P13675 Bike Helmet Mirror System Detailed Design Review

description

Transcript of P13675 Bike Helmet Mirror System Detailed Design Review

P13675Bike Helmet Mirror System

Detailed Design Review

Rob Fish (Industrial Designer) Zachary Kirsch (Mechanical Engineer, PM) Martin Savage (Mechanical Engineer) Olivia Scheibel (Mechanical Engineer) Henry Woltag (Industrial and Systems Engineer)

Team

Guide◦ Dr. Richard Lux

Customer Proxy◦ Dr. B. Brooks

Faculty Support◦ Dr. M. Gomes◦ Dr. M. Lam

Sponsor◦ RIT MSD Project Office

Guides, Advisor, Sponsor

Project Summary Design Objectives Proposed Design

◦ Optical System◦ Support System

Bill of Materials Test Plans Risk Assessment MSD II Schedule

Outline

Current rear view mirrors systems for bicycles are clumsy, unattractive, poor quality, too expensive, or have a small viewing range.

Our solution is to create a low cost alternative that requires no power to operate,

and attaches to any helmet.

Mission Statement

Issues regarding geometric optics◦ Size of mirrors◦ Range of Adjustability◦ Model head, neck, eye, helmet positions◦ Create system in SolidWorks

Team should focus more on shock than vibrations

Testing◦ Deflection analysis◦ Drop testing

Takeaways from Systems Design Review

Concerns:◦ Not enough analysis / data involved in concept

selection◦ Settling on Rob’s prototype vs. alternate designs◦ Need to determine range of adjustability

Takeaways from Systems Design Review

Design Objectives

Optical System ConceptsBased on sensitivity analysis, the 2 mirror system was determined to be advantageous to the 3 mirror system.

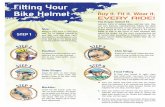

Three mirror optical system concept. Two mirror optical system concept.

Feasibility Tests Conducted Using Prototype Distance a human was recognizable

– 37ft Distance a van was recognizable –

177ft+ Distance a car was recognizable –

110ft

Optical System

Maximum Area of Dual Lock™

Maximum Allowable Break Away Force,

Tensile disengagement of Dual Lock (250 Black),

Support System Attachment

“3M™ Dual Lock™ Reclosable Fastener.” Online image. 2013. 3M. 2 Feb. 2013 <http://www.3m.com/product/information/Dual-Lock-Reclosable-Fastener.html>

Dual Lock™ is a reclosable fastener made of mushroom-shaped stems that snap together. Similar to Velcro®, Dual Lock ™ will allow users to easily attach and detach the bike helmet mirror system.

Support System Attachment

Technical drawings of rear support bracket.

Technical drawings of front support bracket.

One Solid Manufactured Piece ABS Material 3 mm diameter support legs Uses cylindrical snap-fits to

constrain degrees of freedom Mylar coating on underside to

create mirror surface

Front Support System

Standalone Bracket

Bracket with Attachments

Bracket with Gooseneck/Attachments

Front Support System – Attachment Methods

Cylindrical Snapfit – 1 degree of freedom: Cylindrical Insert with adhesive/Epoxy

Mass of MirrorVolume of Top Mirror:

Density of Top Mirror,

Mass of Top Mirror:

Rear Support System MaterialsAssumptions

Entire weight of top mirror acts as a point force on the end of two, six inch sections of “Gooseneck”

“Flexible Gooseneck Tube.” Online image. 2013. Leflexo. 14 Feb. 2013 <http://www.leflexo.com/new_section.php?sid=204>

Material Selection Each six inch section of Gooseneck

needs to support 1.44 oz. Size (O.D.) 0.142-H can support 3.2 oz at

six inches

Impact Analysis

Potential Energy:

Impact Force:

Size (O.D.)0.142-H Gooseneck can support 3.2 oz applied on 6 in.

Gooseneck Feasibility AnalysisAssumptions

Entire weight of top mirror acts as a point force on the end of two, six inch sections of “Gooseneck”

Energy of impact is unabsorbed by body, helmet, etc.

PE (J) s (m) FTotal (N) FOne Section (N)

0.02 0.001 20.432 10.2160.02 0.003 6.811 3.4050.02 0.005 4.086 2.0430.02 0.010 2.043 1.0220.02 0.020 1.022 0.511

0.02 0.025 0.817 0.409

0.02 0.038 (1.5 in) 0.536 0.268

0.02 0.051 0.401 0.200

Impact Analysis for s=1in

Results The gooseneck will deform 12 mm after

a 1 in drop.

Based on the results of the sensitivity analysis, the optical system will still remain functional

Thermal Expansion of GooseneckLinear Thermal Expansion,

Diameter of gooseneck,

Thermal Expansion Coefficient of Steel,

Initial Temperature (SATP),

Final Temperature,

Rear Support System Mirror AttachmentThe gooseneck will be secured with a metal to plastic, weatherproof adhesive.

