Phosphor and radiation image storage panel containing the same

Panel storage system - Woodwork Machinery · The panel storage system CSF combi-nes functionality,...

Transcript of Panel storage system - Woodwork Machinery · The panel storage system CSF combi-nes functionality,...

www.barbaric.at

of innovation in perfection

1995-2015

years20

Panel storage systemcompact - fast - custom-made

einfache BeschickungslösungLCV

CSF

CSF S

Innovationin perfection

barbaric is a successful and dynamic company with headquarters and manufac-turing facility in Austria specialized in sophi-sticated lifting technology. Our goal is the individual production of custom-made solu-tions for our customers in the field of glass and panel manipulation. Through integra-tion of modern components developed in our company we can offer ergonomic and cost-effective systems with short payback periods.

Simple solution for panel feeding

Panel storage system for craft producers

Panel storage system complete solution for industry

barbaricquality

made in Austria

www.barbaric.at

A barbaric LCV feeding system allows an easy and fast feeding of your manufac-turing machine. In this area we can offer custom-made systems built with simp-le yet high-quality components. Benefits are low space requirement and the phy-sical relief of production workers. An investment with tremendous value for craft and industry production.

Simple and functional

All essential functions of the panel storage system CSF were retained at the feeding system LCV. By concentrating on essenti-al functions the system can convince with simplicity and reliability.

Manipulator

All functions are integrated to save space.

• lifting motor• horizontal motor• rotation device (optional)• switch cabinet

Suction traverse -with optionalsize adjustment

• manually adjustable aluminium traverse• automatic size adjustment (optional) • panel sizes of 2000 mm to 4200 mm• panel weight of 200 kg• vacuum generation via energy-saving ejector

Innovationin perfection

FEED

STORE

LCV feeding system

Technical data

Function andoperation

• visualization in 2D and 3D system • simple and intuitive user interface• fully automated standardized hardware interfaces for different saw manufacturers• automated panel feeding

Your benefits at a glance

• optimized material flow• gentle manipulation, no damaging of the panels during transport• optimization of space• reduced personnel expenses• simplification and alleviation of production processes• higher capacity utilization of your manufacturing machine• flexibility in production processes• payback periods below one year possible• fully automated panel handling

» Length up to 50 m

Plant size

Movement speeds

Panel sizes

Stacking

» System design two-axis system (XZ) three-axis system (XYZ)

» Length 2000 – 4200 mm longer on request

» Stack height 1800 mm up to 2500 mm

» Thickness from 8 mm

» Lifting hole 2000 x 600 mm

» X-axis 80 m/min

» Width 600 – 2100 mm longer on request

» Stack distance 150 mm

» Panel weight 200 kg 300 kg

» Z-axis 25 m/min

STANDARD OPTIONAL

LCV feeding system

www.barbaric.at

Know-how and design

CAD optimized product design and low net weights meet the high demands of fast speed and short cycle times. Optimum use of space - only 100 mm lateral distance in all directions is required.

Manipulator

Unique design and narrow body. All essen-tial functions and components are integ-rated. Touch screen and control panel are located at any point on the ground.

Rotation device, panel measurement and angle correction

With the 90° rotation unit, panels can be stored in all directions. In each stacking pro-cess the panels are measured and weighed. High process reliability through continuous measuring and recording of the weight of the panels. Orientation of the angular positi-on while driving. 180° rotation unit optional.

Innovationin perfection

FEED

STORE

ADMINISTRATE

CSF Panel storage system

‚Innovation in perfection‘The panel storage system CSF combi-nes functionality, performance and de-sign in one machine. With hundreds of systems installed worldwide barbaric has become a specialist in warehouse logi-stics and vacuum technology.For each company in the crafts, sup-plying or industry, we offer suitable sto-rage solutions.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

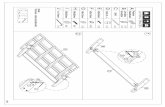

Projekt: Händler - Kunde

26.02.2015

Angebots-/Auftragsnr.: 2140000Benennung:

BestätigungslayoutPlattenlager CSFDatum Name

Gez.:Gepr.:

HaslmayrA1 1 /1

Blatt/BlätterFormat Maßstab Revision1:50(1:75)

barbaricH:\02_Automatische Anlagen\12_Plattenlager CSF\01_CAD\01_Verkaufsartikel\06_Zeichnungen für Produktblätter\02_CSF mit Holz-Her\CSF mit Holz-Her.iam

stacking height: max. 1800mm system height: <3300mm underground: cement C20/25 (200mm thick) safety fence: mesh size=100x20mm; height=2200mm

CSF

OFFICEMASCHINE

The suction traverse - functional yet compact

Functionality in detail. Modern, decentralized control modules and valve terminals enable an easy and com-pact structure.Energy-saving ejectors ensure an econo-mical and silent operation.

