Paint Spec

description

Transcript of Paint Spec

-

5/20/2018 Paint Spec

1/9

RUST CONVERTING PRIMER

CORROSEAL

EPA ApprovedVOC 60 g/l CAGE Code 0X7A6Patented, CORROSEAL Registered trademarkof Corroseal, Inc. 2000 CORROSEAL, INC

CORR OSEAL, INC.

70 EAST SUNSET WAY #251

ISSAQUAH, WA 98027

4 2 5 - 8 3 7 - 0 2 0 0

Fax: 425-837-0300

In d u s t r ia l P a in t in gand

for Ma r ine P a in t in g

www.corroseal.com

Cover 1Advantage - Its Easy 2

Surface Preparation Specification 3Application Specification 4Visual Application Guide 5

Technical Data - 6Technical Description - 7Technical Description - 8

Product Data Sheet - 9

Farm and Home&

-

5/20/2018 Paint Spec

2/9

Non -Flam m able Non -Toxic Non -Corrosive

Converts existing rust to a crystalline layer of black magnetite.

Creates a hard non-rusting layer sealed with high quality co-polymermetal primer.

Protects against future rusting. Lasts as long as the topcoat you use.

No need to sand blast for surface preparation when budget orenvironment wont permit.

Do all of the prep at one time, or spread work out over weeks.

Eliminate labor overtime because of flexible requirements of Corroseal

Improves job site and worker safety.

Works with nearly all conventional industrial grade top coats.

Pleasant odor.

Saves time - no thinning - no 2-part mixing necessary.

Easy to clean up - soap & water does it all.

1. 2. 3.

It s Ea sy Ta k e s 1 / 3 t h e p o we r t o o l p r e p t i m e c o m p a r e d t o c o n v e n t i o n a l m e t a l

p r i m e r s .

1 . Wat er -blas t , or Solven t -c lean & Power-t ool prep a l l a t on et im e - o r over long pe r iod .

No wor ry abou t rus t -back .

2 . Apply Cor rosea l t o en t i r e a r ea & wait 24 h our s

3 . Ap p ly t o p c o a t o r wa it u p t o 3 0 d a y s t o t o p c o a t .

CorrosealAdvantage

-

5/20/2018 Paint Spec

3/9

TO ET CH-PR IME AGED TIGHT PAINT, FI BER GLASS , SOME ALUMINUM

Test for required adhesion to substrate and coating compatibility.

Remove contaminates from surface. Small areas may be solvent-wiped with clean

cloth.

Apply CORROSEAL in 5 mil wet film thickness (127 micron).

If you abrade surface by SP 2, SP 3 or SP 7 to achieve 1-2 mil surface profile (25-51 micron), apply CORROSEAL 6-8 mil wet (to 203 micron) to cover profile with dry film.

Allow 4 hours drying, then topcoat within 30 days with any marine-grade coating

compatible with CORROSEAL

Sur face P repara t ion Spec i f i ca t ion :

SSPC-SP 1 Solvent Cleaning - Do not use hydrocarbon solvents

SSPC-SP 2 Hand Tool Cleaning

SSPC-SP 3 Power Tool Cleaning

SSPC-SP 7 Brush-Off Blast Cleaning

SSPC-SP 12 High & Ultra-High Pressure Water Jetting - WJ4

SSPC-SP TU4 Retrieval and Analysis of Soluble Salts on Substrates

ASTM D 4285 Indicating Oil or Water in Compressed Air

Coat Rust With Corroseal

Conventional PrimerPrep: SSPC C SP3-PWB

Like a CommercialBlast

Corroseal PrepSSPC-SP 2 PWB C Sa 1Like a Brush Off Blast

Place Gage in Wet Film

Read Paint Depth on Tips

See PDF files on this site for current US Navy surface preparation specifications and for

Corroseal surface preparation specifications in detail, including specifications for

CORROSEAL-CHLOR-RID and CORROSEAL-CHLOR-RID TEST applications.

-

5/20/2018 Paint Spec

4/9

CorrosealApplication InstructionsSurface Preparation1. Remove all millscale, flaking rust, and paint with power sanding tools, needle gun, descaler, wire

brush, or water or abrasive blast to SSPC SP2, SP 3, SP7 or SP12 WJ4. Always use a cleaner or sol-

vent wipe to SSPC SP1 to remove oil, and other chemicals and Corroseal-Chlor-Ridto remove

chlorides. Always rinse off cleaner with fresh water. Acetone and ordinary dish washing detergents

should not be used because they leave behind a residue of sulfonic acids or other unknown chemicals

which interfere with primer adhesion. On cold rolled steel, abrade to anchor profile and degrease.

