Gift Wrapping Curling Ribbon Shredder and Curler Tools,Ribbon Decorative Products

Partners in Steel Drum Manufacturing and Reconditioning ... · fl anger/curler, a bead expander, a...

Transcript of Partners in Steel Drum Manufacturing and Reconditioning ... · fl anger/curler, a bead expander, a...

www.merco-machines.com

Partners inSteel Drum Manufacturingand Reconditioning Equipment

Only high quality components from selected brands and suppliers are integrated in our products

About us

Founded in the late 70’s, Merco Machines designs and manufactures machines and entire production lines for both the production and reconditioning of steel drums up to 900 drums per hour.Having the main focus on customer satisfaction, un-compromising quality and a competitive total cost of ownership, Merco Machines already met the needs of customers all over the world, including Europe, North- and South-America, Asia, Australia and Africa.

Relying on the know-how and experience of highly skilled engineers and technicians, we are looking forward to be your partner for the custom design and manufacturing of a whole range of steel drum production and recondi-tioning equipment, including drum ends manufacturing, steel drum body-forming, horizontal and vertical seamers, leakage testers, painting and silk screen printing machines as well as end-of-line equipment. Also for being a one stop supplier for turnkey projects including decoiling, welding, ovenised paint curing and internal handling, or even when it comes to refurbishingor expanding existing production facilities, Merco Machines offers your company a tailor-made solution.

Controlled machine automation using custom-fi t HMI and SCADA interfaces guarantees functional reliability, short changeovers, effi cient and safe operation, and reduces breakdowns, downtime and maintenance costs. In order to meet the most demanding quality standards,only high quality components from selected brands and suppliers are integrated in our products.

The fi nal training of machine operators, fi ne-tuning and optimisation of our machines in the customer’s plant is part of our after sales service.Furthermore, in-house manufacturing of machine parts enables Merco Machines to quickly react to your company’s requirements for spare parts and allows Merco Machines to control, fi rsthand, the quality manufacturing of its products.In short, Merco Machines is committed to keep on satis-fying its customers’ specifi c needs all over the world.

Full support

Equipped with a comprehensive engineering department,2 production facilities totalising 8.000 m2 and a service department, Merco Machines offers your company a full support as from the early stages of designing, installing and commissioning until way beyond turnkey.

CanadaCanada

United States

Mexico

BrazilPeru

Chili

Argentina

MoroccoMorocco

PortugalPortugalPortugal SpainSpainSpain

France

U.K.U.K.Belgium

ItalyItaly

GermanyGermanyGermanyGermanyGermany

Greece

NorwayNorwayNorway

PolandPoland

NorwaySweden

NorwaySweden

NorwaySweden

NorwaySweden

NorwayFinlandFinland

GermanyAustriaAustria

EgyptEgypt

TunesiaTunesia

AlgeriMorocco

AlgeriMorocco

Algeria

Cote d’IvoireNigeriaNigeria

UgandaUganda

South-AfricaSouth-Africa

IndiaIndiaSaudi Arabia

TurkeyTurkeyTurkey

KuwaitKuwaitKuwait

IranIran

PakistanPakistan

Russia

China

ThailandThailandCambodjaCambodja

S.KoreaS.Korea

VietnamVietnamVietnamPhilippinesPhilippines

IndonesiaIndonesia

AustraliaAustralia

JapanJapan

New ZealandNew Zealand

JordanJordanKuwait

U.A.E.

Cambodja

MalaysiaMalaysiaMalaysiaMalaysia

Singapore

Madagascar

Finite Element Analysis Engineering department CAD-CAM designMeasuring dynamic responses

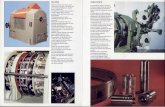

Drum Reconditioning Equipment

Merco Machines designs entire production plants according to the customers’ specifi c requirements, with respect to layout, functionality, desired output and integration into existing production facilities. As shown on the architecture below, a body expander, a fl anger/curler, a bead expander, a combined W-beader/corrugator and a shuttle conveyor are integrated into a single frame appliance.Note that the generalised use of frequency controllers and the latest servo drive systems has distinctive ad-vantages over implementing hydraulic based actuators: they allow faster production rates -up to 900 drums

Settings for a wide variety of product variants are saved inside modern touchscreen control panels, allowing automatic tool exchange and adjustments for fast and save changeover.

Merco Machines can equip your company with state-of-the-art machines for tight head and open head steel reconditioning. This includes chimers, curlers, inside and outside washing equipment, dedenters, fl angers, full length body expanders, body rollers, drum openers, pre-beaders, beaders, ...Also, a wide range of inside and outside painting machines, coating equipment, leakage testers and silk screen printing for steel drum reconditioning applica-tions is available.

Entire production plants

per hour-, are lighter and result in less load on the drive systems. Furthermore, they generate less heat and are more energy effi cient, reliable, easier to control allowingthe use of virtual axes and require less maintenance, thus improving effi ciency and reducing downtime.Smooth movements are generated by electronic cams and advanced positioning controls, drastically reducing shocks, vibration, wear and noise.Higher speeds and increased productivity can be obtained easily, thanks to a perfect and stable synchro-nisation between movements.

Servo Controlled Horizontal Corrugator

Conveyor Systems

Weld-end Flatter - Cutter

Body Silk Screen Printer

Non-stop Sheet Feeder Horizontal Drum Manufacturing Line

Robotic Bottom Feeder

End-of-line Equipment

Top Silk Screen Printer

Horizontal Seamer

Flange Insertion Pre-Curler & Pre-Compounder

Stacker Ends Painting

Drum End Manufacturing Equipment Drum End Manufacturing Equipment

Vertical Painting Machines

Merco Machines manufactures vertical painting machines for steel drums and pails with capacities ranging from 20 liters up to 230 liters and outputs up to 900 drums per hour. A wide range of tailor-made walking beam, indexed conveyor and open chain painting line confi gurations is available.

Walking Beam Painting Line

Indexed Conveyor Painting Line

Open Chain Painting Line

Vertical Seaming Line

ISO OH Neck-in

Vertical Body Forming Line with integrated ISO OH Neck-in

Vertical Body Forming Line

Nijverheidsweg 14B-9821 [email protected]@merco-machines.comt +32 9 210 40 10f +32 9 230 52 62VAT BE 0442 753 827

Merco Machines N.V.

www.merco-machines.com