• automatic length adjustment• panel measurement• weight measurement• MDF– and thin panel package• maintenance-free• power saving function

Individual design for each customer

Each barbaric panel storage system is adap-ted to the specific customer requirements. In close cooperation with our customers, we develop the ideal concept. This results in ergonomic solutions for internal logistics.

Sort, group and chaotic stacking

Flexible design options for stacking in the warehouse. Sorted or chaotic stacks can also be mixed within a warehouse. A change in the stack due to new materials or groups is possible at any time.

Optional Label Printing System

For production processes with a continuous level of automation, we can place produc-tion labels on the panels right before cut-ting. Thus we facilitate the identification of items and the communication with the in-dividual production machines.

Control and operation

Various storage configurations can be rea-lized with our standard software.

• integrated service tool for remote maintenance• simple touch-enabled surface• Windows-based• extensive error analysis, with optional camera tool• integrated warehouse management and inventory management• XY-alignment functions for the alignment of parts on machine stoppers

Interfaces for established manufacturers

The basis for an efficient production is the connection of the storage system with the manufacturing machine.

• open data interfaces• existing hard- and software interfaces for almost all machine manufacturers• automatic monitoring of stock quantities• either storage system controls saw or saw controls storage system• by default a re-integration of cutting rests into the storage is possible• any number of Office stations• status message by e-mail and SMS• customized versions available

Function and operation

Highly efficient production facilities require modern control systems.

• intuitive user interface and modern layout• 21“ touch display • material administration and production control• office terminal• material parameters• SQL-data base• online interface for optimiziation software• external storage management• remote control

Your benefits at a glance

• optimized material flow• gentle manipulation, no damaging of the panels during transport• optimization of space• reduced personnel expenses• simplification and alleviation of production processes• higher capacity utilization of your manufacturing machine• highest flexibility in production processes• best possible material utilization due to re-integration of cutting rests• integrated warehouse management• payback periods of one to two years • Order-picking - operation without saw possible

* Panels up to 5600 mm long can be lifted and transported eccentrically.

Technical data

System size

Movement speeds

Panel sizes

Rest sizes (for re-integration)

Stacking

» Crane runway up to 50 m longer on request

» Length 2000 – 4200 mm* max. 5600 mm

» Length 2000 – 4200 mm* 1200 - 4200 mm

» Stack height 1800 mm up to 2500 mm

» Thickness from 6 mm from 3 mm

» Lifting hole 2000 x 600 mm

» X-axis 130 m/min

» Y-axis 110 m/min

» Crane bridge up to 13 m up to 16,5 m

» Width 600 – 2100 mm others on request

» Width 600 – 2100 mm

» Stack distance 150 mm 100 mm

» Panel weight 200 kg up to 300 kg

» Z-axis 40 m/min

STANDARD OPTIONAL

CSFPlanel storage system

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

Projekt:

25.03.2015

Angebots-/Auftragsnr.: Benennung:

Datum Name

Gez.:Gepr.:

HaslmayrA1 1 /1

Blatt/BlätterFormat Maßstab Revision()

barbaricH:\02_Automatische Anlagen\18_Plattenlager CSF S Industrial\01_CAD\01_Verkaufsartikel\Tür.iam

0°

180°90°

www.barbaric.at

With the panel storage system CSFs in-dustrial we can offer an individual solu-tion for your special demands. There are almost no constraints on your wishes. Renowned industrial enterprises rely on the stability and reliability of barbaric systems.

Performance for industrial producers

Our panel storage system CSFs meets the high industrial demands for functionality and performance.

• cycle times below 1 minute• movement speeds up to 150 m/min• crane bridge lengths up to 25 m• integration of chain conveyors or conveyor belts

Manipulator

The equipment of the manipulator provides high system security. Throughout, main-tenance-free components ensure high avai-lability of the system.

