Part B: Project Description - Alberta€¦ · Northern Lights Upgrader Project Part B September 29,...

Transcript of Part B: Project Description - Alberta€¦ · Northern Lights Upgrader Project Part B September 29,...

Northern Lights Upgrader Project

Part B: Project Description

Northern Lights Upgrader Project

Part B September 29, 2006 Page i

Table of Contents

Page TABLE OF CONTENTS..................................................................................................... i LIST OF TABLES.............................................................................................................. v LIST OF FIGURES............................................................................................................vi B PROJECT DESCRIPTION................................................................................1

B.1 Project Overview ...............................................................................................1 B.1.1 Upgrader................................................................................................4 B.1.2 Infrastructure, Utilities And Offsites .......................................................4 B.1.3 Site Selection.........................................................................................5

B.2 Need For And Purpose Of The Project .............................................................5 B.2.1 Need For The Project ............................................................................5 B.2.2 Benefits Of The Project..........................................................................6 B.2.3 Economic Viability..................................................................................7 B.2.4 Schedule And Timing.............................................................................8

B.3 Upgrading..........................................................................................................8 B.3.1 Overview................................................................................................8 B.3.2 Primary Upgrading.................................................................................8 B.3.3 Secondary Upgrading ..........................................................................12 B.3.4 Air Separation Unit...............................................................................14 B.3.5 Asphaltene Gasification And Hydrogen Purification ............................14 B.3.6 Sulphur Recovery Complex .................................................................15 B.3.7 Supporting Utility Systems...................................................................19 B.3.8 Upgrader Product ................................................................................19 B.3.9 Material And Energy Balances ............................................................20

B.4 Infrastructure ...................................................................................................20 B.4.1 Overview..............................................................................................20 B.4.2 Site Preparation ...................................................................................26

B.4.2.1 Demolition.......................................................................................27 B.4.2.2 Concrete Batch Plant......................................................................27

B.4.3 Transportation......................................................................................29 B.4.3.1 Roads .............................................................................................29

B.4.3.1.1 Construction Access .....................................................................29 B.4.3.1.2 Upgrading Of Access Roads And Intersections ............................29

B.4.3.2 Rail..................................................................................................31 B.4.4 Temporary Infrastructure Tie-Ins .........................................................36 B.4.5 Buildings ..............................................................................................36

B.4.5.1 Temporary Construction Management Buildings............................36 B.4.5.2 Administration And Maintenance Buildings ....................................36

Northern Lights Upgrader Project

Part B September 29, 2006 Page ii

B.4.5.3 Utilities Buildings.............................................................................38 B.4.5.4 Process Buildings ...........................................................................39

B.5 Utilities And Offsites ........................................................................................40 B.5.1 Overview..............................................................................................40 B.5.2 Water And Water Treatment................................................................44

B.5.2.1 Water Demand And Supply ............................................................44 B.5.2.1.1 Demand.........................................................................................44 B.5.2.1.2 Supply Sources.............................................................................45 B.5.2.1.3 Demand/Supply Summary ............................................................49 B.5.2.1.4 Raw Water (River) Intake And Pipeline System Description.........49 B.5.2.1.5 Raw Water Consumption ..............................................................51

B.5.2.2 Water Management And Treatment ...............................................52 B.5.2.3 Potable Water Supply And Distribution...........................................54 B.5.2.4 Boiler Feedwater/Condensate/Service Water Treatment ...............54

B.5.2.4.1 Service Water................................................................................54 B.5.2.4.2 Boiler Feedwater/Condensate.......................................................57 B.5.2.4.3 Chemical Feed..............................................................................57

B.5.2.5 Process Cooling Water And Cooling Tower ...................................58 B.5.2.5.1 Process Cooling Approach............................................................58

B.5.2.6 Ponds..............................................................................................60 B.5.2.7 Overall Water Balance....................................................................61

B.5.3 Wastewater..........................................................................................62 B.5.3.1 Domestic/Sanitary Wastewater Management.................................63 B.5.3.2 Industrial Wastewater Management And Treatment ......................65 B.5.3.3 Stormwater Management ...............................................................66

B.5.4 Fuel Gas Supply And Distribution........................................................67 B.5.4.1 Natural Gas Demand ......................................................................67 B.5.4.2 Natural Gas Supply And Distribution ..............................................68

B.5.5 Steam And Power Demand .................................................................71 B.5.6 Electric Power Supply And Distribution ...............................................74

B.5.6.1 High Voltage Substation And Grid Connection...............................74 B.5.6.2 Ac Power Distribution .....................................................................74 B.5.6.3 Dc Power Distribution .....................................................................75 B.5.6.4 Emergency Power Generation And Distribution .............................75 B.5.6.5 Lighting, Heat Tracing And Other Services ....................................77

B.5.7 Instrument And Control Systems .........................................................77 B.5.7.1 Integrated Control Systems ............................................................77 B.5.7.2 Local Controls And Instrumentation................................................78

B.5.8 Other Auxiliary Systems ......................................................................78 B.5.8.1 Compressed Air And Nitrogen Supply ............................................78 B.5.8.2 Product Tank Farm And Pipelines ..................................................79

Northern Lights Upgrader Project

Part B September 29, 2006 Page iii

B.5.8.3 Other Storage Tanks ......................................................................83 B.5.8.4 Fire Protection ................................................................................85 B.5.8.5 Flare Systems.................................................................................86

B.5.8.5.1 Low Pressure Hydrocarbon Flare .................................................86 B.5.8.5.2 High Pressure Hydrocarbon Flare.................................................87 B.5.8.5.3 Acid Gas Flare ..............................................................................87

B.5.8.6 Equipment Protection .....................................................................88 B.5.9 Utilities Major Equipment List ..............................................................89

B.6 Alternative Analysis .........................................................................................90 B.6.1 Gasification Vs. Delayed Coking .........................................................92 B.6.2 Gasification Vs. Steam Methane Reforming........................................93 B.6.3 Hydrogen Sales Vs. Cogeneration ......................................................93

B.7 Air Emission Management ..............................................................................95 B.7.1 Sulphur Dioxide ...................................................................................95 B.7.2 Nitrogen Oxides ...................................................................................95 B.7.3 Volatile Organic Compounds ...............................................................96 B.7.4 Particulate Matter.................................................................................97 B.7.5 Odours .................................................................................................97 B.7.6 Visible Emissions.................................................................................97 B.7.7 Air Quality Monitoring ..........................................................................98

B.8 Greenhouse Gas Emissions And Climate Change .........................................98 B.8.1 Introduction ..........................................................................................98 B.8.2 Greenhouse Gas Management Strategy .............................................98

B.8.2.1 Project Ghg Emissions .................................................................100 B.8.3 Climate Change .................................................................................103

B.8.3.1 Effects On The Project..................................................................105 B.9 Waste And Chemical Management...............................................................107

B.9.1 Waste Management Overview...........................................................107 B.9.2 Waste Streams ..................................................................................108 B.9.3 Waste Minimization............................................................................110

B.9.3.1 Pollution Prevention......................................................................111 B.9.3.2 Recycling Program .......................................................................111

B.9.4 Waste Storage And Disposal.............................................................112 B.9.4.1 Waste Streams .............................................................................112 B.9.4.2 Hazardous Waste Storage............................................................112

B.9.5 Chemical Management......................................................................113 B.10 Health, Safety And Environmental Management System And

Contingency Plans ........................................................................................118 B.10.1 Overview............................................................................................118 B.10.2 Hse Leadership And Accountability ...................................................118 B.10.3 Health, Safety And Environment Management System.....................119

Northern Lights Upgrader Project

Part B September 29, 2006 Page iv

B.10.4 Hse And Related Corporate Policies .................................................119 B.10.5 Planning.............................................................................................122

B.10.5.1 Corporate Hse Goals And Objectives...........................................122 B.10.5.2 Regulatory Requirements .............................................................123 B.10.5.3 Industry Practices And Corporate Expectations ...........................123

B.10.6 Implementation And Operations ........................................................123 B.10.6.1 Occupational Health And Safety...................................................124 B.10.6.2 Environmental Protection..............................................................125 B.10.6.3 Emergency Preparedness And Response....................................125 B.10.6.4 Asset Integrity Management .........................................................127 B.10.6.5 Stakeholder Involvement ..............................................................128 B.10.6.6 Worker Competence And Training ...............................................129 B.10.6.7 Contractor Management ...............................................................129

