaphragm and valve kit 750734001300 series diaphragm and valve kit 75073600361 & 363 series diaphragm and valve kit 75073700364 series diaphragm and valve kit 75585900463 series diaphragm and valve kit 75073900464 series diaphragm and valve kit 75586000503, 603 & 363 series Valve kit(2x 728146 & 2 x 330072 in kit) 7501271203, 1303 & 463 series valve kit(2x 728148 & 2 x 330072 in kit) 750131

12 HARDI Parts List 2019

PTO / Operating Units / Kits

Part No

PTO Shafts900 x 25mm HARDI taper - 1 3/8”6-spline suit 503, 603, 1203 5913850 900 x 30mm HARDI taper -6-spline suit 321, 1303 5913851900 x 1 3/8” - 6-spline both ends 5913864900 x 25mm taper - 1 3/8”21-spline suit 503, 603, 1203 5913862 900 x 30mm taper - 1 3/8”21-spline suit 321, 1303 5913863B2 shaft 900 x I 3/8” 21-spline both ends 5913861B2 shaft 1410 x I 3/8” 6-spline both ends 5913866B2 shaft 1410 x I 3/8” 21-spline both ends 5913867PTO wide angle series 60W60 shaft 900 x 1 3/8” -6-spline both ends 5913822PTO wide angle series 60W60 shaft 1300 x 1 3/8” -6-spline both ends 5913832PTO series B5 shaft 900 x I 3/4” 20 spline to 1 3/8”21-spline both ends 5913873Universal Joint 280081

Hydraulic motor pump drive kits363/364 hydro-motor kit, rpm sensor suitNAVIGATOR 72033204 463/464 hydro-motor kit, rpm sensor suitCOMMANDER 83316504 464 hydro-motor kit, for CM FlexCapacity pump 72076304

Operating unitsBrass operating unit, M600 with pressure gauge & pulsation dampers suitable for direct attachment to pump models 503 & 603, 1203 727862M70 operating unit bare with remote mountingfrom the pump models 503, 603, 321, 1203, 1303 841013M70 operating unit with pressure gauge & pulsationdampers suitable for remote mounting on pumpmodels 503, 603, 321, 1203, 1303 818013BK180 operating unit on/off valve 841422BK180-3 operating unit - kit with pressure control,on/off valve, 3 section distribution and in-line filter 84190212 volt relief valve kit with pressure regulation,bypass and gauge 84100004

3-way manifold to suit M600, M70 & M74 for 3 way boom section distribution 3-way manifold, with 1/2” tails 5905111

Operating unit repair kitsM70 seal/gasket repair kit 750269M70 repair kit 750208M74 seal repair kit 750209Seal Kit EFC section valve 741822BK180 seal repair kit 750268SC seal repair kit for 3 soleniod 750722EVC/EFC spare parts kit (single bypass) 755726EVC/EC spare kit 4 sections 750271EVC repair kit single valve (double bypass) 755754EVC pressure valve & cone repair kit - FAST 741293EVC pressure valve & cone repair kit - STD 740994DF4 Oring kit for pressure valve 74192600

HC451 Electric Tank Gauge Kit - must have HC6500 controller up and tank sensor fittted HC451 tank gauge kit suit SP 72363804HC451 tank gauge kit suit trailer 72364204

13HARDI Parts List 2019

Electronic Controls

Part No

Solenoid Control operating unit - solenoid valve boom section distribution with manual pressure regulation - include in cab switch box SC - 3 section operating unit 840107 Solenoid valve parts Solenoid 262104Cover 334965S40 3/8” tail 726554S40 1/2” elbow tail 726567U-pin 145994

EVC operating unit with inter connected pressure regulation and distribution valves - includes in cab SprayBox, junction box, cable, gauge, fittings, mounting bracket. EVC - 2 section operating unit ideal for mistblowers 84100504EVC - 3 section operating unit ideal field sprayers 841173 For fully integrated in-cab application rate control choose the following componentsHC2500 computer controller 840166HC5500 computer controller 842264 Add transducer kit Flowmeter & Speed Transducer kit 840169 Add tractor mounting bracket kit - for rate controller 2 pole bracket for control box 722365003 pole bracket for control box 72050000

EVC operating unit with split pressure regulation and distribution valves. Includes in cab SprayBox, electric pressure regulation, gauge, fittings and mounting bracket.Must add the junction board, box and cable length required EVC-3 section distribution & pressure regulation 84101104EVC-4 section distribution & pressure regulation 84101204EVC-5 section distribution & pressure regulation 84101604EVC-6 section distribution & pressure regulation 84101004EVC-7 section distribution & pressure regulation 84101704EVC-8 section distribution & pressure regulation 84101304EVC-9 section distribution & pressure regulation 84101804 Add junction board - in weather proof box, to connect cable to distribution valvesEVC/EC 9 section junction box 72115400 Add cable length required - Cab to distribution valves Cable 37-39 pin 5m 28028800Cable 37-39 pin 8m 28028900Cable 37-39 pin 14m 28028700Cable 37-39 pin 17m 26004200

Norac UC4 sensor (round plug) 28086400UC5 sensor (square plug) 26043700Active roll cylinder 78133500Sensor foam pads 28086600Norac UC5 severe terrain option 27005504Norac UC5 3 sensor boom height kit force boom 72077104

14 HARDI Parts List 2019

Part No

Tanks

Gauges0-6 bar, bottom mount 63mm 59131500-6 bar, rear mount 63mm 59131510-16 bar, bottom mount 63mm 59131540-16 bar, rear mount 63mm 59131550/8-16 bar, rear mount 100mm 2848300/8-16 bar, bottom mount 100mm 2848310-16 bar, bottom mount 100mm 59131680-16 bar, rear mount 100mm 5913169

Filters in-line1/2” barbed in- line filter, 100 mesh, (HARDI) 8452073/4” barbed in-line filter, 100 mesh, (HARDI) 8452103/4” bsp in-line filter, 100 mesh, (HARDI) 845220T25 inline filter 80 mesh 84101100T25 inline filter 100 mesh 84101200

3 PL tank and frames - size, type by LxWxHTop link extension kit 72084600NK400 tank and frame - 700x1120x1170 824197NK600 tank and frame - 800x1120x1400 824198NK800 tank and frame - 800x1600x1449 824199NK1000 tank and frame - 550x1600x1920 70039904Tanks onlyNK400L tank only - 630x1130x1370 726866NK600 tank only - 650x1130x1370 727878NK800 tank only - 600x1570x1369 727879NK1000 tank only - 550x1600x1700 72148700

Hand wash tank - size, type by LxWxH15 litre hand wash with frame - 300x260x550 72207240 litre hand wash, frame & tap - 290x290x780 5907260

Foam marker tank - size, type by LxWxH40 litre foam vertical - 290x290x830 590715050 litre foam horizontal - 450x440x510 5907152100 litre foam vertical - 850x430x430 5907153100 litre foam horizontal - 850x430x430 5907154Foam mark lid - suit above tanks 5914690Gasket to suit lid 5914690 5914690-1

Bike tank - size, type by LxWxH50 litre front bike - 720x440x330 590711075 litre saddle bike - 970x900x300 S107650 litre Swift - 580x360x330 S1051100 litre Swift - 780x380x450 S1101

Multipack - size, type by LxWxH250 litre Multipack - 840x730x730 5907102

15HARDI Parts List 2019

Tanks

Part No

BL tank - size, type by LxWxH 50 litre BL - 470x430x530 590712050 litre BL with steel base - 470x500x590 5907220100 litre BL - 900x430x530 5907121100 litre BL with steel base - 900x500x590 5907221200 litre BL - 820x570x720 727498200 litre BL with steel base - 820x600x720 5907222300 litre BL - 1120x600x770 727499300 litre BL with steel base - 1120x600x920 5907223400 litre BL - 960x815x910 5907124400 litre BL with steel base - 950x920x1030 5907224600 litre BL - 1080x820x920 5907125600 litre BL with steel base - 1250x920x1020 5907225