2. Ensure surfaces are oil-free by visual examination. Check entire structure with water misted ontosurface. Any beading of water is indication of oil or grease contamination. Clean contaminated surfacin accordance with SSPC SP 1 and recheck for contamination until surfaces are grease and oil-fre. UseCorroseal-Chlor-RidTestkit to confirm surface is free of chlorides contamination.

Prepared surface shall have a neutral pH of 6-8 before CORROSEAL appliction.

Prepared surface shall be eye-visible dry. Do not apply to sweating steel.

Air and steel temperature shall be between 45F (7.2C) and rising or 100F(37.7C)& falling

Check dew point and temperature. Do not apply within 4 hours of expected rain fall. Wait unt morning dew is off the surface before coating.

Application3. Do not thin! Brush or roll Corroseal from a plastic or stainless pan, using a synthetic bristlebrush or short nap roller. Do not pattern or groove. Deep grooves from poor application will re-rust.

4. If spraying, use a 19 or 21 tip. Airless or Air powered both work. Do not over mist during applica

tion. With air unit, work about 10", 25 cm. from surface with 6"-8", 15 to 25 cm., fan. Airless workdepends on the equipment. Electrostatic works well with Corroseal.

Test compressed air system for oil contamination before using.

There shall be no runs, sags, streaks, flashes, laps, pinholing or cratering.

5. Apply 8-10 mils, 200 to 250 microns, wet coat, checking with wet film gauge. Theoretical

spread rate is 1 gallon per 200 sq. ft. This will appear as a thick off-white film with no rust showing

through. Corroseal turns from white to black with rust conversion. If Corroseal turns gray uponapplication, more Corroseal needs to be applied. See visual coating guide samples in this publicatio

There shall be no picking up or rolling up of the first coat during application of second pass.

Second coat (if needed) should be applied when first coat is still damp and tacky.

Do not pour un-used CORROSEAL from roller pan or air pot back into original

container to avoid contamination.

6. Drying time is generally related to air circulation, temperature, film thickness, and number of coats

At 77F CORROSEAL should be dry to touch within 30 minutes. In enclosed compartments you must have two way air flow. Apply mechanical air movemen

of at least 10 to 12 atmosphere changes per hour. If temperature is low add heat.

Clean up with soapy water and rinse well. For hard dry splatter use lacquer thinner.

Topcoat ON STEEL DO NOT TOP COAT BEFORE 2 4 HOURSor re-rusting may occur. (24 h our cure is required by the chemical conversion process w ithin the rust .)The surface shall be free from any contamination prior to applying any topcoat.

-

5/20/2018 Paint Spec

5/9

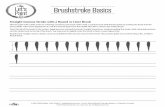

Correct FinalAppearance

after Corrosealapplied @ 8-10mil wet

(200-250microns)

White epoxy topcoatcovers & no blackshows through.

Incomplete conversionunderneath.

Apply at 8-10 mil (203-254 microns) wet in one coat by spray (19-21tip), brush or roller. Defects from improper application appear in afew minutes to within the 24 hour window prior to topcoating.Please call our toll-free customer technical support at 800-237-1573 with any questions about problems that may arise.

Improper PreperationSpeckled discoloratio

shows salt or chemiccontaminates.

Remove coating.

Clean area,and reapplyCorroseal.

VISUAL APPLICATION GUIDE

InsufficientApplication

Gray color inareas indicates

need for moreCorroseal.

Apply 2nd lightpass while

surface is stilltacky.

ImproperApplication.

Brown streaks showincomplete conversion,

or on wet steel orthinned with water.

To fix, removeCorroseal & reapply at

8-10 mils wet(200-254 microns).

Cant Sandblast? Use Corroseal!

Converts rust to magnetite - Fe3O

4

Corroseal Rust Converter is self-inspecting in a short period of time

-

5/20/2018 Paint Spec

6/9

TECHNICAL DESCRIPTION OF CORROSEAL - 1

Technical Information

Description: Water based, unpigmented, styrene butadiene, elastomeric polymer,

with rust converting modifiers.Appearance: Milky, off-white to tan liquid.

Odor: Very Mild

Coverage: 200 square feet per gallon, 4.9 square meters per liter (at 2.5 mil DFT)

VOC (ASTM D 3960) 60 grams per liter, - 8 oz. per gallon

Non-volatiles by volume 31%

Non-volatiles by weight 35%

pH 3.0

Application temperature: Minimum: 45 F and rising (7.2C and rising)

Maximum: 100 F and falling (38C and falling)

Protect from freezing.Weight per gallon (ASTM D 1475) 8.6 lbs., 3.91 Kg.