B.10.7 Monitoring And Review......................................................................130 B.10.7.1 Hse Meetings And Communications.............................................131 B.10.7.2 Incident Reporting And Follow-Up ................................................131 B.10.7.3 Compliance Audits And Inspections .............................................132 B.10.7.4 Performance Measuring, Monitoring And Reporting.....................132 B.10.7.5 Records Management ..................................................................133 B.10.7.6 Review And Improvement.............................................................133

B.10.8 Implementation Of Hse Management System ...................................134 B.11 Approach And Application Of Adaptive Management ...................................134

Northern Lights Upgrader Project

Part B September 29, 2006 Page v

List of Tables Page

Table B.3.2-1: Typical Asphaltene Characteristics .......................................................... 9 Table B.3.8-1: SCO Characteristics ............................................................................... 19 Table B.3.8-2: Upgrading By-Products .......................................................................... 20 Table B.4.5.2-1: List of Buildings and Sizes................................................................... 38 Table B.4.5.3-1: List of Utilities Buildings and Sizes ...................................................... 39 Table B.4.5.4-1: List of Process Unit Buildings and Sizes ............................................. 40 Table B.5.2.1.2-1: Comparison of Project Water Sources ............................................. 48 Table B.5.2.6-1: Pond Inventory .................................................................................... 60 Table B.5.2.7-1: Overall Water Balance......................................................................... 61 Table B.5.4.1-1: Natural Gas Requirements .................................................................. 68 Table B.5.4.2-1: Project Natural Gas Characteristics .................................................... 69 Table B.5.5-1: Project Steam Demand- High Pressure Steam...................................... 71 Table B.5.5-2: Project Electric Power Demand.............................................................. 72 Table B.5.8.2-1: Process Storage Tank Summary......................................................... 80 Table B.5.8.2-1: Process Storage Tank Summary (Continued)..................................... 81 Table B.5.8.3-1: Storage Tanks ..................................................................................... 83 Table B.5.8.5.3-1: Flare Summary ................................................................................. 88 Table B.5.8.6-1: Utility Housing Summary ..................................................................... 88 Table B.5.9-1: Utilities Major Equipment........................................................................ 90 Table B.6.3-1 Comparison of Key Air Quality Parameters – Power Generation vs.

Maximum Hydrogen Generation.............................................................. 94 Table B.8.2.1-1: Expected GHG Emissions for Construction Phase ........................... 100 Table B.8.2.1-2: Expected GHG Emissions for Operations Phase .............................. 101 Table B.8.2.1-3: Expected GHG Emissions for Decommissioning Phase ................... 101 Table B.8.2.1-4: Expected Total Greenhouse Gas Emissions..................................... 102 Table B.8.2.1-5: Project Contribution to Total Provincial and National GHG Emissions102 Table B.8.2.1-6: Comparison of GHG Emissions with Other Upgrader Projects ......... 103 Table B.8.3-1: Climate Change Scenarios for Edmonton 2050s (2040-2069)............. 105 Table B.9.2-1: Waste Management Summary ............................................................. 108 Table B.9.5-1: Chemical Product Consumption ........................................................... 116

Northern Lights Upgrader Project

Part B September 29, 2006 Page vi

List of Figures Page

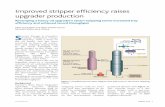

Figure B.1-1: Map of Project Area.................................................................................... 2 Figure B.1-2: Aerial Photo of Project Area ....................................................................... 3 Figure B.3.2-1: Primary Upgrading Process Schematic................................................. 10 Figure B.3.2-2: Solvent Deasphalting Process Schematic............................................. 11 Figure B.3.3-1: Hydroprocessing Unit Schematic .......................................................... 13 Figure B.3.5-1: Gasification and Hydrogen Purification Process Schematic ................. 17 Figure B.3.6-1: Sulphur Recovery Complex................................................................... 18 Figure B.3.9-1: Overall Block Flow Diagram.................................................................. 21 Figure B.3.9-2: Process Streams Balance..................................................................... 22 Figure B.3.9-3: Sulphur Balance.................................................................................... 23 Figure B.3.9-4: Energy Balance..................................................................................... 24 Figure B.4.1-1: General Arrangement – Plant Area Site Plan........................................ 25 Figure B.4.2.1-1: Existing Pipelines and Re-Routing Plan............................................. 28 Figure B.4.3.1.1-1: Temporary Facilities – Site Plan...................................................... 30 Figure B.4.3.1.2-1: Transportation Highway 38 and Highway 643 Access Plan............ 32 Figure B.4.3.1.2-2: Highway 38 Intersection Treatment Plan ........................................ 33 Figure B.4.3.1.2-3: Highway 643 Intersection Treatment 4 Lane Alternate Plan ........... 34 Figure B.4.3.2-1: Transportation Rail Yard Plan ............................................................ 35 Figure B.5.1-1: Project Utilities Interfaces...................................................................... 42 Figure B.5.2.1.1-1: Overall Water Supply Block Flow Diagram ..................................... 46 Figure B.5.2.1.1-2: Water Balance (Gross) Block Flow Diagram................................... 47 Figure B.5.2.1.3-1: River Water Intake and Supply Schematic...................................... 50 Figure B.5.2.1.5-1: Raw and Fire Water Supply Schematic........................................... 55 Figure B.5.2.2-1: Recycle Water Supply Schematic ...................................................... 56 Figure B.5.2.4.2-1: Boiler Feedwater Pre-Treatment/Treatment Schematic.................. 59 Figure B.5.3-1: Industrial, Storm and Domestic Wastewater Schematic ....................... 64 Figure B.5.4.2-1: Natural Gas Supply Schematic .......................................................... 70 Figure B.5.5-1: Steam Distribution Schematic ............................................................... 73 Figure B.5.6.1-1: Power Distribution Schematic ............................................................ 76 Figure B.5.8.2-1: Product Tank Farm Schematic........................................................... 82 Figure B.9.4.2-1: Buildings – Waste Management Facility Hazardous Materials and

Special Waste Building Plan, Section, Elevation ............................. 115 Figure B.10.3-1: Synenco HSE Management System Elements ................................. 120 Figure B.10.3-2: HSE Management Plan Summary .................................................... 121

Northern Lights Upgrader Project

Part B September 29, 2006 Page 1

B PROJECT DESCRIPTION

B.1 Project Overview

The Northern Lights Upgrader Project (the Project) will upgrade bitumen from Alberta’s oil sands into a higher quality, more valuable, synthetic crude oil (SCO) for market. The Project is a complementary project to the Northern Lights Mining and Extraction Project located northeast of Fort McMurray (for which a separate regulatory application was submitted on June 29, 2006). The Project will receive diluted bitumen from the Mining and Extraction Project and produce nominally 15,900 cubic metres per calendar day (m3/d) (100,000 barrels per day (bpd)) of high quality SCO.

The Project will be located in Sturgeon County, approximately nine kilometres (km) southeast of the Town of Redwater and about 45 km northeast of the City of Edmonton, Alberta. The legal land description is Township 56, Range 21, West of the 4th Meridian. The Project is bounded by Highway 38 on the north, Highway 643 on the west and the North Saskatchewan River (the NSR) on the south, as shown in Figure B.1-1. An aerial photo of the area is presented in Figure B.1-2.

The Project will comprise primary and secondary upgrading of low value, high molecular weight bitumen into higher value, lower molecular weight SCO. By-products that will be produced by the Project are butane, hydrogen, nitrogen, gasifier slag, elemental sulphur and carbon dioxide. A more detailed description of the Project’s upgrading process, infrastructure, utilities and offsites is presented in the following sections.