Top Mirror

Mirror-Gooseneck Attachment

“Gooseneck”- Flexible Tubing

Towards Front of Helmet

Proposed Design – Solidworks Model

Bill of MaterialsPart # Part Name Quantity Material Weight (lb)

Manufacturing Cost ($)

1 Front Mirror 1 Mylar 0 0.004

2 Front Mirror Housing 1 ABS 0.012 0.014

3 Front Support 1 ABS 0.013 0.016

4 Front Support Bracket 2 ABS 0.003 0.003

5 Top Mirror 1 Mylar 0 0.041

6 Top Mirror Housing 1 ABS 0.184 0.217

7 Flexible Tube 1 Steel 0.044 3.317

8 Rear Support Bracket 2 ABS 0.002 0.003

9 Dual Lock 4 Dual Lock 0 0.278

10 Adhesive Beacon GM2OZ 0 0.000

Total 0.258 3.89

Approximate Sales Cost $15.56

Engineering Specification VerificationCustomer Needs Rating

Safe to wear 9 Break away force: 45 lbs X

Provides a wide angle view behind the cyclist 9 Rear image angle: 25 degrees Calculated image angle: 47 degrees X

Holds mirror orientation as set by user 9 Image oriented properly Yes X

Minimizes obstruction to the cyclist's forward field of vision 9 Lateral forward viewing

angle:170 degrees X

Attaches to a typical helmet without compromising the helmets integrity

9 X

Is lightweight and comfortable to wear 9 Marginal Weight: .775 lbs Estimated Weight: .258 lbs X

Is durable 9 Survives drop from: 3 feet Test

Provides a clear, correctly oriented image 9 Distance behind at which

vehicles are visable130 ft Test

Is adjustable to provide optimal view for the rider 9 X

Is inexpensive ($10-$20) for the consumer 3 Marginal Cost: $30.00 Estimated sale cost: $15.56 X

Detaches from the helmet 3 X

Can be adjusted without the use of tools 3 X

Requires no power input 3 X

Is aesthetically pleasing 3 Ongoing

Refrains from significantly increasing wind resistance 1 Survives wind speeds 45 mph Test

Is fabricated in an environmentaly friendly way 1 Recycleability of materials

used:100% Ongoing

Related to Specifications Product Design

Angle of front mirror will be adjusted via ball joint. Top concave mirror will be stationary.

Will receive input from Rob Fish

Front attachments fabricated from plastic, will break before penetrating Helmet. Rear attachements fabricated from gooseneck, will bend before penetrating helmet.

Ball joint will hold front mirror orientation

Depends on if film will be removable from rapid plastic body

Front mirror will not affect lateral view. Placed 2 inches above eye level (y direction).

Designed to attach to helmets via dual lock, does not compromise material integrity.

Will not require power

No tools are needed

Utilizes dual lock to attach / detach from helmet

Specification: The mirror system must be mountable to at least 3 distinctly different helmet styles Test: Mount the system to three different helmet styles

Test Plan: Specification S4

http://bertsbikes.com/product/giro-rift-154856-1.htm

How to test:◦ Acquire three

distinctly different helmets and mount the mirror system

◦ Go to the bike shop and mock mount the mirror system to three distinctly different helmets

Test Plan: Specification S4 Pass Criteria: Successfully mount to three helmets in either test Risks and

Mitigations:◦ No foreseen risk

Specification: Survive drop from height of 3 feet

Test: Release helmet at 3 feet in the following impact orientations

◦ Correct, inverted, nose, back, side

Test Plan: Specification S5

http://static6.depositphotos.com/1025312/628/i/950/depositphotos_6280277-Helmet-on-handlebar.jpg

How to test: Hold the helmet at a 3 foot height above a concrete surface. Release in the required orientations.

Test Plan: Specification S5 Pass Criteria: No part failures. System operable after impact. Risks and

Mitigations:◦ Part fails during test

All team members wear appropriate PPE while test in progress (eye protection, gloves)

Specification: Operate in wind speeds of 45 mph (marginal) and 60 mph (ideal) Test: Place helmet in proper orientation within wind tunnel and subject helmet to various wind speeds

Test Plan: Specification S7

20”

30”

* Helmet with mirror measures: 9”W x 8”H x 12.5”L

How to test: Create a mount to secure helmet within wind tunnel. Subject helmet to speed increments of 5 mph from 0 to 60 mph

Test Plan: Specification S7 Pass Criteria: Mirror position does not deform under wind loading Risks and

Mitigations:◦ No foreseen risk

Specification: Mirror mount needs to break away from helmet under a 45 lb applied load to meet NHTSA standards Test: Measure force required to remove mirror system from helmet