HP tank - size, type by LxWxH 800 litre HP - 1150x1100x1080 5907130800 litre HP with feet - 1200x1070x1100 59072301000 litre HP - 1400x1070x1070 59071311000 litre HP with feet - 1470x1070x1130 59072311200 litre HP - 1760x1070x1030 59071321200 litre HP with feet - 1700x1070x1100 5907232HP tank feet (1 only) - 910x245x260 5907135

TLV tank - size, type by LxWxH 1000 litre TLV - 1480x1300x780 59071401000 litre TLV with steel base - 1700x1330x980 59072401200 litre TLV - 1700x1300x1040 59071411200 litre TLV with steel base - 1720x1330x1240 59072412000 litre TLV - 2200x1160x1270 59071422000 litre TLV with steel base - 2200x1320x1440 59072422700 litre TLV - 2100x1550x1450 59071432700 litre TLV with steel base - 2130x1480x1650 59072433200 litre TLV - 2500x1350x1350 59071443200 litre TLV with steel base - 2600x1550x1540 59072443500 litre TLV - 2600x1500x1570 350017044000 litre TLV - 2550x1500x1740 5907145

Tie down tank webbing and buckle Tank webbing, per metre 5914410Tank strap buckle kit (two required per strap) 5914600

Front tank 1400 litre front tank 59071821400 litre front tank and frame - 1900x1800x1200 5901721

16 HARDI Parts List 2019

Part No

Fittings

S - FittingsO-ring sealed, U-pin retained, modular manifold fluid system. The tank hole size for S40 is 40mm, S53 is 53mm, S67 is 67mm and S93 is 93mm.

Tank flange bulk head Part NoS40 726462S53 726463S67 726464S93 726465S93 - flat for drain 727339

Flange nutS40 322106S53 322107S67 322108S93 322109

Blanking plugS40 726577S53 726578S67 726579S93 726580

Slide retaining U-pinS40 145994S53 145995S67 145996S93 145997

Threaded reducerS40 1/8” female 726693S53 1/2” female 726694S67 1” female 726695S93 2” female 727476

Hose tail straight for pressureS40 3/8” 726554S53 1/2” 726556S53 3/4” 726558S53 1” 726559S67 1” 726560S67 1 1/4” 726561S67 1 1/2” 726562S93 1 1/2” 728523S93 2” 726563S93 2 1/2” 726564

Hose tail elbow for pressureS53 1/2” 726568S53 3/4” 726570S53 1” 726571S67 1” 726572S67 1 1/4” 726573S67 1 1/2” 726574S93 2” 726575S93 2 1/2” 726576

Hose tail straight for suctionS67 1 1/2” 727223S93 1 1/2” 728523S93 2” 727227S93 2” 45° 72072700S93 2 1/2” 727133

Hose tail elbow for suctionS67 1 1/2” 727224S93 1 1/2” 728395S93 2” 727225S93 2 1/2” 727226S93 2 1/2” 45° 72072900

17HARDI Parts List 2019

Fittings

Part No

Manifold teeS53 manifold tee 322352S67 manifold tee 322224S93 manifold tee 334545

Manifold joinerS53 manifold joiner 72114300S67 manifold joiner 728526S93 manifold joiner 728525

Manifold reducerS67 Male to 53 Female manifold reducer 728561S93 Male to S67 Female manifold reducer 728562S93 Male to S67 Male manifold reducer (pictured) 728527

Manifold ball valvesS67 two-way suction ball valve 72293700S93 two-way suction ball valve 840110S67 three-way pressure ball valve 728391S67 three-way return flow ball valve 728393S67 four-way SmartValve 72172300S93 four-way SmartValve 72183700

Floating filterFloating filter with 1-1/2” tail 841481

Single saddle assembliesSingle saddle assembly screw fit 716037Single saddle assembly snapfit 725079Triplet saddle assembly snapfit 725078

Boom plumbing2 hole poly boom tube - 500mm spacing 6128723 hole poly boom tube - 500mm spacing 6128834 hole poly boom tube - 500mm spacing 6128945 hole poly boom tube - 500mm spacing 612905

3/4 cap for poly boom tube 320283End plug for poly boom tube 7164133/4 hose tail union for poly boom tube 7246211/2 hose tail union for poly boom tube 7162361/2 thread union for poly boom tube 7208561/2 boom tube flush tap 59048061/2 boom tube flush tap with boom prime 72356604Manual End Nozzle Kit 5908200

Boom tube T25 styleBoom tube SS 25mm 2 hole - 500mm spacing 15150400Boom tube SS 25mm 3 hole - 500mm spacing 15150500Boom tube SS 25mm 4 hole - 500mm spacing 15150600Boom tube SS 25mm 5 hole - 500mm spacing 15150700Boom tube SS 25mm 6 hole - 500mm spacing 15150800Boom tube SS 25mm 7 hole - 500mm spacing 15150900

18 HARDI Parts List 2019

Part No

Hoses / ATV Booms

T25 fittingsTriplet nozzle body T25 non drip clip on 72623700Triplet nozzle body T25 non drip bolt on 72622900Boom flush tap T25 assembly 72179504Boom flush tap T25 assembly with boom prime 72355504Remote boom flush tap T25 assembly with boom prime 72355704Gasket/seal for nozzle filter 390639

3/8 nozzle screw cap for ISO nozzle 321517Snap fit nozzle cap for IJ/MD/DUO nozzle 334083DUOCAP 28063000Blind nozzle for DUOCAP 372140Gasket/seal - for snap fit nozzle cap 242252Snap fit nozzle cap to suit TeeJet nozzle bodies 334862Gasket to suit TeeJet nozzle cap 24022901

Snap fit nozzle cap suit cone 334082Blank piece- for snap fit nozzle cap 334102Gasket/seal - for snap fit nozzle cap 242252

Underleaf droplets - 5 kits in pack 834281

Nozzle attachment upper mounting bracket 334874Nozzle attachment lower mounting bracket 33487300Retaining bolt nozzle mounting bracket 322116Retaining nut nozzle mounting bracket 322114Nozzle bracket kit complete with cable ties 833288ADual Nozzle Bracket 16061404

Hose reelBARE 20m hose reel - no hose or gun 7410040420m hose reel, 20m hose, no gun 590410220m hose reel, 20m hose and 60S spray gun 590410130m hose reel, 30m 3/8 hose 2802620430m hose reel, 30m 3/8 hose and 60S gun 8180040450m hose reel, no hose, 25 bar 818377100m hose reel, no hose, 25 bar 81838150m HR, 50m hose and 60S spray gun 81800304100m HR, 100m hose and 60S spray gun 590411250/100m hose reel mounting bracket 834764

Spray gun60S, adjustable cone spray, 60 bar 84319660L adjustable cone spray, 60 bar 843197Type 60 spray gun repair kit 750270

19HARDI Parts List 2019

Hoses / ATV Booms

Part No

Tubing4mm or 5/32” poly tube (pressure gauge) 9272536mm or 1/4” poly tube (foam line) 59137008mm or 5/16” poly tube (foam line) 59137018mm or 5/16” poly tube (Red foam line) 5913701RD10mm or 3/8” poly tube (foam line) 591370212mm or 1/2” nylon tube 5913703

Pressure hose – see table below for coil prices8mm or 5/16” pressure hose 591370910mm or 3/8” pressure hose 591371012mm or 1/2” HARDI rubber hose 60 bar 92702112mm or 1/2” pressure hose 591371119mm or 3/4” pressure hose 60 bar 92703225mm or 1” pressure hose 60 bar 92712432mm or 1 1/4” pressure hose 60 bar 9274110038mm or 1 1/2” pressure hose 92741200

Suction hose – see table below for coil prices25mm or 1” spiral suction hose 92708732mm or 1 1/4” spiral suction hose 92727138mm or 1 1/2” spiral suction hose 92714650mm or 2” spiral suction hose 92726662mm or 2 1/2” spiral suction hose 92737175mm or 3” spiral suction hose 92700304