643

38

38

Nort

h S

ask

atc

hew

an Riv

er

5 46

3231

30

33

2928

Ma

p D

ocu

me

nt:

(C

:\D

ocu

me

nts

an

d S

ett

ing

s\P

ete

r\M

y D

ocu

me

nts

\Me

rid

ian

\06

-01

0 S

yn

en

co

\Ap

plic

atio

n\F

ig D

.6.3

.1 P

DA

.mxd

) 8

/17

/20

06

--

10

:25

:26

AM

Legend

Principal Development Area

Project Lands

Hydrography

Highway - Paved 2L

Road - Gravel

Road - Unimproved

0 400 800200

Meters

Tp. 56 Rg. 21 W4M

Mapof

Project Area

PREPARED BY

DATE

DRAWN CHECKED

PROJECT

SCALE

FIGURE No.

Millennium EMS Solutions Ltd.

08/17/2006 06-010

PS RB

B.1-1

[

Areaof

Detail

TITLE

5 46

3231

30

33

2928

Ma

p D

ocu

me

nt:

(C

:\D

ocu

me

nts

an

d S

ett

ing

s\P

ete

r\M

y D

ocu

me

nts

\Me

rid

ian

\06

-01

0 S

yn

en

co

\Ap

plic

atio

n\F

ig D

.6.3

.1 P

DA

.mxd

) 8

/17

/20

06

--

10

:25

:26

AM

Principal Development Area

Project Lands

0 400 800200

Meters

Tp. 56 Rg. 21 W4M

Aerial Photoof

Project Area

PREPARED BY

DATE

DRAWN CHECKED

PROJECT

SCALE

FIGURE No.

Millennium EMS Solutions Ltd.

08/17/2006 06-010

PS RB

B.1-2

[

Areaof

Detail

TITLE LEGEND

Northern Lights Upgrader Project

Part B September 29, 2006 Page 4

B.1.1 Upgrader

The Project will employ a Primary Upgrading stage to separate the fraction found in the bitumen which is not desired for the SCO product, and a secondary upgrading stage to process the desirable oil fractions into a SCO product.

In the Primary Upgrading stage, a Diluent Recovery Unit (DRU), a Vacuum Distillation Unit (VDU) and a Solvent Deasphalting Unit (SDA) Unit will perform the physical separation of the various fractions of the bitumen. The diluent added to the bitumen during the extraction process to make it less viscous for pipeline transmission will be removed by distillation in the DRU and recycled to the extraction plant (which is part of the Northern Lights Mining and Extraction Project described in a separate Application dated June 29, 2006). The gas oils, removed from the bitumen in the DRU and VDU, and Deasphalted Oil (DAO) from the SDA Unit will be sent to the Hydroprocessing Unit (HU) for further processing. The heavier hydrocarbon compounds (vacuum bottoms) from the VDU will be sent to the SDA Unit for the removal of the asphaltene fraction.

The secondary upgrading stage will be a fixed-bed HU that combines demetalization, hydrotreating and hydrocracking of the deasphalted bitumen. Catalytic processes will be used to remove the heavy metals, sulphur and nitrogen from the deasphalted bitumen. Heavier weight hydrocarbon compounds will be converted to lower molecular weight hydrocarbons in the hydrocracking section.

The Project will include a gasification unit to produce synthetic gas (syngas) from asphaltenes, from which hydrogen will be extracted for use in the HU. This will eliminate the need for natural gas as a source of hydrogen and may reduce the Project’s import of power.

B.1.2 Infrastructure, Utilities and Offsites

The Project will be connected to external utilities and related infrastructure existing at the site boundary or offsite within Sturgeon County. These connections include natural gas supply, potable water supply, North Saskatchewan River water supply, sanitary wastewater discharge, and product pipeline, high voltage electric power line, and telecommunications interfaces. Transportation system interfaces include the site access from Highways 38 and 643 and extension of a local railroad system onto the site. Product pipelines will transport diluted bitumen and diluent from/to the Upstream Mining and Extraction Plant, and SCO to market. Other product pipelines will transport gases and liquids to industrial customers.

Northern Lights Upgrader Project

Part B September 29, 2006 Page 5

B.1.3 Site Selection

Alternative locations for the Project were considered by the NLP. Initially, the NLP envisioned an integrated mining, production and bitumen upgrading operation all on the NLP’s Northern Lights Mining and Extraction Project site, north of Fort McMurray. However, due to the significant activity in that area, the NLP considered it appropriate to contemplate other locations for the Project. In terms of connection to existing infrastructure such as power transmission and oil pipelines, and the potential for synergies with other industries (by-product sales, etc.), it was determined that the preferred location for the Project was within the Alberta Industrial Heartland (AIH). Overall, the advantages for locating within the AIH are many and include:

access to market and other infrastructure; synergies with other local industries (availability of feedstock); economics; capacity of local communities to support additional development; labour force availability; and industrial land availability.

During the first seven months of 2005, several potential sites in the AIH, principally in Strathcona and Sturgeon Counties, were investigated for their technical, commercial and economic suitability to become the Project site. High on the list of desired characteristics was a site’s ability to handle the physical needs of the Project. In August 2005, it appeared that land owned, or under option, by Sturgeon County would be the most suitable site. In the period from August through December 2005, Synenco optioned or acquired real property in Sturgeon County. In December 2005, the NLP formally decided to locate the Upgrader on the Sturgeon County site. Since that time, Synenco has continued to pursue the acquisition of various parcels of real property.

B.2 Need for and Purpose of the Project

B.2.1 Need for the Project

Alberta’s oil sands deposits represent one of the world’s greatest concentrations of crude oil and a secure source of energy to meet rising global consumption. These oil sands contain an estimated 175 billion barrels of reserves deemed economically recoverable with today’s technology, placing Canada second only to Saudi Arabia in terms of proven oil reserves.

Industry projections indicate a need for additional oil production to fill the growing gap between global oil demand and the ability of conventional production to satisfy that need.

Northern Lights Upgrader Project

Part B September 29, 2006 Page 6

The situation of rising demand and growing constraints on conventional production has resulted in higher projections for future world oil prices. Over the decades, significant technological improvements have been made in bitumen production and upgrading, resulting in an economic alternative for meeting growing demand for crude oil. The Northern Lights Upgrader Project will provide enhanced upgrading capacity and result in more Alberta oil sands products for world energy markets.

The Project will be developed as an upgrading complex for diluted bitumen transported by pipeline from the Northern Lights Mining and Extraction Project northeast of Fort McMurray. On December 31, 2005, Norwest Corporation, an independent geological consulting firm, issued a report on the bitumen resources contained on the NLP's lands. Based on cumulative drilling data to date and standard reporting requirements, the Norwest report identified best, low and high estimates for the NLP’s bitumen resource base. The best estimate is 1.49 billion barrels of discovered, in-place, bitumen resources, with the low and high estimates being 836 million and 2.38 billion barrels, respectively.

The Upgrader design also provides the option to receive and process third-party bitumen. Bitumen supply from the Northern Lights Mining and Extraction Project is sufficient to supply the bitumen for the Upgrader and support the planned production capacity of 100,000 bpd of high quality SCO from the Upgrader for 30 years.

The Project will add value to Alberta’s bitumen and heavy oil resources by providing the upgrading capacity to produce high quality SCO for downstream refineries to convert into end products. An added benefit of the high quality SCO is greater access to North American refineries.

B.2.2 Benefits of the Project

The Project will result in significant long-term benefits for Albertans and the Alberta economy, including:

a construction workforce of about 2000 (with a peak of almost 3000), which will result in 12,260 direct person years of work;

up to 300 full-time staff personnel for Upgrader operation plus 100 full time contractor roles;

direct government revenues through corporate income taxes and property taxes, of about $4.3 billion dollars (2005 Canadian dollars) accruing to all levels of government over the life of the Project;

more upgrading capacity, which may assist in reducing current heavy oil price differentials, encouraging the further development of Alberta’s bitumen and

Northern Lights Upgrader Project

Part B September 29, 2006 Page 7

heavy oil resources, and which will also help North American refiners by providing useful feedstock for their operations; and

synergies with other industrial facilities in managing environmental and resource issues, including energy, water, air and materials, to achieve mutual enhanced environmental and economic performance.

B.2.3 Economic Viability

A variety of factors affect the economic viability of the Project, including capital cost, operating cost,taxes, technical performance, and commodity prices. Through careful and thorough economic analysis, the NLP believes the Project is economically viable. Thus, the NLP has invested significantly in the Upgrader’s design engineering, land acquisition, environmental impact assessment, and regulatory application. Project economics are based on West Texas Intermediate crude price of US$40 per barrel, future tax expectations and risk allowances that reflect current conditions.