Flash point (Closed Cup ASTM D 56) >200 F, >93 C

Viscosity (Brookfield LVF#2 spindle,60 rpm) 400 cps

Mechanical Properties @ 77F:

Impact Resistance* (ASTM D 2794) Direct: 40 in lbs Reverse:10 in lbs

Elongation* (ASTM D 522) 8%

Shelf life (ASTM D 1849) Pass Resists greater than 1 week at 140 F and

up to or over one year at normal room ambient temperatures.

Store between 38 F and 105 F, 3C and 41 C, avoiding continuous direct sunlight.

Pencil Hardness (Modified using 20 gauge rusted steel) B to HB

Heat Resistance: Resists heat aging up to 270 F. Useful properties up to 350 F.Adhesion with top coat ASTM D 4541 600psi (no topcoat) to Over 1000 psi (+ urethane)

Corroseal in combination with epoxy, polyurethane and polyester marine grade top coats has

exhibited unique adhesion to rusted steel. Laboratory testing of moisture-cure urethane

topcoated Corroseal exceeds 1000 psi, ASTM D 4541.

Recommended Uses

Corroseal is recommended for use on all steel surfaces as a rust converting paint primer;

and as an etch primer/sealer on aged tight paint, which normally must be removed before

topcoating, on fiberglass and on some non-ferrous metals..

Product Description :

Corroseal is a water based copolymer latex rust converting primer.

Corroseal when applied to rusted steel chemically converts the rust into magnetite,and primes the steel for a top coat of paint.

-

5/20/2018 Paint Spec

7/9

Dry time to (ASTM D 1640)(3 mils wet film - 76 microns)

Set to touch ............................3 minutes

Cotton free................................10 minutes

Dry to touch..............................30 minutes

Hard dry....................................40 minutes

Through..(fingernail hard)........60 minutes

Rejects rainwater (77F, 25C) No wash off......240 minutes

Recommended top coat time After 24 hours minimum,

36 to 40 hours minimum in heavy applications and/or in cold weather,or wait up to 30 days if desired.

Recommended total dry film thickness: 2.5 mils, minimum to 3.5 mils optimum, 65 to 90 micro

Recommended total wet film thickness: 8 to 10 mils, 200 to 250 microns

Thinners: Thinning causes converter failure.

Technical Description of Corroseal - 2

Top Coat Recommendations

Acrylic Oil based coatings

Alkyd based enamels Polyurethane

Bituminous coatings Thermoplastic epoxy

Chlorinated rubber Urethane-asphalt

Epoxy/amines Urethane/coal tar

Epoxy/coal tar Urethane-water based

Epoxy/esters Vinyl

Epoxy/polymides Vinyl/tar

Latex

Note: If rust is not present the converter will not turn black and instead will dry clear.

This coating is very effective as etch-primer on aged tight paint. It may be used to cover, seal

and protect painted signs, logos, instructions, etc.

Do not overthin topcoats as excess solvent creates cohesive failure.

Some brands of waterbased viny/acrylic or light colored waterborne topcoats will react with the

tannic acid in Corroseal. Do a test patch of the topcoat over Corroseal and if brownish

stains appear use an oil-based stain blocker as an intermediate coat or use another type topcoat.

Corroseal primer chemistry is water based styrene butadiene copolymer.

Since it contains no pigment it eliminates the pin hole problems of other latex primers created

when latex traps air around pigment particles.

-

5/20/2018 Paint Spec

8/9

Technical Description ofCorroseal- 3

Handling & Toxicity

Refer to MSDS sheet for complete details. Corroseal contains no chemicals listed in EPA 40 CFR cp 1

Part 433. If swallowed, induce vomiting. Corroseal presents no significant vapor hazard but you should

not breathe mist during spraying. Non flammable and non corrosive. Wear rubber gloves and protective

glasses. In case of eye contact flush with plenty of water. Skin contact takes normal detergent and water.

Follow all local, state and federal guidelines and laws for the safe handling of waterborne coatings. Dark

stains clean up with 1:4 bleach to water. Normal clean up: detergent and water. Use no mineral spirits.Use lacquer thinner to remove Corroseal from equipment.

Do Not Apply Corroseal Over The Following:

Galvanized steel Any Zinc present as pigment or as Galvanizing cancels the chemical reactioZinc necessary for Corroseal conversion to occur. Once Corroseal is applied

Zinc Chromate rusted steel, zinc coating may be applied over the Corroseal.

Zinc Phosphate

Strontium Chromate, Copper powder, Magnesium borate, Graphite, and Carbon black.

Carbon black is a problem only in high concentrations such as conductive black primers.

Do not use with any lead pigments or chromate pigments. These metals are not found in modern coatings.