Hose by the coil12mm or 1/2” pressure hose 20m coil 2500430412mm or 1/2” pressure hose 50m coil 2500440412mm or 1/2” pressure hose 100m coil 2500450412mm or 1/2” pressure hose 200m coil 2500540419mm or 3/4” pressure hose 10m coil 2500460419mm or 3/4” pressure hose 20m coil 2500550425mm or 1” pressure hose 10m coil 2500470425mm or 1” suction hose 10m coil 2500480438mm or 1 1/2” suction hose 10m coil 2500490450mm or 2” suction hose 10m coil 25005004

ATV boom1.5 m rigid fixed with 3 nozzles 59081002.0 m rigid fixed with 4 nozzles 59081023.0 m with breakaway wings 6 nozzles 59081044.0 m with breakaway wings 8 nozzles 5908105

Olive & Vine T-Boom - designed to spray two vertical half rows8 nozzle vine T-Boom for 2 half rows (fixed cone) 590831010 nozzle vine T-Boom for 2 half rows (fixed cone) 5908311

JetChester is a boomless nozzle - delivers up to a 10m spray coverage from an assembly of 3 nozzlesJetChester 825156

NK & NL under-vine/tree herbicide boom - NO CENTRE BOOM RAIL - Robust design, adjustable for row width with breakaway and protected nozzlesUnder-vine boom double row no centre boom rail 83317304Under-vine boom LHS 83317404Under-vine boom RHS 83317504Under-tree boom LHS 83317704Under-tree boom RHS 83317604Under-vine/tree mount kit 83317804Under-vine/tree centre boom rail 83317904

20 HARDI Parts List 2019

Part No

Booms

SB Linkage boom6m - boom kit complete with 12 nozzles 8170478m - boom kit complete with 16 nozzles 81706210m - boom kit complete with 20 nozzles 8170846m SB wing set - steel parts only 7217558m SB wing set - steel parts only 72176610m SB wing set - steel parts only 721777Hi mount transport bracket SB boom 726254Hydraulic SB boom tower with height control kitincludes trapeze 831272SB hydraulic wing lift centre only * NO TRAPEZE * 5908130Trapeze suspension kit suit SB boom (can not be used with p/n 5908130) 727571SB/MB wing skid guard kit (loop style) 722094

MB boom12m fixed boom with trapeze (no hydraulic lift) 590815112m with hydraulic gantry lift 5908191Air bag suspension for MB boom 590816012m MB boom wing set - steel parts only 720532

HYS boom12m HYS hyd fold boom 83519515m HYS hyd fold boom 7238490418m HYS hyd fold boom 72385004

FALCON SPL boom12.5m boom with hydraulic fold 81840216.5m boom with hydraulic fold 818406Gantry & hydraulic lift for FALCON boom 831314Hydraulic wing tilt kit for FALCON boom 834654

EAGLE SPB, SPC boom - with vertical lift tower18m SPB with hydraulic fold 81835018m SPB with hydraulic fold - for optional tilt 81833120m SPB with hydraulic fold 81835120m SPB with hydraulic fold - for optional tilt 81833224m SPC with hydraulic fold - for optional tilt 8185620428m SPC with hydraulic fold - for optional tilt 8185630430m SPC with hydraulic fold - for optional tilt 81856404

EAGLE SPC boom - with paralift28m SPC with hydraulic fold - for optional tilt 8185600430m SPC with hydraulic fold - for optional tilt 81856104

EAGLE SPB, SPC boom - EXTRASTilt cylinders for 18/20m EAGLE SPB booms 5908258Tilt cylinders for 24/28/30m EAGLE SPC booms 833156EAGLE boom end wing guard 70007304EAGLE boom end wing guards - PAIR 70007704Spring skid ground striker eagle boom 715606Boom wheel SPC MK2 single assembly 72144700Boom wheel SPC MK2 - SET of 2 831391

FORCE FTZ Boom Complete with fluid - single nozzlesForce FTZ boom 30m 818547Force FTZ boom 36m 818549

Boom accessoriesFORCE FTZ Air bag boom wheel left 83318704FORCE FTZ Air bag boom wheel right 83318804FORCE FTZ Air bag boom wheels set left & right 83312204

Solenoid end nozzle kitsDouble sided to suit HC5500 & 6500 5905107Single sided to suit HC5500 & 6500 5905108End nozzle assembly manual - suit 1/2 boom tube 5908200

21HARDI Parts List 2019

Part No

cable

1 HC5500 display, speed sensor and mounting kit 842264

2 39 pin cables options (from SprayBox to junction box): 5 m cable 28028800 8 m cable 28028900 14 m cable 28028700 17 m cable 26004200

3 EVC/EC 9 section junction box 72115400

4 Hall effect flow meter 72117500

5 Flow Meter Housing (if rate control needed) Flow housing D13.5 EC operation 725129 (Tronic or Pilot) Flow house D13.5 EVC + BK180 732076 + SC3

6 High Speed motor (recommended for fast reaction) Yellow 150 to 1 motor EVC + EC 729997 + SC3

7 SprayBox 2 options (39 pin plug) 2 section 26010200 3 section 26010300 4 section 26010400 5 section 26010500 6 section 26010600 7 section 26010700 8 section 26010800 9 section 26010900 Manual for HC 5500 67000400-201

Allow approx 6 hrs for fitting time

HC 5500 upgrade from old TRONIC, NOVA & PILOT

To upgrade to a HC 5500 from your old Tronic, Nova or Pilot just simply follow the steps from 1 to 7 and order the parts that you will need:

Step 1: Order p/n 842264 HC 5500 display kits: Comes with display, speed sensor and mounting kit.

Step 2: Order 39 pin communication cable for junction box to SprayBox 2. Make sure you order the length that you require for your machine.

Step 3: Order p/n 72115400 new junction box with 9 section fluid board.

Step 4: Flow meter only required for upgrading from Tronic or Nova.

Step 5: Flow meter housing required for rate control if no existing flow meter fitted.

Step 6: Pressure motor only required if you have old style pressure motor with green finger grip.

Step 7: Order new SprayBox 2 control box, matching number of boom sections for your machine.

HC 5500 and SprayBox 2

1

+/–

2 3 4

5

67

Tronic, Nova or Pilot replacement

22 HARDI Parts List 2019

Part No

Nozzles

NOZZLE TIP ONLY

Standard flat fan syntal nozzlesF-110-075 Syntal single - pink 371963F-110-01 Syntal single - orange 371706F-110-01 Syntal 12 pack - orange 755643F-110-015 Syntal single - green 371707F-110-015 Syntal 12 pack - green 755646F-110-02 Syntal single - yellow 371708F-110-02 Syntal 12 pack - yellow 755649F-110-025 Syntal single - lilac 371946F-110-025 Syntal 12 pack - lilac 750628F-110-03 Syntal single - blue 371709F-110-03 Syntal 12 pack - blue 755652F-110-04 Syntal single - red 371710F-110-04 Syntal 12 pack - red 755655F-110-05 Syntal single - brown 371711F-110-05 Syntal 12 pack- brown 755658F-110-06 Syntal single - grey 371712F-110-06 Syntal 12 pack - grey 755661F-110-08 Syntal single - white 371713F-110-08 Syntal 12 pack - white 755664F-110-10 Syntal single - light blue 371966F-110-10 Syntal 12 pack - light blue 750638

LowDrift Syntal nozzlesLD-110-01 Syntal single - orange 371817LD-110-01 Syntal 12 pack - orange 755698LD-110-015 Syntal single - green 371818LD-110-015 Syntal 12 pack - green 755699LD-110-02 Syntal single - yellow 371819LD-110-02 Syntal 12 pack - yellow 755700LD-110-025 Syntal single - lilac 371957LD-110-025 Syntal 12 pack - lilac 750632LD-110-03 Syntal single - blue 371820LD-110-03 Syntal 12 pack - blue 755701LD-110-04 Syntal single - red 371821LD-110-04 Syntal 12 pack - red 755702LD-110-05 Syntal single - brown 371893LD-110-05 Syntal 12 pack - brown 755817