Capital costs for the Project were last estimated to be $3.6 billion (2005 Canadian dollars).

Synthetic crude supply from Western Canada has the potential to more than double in the next five to ten years. However, the quality of current SCO supply may limit its market penetration as most refineries have limited processing capabilities to run significant quantities of SCO. The Upgrader design will allow the NLP to produce a range of SCOs (from approximately 45 API to 49 API) with a sulphur content of less than 0.002%, compared to most other SCOs which have a 34 API and a higher sulphur content. These favourable quality characteristics should enable more refineries to process SCO produced by the Upgrader, which is expected to result in a premium market price. The Project is able to achieve this higher quality product due to the hydroprocessing technology used and the availability of hydrogen from the gasification process.

Bitumen needs to be diluted to be transported by pipeline. The traditional diluent has been condensate, a by-product of natural gas production. With increasing production of bitumen, the demand for diluent is outpacing the supply of condensate. This results in a premium market price for condensate and a demand for diluent alternatives. The Upgrader’s high quality SCO provides a diluent alternative for bitumen producers. The quality of SCO that the NLP chooses to produce will likely vary, depending on the market price for diluent and SCO at the time.

Northern Lights Upgrader Project

Part B September 29, 2006 Page 8

B.2.4 Schedule and Timing

For the purposes of the Application, the Project is treated as a single 15,900 m3/d facility but the Project may be constructed in two stages with each stage producing 7,950 m3/d (50,000 bpd) of SCO. Construction is scheduled to begin in 2008, to achieve first stage production in 2010. Construction for the second stage is scheduled to commence in 2010, to achieve production in 2012. The staged construction of the Project is intended to levelize labour and material requirements, thus improving the ability to effectively manage the Project’s capital cost and schedule performance. However, it is possible that a decision will be made to construct the Project in a single 15,900 m3/d (100,000 bpd) stage during final engineering design. The Project is expected to be in operation for 30 years.

The schedule is dependent on timely regulatory approvals, sufficient engineering definition to reduce uncertainty, construction labour availability and equipment delivery schedules, owners’ business considerations, and owners’ approval to proceed.

B.3 Upgrading

B.3.1 Overview

The Project will use carbon rejection and hydrogen addition upgrading processes to produce a high quality SCO. The major process components of the Project are:

primary upgrading including diluent recovery, vacuum distillation and solvent deasphalting;

secondary upgrading using hydroprocessing; gasification and hydrogen production; sulphur recovery; and supporting utility systems.

B.3.2 Primary Upgrading

The purpose of primary upgrading is to separate out those fractions in the diluted bitumen feedstock which cannot be processed in the secondary upgrader. Diluted bitumen will be received by pipeline and fed to the distillation section, which will consist of a:

Diluent Recovery Unit; Vacuum Distillation Unit; and Solvent Deasphalting Unit.

Northern Lights Upgrader Project

Part B September 29, 2006 Page 9

The first step in the primary upgrading is the DRU, the purpose of which is to recover the diluent used in the extraction process at the mine site. The diluent will be recovered as an overhead stream, collected in product storage and recycled to the extraction plant (which is part of the Northern Lights Mining and Extraction Project described in a separate Application dated June 29, 2006) for reuse. The atmospheric gas oil (AGO) fraction will be recovered from the DRU and sent to the HU. The DRU bottoms stream will be fed to the VDU for further fractionation.

The VDU will recover vacuum gas oil (VGO) for further processing in the HU. Sour gases from the DRU and VDU overhead streams will be sent to a gas treating section for removal of hydrogen sulphide (H2S) so that the gas can be used as fuel. Any water condensed from the DRU and VDU overhead streams will be collected and sent to the Sour Water Stripper (SWS) for the removal of H2S. The gas free water is used within the Project. A schematic of the DRU and VDU is presented in Figure B.3.2-1.

The VDU bottoms stream will be sent to the SDA Unit which is also part of the Primary Upgrading section of the Project. The first stage in solvent deasphalting will consist of mixing the vacuum residue from the VDU with a butane/pentane solvent in a specially designed extractor vessel. A mixture of solvent/deasphalted oil will exit the extractor in the overhead stream and a mixture of solvent/asphaltenes will exit in the bottoms stream. The bottoms stream will be sent to the second-stage stripper for the separation of solvent and asphaltenes. The recovered solvent will be recycled to the extractor and the asphaltenes will be sent to the gasification unit for the production of hydrogen. The extractor overhead stream will be separated into solvent, which will be recycled to the extractor, and DAO, which will be sent to the HU.

Typical characteristics of the asphaltene stream are presented in Table B.3.2-1. A schematic of the SDA Unit is presented in Figure B.3.2-2.

Table B.3.2-1: Typical Asphaltene Characteristics

Characteristic Value Gravity (°API) -7 Sulphur (wt%) 8.20

Energy Content (MJ/kg HHV) 38.9

Primary Upgrading Process Schematic

OFFGAS TO TREATING

VACUUM COLUMN

SOUR WATER TO SWS

VACUUM RESID

OFFGAS TO TREATING

RECOVERED DILUENT TO H2S

REMOVAL

DILUENT RECOVERY UNIT

SOUR WATER TO SWS

AtmosphericHeater

PREHEAT EXCHANGER

DILUTED BITUMEN PREFLASH

COLUMN

RECOVERED DILUENT

AGO

VAC HEATER

LVGO

HVGO

CHECKEDDRAWN

FIGUREPROJECTDRAFT DATE

31 August2006

JHFigure B.3.2-1

06-010

SCALE

N/A

Millennium EMS Solutions Ltd.

DW

PREPARED BY

LEGENDTITLE

Atmospheric Column

VACUUM RESID

Solvent Deasphalting

Process Schematic

ASPHALTENE

Steam

ASPHALTENESEPARATOR

DAO SEPARATOR

Hot Oil

ASPHALTENESTRIPPER

Steam

DAOSTRIPPER

DEASPHALTED OIL

COOLER

GAS TO H2S ABSORBER

SOUR WATER

COOLER

SOLVENT

RECOVERED SOLVENT RECYCLE

MAKEUP SOLVENT

CHECKEDDRAWN

FIGUREPROJECTDRAFT DATE

31 August2006

JHFigure B.3.2-2

06-010

SCALE

N/A

Millennium EMS Solutions Ltd.

DW

PREPARED BY

LEGENDTITLE

Northern Lights Upgrader Project

Part B September 29, 2006 Page 12

B.3.3 Secondary Upgrading

Secondary upgrading of the primary upgrading products will take place in a HU, which converts AGO from the DRU, VGO from the VDU and DAO from the SDA Unit into high quality SCO.

Two identical hydroprocessing trains will be constructed. Each train will consist of a demetalization section and a hydrotreating/hydrocracking section. The demetalization and hydrotreating/hydrocracking sections will have high pressure high temperature reactors that contain fixed beds of catalyst. When the catalyst is spent, the units will be shut down and the catalyst replaced with fresh catalyst. The spent catalyst will be sent off site for disposal.

In addition to the removal of nickel and vanadium, the demetalization section also reduces the Conradson Carbon Residue (CCR) of the DAO. The pretreated DAO product is then processed in the hydrotreating/hydrocracking section together with the AGO and VGO. The hydrotreating section removes the sulphur, nitrogen, residual metals and CCR prior to hydrocracking in which the heavy hydrocarbon molecules are cracked to lighter molecules.

Product from the hydrotreating/hydrocracking reaction section will be cooled to separate hydrocarbon liquids and gases (primarily recycle hydrogen).

The hydrocarbon liquids will be further reduced in pressure and sent to a product stripper. The stripper bottoms product will become the primary SCO blending component. The stripper overhead stream will be routed to a Light Ends Recovery Unit for recovery of diluent, natural gas liquids and fuel gas.

Wash water and condensed stripping steam will be sent to the sour water collection system for further processing in the SWS.

The recycle hydrogen stream will be routed to an amine scrubber to remove hydrogen sulphide. The recycle hydrogen will be supplemented with fresh make-up as required for the HU operation. Rich amine containing dissolved H2S will be routed to the amine regeneration unit within the sulphur recovery complex for the recovery of H2S and returned as a lean solution for reuse. The flash gas from the low pressure section will be sent for hydrogen recovery.