Do not use Corroseal on Food Preparation Lines where Corroseal is in direct contact with the food orbeverage. It can be used when topcoated with an FDA approved topcoat. Check with the top coat supplie

to see if an extraction test is required before proceeding.Always prepare a test patch to ensure compatibility with the substrate and follow on coatings.

LIMITED WARRANTY

The facts stated and the recommendations and suggestions herein are based upon experiments, standard

industry tests, practical experience and customer use. The information is believed to be reliable. No guar

tee is made for their accuracy. The products and information are intended for use by buyers having requi

site skill and know-how in the industry, and therefore it is for the buyer to satisfy himself on the suitability

of the products for his own particular use and it shall be deemed that buyer has done so, at his sole discreti

and risk. No statement contained herein shall be construed as an inducement to infringe existing patents o

as an endorsement of products of specific manufacturers.

CORROSEAL, INC. ASSUMES NO LIABILITY FOR PRODUCT FAILURE OTHER THAN TO

SUPPLY REPLACEMENT MATERIAL FOR PRODUCTS SHOWN TO BE DEFECTIVE WHEN

DELIVERED OR TO REFUND THE PURCHASE PRICE. EXCEPT AS NOTED, THERE ARE N

WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANTABILITY FITNESS OR OTHERWIS

CORROSEAL, INC. SHALL NOT BE LIABLE FOR SPECIAL INCIDENTAL AND CONSEQUEN

TIAL DAMAGES.

-

5/20/2018 Paint Spec

9/9

PRODUCT IDENTIFICATIONCAGE CODE 0X7A6

CORROSEALRUST CONVERTING-COPOLYMER PRIMERCS-52 52 gallon fiber drumsCS-32 1 quart containers / 12 per caseCS-5 5 gallon pail with pour spoutCS-1 1 gallon containers 4 per case

Trade Codes: Tariff Code: 149980.2Hamonized Code: 3810.10.0000

PRODUCT DESCRIPTION:

CORROSEAL is a water based rust convertercombined with an unpigmented high qualitylatex paint primer. The converter segments turnrust into a barrier layer of black non rustingmagnetite. The primer acts as a bonding agentfor epoxy, enamel, acrylic, and oil-based fin-ishes. Exceptional bonding with moisture curedpolyurethanes. Contains no chemicals listed inEPA 40 CFR Cp 1, Part 433. Non flammable,non corrosive. VOC compliant at 60 grams perliter. Not restricted by Federal DOT shippingregulations.

BASIC USE:

CORROSEAL is recommended for use on allsteel surfaces as a rust converter / paint primer,and as an etch primer or sealer on non ferrousmetals such as aluminum, copper, brass andgalvanized steel. Protects against future rusting.Can be used on welds. Eliminates need tomechanically blast to white metal.

LIMITATIONS:Keep from freezing.Apply at temperatures above 45 F andbelow 100 F ( 7.2C - 37.7C ).. Do not thin. Wait 24 hours before topcoating.Do not use with zinc chromate, galvanizing,zinc phosphates, chromates, copper powder,magnesium borate, graphite, and lead pig-ments. Do not use where in direct contact withfood. Coatings subject to tannin staining shouldbe tested before large scale use.

APPLICATION:

Remove all salt, loose rust, millscale, dirt,grease, oil, old paint and other deposits. Toremove oil, dirt and salt apply cleaner ac-cording to manufacturers directions andrinse. A residue free surface is essentialbefore coating application begins. Do not useAcetone or dishwashing detergent to cleanrusted steel surface. Brush, roll or sprayundiluted CORROSEAL in a heavy whitecoat with no surface show-through at 8-10mils wet film thickness. When black color

appears, rust conversion has started. If grayareas appear apply more Corroseal whilesurface is tacky. Refer to color chart andtechnical guide for complete applicationanalysis. Wait at least 24 hours to topcoat.

COVERAGE:

The actual surface condition and thickness ofrust will dictate amount of CORROSEALneeded. For estimating purposes, 1 gallon ofCorroseal covers approximately 200 sq. ft. (10mil wet coat).

TECHNICAL SERVICES:Technical advice or service on suitability forspecific application and end-use require-ments is available from calling Corroseal, Inc.800 237-1573. Refer to Material Safety DataSheet (MSDS) and label for precautionaryinformation.

WARRANTY:

Manufacturers liability is limited to thereplacement or refund of purchase priceupon return of unused portion with proof ofpurchase.

Pr o d u c t Da t a S h e e t

Corroseal, 70 E. Sunset Way #251

Issaqwuah, WA 98027 USA 425-837-0200-

www.corroseal.com