MINIDRIFT DUO air inclusion nozzlesMINIDRIFT DUO-110-02 Syntal single - yellow 37218400MINIDRIFT DUO-110-025 Syntal single - lilac 37218500MINIDRIFT DUO-110-03 Syntal single - blue 37218100MINIDRIFT DUO-110-04 Syntal single - red 37218200MINIDRIFT DUO-110-05 Syntal single - brown 37218300

23HARDI Parts List 2019

Part No

Nozzles

MINIDRIFT air inclusion nozzlesMINIDRIFT-110-015 Syntal single - green 372111MINIDRIFT-110-015 Syntal 12 pack - green 75082100MINIDRIFT-110-02 Syntal single - yellow 372112MINIDRIFT-110-02 Syntal 12 pack - yellow 75082200MINIDRIFT-110-025 Syntal single - lilac 372113MINIDRIFT-110-025 Syntal 12 pack - lilac 75082300MINIDRIFT-110-03 Syntal single - blue 372114MINIDRIFT-110-03 Syntal 12 pack - blue 75082400MINIDRIFT-110-04 Syntal single - red 372115MINIDRIFT-110-04 Syntal 12 pack - red 75082500MINIDRIFT-110-05 Syntal single - brown 372116MINIDRIFT-110-05 Syntal 12 pack - brown 75082600

INJET air inclusion nozzlesINJET-110-01 Syntal single - orange 371926INJET-110-01 Syntal 12 pack - orange 75078800INJET-110-015 Syntal single - green 371872INJET-110-015 Syntal 12 pack - green 75081500INJET-110-02 Syntal single - yellow 371873INJET-110-02 Syntal 12 pack - yellow 75081600INJET-110-025 Syntal single - lilac 371874INJET-110-025 Syntal 12 pack - lilac 75081700INJET-110-03 Syntal single - blue 371875INJET-110-03 Syntal 12 pack - blue 75081800INJET-110-04 Syntal single - red 371876INJET-110-04 Syntal 12 pack - red 75081900INJET-110-05 Syntal single - brown 371927INJET-110-05 Syntal 12 pack - brown 75078900INJET-110-06 Syntal single - grey 371928INJET-110-06 Syntal 12 pack - grey 750790003INJET-110-08 Syntal single - white 371929INJET-110-08 Syntal 12 pack - white 75078100

QUINTASTREAM Syntal nozzlesQUINTASTREAM 015 Syntal single - green 372002QUINTASTREAM 02 Syntal single - yellow 372003QUINTASTREAM 02 Syntal 12 pack - yellow 75079300QUINTASTREAM 03 Syntal single - blue 372004QUINTASTREAM 03 Syntal 12 pack - blue 75079400QUINTASTREAM 04 Syntal single - red 372005QUINTASTREAM 04 Syntal 12 pack - red 75079500QUINTASTREAM 05 Syntal single - brown 372006QUINTASTREAM 05Syntal 12 pack - brown 75079600QUINTASTREAM 06 Syntal single - grey 372007QUINTASTREAM 08 Syntal single - white 372008QUINTASTREAM 10 Syntal single - light blue 372009QUINTASTREAM 15 Syntal single - light green 372010

F-80 Flat fan nozzlesF-80-01 Syntal single - orange 371931F-80-015 Syntal single - green 371932F-80-02 Syntal single - yellow 371933F-80-03 Syntal single - blue 371934

24 HARDI Parts List 2019

Part No

Nozzles

CAP AND NOZZLE TIP

Standard flat fan syntal nozzlesF-110-075 Syntal single - pink 371964F-110-075 Syntal 12 pack - pink 750634F-110-01 Syntal single - orange 371764F-110-01 Syntal 12 pack - orange 755627F-110-015 Syntal single - green 371765F-110-015 Syntal 12 pack - green 755628F-110-02 Syntal single - yellow 371766F-110-02 Syntal 12 pack - yellow 755629F-110-025 Syntal single - lilac 371950F-110-025 Syntal 12 pack - lilac 750626F-110-03 Syntal single - blue 371767F-110-03 Syntal 12 pack - blue 755630F-110-04 Syntal single - red 371768F-110-04 Syntal 12 pack - red 755631F-110-05 Syntal single - brown 371769F-110-05 Syntal 12 pack- brown 755632F-110-06 Syntal single - grey 371770F-110-06 Syntal 12 pack - grey 755633F-110-08 Syntal single - white 371771F-110-08 Syntal 12 pack - white 755634F-110-10 Syntal single - light blue 371970F-110-10 Syntal 12 pack - light blue 750636

LowDrift Syntal nozzlesLD-110-01 Syntal single - orange 371837LD-110-01 Syntal 12 pack - orange 755708LD-110-015 Syntal single - green 371838LD-110-015 Syntal 12 pack - green 755709LD-110-02 Syntal single - yellow 371839LD-110-02 Syntal 12 pack - yellow 755710LD-110-025 Syntal single - lilac 371958LD-110-025 Syntal 12 pack - lilac 750630LD-110-03 Syntal single - blue 371840LD-110-03 Syntal 12 pack - blue 755711LD-110-04 Syntal single - red 371841LD-110-04 Syntal 12 pack - red 755712LD-110-05 Syntal single - brown 371894LD-110-05 Syntal 12 pack - brown 755815

MINIDRIFT air inclusion nozzlesMINIDRIFT-110-015 Syntal single - green 372121MINIDRIFT-110-015 Syntal 12 pack - green 75083100MINIDRIFT-110-02 Syntal single - yellow 372122MINIDRIFT-110-02 Syntal 12 pack - yellow 75083200MINIDRIFT-110-025 Syntal single - lilac 372123MINIDRIFT-110-025 Syntal 12 pack - lilac 75083300MINIDRIFT-110-03 Syntal single - blue 372124MINIDRIFT-110-03 Syntal 12 pack - blue 75083400MINIDRIFT-110-04 Syntal single - red 372125MINIDRIFT-110-04 Syntal 12 pack - red 75083500MINIDRIFT-110-05 Syntal single - brown 372126MINIDRIFT-110-05 Syntal 12 pack - brown 75083600

25HARDI Parts List 2019

Part No

Nozzles

INJET air inclusion nozzles & capINJET-110-01 Syntal 12 pack - orange 75078400INJET-110-015 Syntal 12 pack - green 75077900INJET-110-02 Syntal 12 pack - yellow 75078000INJET-110-025 Syntal 12 pack - lilac 75078000INJET-110-03 Syntal 12 pack - blue 75078200INJET-110-04 Syntal 12 pack - red 75078300INJET-110-05 Syntal 12 pack - brown 75078500INJET-110-06 Syntal 12 pack - grey 75078600INJET-110-08 Syntal 12 pack - white 75078700

QUINTASTREM Syntal nozzlesQUINTASTREAM 015 Syntal single - green 372011QUINTASTREAM 02 Syntal single - yellow 372012QUINTASTREAM 02 Syntal 12 pack - yellow 75080200QUINTASTREAM 03 Syntal single - blue 372013QUINTASTREAM 03 Syntal 12 pack - blue 75080300QUINTASTREAM 04 Syntal single - red 372014QUINTASTREAM 04 Syntal 12 pack - red 75080400QUINTASTREAM 05 Syntal single - brown 372015QUINTASTREAM 06 Syntal single - grey 372016QUINTASTREAM 06 Syntal 12 pack - grey 75080600QUINTASTREAM 08 Syntal single - white 372017QUINTASTREAM 10 Syntal single - light blue 372018QUINTASTREAM 15 Syntal single - light green 372019

Adjustable hand sprayer nozzle7000-3.4 White - Blue 80° - 0.74 to 1.53 3716257000-3.5 White - Orange 90° - 1.05 to 2.74 371626

REFLEX nozzlesReflex nozzles 0.5m coverage yellow 372020Reflex nozzles 1.0m coverage green 372021Reflex nozzles 1.5m coverage blue 372022Reflex nozzles 2.0m coverage red 372023