A schematic of the HU is presented in Figure B.3.3-1.

HYDROPROCESSING UNIT

SCHEMATIC

INTEGRATED HYDROPROCESSING REACTOR SECTION

AGO FEED

HYDROGEN

HOT HIGH PRESSURE

SEPARATOR

HOT LOW PRESSURE

SEPARATOR

COLD LOW PRESSURE

SEPARATOR

FUEL GAS TO AMINE ABSORBER

LIGHT ENDS

STRIPPER

AMINE SCRUBBER

RECYCLE GAS COMPRESSOR

LEAN AMINE

RICH AMINE

COLD HIGH PRESSURE

SEPARATOR

RECYCLE WASH WATER

SOUR WATER TO SWS

VGO FEED

DAO FEED

SOUR WATER TO SWS

TO SCO PRODUCT BLEND

OFFGAS TO H2 RECOVERY

MAKEUP HYDROGEN FROM GASIFIER

Steam

CHECKEDDRAWN

FIGUREPROJECTDRAFT DATE

31 August2006

JHFigure B.3.3-1

06-010

SCALE

N/A

Millennium EMS Solutions Ltd.

DW

PREPARED BY

LEGENDTITLE

Northern Lights Upgrader Project

Part B September 29, 2006 Page 14

B.3.4 Air Separation Unit

A two-train cryogenic Air Separation Unit (ASU) will provide the oxygen required for the partial oxidation of the asphaltenes in the gasifier. Nitrogen produced from the ASU will be used as an inert gas for the entire complex, as a diluent in syngas, or for sale as a by-product. The ASU will use electrically driven compression and will require no other energy source. Cooling for the ASU will be provided from the cooling water system (described in Section B.5.2.5)

B.3.5 Asphaltene Gasification and Hydrogen Purification

The asphaltene gasification unit will comprise the gasifier, process water treating, sour high temperature (HT) CO shift, acid gas removal and hydrogen purification. The gasification section will produce all of the hydrogen required for the HU’s with the remainder available for sale. The asphaltene will be sourced from the SDA Unit; however, the gasifier is also capable of handling additional asphaltenes from third parties.

The asphaltenes will be fed to the gasifier with oxygen from the ASU for the partial oxidation of the asphaltenes into raw syngas(comprising CO, H2, CO2, H2S, COS). The raw syngas from the gasifier will be directed to the sour HT CO shift converter for the hydrolysis of COS to H2S and water and the conversion of CO and H2O to H2 and CO2. The shifted gas will feed the acid gas removal unit, where H2S and CO2 will be removed. The H2S and some of the CO2 will be sent to the Sulphur Recovery Complex, and the majority of the CO2 will be cleaned up so as to be suitable for off-site use (e.g., fertilizer or enhanced oil recovery) or venting. The hydrogen stream from the CO2 removal section will be directed to the Pressure Swing Adsorption (PSA) unit for the purification of the hydrogen stream (removal of CO, CO2, and CH4). The 99.9% pure hydrogen will then be sent to compression for the HU. The offgas from the PSA unit, containing light hydrocarbons plus some residual hydrogen will be used as fuel gas within the Project.

A fluxing agent will be added to the gasifier to ensure the production of an inert vitreous slag instead of a fine soot waste stream. The slag will flow from the bottom of the gasifier to a water quench section where it will be cooled and solidified. The slag will exit the quench chamber with some of the quench water. The slag and quench water will be separated, and most of the water will be recycled to the gasification process. Some quench water will be removed constantly from the gasifier water pretreatment circuit and sent as grey water to the IWT Plant for treatment and reuse (see Section B.5.3.2).

Slag from the gasifier is expected to have vitreous characteristics, as the high temperature of the process will be above the melting temperature of most of the minerals in the slag (fluxant and asphaltenes). Unmelted nickel and vanadium from the

Northern Lights Upgrader Project

Part B September 29, 2006 Page 15

asphaltenes will be encapsulated in the glass. Slag from comparable operating gasifier in the United States has consistently been determined to be non-hazardous under U.S. regulations (U.S. DOE 2000). The NLP will investigate the use of slag as a road building material, options that will add economic value to the Project, or will dispose of the material off site in an approved landfill.

A schematic of the gasification and hydrogen production process is presented in Figure B.3.5-1.

B.3.6 Sulphur Recovery Complex

The Sulphur Recovery Complex will include processes for SWS, amine regeneration and sulphur recovery.

Primary and secondary SWS units will process water streams containing H2S, organic sulphur compounds, ammonia and other contaminants. The primary SWS will treat sour water from the various Upgrader process units exclusive of the HU. Sour water from the HU will be collected and processed in a dedicated Secondary SWS to provide recycle wash water of adequate quality for the HU. Operation of the primary and secondary SWS units will be similar and the following description applies to both.

Sour water streams will be collected and combined into a flash drum that will also skim liquid hydrocarbons that will be routed to a recovered oil system. Sour water from the flash drum will flow to a feed surge tank and then to the SWS column. H2S and NH3 will be removed from the sour water using a stripper with a steam-heated reboiler. The reboiler will provide the necessary heat to generate vapour up the column to strip the H2S and NH3 from the sour water flowing down the column. Overhead vapours from the Primary and Secondary SWS will be combined and routed to the Sulphur Recovery Unit (SRU) as feed. A portion of the Secondary SWS stripped water will be recycled to the HU as wash water. The stripped water from the Primary SWS and the portion not recycled from the Secondary SWS to the HU will be sent to the gasifier water circuit.

Rich amine solution from the fuel gas conditioning plant and the HU will be sent to the amine regeneration system for removal of acid gas components. The Amine Regenerator will be a stripper column with a steam-heated reboiler. Rich amine solutions will be fed to the column; the acid gases will be stripped to the overhead product and routed to the SRU. The stripped lean amine from the bottom of the Amine Regenerator will be filtered and recycled to the amine absorber towers located in the upgrading process units.

Northern Lights Upgrader Project

Part B September 29, 2006 Page 16

The SRU will process acid gas streams from the Acid Gas Recovery unit in the gasifier block, the SWS and the Amine Regenerator. For reliability, the plant will use two parallel sulphur recovery trains and a common tail gas thermal oxidizer. The design capacity of the SRU will be 1,300 tonnes per day (tpd) with a stream day throughput of 1,177 tpd of sulphur.

Each sulphur recovery train will consist of a thermal stage followed by a catalytic reactor stage to convert a minimum of 98.8 percent of the feed sulphur to elemental sulphur. The unrecovered sulphur compounds will be oxidized to SO2 in the Thermal Oxidation Unit (TOU) and discharged to a stack.

Two sulphur recovery trains are planned. Each train will process 50 percent of the acid gas throughput under normal operating conditions. The sulphur in the vapours from the catalyst furnace and the catalyst beds will be condensed and flow through seal legs to the sulphur pits. One sulphur pit for each train is planned. The vapour from the last stage will then be routed to the TOU.

During upset conditions or maintenance events, it may be necessary to operate only one sulphur train. In this reduced throughput scenario, the combustion air will be enriched with high-purity oxygen. This will reduce the inert gas flow through the process resulting in increased capacity of the train.

Sulphur in the pit will be degassed and an ejector will sweep air across the headspace to capture sulphur-containing vapours. The sweep air stream will be routed to the TOU. Liquid sulphur in the pits will be transferred to heated storage tanks, prior to shipment for sale via railcars or trucks. Acid gas produced during emergency or upset conditions will be directed to an acid gas flare (see Section B.5.8.5).

A schematic of the Sulphur Recovery Complex is presented in Figure B.3.6-1.