Panel rotation up to 180°

With the 180° rotation device parts can be aligned on both sides. A special angle cor-rection of +/- 5° guarantees straight and correct stacks. The XY-alignment functions ensure the alignment of parts on machine stoppers. This allows doors to match the ori-entation and the veneer or can be outsour-ced to a further processing machine.

CSFsindustrial Panel storage system

Innovationin perfection

FEED

STORE

ADMINISTRATE

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

AA

BB

CC

DD

EE

FF

Projek

t:Ho

lz-H

er -

Bay

er B

uilt W

oodw

orks

Inc.

31.07.20

14

Ange

bots

-/Au

ftra

gsnr

.:2140

280

Bene

nnun

g:

Pref

inish

Sorting

Syst

emSt

orag

e Sy

stem

CSF

Datu

mNa

meGe

z.:

Gepr

.:Ha

slma

yrA2

2 /2

Blat

t/Blät

ter

Form

atMa

ßsta

bRe

vision

1:100

()

barb

aric

H:\02_A

utomat

ische A

nlagen\

02_Auf

träge\2

14xxxx

\214028

0_Holz-

Her U.S

. - Bay

er Built

Prefin

ish Sor

ting Sy

stem\0

2_CAD\

214028

0_Holz-

Her US

- Baye

r Built

- Prefi

nish So

rting S

ystem.i

am

st

acking

heigh

t: m

ax. 2

500m

m sy

stem

heigh

t: <4

300m

m un

derg

roun

d: cem

ent C2

0/25

(120m

m th

ick)

sa

fety

fen

ce:

me

sh s

ize=

100x

20mm

; heigh

t=22

00mmSuction traverse -

equipped with all the functions you need

Depending on the application, the suction traverse is adapted to specific customer re-quirements and materials. Optional load in-crease and increase of stroke are realized.

• standard suction traverse• vacuum grippers• special suction traverse• separation unit • ionization nozzle for the plastic panels• handling for wooden boards

Safety system

Our safety facilities comply with all local standards. In conjunction with other machi-nery, special safety concepts are realized in agreement with the customer.

• centralized safety PLC with online access• possibility of integration of various machines

Software

Requirements to customer databases and ERP systems are implemented in the house.Integration options of• various databases• ERP systems• RFID systems• CAM systems• optimization systems

Individual customer solution implemented at Bayer Built Woodworks Inc., USA

Innovationin perfection

Functions and operation

• all basic functionalities of the panel storage system CSF integrated• adjustment to existing software solutions• optimized utilization of storage space• transparency with regards to stock quantities

• simple inventory proceedure, current stock levels at all times• fully automated panel handling• highly flexible system, cycle times below 45 seconds possible• special designs according to your requirements

Your benefits at a glance

• extremely large storage areas possible (up to 25 m x 70 m) • optimized material flow• gentle manipulation, no damaging of the panels during transport• optimization of space• reduced personnel expenses• simplification and alleviation of production processes• high transportation services• highest machine availability• highest flexibility in production processes• significant increase in productivity

* Panels up to 5600 mm long can be lifted and transported eccentrically.

Technical data STANDARD OPTIONAL

System size

Movement speeds

Panel sizes

Panel rest sizes (for re-integration)

Stacking

» Crane runway up to 70 m

» Length 2000 – 4200 mm* max. 5600 mm

» Length 2000 – 4200 mm* 1200 - 4200 mm

» Stack height 1800 mm up to 2500 mm

» Thickness from 6 mm others on request

» Lifting hole 2000 x 600 mm

» X-axis 150 m/min

» Y-axis 150 m/min

» Crane bridge up to 25 m

» Width 600 – 2100 mm others on request

» Width 600 – 2100 mm

» Stack distances 150 mm up to100 mm

» Panel weight 200 kg others on request

» Z-axis 60 m/min

CSFsindustrial Panel storage system

of innovation in perfection

1995-2015

years20 20 years of handling technology

The product world of barbaric

Barbaric GmbHPummererstrasse 124020 Linz/Austria

Phone: +43 732 779800Fax: +43 732 779800-10e-mail: [email protected]

AA

_Pla

ttenh

andl

ing_

EN

_201

5_01

project glassGLASS window

WOOD doorspanels

LIFTING ROTATING TILTING BATTERY

STORE ADMINISTRATEFEED

TRANSPORT DESTACKBRING BACK

LIFTING ROTATING TILTING