80° Even spray nozzles for band spraying4680E-7E even spray nozzle 3715764680E-9E even spray nozzle 3715774680E-11E even spray nozzle 3715784680E-13E even spray nozzle 3715794680E-15E even spray nozzle 3715804680E-21E even spray nozzle 3715814680E-27E even spray nozzle 371583

65° Flat spray nozzle4665-10 flat spray nozzle 3702854665-12 flat spray nozzle 3702964665-14 flat spray nozzle 3703074665-16 flat spray nozzle 3703114665-20 flat spray nozzle 3703224665-24 flat spray nozzle 3703334665-30 flat spray nozzle 370344

26 HARDI Parts List 2019

Part No

Nozzles

25° Flat spray nozzle4625-20 flat spray nozzle 3705064625-30 flat spray nozzle 3705214625-36 flat spray nozzle 3705324625-46 flat spray nozzle 3705434625-54 flat spray nozzle 370554

Cone nozzle 15531553-08 cone nozzle single 3700161553-10 cone nozzle single 3700271553-12 cone nozzle single 3700311553-14 cone nozzle single 3700421553-16 cone nozzle single 3700531553-18 cone nozzle single 3700641553-20 cone nozzle single 3700751553-22 cone nozzle single 3700861553-24 cone nozzle single 3700971553-30 cone nozzle single 3701011553-35 cone nozzle single 3701121553-40 cone nozzle single 370123 Swirl Plate 15541554 Grey swirl plate single 3701341554 Grey swirl plate 12 pack 7551561554 Black swirl plate single 3701451554 Blue swirl plate single 3701561554 White swirl plate single 370167

Cone nozzle 10991099-08 ceramic cone nozzle 3713091099-10 ceramic cone nozzle 3713101099-12 ceramic cone nozzle 3713111099-15 ceramic cone nozzle 3713121099-18 ceramic cone nozzle 3713131099-20 ceramic cone nozzle 3713141099-23 ceramic cone nozzle 3713151099-30 ceramic cone nozzle 371884

Cone nozzle 1299Lilac 1299-08 ceramic cone nozzle 371508Brown 1299-10 ceramic cone nozzle 371509Yellow 1299-12 ceramic cone nozzle 371510Orange 1299-14 ceramic cone nozzle 371511Red1299-16 ceramic cone nozzle 371512Grey1299-17 ceramic cone nozzle 371972Green 1299-18 ceramic cone nozzle 371513Black 1299-19 ceramic cone nozzle 371973Blue 1299-20 ceramic cone nozzle 371514

27HARDI Parts List 2019

Part No

Nozzles

Off centre nozzle1850 G150 off centre nozzle 3/8” 3703661850 G200 off centre nozzle 3/8” 3703771850 G250 off centre nozzle 3/8” 3703811850 G300 off centre nozzle 3/8” 3703921850 G350 off centre nozzle 3/8” 3704031850 G400 off centre nozzle 3/8” 3704141740 G500 off centre nozzle 1/2” 3704251740 G600off centre nozzle 1/2” 3704361740 G700 off centre nozzle 1/2” 3704471740 G800 off centre nozzle 1/2” 370451G-series G1200 off centre nozzle 1” 371557G-series G1600 off centre nozzle 1” 371558

Pack of 10 snap fit saddle & nozzle assemblyFlatFan SeriesSaddle assembly with F-110-01 Syntal 5908901Saddle assembly with F-110-015 Syntal 5908902Saddle assembly with F-110-02 Syntal 5908903Saddle assembly with F-110-025 Syntal 5908904Saddle assembly with F-110-03Syntal 5908905Saddle assembly with F-110-04 Syntal 5908906Saddle assembly with F-110-05 Syntal 75501004

LowDrift SeriesSaddle assembly with LD-110-02 Syntal 75500004Saddle assembly with LD-110-025 Syntal 75500104Saddle assembly with LD-110-03 Syntal 75500204Saddle assembly with LD-110-04 Syntal 75500304Saddle assembly with LD-110-05 Syntal 75500404

MINIDRIFT SeriesSaddle assembly with MD-110-015 Syntal 75501104Saddle assembly with MD-110-02 Syntal 75500504Saddle assembly with MD-110-025 Syntal 75500604Saddle assembly with MD-110-03 Syntal 75500704Saddle assembly with MD-110-04 Syntal 75500804Saddle assembly with MD-110-05 Syntal 75500904

Nozzle filters50 mesh nozzle filter without seal 61436680 mesh nozzle filter without seal 614367100 mesh nozzle filter without seal 61436850 mesh nozzle filter without seal 12 pack 75541080 mesh nozzle filter without seal 12 pack 755215100 mesh nozzle filter without seal 12 pack 75541150 mesh nozzle filter with seal for snap filter cap 72504380 mesh nozzle filter with seal for snap filter cap 725042100 mesh nozzle filter with seal for snap filter cap 72504450 mesh nozzle filter w/seal for snap filter 12 pack 75022980 mesh nozzle filter w/seal for snap filter 12 pack 750228100 mesh nozzle filter w/seal for snap filter 12 pack 750234

Nozzle key for restrictor in LowDrit nozzleOrange 334845Green 334853Yellow 334854Blue 334855Red 334856

For more than 50 years, the basic philosophy of HARDI INTERNATIONAL has been the development, design and manufacture of sprayers and spraying equipment for the application of plant protection products. The success of this philosophy is reflected in the sales of HARDI products in over 100 countries, many of which have specific needs.HARDI has become a specialist in liquid systems and this Components Guide shows the comprehensive range.

ContentsCalibration ................................................................. 3Control units .............................................................. 4Controllers & accessories ........................................... 5Droplegs ................................................................... 6Hose ......................................................................... 7Hose reels and accessories ........................................ 7Filters ........................................................................ 8Fittings ...................................................................... 9Foam Markers...........................................................11Flush Nozzle .............................................................12Liquid mixing & transfer equipment ............................12Nozzles ....................................................................13HARDI ISO reference number for nozzles ....................14Pressure gauges .......................................................14Pumps .....................................................................15

HARDI pump 503 ................................................16HARDI pump 603 ................................................18HARDI pump 321 ................................................20HARDI pump 1203 ..............................................22HARDI pump 1303 ..............................................24HARDI pump 363 ................................................26HARDI pump 463 ................................................28HARDI hot liquid pump .........................................30

Spray lines ...............................................................32Spray guns ...............................................................33Tanks .......................................................................33Valves ......................................................................34

HARDI Component guideYour

Spra

yer

Specia

list

3

818492

285802285721

284554893212

893211

Part no.

Component guide

Your Sprayer Specialist

Field sprayer kitA quality kit for calibration is indispensable when using application equipment for quick and easy calculations of application rate, speed, ISO noz-zle size and pressure.

Features:• Robust 2 litre jug,• Spray technique booklet• Cleaning tool• Nozzle Calibrator disc

Field sprayer kit, metric · · · · · · · · · · · · · · · · ·

Calibrator disc only, metric · · · · · · · · · · · · · · ·Calibrator disc only, US · · · · · · · · · · · · · · · · · ·

Mistblower and BackpackMistblower Calibrator disc, metric · · · · · · · · ·Backpack sprayer kit: 10 pcs. KALIBOTTLE · ·

Spray Test Paper A quick and easy way to evaluate drop cover-age and penetration. It turns blue upon contact to liquid. Pictogram instructions with drop count indicator are included.

Bag with 50 pieces 2.5 cm x 7.5 cm paper · · ·

Calibration

4

727862

841013

841902

Part no.

Component guide

Your Sprayer Specialist

Control unitsM-600Brass control unit with pressure gauge and pul-sation dampers. Suitable for direct attachment to pump.

M-600 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·Inlet: ¾"Outlet: ½"Bypass: ¾"Max. pressure: 15 barPressure gauge: Dual scale glycerine dampened, 63 mm diameter

M-70Control unit with pressure gauge made of hard wearing synthetic materials for long life and chemical resistance.