AIR SEPARATION UNIT

GASIFIERS

QUENCH SECTION

GASIFICATION SECTION

ASPHALTENE

OXYGEN

WATER HANDLING

SYNGAS

QUENCH WATER

LOCKHOPPER

SLAG

SLAG SUMP TANK & DRAG CONVEYOR

SLAG FOR DISPOSAL

SOUR SHIFT UNIT

ACID GAS REMOVAL

HYDROGEN PURIFICATION

(PSA)

HYDROGEN TO UPGRADER

OFF GAS TOUPGRADER

ACID GAS TOUPGRADER SRU

AIR

Gasification and Hydrogen Purification

Process Schematic

BLACK WATER HANDLING&

RECYCLE

NITROGEN

CAPTURED CO2

EXCESS HYDROGEN FOR SALE

BLOWDOWN WATER PRETREATMENT

PRETREATED WATER TOUPGRADER WWT

Condensate Return

Makeup Water

BFW STEAMHCU

Off Gas

Fluxant

SCRUBBER

CHECKEDDRAWN

FIGUREPROJECTDRAFT DATE

31 August2006

JHFigure B.3.5-1

06-010

SCALE

N/A

Millennium EMS Solutions Ltd.

DW

PREPARED BY

LEGENDTITLE

Sulphur Recovery Complex

RICH AMINE FROM FUEL GAS SYSTEM

AMINE REGEN

SWS#1

SOUR WATER FROM UPGRADER

STRIPPED SOUR WATER TO GASIFIER

OR TREATMENT

SOUR WATER ACID GAS

RICH AMINE FROM HYDROPROCESSING UNIT

LEAN AMINE TO UNITS

SWS#2

SOUR WATER FROM HYDROPROCESSING UNIT

STRIPPED SOUR WATER TO HYDROPROCESSING

UNIT OR GASIFIER OR TREATMENT

AMINE ACID GAS

SOUR WATER ACID GAS

ACID GAS FROM GASIFIER

THERMAL OXIDIZER UNIT

SULPHUR DEGASSING

ACID GAS FEED

ACID GAS FEED

ACID GAS

TO STACK

TRUCK OR RAIL CAR LOADING

SULPHUR STORAGE

CHECKEDDRAWN

FIGUREPROJECTDRAFT DATE

31 August2006

JHFigure B.3.6-1

06-010

SCALE

N/A

Millennium EMS Solutions Ltd.

DW

PREPARED BY

LEGENDTITLE

SULPHUR DEGASSING

SULPHUR STORAGE

Sulphur Recovery Unit #2Incremental Conversion

Unit

Sulphur Recovery Unit #1Incremental Conversion

Unit

Northern Lights Upgrader Project

Part B September 29, 2006 Page 19

B.3.7 Supporting Utility Systems

The Project will require a number of supporting utility systems, including:

natural gas supply; electric power supply; raw and potable water supply; water treatment; wastewater treatment and reuse or disposal; cooling water supply; compressed (plant/service and instrument quality) air; stormwater collection and reuse or release; fire protection; flare; product tankage and pipelines; process buildings; and operation and maintenance buildings.

A detailed description of the supporting utility systems is provided in Section B.4 and Section B.5.

B.3.8 Upgrader Product

The primary purpose of the Project is to produce a high quality SCO, with properties as shown in Table B.3.8-1. In addition to this primary product, the Project will produce several materials for use internally in the upgrading process, including make-up bitumen diluent, make-up asphaltene solvent, hydrogen, electric power, steam, water for reuse, and fuel gas. In addition to the primary product of SCO, some by-products also will be produced and marketed to outside parties (Table B.3.8-2). Although the Project will have the ability to produce a SCO ranging from 45 API to 49 API, the engineering and technical information presented in this Application are based on a 49 API case.

Table B.3.8-1: SCO Characteristics

Parameter Value Product sulphur (ppm by weight) 20 Product density (°API) 49 Product yield (volume % on bitumen feed) 89.5%

Northern Lights Upgrader Project

Part B September 29, 2006 Page 20

Table B.3.8-2: Upgrading By-Products

By-Product Quantity Butane 859 m3/sd Hydrogen 5,580,000 m3/sd Liquid Sulphur 1,177 t/sd Slag (wet – 50% water)1 500 t/sd Carbon Dioxide 13,344 t/sd Nitrogen 16,995 t/sd

1: Maximum Design Slag 2: Make-up diluent of approximately 80 m3 /sd returned to Northern Lights Mining and Extraction Project

B.3.9 Material and Energy Balances

An overall block flow diagram of the upgrading process is presented in Figure B.3.9-1. A process stream balance is shown in Figure B.3.9-2. A sulphur balance is provided in Figure B.3.9-3. An energy balance is presented in Figure B.3.9-4.

B.4 Infrastructure

B.4.1 Overview

The layout and location of the proposed facilities are shown on Figures B.4.1-1. The Project site will include the upgrading process area, the utilities area, the tank farm, water ponds and the administration support area.

The site is bounded on the north by Highway 38 and on the west by Highway 643. Access to both of these highways is proposed. Sturgeon County is currently conducting a Transportation Master Plan (TMP) that will address road, rail, and pipeline access for the Heartland Industrial Area. The TMP will define potential changes to the roadway system in the area.

DiluentRecovery

Unit(DRU)

Sulphur 1,072 t/d

Deasphalted Oil (DAO)

Vacuum Gas Oil (VGO)

Atmospheric Gas Oil (AGO)Light End Recovery

Nitrogen

Diluent Return 7,778 m3/d (48,921 bpd)

Diluted Bitumen Feed

Diluent

VDU Feed

Oxygen

Slag

Sour Water

Sour Water

Sour Gas

LEGEND

CHECKEDDRAWN

FIGUREPROJECTDRAFT DATE18 September 2006

JHFigure B.3.9-1

TITLE

OVERALL BLOCK FLOW DIAGRAM 06-010

Gas Stream

Water Stream

VacuumDistillation

Unit(VDU)

Vacuum Bottoms

Solvent Deasphalting

Unit(SDA)

Hydroprocessing

Asphaltenes

Sour Water

Gasifiers

AirSeparation

Fuel Gas For Process Use

Butane773 m3/d(4,864 bpd)

Synthetic Crude Oil16,087 m3/dSulphur 0.25 t/d(101,187 bpd){Note 1}

Sour WaterStripping

AmineRegeneration

Acid Gas

Hydrogen

Hydrogen toHydroprocessing

CO2

Hydrogen to Sales

Acid Gas

Sulphur Recovery Unit

(SRU)

Sulphur 1,071.75 t/d

Sulphur1,058.9 t/d

SO2 to Atmosphere12.85 t/d of SulphurEquivalent

PREPARED BY

To ExtractionFacility

SCALE

N/A

17,982m3/d Bitumen (113,105 bpd) 7,706 m3/d Diluent ( 48,471 pbd)

25,688 m3/d Diluted Bitumen (161,576 bpd)

Fluxant

Acid Gas Removal CO2

(H2S & CO2)

Hydrogen Purification

Purge gas to Fuel

HydrocarbonLiquid Stream

Air

Acid Gas

Note 1:The nominal capacity of the facility is 15,900 m3/d (100,000 bpcd) butthe estimated production could reach 16,087 m3/d (101,187 bpcd) forthe same bitumen feed.

Note 2:All flowrates are in calendar days

Millennium EMS Solutions Ltd.

DW

SCALE 1:15000m

HSASKATCHEWAN

RIVER

ABANDONED

ABANDONED

ABANDONED

WELLHEADWELLHEAD

WELLHEAD

WELLHEAD

WELLHEAD

WELLHEAD

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH

OH OH OH OH OH OH OH OH

ABANDONED

UMA Engineering Ltd.PREPARED BY

1:15000

15 August 2006SCALE

DATE

F779PROJECT

PL BHCHECKED Figure B.4.1-1

FIGURE No.

DRAWN

F779

-005

-00_

70-G

-F00

2_R

X.D

WG

Has

sler

, Bra

dW

edne

sday

, Aug

ust 2

3, 2

006

4:40

:58

PM

General ArrangementPlant Area Site Plan

LEGENDTITLEArea

Detailof

Area

Northern Lights Upgrader Project

Part B September 29, 2006 Page 26

B.4.2 Site Preparation

The objective of site preparation will be a well-graded, self-draining site that will allow all-weather access for construction and ultimately operation and maintenance. Regional surface drainage will be directed around the planned development. Diversions will be constructed so that drainage will occur into the existing drainage courses away from the site, to waterbodies including the Redwater River and the NSR. Topsoil will be stripped and stockpiled for future use in reclamation activities. The NLP’s approach to topsoil handling and management is described in the conservation and reclamation plan, presented in Volume 2, Section E.5 Soils and Terrain and in Volume 3, CR #5 Soils and Terrain. Some of the topsoil will be stored in berms around the site on the north and west sides and some will be stored as shown on Figure B.4.1-1. The berms will also serve to attenuate noise and visual intrusion onto surrounding properties and be used as a landscape element to enhance the visual blending of the plant area into the surrounding environment.