Test Plan: Specification S8

http://www.transducertechniques.com/images/hfg-series-force-gauge.gif

How to test: Attach force gauge to the front of the mirror mount system. Apply force until the mounting system is removed from the helmet

Test Plan: Specification S8 Pass Criteria: Force applied to remove the helmet does not exceed the 45 lb standard Risks and Mitigations:

◦ The mirror system could violently rip off the helmet All team members

wear appropriate PPE while test in progress (eye protection)

Specification: The rider must see a horizontal rear image encompassing 10 degrees (marginal) and 25 degrees (ideal) Test: Measure the rear viewing angle of a team member using the system

Test Plan: Specification S9

How to test: A team member wearing the helmet stands a measured distance from a white board. Another team member walks behind the one wearing the helmet and marks the extent of vision. This distance is measured and the angle calculated.

Test Plan: Specification S9 Pass Criteria: The calculated angle meets or exceeds the angle specified Risks and

Mitigations:◦ No foreseen risk

Specification: Vehicles behind cyclist must be visible at 130 ft (marginal) and 200 ft (ideal) Test: Team member wearing helmet attempt to identify objects at these distances

Test Plan: Specification S14

http://turningplace.files.wordpress.com/2013/01/aaaa.jpg

How to test:◦ Team member wearing

helmet stands on end zone line of football field and attempts to identify another team member standing 130 and 200 ft away

◦ Team member wearing helmet stands along the edge of the road and attempts to identify a vehicle driven by another team member at 130 and 200 ft away

Test Plan: Specification S14

Pass Criteria: Person visible at given distances or car visible at given distances Risks and

Mitigation:◦ Safety concern with

team members being on the road for testing Look into traffic control

options

Risk AssessmentID Risk Item Effect Cause

Likelihood

Severity

Importance Action to Minimize Risk Owner

1Reflective film does not display image to meet specifications

Reflective film is unaccepatable

Does not pass rear viewing distance tests

2 3 6Test image quality as early as possible and prepare contingencies.

Olivia Scheibel

2Exceeding the designated budget.

Team will run out of funds to build working prototype.

Cost of materials to build system and/or number of redesigns

2 3 6Ensure all costs are documented before any purchasing.

Zachary Kirsch

3Parts and materials do not arrive on time

Prototype cannot be completed on schedule

Item lead times do not match anticipated values.

2 2 4 Accurately identify lead times of materials.

Zachary Kirsch

4 Group dysfunction

Group does not work as efficiently as possible.

Lack of communication and poor compromising. Group members do not contribute equally to the project.

2 2 4

Consistent communication among team members. Each team member will complete individual responsibilities to expected quality and on time.

Zachary Kirsch

Risk Assessment

ID Risk Item Effect Cause

Likelihood

Severity

Importance Action to Minimize Risk Owner

5Final product is not aesthetically pleasing

Product will not be marketable.

Aesthetics were not considered during design and/or manufacturing.

2 2 4Coordinating with Rob to ensure the design meets his product vision.

Henry Woltag

6 Poor documentation

Disorganization of team. Follow up projects lack foundation.

Inconsistent documentation. 3 1 3

Update EDGE weekly with meeting minutes, notes, and other important information.

Henry Woltag

7Dual Lock ™ does not support system

Redesign is needed.

System is heavier or Dual Lock™ is not as strong as anticipated.

1 3 3 Prepare contingencies. Olivia Scheibel

8

Improper design provided to rapid prototyping machine

Prototype can not be created on schedule

Improper formatting, not understanding needs of rapid prototyping system

1 3 3Contact professors involved with rapid prototyping and obtain information regarding necessary machine inputs.

Martin Savage

MSD II ScheduleSu M T W R F S Su M T W R F S Su M T W R F S Su M T W R F S Su M T W R F S

Assess RisksUpload Documents to EDGEReevaluate Detailed DesignFinalize Test PlansOrder MaterialsRapid Prototype Support System ComponentsAssemble Support SystemAssemble Mirror SystemMount Entire AssemblyTest For FailuresImplement Modifications as NeededDocumentation of Assembly, Tests, Etc.Prepare PosterPrepare Final Technical Paper

Week 1 Week 2 Week 3 Week 4 Week 5

Su M T W R F S Su M T W R F S Su M T W R F S Su M T W R F S Su M T W R F SAssess RisksUpload Documents to EDGEReevaluate Detailed DesignFinalize Test PlansOrder MaterialsRapid Prototype Support System ComponentsAssemble Support SystemAssemble Mirror SystemMount Entire AssemblyTest For FailuresImplement Modifications as NeededDocumentation of Assembly, Tests, Etc.Prepare PosterPrepare Final Technical Paper

Week 6 Week 7 Week 8 Week 9 Week 10

Thank you for your time and support.