M-70 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·Inlet: 1"Outlet: 2 x ½"Bypass: 1"Max. pressure: 15 barPressure gauge: Dual scale glycerine dampened, 63 mm diameter

BKControl unit with section valves and HARDI-MATIC proportional valve. Ideal for field sprayers.

Features:• Control of main valve• Equipped with three valve sections• Pressure equalization device maintaining the

same pressure when the valve is turned off• Pressure agitation valve for effective agitation• Easy to read, dual scale pressure gauge• HARDI-MATIC volumetric valve for constant

application rate even with speed variations within the same gear

• Pressure filter with 50 mesh net• 15 bar safety valve.

BK with 3 sections · · · · · · · · · · · · · · · · · · · · ·Inlet: 1"Outlet: 3 x ¾"Bypass: 1"Pressure agitation: ½"Max. pressure: 15 barPressure gauge: Dual scale glycerine dampened, 63 mm diameter

5

840193840195

840165840166840169

72236500

Part no.

Component guide

Your Sprayer Specialist

Control units

Controllers & accessories

EVCRemote controlled units utilize 12 Volt motorized valves (not solenoid) to operate the spray func-tions. It is the best choice for maximum operator comfort and safety.

Features:• Remote control of main ON/OFF function• Three or five section valves • HARDI-MATIC volumetric pressure regulation

valve for constant application rate even with speed variations within the same gear

• Equalization device maintaining the same pres-sure when section valve is turned off

• Remote control box with five metre of cable• Pressure agitation valve• Large, easy to read, stainless steel, glycerine

dampened pressure gauge• Note: The HARDI Self-Cleaning filter or a 15

bar safety valve must also be fitted

EVC with 3 section · · · · · · · · · · · · · · · · · · · · ·EVC with 5 section · · · · · · · · · · · · · · · · · · · · ·Inlet: 1"Outlet: ¾"Bypass: 1"Pressure agitation: ½"Max. pressure: 15 barPressure gauge: Dual scale, 100 mm diameter

HM 1500 & HC 2500Genuine HARDI Controller for spraying. It measures and displays travel speed, applica-tion rate, total sprayed liquid, total treated area, etc. It is easy add-on to the HARDI EVC control unit. The transducers based on solid state elec-tronics. HM 1500 will monitor application rate and HC 2500 will control application rate.

Features:• Full integration with EVC control unit• Compact two line display with back-light• Simple four button control• Only one connection cable to control box

HM 1500 Monitor · · · · · · · · · · · · · · · · · · · · · ·HC 2500 Controller · · · · · · · · · · · · · · · · · · · · ·Transducer kit for EVC · · · · · · · · · · · · · · · · · · ·

Tractor mount kit, two pole · · · · · · · · · · · · · · ·

6

840167840169

72050000

842022

72173800

72173600741727

834281

Part no.

Component guide

Your Sprayer Specialist

Controllers & accessoriesHC 5500HARDI Controller for controlling spray applica-tion. The large four line display is very informative with both icons and text. It is easy add-on to the HARDI EVC control unit and can be used for GPS applications. HC 5500 can send data to a printer or a computer. The transducers based on solid state electronics.

Features:• Full integration with EVC control unit• Large four line display with back-light• Preset buttons for most used readouts• GPS compatible• Printer compatible• Only one connection cable to control box

HC 5500 Controller · · · · · · · · · · · · · · · · · · · · ·Transducer kit for EVC · · · · · · · · · · · · · · · · · · ·Tractor mount kit, three pole · · · · · · · · · · · · · ·

Pressure transducerSolid state transducer for digital readout of pres-sure. Pressure range is from 0 to 10 bar. Reliable signal technique based on amp readout and the kit caters for ½" and ¾" hose

Pressure transducer 0-10 bar · · · · · · · · · · · · ·

Pedal ON/OFF switchThe pedal remote switch is an option for the HC 5500. It allows the operator to operate the main ON/OFF via the foot switch.

Pedal ON/OFF for HC 5500 · · · · · · · · · · · · · ·

PrinterThe printer is an option for the HC 5500 and permits hard copies of stored data.

Printer · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·Printer paper (2 roll) · · · · · · · · · · · · · · · · · · · ·

DroplegsDROP NOZZLESnap-on drop-leg designed for spraying low dense crops up under the leaves. It has strong synthetic dropper tube with two nozzle holders. Suitable for 1553 series nozzles (nozzles not included).

Features:Easily adjusted nozzle anglesTube length is 60 cmSupplied with 40 cm feed hose with SNAP-FIT adapter and 3⁄8" capSnap Lock mounting bracket for boom

DROP NOZZLE Pack with 5 units · · · · · · · · · ·

7

927269927270

927021927032927124

927387009273880092738900927390009273910092739200

723328007233290072385300

818377835321835332843196

Part no.

Component guide

Your Sprayer Specialist

Hose reels and accessories

The HARDI hose reel range comes in 25 and 50 metre versions. There is a range of mounting brackets to suit your needs. See also section on spray guns.

Features:• Metallic construction• Synthetic bushes to ease winding• Quality braded hose in 3⁄8" or ½"• Working pressure up to 25 bar

Hose reel 25 m Complete with brackets and S60 spray gunFor MASTER PRO · · · · · · · · · · · · · · · · · · · · · ·For MASTER MB & NK · · · · · · · · · · · · · · · · · ·For MASTER HAL · · · · · · · · · · · · · · · · · · · · · ·

Hose reel 50 m Hose reel · · · · · · · · · · · · · · · · · · · · · · · · · · · ·50 m 3⁄8" hose · · · · · · · · · · · · · · · · · · · · · · · · ·50 m ½" hose · · · · · · · · · · · · · · · · · · · · · · · · ·Model S60 Spray gun · · · · · · · · · · · · · · · · · · ·

See also Spray guns

HARDI hose is suitable for working with pesti-cides. The hose is also available in rolls.

Features:• Reinforced fibre braid pressure hose• PVC or rubber material• For pressure hose, working pressure up to

25 bar • Spiral reinforced suction hose to prevent

collapse

Pressure hose, PVC, per metre½" Black · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·¾" Black · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Pressure hose, Rubber, per metre½" Black, BP 60 · · · · · · · · · · · · · · · · · · · · · · ·3⁄4" Black BP 60 · · · · · · · · · · · · · · · · · · · · · · ·1" Black BP 60 · · · · · · · · · · · · · · · · · · · · · · · ·

Suction hose, per metre 3⁄4" Black, BP 20 · · · · · · · · · · · · · · · · · · · · · · ·1" Black, BP 20 · · · · · · · · · · · · · · · · · · · · · · ·1¼" Black, BP 18 · · · · · · · · · · · · · · · · · · · · · ·1½" Black, BP 18 · · · · · · · · · · · · · · · · · · · · · ·2" Black, BP 18 · · · · · · · · · · · · · · · · · · · · · · ·2½" Black, BP 18 · · · · · · · · · · · · · · · · · · · · · ·

Hose

8

845205845206845207845208845209845210845218845219845220

845193

841481

Part no.

Component guide

Your Sprayer Specialist

FiltersIn-Line FilterThis bowl type filter is typically fitted to each boom line. It is easy to dismantle due to the radial sealing system making it quick to clean. It is available in different mesh sizes, the higher the number, the finer the mesh.

Features:• ½" or ¾" hose• Colour coded filter• 50 (Blue), 80 (Red) or 100 (Yellow) mesh

50 mesh for ½" hose · · · · · · · · · · · · · · · · · · · 80 mesh for ½" hose · · · · · · · · · · · · · · · · · · ·100 mesh for ½" hose · · · · · · · · · · · · · · · · · · · 50 mesh for ¾" hose · · · · · · · · · · · · · · · · · · · 80 mesh for ¾" hose · · · · · · · · · · · · · · · · · · ·100 mesh for ¾" hose · · · · · · · · · · · · · · · · · · · 50 mesh for ¾" BSP thread · · · · · · · · · · · · · 80 mesh for ¾" BSP thread · · · · · · · · · · · · ·100 mesh for ¾" BSP thread · · · · · · · · · · · · ·

Self-Cleaning FilterThe filter minimizes annoying downtime by con-tinually cleaning the filter screen. A by-pass system ensures the filter screen is always clean. The housing has a large screw top for easy maintenance and inspection. Seals are highly resistance to chemicals. A 15 bar safety valve is included.