Site grading will begin after the topsoil has been removed and stockpiled and the initial drainage ditches constructed. The stripped areas are to be graded at 2% towards the nearest construction-phase drainage ditch. Drainage ditches will be constructed for a design velocity of 0.9 metres per second (m/s) or less during a 1 in 25 year precipitation event. During site development, entry of overland flows from the surrounding catchment areas will be restricted by the existing roads around Sections 32 and 33. These flows will be collected in existing side ditches that run along the exterior roads.

Rainfall on the Project site during construction will be collected using a system of ditches that will carry the water by gravity to a sediment pond where it will be clarified by settling time prior to being discharged to the NSR. The sediment pond will be designed to allow the water collected in a 1 in 100 year storm event to be stored and released over a 24-hour period. Erosion protection will be installed at the pond outfall, and may include gabion baskets, geotextiles, culverts and stilling basins. The location of the sediment pond is shown on Figure B.4.1-1.

An erosion and sediment control plan will also be implemented during construction for all work areas, including the construction lay down areas. A spill control and countermeasures program will be implemented during construction and operation to ensure that hydrocarbons are properly managed and kept out of all water sources, storage ponds, and waterway flows, and that spills are detected early and addressed properly.

The recommended structural fill for the Project site is based on a 150 mm sub-grade and a California Bearing Ratio of >3 percent. On top of the subgrade, an additional 150 mm of 20 mm minus granular material will be placed and compacted to 98% Standard

Northern Lights Upgrader Project

Part B September 29, 2006 Page 27

Proctor Dry Density. Road grades are designed with additional crush and pit run gravel over the prepared subgrade. Internal roads will be designed for future asphalt paving.

A temporary lay down and storage area will be established in the northeast quarter of Section 32, adjacent to the temporary construction management and contractors’ offices. The lay down area will be approximately 158,000 m2 in area and will have a gravel surface. Temporary structures with concrete floors will be installed to protect certain components from the elements.

B.4.2.1 Demolition

There are existing facilities such as abandoned and operating oil wells, associated underground piping, and abandoned buildings on the property that will be removed as required prior to developing the site. In addition there is a 138 kVA powerline and an oil transmission pipeline that are to be relocated as part of the site development. The locations of the existing pipeline and transmission line are shown on Figure B.4.2.1-1. The powerline will be re-routed through the easement around the NLP property to the west and along the west border.

B.4.2.2 Concrete Batch Plant

Concrete will be one of the construction materials used during construction of the Upgrader. The location of the batch plant will be near the Project site to minimize the travel distances for transporting concrete. The equipment, silos and buildings will be provided by a concrete batch plant contractor. The contractor will be responsible for the transportation of cement, water, and aggregate. These materials will be trucked to the site on a demand basis as required by the contractor. Water supply will be arranged by the concrete batch plant contractor.

0SCALE 1:1000m

ABANDONED

ABANDONED

ABANDONED

WELLHEADWELLHEAD

WELLHEAD

WELLHEAD

WELLHEAD

WELLHEAD

OH

OH

OH

OH

OH

ABANDONEDOIL

OIL

OIL

OIL

OIL

OIL

GA

SG

AS

GA

S

GA

SG

AS

GAS GAS GASGAS

GAS

GAS

GAS

GAS

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

GA

SG

AS

GAS

GAS

GAS

Area

Detailof

Area

PREPARED BY

SCALE

DATE

F779PROJECT

CHECKED B.4.2.1-1

FIGURE No.

DRAWN

F779

-005

-00_

70-G

-F00

3_R

X.D

WG

Has

sler

, Bra

dTu

esda

y, A

ugus

t 22,

200

6 11

:09:

06 A

M

InfrastructureExisting Pipelines & Rerouting Plan UMA Engineering Ltd.

1:1000

15 August 2006

PL BH

LEGENDTITLE

Northern Lights Upgrader Project

Part B September 29, 2006 Page 29

B.4.3 Transportation

B.4.3.1 Roads

B.4.3.1.1 Construction Access

Temporary parking and bus marshalling facilities will be constructed on the northeast quarter of Section 32. The site will be near the Highway 38 access, adjacent to the temporary security gate. The area provided for the bus terminal and vehicle parking areas will be constructed with a gravel base. The layout of the temporary parking and bus marshalling areas is shown on Figure B.4.3.1.1-1.

Roads on the site will be required early in construction to provide access to the construction management offices, the contractor offices, temporary security gate and emergency medical facilities, the parking lots for buses and cars, and lay down and storage areas. The main access to the site will be off Highway 38. Gravel surface finished roads will be constructed to and within the site to access the various temporary facilities. Temporary access plans and parking facilities during construction are shown on Figure B.4.3.1.1-1.

B.4.3.1.2 Upgrading of Access Roads and Intersections

The need for and extent of upgrading the roadways and intersections to be used in accessing the Project site has been assessed based on a preliminary traffic impact assessment (TIA) completed for the site. Information regarding the TIA and predicted effects is presented in Volume 4, CR#12 Socio-Economic Impact Assessment and in Volume 4, CR#13 Traffic Impact Assessment.

Two access points are planned for the site, one off Highway 38 and one off Highway 643. The location of the access points is shown on Figure B.4.3.1.2-1. The main access point for construction and operations personnel will be from Highway 38. The proposed configuration of this access point (referred to as the North Access Road) is shown on Figure B.4.3.1.2-2. The secondary access which will be used for delivery vehicles and materials supply is to be located off Highway 643 (referred to as the West Access Road). The layout of this intersection is shown on Figure B.4.3.1.2-3.

SCALE 1:2500m

PREPARED BY

SCALE

DATE

F779PROJECT

CHECKED

FIGURE No.

DRAWN

F779

-005

-01_

71-C

-F00

1_R

X.D

WG

Has

sler

, Bra

dTu

esda

y, A

ugus

t 22,

200

6 11

:08:

13 A

M

Temporary Facilities Site Plan

B.4.3.1.1-1

UMA Engineering Ltd.

1:4000

15 August 2006

PL BH

LEGENDTITLEArea

Detailof

Area

Northern Lights Upgrader Project

Part B September 29, 2006 Page 31

Analysis completed for the TIA indicates that the intersection of Highway 38 and 643 will require upgrading with additional turning lanes as a result of increased traffic from the project and other developments in the area. The proposed new intersection layout is shown on Figure B.4.3.1.2-1. Turning lanes will also be required on Highway 38 at the North Access Road and on Highway 643 at the West Access Road. The proposed layouts of these intersections are shown on Figures B.4.3.1.2-2 and B.4.3.1.2-3. Currently the TIA analysis indicates that signals are not required at these intersections, however this could change depending on future development in the area.

The intersections and roadways will be designed to accommodate peak traffic based on the TIA and will meet standards and guidelines of Alberta Infrastructure and Transportation.

B.4.3.2 Rail

The Project site will be serviced by rail in addition to the vehicular traffic discussed in Section B.4.3.1. The rail yard will be used for shipping and receiving bulk commodities such as sulphur, flammable hydrocarbons, and wastes such as the gasifier slag. The rail yard will consist of:

one receiving track for arriving inbound traffic; one departure track for outbound traffic; one thoroughfare for internal switching access to the loading/unloading tracks

and for moving of the locomotives; one or two future receiving/departure tracks for use if future traffic warrants their

addition; and tracks for loading/unloading with three loading/unloading locations.

The location and layout of the rail facility is shown on Figure B.4.3.2-1.

CN’s rail carrier service provides for the pick up or drop off of cars to the receiving or departure tracks. Synenco will be responsible for moving cars from the loading/unloading tracks to and from the receiving/departure tracks with a yard engine or trackmobile.