Self-Cleaning filter, 80 mesh · · · · · · · · · · · · · ·

Floating FilterThe specially designed floating suction filter aspirates water 15 cm under the surface thereby avoiding mud and surface weeds. Only clean water is sucked into the tank. Hose tail is 1½".For trailed sprayers, 8 m of suction hose is standard and for lift it is 5 m.

Float Filter with 1½" hose tail · · · · · · · · · · · · · ·

9

726462726463726464726465727339

322106322107322108322109

726577726578726579726580

145994145995145996145997

726693726694726695727476

Part no.

Component guide

Your Sprayer Specialist

Fittings

Size group Hole saw size Hose tail sizeS40 40 mm 3⁄8" to ½"S53 53 mm ½" to 1"S67 67 mm 1" to 1½"S93 93 mm 1½" to 2½"

S seriesThe “S" series of modular components are pro-fessional fittings for liquid systems. Assembly and disassembly is quick and easy: Simply press in and secure with the “U" pin. The sealing quality is excellent due to the radial seal system. The wall flanges have a captive gasket to ease installation.

Features:• Quick to assemble• Excellent seal quality due to radial system• O-ring seals are made of highly chemical

resistant material• No messy gluing or thread tape• Easy to expand with many combinations• Flexibility orientation• High flow capacity (minimal internal restric-

tions)• Easy to pull apart and re-usable• Working pressure up to 15 bar• Chemical and UV resistant materials (rein-

forced nylon)

Tank flange bulkhead with gasketS40 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 single side · · · · · · · · · · · · · · · · · · · · · · · ·

Flange nutS40 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

PlugS40 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Retaining “U" pinS40 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Threaded reducerS40 1⁄8" female · · · · · · · · · · · · · · · · · · · · · · · ·S53 ½" female · · · · · · · · · · · · · · · · · · · · · · · ·S67 1" female · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2" female · · · · · · · · · · · · · · · · · · · · · · · · ·

10

726554726556726558726559726560726561726562

72041500726563726564

726566726567726568726570726571726572726573726574726575726576

72072800

731384727223728523727227

72072700727133

731385727224728395727225727226

72072900

322352322224334545

72114300728526728525

728561728562728527

Part no.

Component guide

Your Sprayer Specialist

Tail straight for pressure hose

S40 3⁄8" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 ½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 ¾"" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 1" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1¼" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 1½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Tail elbow 90 degree for pressure hoseS40 3⁄8" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S40 ½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 ½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 ¾" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S53 1" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1¼" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2½" with 45 degree · · · · · · · · · · · · · · · · ·

Tail straight for suction hoseS67 1¼" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 1½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2" with 45 degree · · · · · · · · · · · · · · · · · ·S93 2½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Tail elbow 90 degree for suction hoseS67 1¼" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 1½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 1½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2" · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2½" · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 2½" with 45 degree · · · · · · · · · · · · · · · · ·

Manifold TeeS53 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Manifold joinerS53 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S67 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·S93 · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

Manifold reducer S67 - S53 male/female · · · · · · · · · · · · · · · · · ·S93 – S67 male/female · · · · · · · · · · · · · · · · · ·S93 – S67 male/male · · · · · · · · · · · · · · · · · · ·

Fittings

11

8274337200030072000400

8181187200030072000400

Part no.

Component guide

Your Sprayer Specialist

Foam Marker ClassicPrecision in application is increased with the marker, especially when working on bare ground. This equipment is suitable for widths up to 18 metre and all necessary hoses and fittings are included. A 12 Volt compressor in the red control box sends air to the foam solution tanks to gen-erate the foam. The foam comes out as white blobs at the dropper units.The HARDI Foam Concentrate is non-toxic and is recommended for the HARDI Foam Markers.

Features:• Suitable for up to 18 m width• Two 15 litre tanks to contain up to 12 litres of

foam solution• Foam blob distance can be adjusted• Each foam outlet can be turned on or off• Supplied air tubes are 9 m long

Foam Marker Classic · · · · · · · · · · · · · · · · · · ·HARDI Foam concentrate, 1 l · · · · · · · · · · · · ·HARDI Foam concentrate, 12 x 1 l · · · · · · · · ·

Electric Remote Foam MarkerIncreased operator comfort with widths up to 28 metre is achieved with this equipment. Foam rate as well as on off function is done from the compact control box inside the tractor cabin. The high volume 12 Volt compressor is placed on the sprayer.

Features:• Suitable for up to 28 m width• Two 15 litre tanks to contain up to 12 litres of

foam solution• Remote control of foam blob distance and

ON/OFF function• 8 m heavy duty power supply cable standard• 10.5 m cable for control box standard

Electric Remote Foam Marker · · · · · · · · · · · · ·HARDI Foam concentrate, 1 l · · · · · · · · · · · · ·HARDI Foam concentrate, 12 x 1 l · · · · · · · · ·

Foam Markers

12

834376834375833348

7259570072596300

84168972576200

841481833767

Part no.

Component guide

Your Sprayer Specialist

Flush Nozzle

Liquid mixing & transfer equipment

Tank Flushing NozzleA simple and effective method to flush tanks. The rotating nozzle inside the tank flushes the tank surface with a minimal amount of water. A pressure of 4 to 5 bar is optimum for flushing.

Features:One nozzle for lift-mounted sprayers Two nozzles trailed sprayers Fittings for the rear nozzle on trailed permits easy installation and removal

One nozzle · · · · · · · · · · · · · · · · · · · · · · · · · · ·Two nozzle · · · · · · · · · · · · · · · · · · · · · · · · · · ·One nozzle with 80 litre flush tank · · · · · · · · · ·

TurboFillerA high capacity venturi system for transferring all types of crop protection chemicals be it liquids, powders or granules to the tank. It consists of a hopper with lid, valve set and cleaning pipe.

Features:Cleaning pipe to wash remaining chemicalOne metre hose on cleaning pipeWhen used, it can be lowered to a natural work-ing heightAvailable in 25 and 35 litre versionsRotating nozzle with spike for container rinsing

TurboFiller 25 for 1303 pump · · · · · · · · · · · · ·TurboFiller 35 for 363 pump · · · · · · · · · · · · · ·

Filling DeviceThe equipment utilizes the pump to transfer the liquid. Two optional suction filters are available. The floating suction filter aspirates water 15 cm under the surface thereby avoiding mud and surface weeds. Only clean water is sucked into the tank.Hose holder is optional.

Features:5 m of 1½" suction hose standard3-way valve

Filling Device for 503/603/1203/1303 pump · ·1½" line filter, 30 mesh · · · · · · · · · · · · · · · · · ·Floating suction filter for filling from stream · · ·Hose holder · · · · · · · · · · · · · · · · · · · · · · · · · ·

13

Component guide

Your Sprayer Specialist

Nozzles

HARDI ISO F-110 Features: • Standard all-round Flat Fan nozzle• Superior distribution under ideal conditions• From Fine to Very Course spray quality• Recommended for HARDI TWIN sprayers• Recommended from 1.5 to 5.0 bar• Nozzle to target distance; 50 cm (min. 35 cm, max. 70 cm)• 110° spray angle with elliptical pattern• Made from high quality long life SYNTAL thermoplastic• ISO standards (colour-code etc.)• Available as ISO nozzle or ISO SNAP-FIT

HARDI ISO LD-110 Features:• LowDrift flat fan nozzle• Reduces drift• From Medium to Course spray quality• Easy to clean as the restrictor is removable• Recommended from 1.5 to 5.0 bar• Nozzle to target distance; 50 cm (min. 35 cm, max. 70 cm)• 110° spray angle with elliptical pattern• Made from high quality long life SYNTAL thermoplastic• ISO standards (colour-code etc.)• Available as ISO nozzle or ISO SNAP-FIT