SCALE 1:8000m

ABANDONED

ABANDONED

OH

GA

S

GA

SG

AS

GA

S

GAS GAS

GAS

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

GAS

GAS

GAS

GAS

PREPARED BY

SCALE

DATE

F779PROJECT

CHECKED

FIGURE No.

DRAWN

F779

-005

-03_

73-C

TF00

7_R

X.D

WG

Has

sler

, Bra

dTu

esda

y, A

ugus

t 22,

200

6 11

:13:

25 A

M

TransportationHighway 38 and Highway 643 Access

PlanB.4.3.1.2-1

UMA Engineering Ltd.

1:8000

15 August 2006

PL BH

LEGENDTITLEArea

Detailof

Area

SCALE 1:2500m

18R

PREPARED BY

SCALE

DATE

F779PROJECT

CHECKED

FIGURE No.

DRAWN

F779

-005

-03_

73-C

TF00

8_R

X.D

WG

Has

sler

, Bra

dTu

esda

y, A

ugus

t 22,

200

6 11

:12:

54 A

M

TransportationHighway 38 Intersection Treatment

PlanB.4.3.1.2-2

UMA Engineering Ltd.

N.T.S.

15 August 2006

PL BH

LEGENDTITLEArea

Detailof

Area

SCALE 1:2500m

PREPARED BY

SCALE

DATE

F779PROJECT

CHECKED

FIGURE No.

DRAWN

F779

-005

-03_

73-C

TF00

9_R

X.D

WG

Has

sler

, Bra

dTu

esda

y, A

ugus

t 22,

200

6 11

:12:

17 A

M

TransportationHwy 643 Intersection Treatment

4 Lane Alternate PlanB.4.3.1.2-3

UMA Engineering Ltd.

1:2500

15 August 2006

PL BH

LEGENDTITLEArea

Detailof

Area

SCALE 1:7500m

ABANDONED

OH

OH

GA

SG

AS

GA

SG

AS

GA

SG

AS

GAS

GASGAS

OIL

OIL

OIL

OILO

ILO

ILO

ILO

ILO

IL

OIL

OIL

OIL

GA

SG

AS

GA

S

GAS

GAS

PREPARED BY

SCALE

DATE

F779PROJECT

CHECKED

FIGURE No.

DRAWN

F779

-005

-03_

73-C

TF01

0_R

X.D

WG

Has

sler

, Bra

dW

edne

sday

, Aug

ust 2

3, 2

006

4:35

:30

PM

TransportationRail Yard Plan

B.4.3.2-1

UMA Engineering Ltd.

1:7500

15 August 2006

PL BH

LEGENDTITLEArea

Detailof

Area

Northern Lights Upgrader Project

Part B September 29, 2006 Page 36

B.4.4 Temporary Infrastructure Tie-ins

Temporary power will be required for construction activities, construction management offices, other temporary activities, and lighting of parking lots and other areas. This power may be obtained from Fortis Alberta, or provided via temporary on-site generation (diesel generators). Pad mount transformers will be installed at four locations throughout the site to distribute the construction-phase power and service the construction offices and the needs of the contractors.

During construction, potable water will be trucked from a nearby water treatment facility or obtained from the Capital Region Northeast Water Services Commission (CRNWSC) pipeline located near the site.

Temporary sewage collection tanks will be installed for the construction management offices and other temporary facilities during construction. Wastewater will be hauled from the collection tanks by truck to the nearest available wastewater treatment plant.

B.4.5 Buildings

B.4.5.1 Temporary Construction Management Buildings

Temporary construction management offices for Project personnel and contractors including engineers, surveyors and supervisors, will consist of trailer/skid-type offices installed near the temporary security gate, Fire Hall/Emergency Medical Services (EMS) building, and temporary lay down area. The management offices will initially accommodate 80 personnel but will allow for expansion to 320 personnel. At completion of the construction, the temporary facilities will be decommissioned and removed from the site.

B.4.5.2 Administration and Maintenance Buildings

The administration and maintenance buildings include the Administration Office Centre, Warehouse/Maintenance Building, Upgrader Operations Centre, Upgrader Maintenance Buildings, other warehouse type buildings, Fire Hall/EMS Building, and Security Gate and Booth. The Administration Office Centre will be occupied by Project site administration personnel, engineering and certain operations personnel, and will comprise a built-in-place, multi-story structure. The various functions of the Administration Office Centre will include:

visitors’ orientation and security area; first aid room; men’s and women’s locker rooms;

Northern Lights Upgrader Project

Part B September 29, 2006 Page 37

conference and training areas; laboratory with direct access to the exterior for sample receiving; mail room; and offices and workstations.

The Warehouse/Maintenance Building will be occupied by warehouse and maintenance personnel including supervisors and maintenance staff, and will include:

two maintenance bays with 25 tonne overhead cranes; shop bays for electrical/instrument repairs, welding, and machine repairs that will

be equipped with jib cranes; interior drive aisle; tool crib, warehouse and storage; warehouse storage with floor to ceiling pallet metal racking that will be accessed

by forklifts; other types of storage areas including floor storage, reel racks, cantilever racks

and a flammable storage area; lockers; offices; and shipping and receiving.

Other smaller and separate buildings will also have operations, maintenance, and storage functions. These are the Upgrader Maintenance Building, the Upgrader Operations Centre, Cold Storage Building, Hazardous Materials and Waste Management Building and the Bundle Wash Building. The Upgrader Operations Centre will house the main control room, electronics/telecommunications room, training room, lunch and lavatory facilities, files, and other facilities. The Bundle Wash Building is where heat exchange bundles will be periodically cleaned when the efficiency is reduced due to fouling.

The Hazardous Materials and Waste Management Building will house paint, painting materials, solvents, oils, and other materials and wastes that are considered flammable, combustible or hazardous. The building will provide suitable containment to prevent spills, will be equipped with automatic fire protection systems, and will be situated away from other Upgrader facilities for security and fire separation.

The functions of the Fire Hall/EMS Building will include:

EMS walk-in clinic;

Northern Lights Upgrader Project

Part B September 29, 2006 Page 38

fire hall designed for three fire trucks and two ambulances; facilities for fire extinguisher and air-pack maintenance; decontamination area with emergency showers and treatment rooms; lockers, laundry and equipment storage; administrative area and lunchroom; and training and fitness area.

The Security Gate and Booth will serve as primary control for access to and from the Project site. The Booth facility will incorporate a guard booth, a mobilized gate for vehicles, a pedestrian gate, offices and a site monitoring system using remote cameras.

The on-site administration, maintenance and warehouse buildings with their respective sizes are listed in Table B.4.5.2.-1.

Table B.4.5.2-1: List of Buildings and Sizes

Building Name/Description Area (m2) Height (m) Administration Office Centre 2,520 7 Upgrader Operations Centre 3,600 7 Fire Hall / EMS Building 2,775 7 Warehouse/Maintenance Building 5,655 15 Upgrader Maintenance Building 864 15 Security Gate and Booth 16 3.6 Bundle Wash Building 225 10 Cold Storage Building 480 7 Hazardous Materials and Waste Management Building 900 7 Weigh Scale Building 16 3.6

B.4.5.3 Utilities Buildings

There are also a number of buildings associated with the utilities of the plant site. These include specialty engineered, pre-engineered, or small pre-manufactured buildings. The final size of many of these buildings has not yet been determined. The most substantive buildings associated with the utilities and the major equipment contained in these buildings are listed on Table B.4.5.3.-1.

Northern Lights Upgrader Project

Part B September 29, 2006 Page 39

Table B.4.5.3-1: List of Utilities Buildings and Sizes

Building Name Description Area (m2) Height (m) Water Treatment Building

Boiler feedwater, air compressors, boiler auxiliaries 8,125 11

Substation Control Building

High voltage electrical equipment (breaker controls, SCADA, protective relays, metering)

54 4

Steam Turbine/Generator Building

Steam turbine/generator and auxiliaries 1,120 14

Electrical Building High and medium voltage switchgear and control centers, station battery, uninterruptible power supply

N/A N/A

Raw/Fire Water Pump Station

Raw water and fire suppression pumps and related equipment 1,140 12

River Water Intake Pump Station

River water intake pumps, traveling screens, and related equipment 96 10

Recycle Pump Station

Recycle water pumps and treatment equipment 1,680 14