HARDI ISO MD-110 Features:• MINIDRIFT flat fan air inclusion nozzle• Dramatically reduces drift• From Medium to Very Course spray quality• Easy to clean as the restrictor is removable• Recommended from 1.5 to 5.0 bar• Nozzle to target distance; 50 cm (min. 40 cm, max. 90 cm)• 110° spray angle with elliptical pattern• Made from high quality long life SYNTAL thermoplastic• ISO standards (colour-code etc.)• Available as ISO nozzle or ISO SNAP-FIT

HARDI ISO Q-110 Features:• QUINTASTREAM nozzle for liquid fertiliser application• Patented proportional outputs from the five holes• Course spray quality• Easy to clean as the restrictor is removable• Recommended from 1.5 to 5.0 bar• Nozzle to target distance; 50 cm (min. 35 cm, max. 100 cm)• Directed outputs for uniform distribution• Made from high quality long life SYNTAL and ceramics• ISO standards (colour-code etc.)• Available as ISO nozzle or ISO SNAP-FIT

See Nozzle product guide for other types e.g.• Hollow cone nozzles• Adjustable nozzles• End nozzles• Off-centre nozzles• Reflex nozzles

See also www.hardi-nozzles.com

HARDI nozzles are precision components. They meet and often exceed stringent quality requirements and many are also rated for drift reduction. Some of the nozzles are also available in ceramic materials.

14

284270284277284831284830

Part no.

Component guide

Your Sprayer Specialist

F-110 COLOR TIP

1 371964 371764 371765 371766 371950 371767 371768 371769 371770 371771 371970 – 100 831358 833089 833091 833094 831352 833096 833098 833100 833102 833105 831360 – 500 831359 833090 833093 833095 831353 833097 833099 833101 833104 833106 831361 –

LD-110 COLOR TIP

1 – 371837 371838 371839 371958 371840 371841 371894 – – – – 100 – 833120 833122 833124 831356 833127 833129 831328 – – – – 500 – 833121 833123 833126 831357 833128 833130 831329 – – – –

MINIDRIFT COLOR TIP

1 – – 372121 372122 372123 372124 372125 372126 – – – – 100 – – 74188200 74188300 74188400 74188500 74188600 74188700 – – –

QUINTASTREAM COLOR TIP

1 – – 372011 372012 – 372013 372014 372015 372016 372017 372018 372019 100 – – 831373 831374 – 831375 831376 831377 831378 831379 831380 831381

F-110 COLOR TIP

1 371963 371706 371707 371708 371946 371709 371710 371711 371712 371713 371966 – 100 741754 741755 741756 74188800 74188900 74189000 74189100 74189200 741762 741763 741764 – 500 – – – 741757 741758 741759 741760 741761 – – – –

LD-110 COLOR TIP

1 – 371817 371818 371819 371957 371820 371821 371893 – – – – 100 – 74189300 74189400 74189500 74189600 74189700 74189800 74189900 – – – –

MINIDRIFT COLOR TIP

1 – – 372111 372112 372113 372114 372115 372116 – – – – 100 – – 74190000 74190100 74190200 74190300 74190400 74190500 – – – –

QUINTASTREAM COLOR TIP

1 – – 372002 372003 – 372004 372005 372006 372007 372008 372009 372010 100 – – 741765 741766 – 741767 741768 741769 741770 741771 741772 741773

INJET COLOR TIP

1 – 371926 371872 371873 371874 371875 371876 371927 371928 371929 – – 100 – 831347 833143 833144 833145 833146 833147 833148 831349 831350 – –

HARDI ISO reference number for nozzles Qty 0075 01 015 02 025 03 04 05 06 08 10 15

Pressure gauges

The HARDI quality range of easy to read pres-sure gauges come in 2 sizes.

Features:Easy to read with a split scaleDampened, glycerine filledCorrosion free stainless steel fittings

0-8/16 bar, ∅ 63 mm ¼" bottom fit · · · · · · · · ·0-100/200 PSI, ∅ 63 mm ¼" bottom fit · · · · · · · ·0-8/16 bar, ∅ 100 mm ¼" bottom fit · · · · · · · ·0-8/16 bar, ∅ 100 mm ¼" rear fit · · · · · · · · · ·

15

28050100

28084100

Part no.

Component guide

Your Sprayer Specialist

HARDI diaphragm pumps HARDI diaphragm pumps with their simple con-struction and robust design are a very reliable pump. Capacities range from 14 to 388 l/min and pressures up to 25 bar.

Features:Simple constructionDry sumpVery easy to maintain and serviceSelf-priming Can be run dryRotate clockwise/anti-clockwise without damageChoice of crankshaft type

12 Volt diaphragm pumpsFeatures:Eor intermittent duty applicationsSelf-primingCan run dryViton valves and Santoprene diaphragms

Model LF 14 · · · · · · · · · · · · · · · · · · · · · · · · · ·• For demand operation, switch included.• 2.3 l/min.• 2.8 bar max.• 3/8” hose barb inlet & outlet.• L x W x H=173 x 100 x 65 mm.

Model 3000-501 · · · · · · · · · · · · · · · · · · · · · · ·• 7.6 l/min.• 4.0 bar max.• 3/8” NPTF inlet & outlet.• Weight,1.5 kg / 3.3 lb.

Rear

Front

1. Model2. Stroke in millimetres3. Capacity in l/min at 0 bar and normal r/min4. Normal working r/min5. Maximum pressure in bar6. Crankshaft type: S for Spline, C for Conical, Y for Cylindrical7. Inlet/outlet in inches8. Notes

Example

1 2 3 4 5 6 7 8 1303 9.0 - 114 / 540 - 15 bar - C - 1¼" / 1" + notes

Pumps

16

821618

821026

821617

821616

Part no.

Component guide

Your Sprayer Specialist

General specifications• Compact single diaphragm positive displac-

ment pump.• Low power consumption. • Self-priming. • Can be run dry.• Can rotate clockwise or anticlockwise.• Single grease point for lubrication. • Dry sump to simplify maintenance.• No special tools needed for maintenance.• Polyurethane diaphragms and seals.• Cast iron crankcase and covers.• 3/4" suction port, 3/4" pressure port.• Recommended to use HARDI suction and

pressure dampers.

503/4.0-14/800-15bar-Y-3/4”/3/4” + base · · ·• Cylindrical shaft, 25 mm / 0.98".• For combustion and electric engine use.• Supplied with narrow base plate. • Normal operating revolutions, 800 r/min. • Maximum pressure, 15 bar / 220 PSI.• Maximum vacuum, 0.82 bar / 12.0 PSI.• Weight, 9.0 kg / 20 lb.

503/4.0-14/800-25bar-Y-3/4”/3/4” · · · · · · · · ·• Cylindrical shaft, 25 mm / 0.98". • For combustion and electric engine use.• Supplied with narrow base plate. • Normal operating revolutions, 800 r/min. • Maximum pressure, 25 bar / 367 PSI.• Maximum vacuum, 0.82 bar / 12.0 PSI.• Weight, 9.0 kg / 20 lb.

503/7.0-16/540-15bar-C-3/4”/3/4” + foot · · · ·• Tapered shaft. • For tractor use with HARDI transmission shaft.• Supplied with wide base plate. • Normal operating revolutions, 540 r/min. • Maximum pressure, 15 bar / 220 PSI.• Maximum vacuum, 0.9 bar / 13.2 PSI.• Weight, 9.2 kg / 20 lb.

503/7.0-16/540-15bar-C-3/4”/3/4” + coupling • Tapered shaft.• With 6-splined coupling for tractor P.T.O. shaft.• Normal operating revolutions, 540 r/min. • Maximum pressure, 15 bar / 220 PSI.• Maximum vacuum, 0.9 bar / 13.2 PSI.• Weight, 10.3 kg / 23 lb.

HARDI pump 503

17

Component guide

Your Sprayer Specialist

503/4.0

503/7.0