P13222: FSAE Turbocharger Integration

description

Transcript of P13222: FSAE Turbocharger Integration

P13222: FSAE Turbocharger Integration

Kevin Ferraro, Phillip Vars, Aaron LeagueIan McCune, Brian Guenther, Tyler Peterson

Introduction• Turbocharger integration to improve scoring potential of 2013

car • GT-Power simulation

– Used to select turbocharger– Assisted with intake and exhaust design– Used to simulate torque and fuel consumption map for Lap Time

Simulator• Lap Time Simulator

– Used to compare vehicle parameters to determine scoring tradeoffs – Shows that performance gain of turbocharging is worth the fuel

efficiency and weight penalties

Project Goals

• Select appropriate turbocharger for engine package• Design engine peripherals to maximize efficiency and

power of powertrain• Utilize electronic boost control to enable tuning of

fuel efficiency and power for each event via different engine maps

• Comply with FSAE and FSG rules• Design and test for reliability and relatively easy

maintenance

Customer Needs ReviewImportance Description Was It Addressed?

5 Overall Power and Torque Gains: Yes, verified with simulation, needs to be verified on dyno

5 Optimized ECU Map for Best Performance Optimized with simulation, will be finalized on dyno

5 Consistent Engine Performance Will be addressed with repeated dyno testing

5 Necessary Engine Internals are Included with System Yes-Carillo Rods and Swain Tech coated parts

4 Adequate System Cooling Yes-intercooler and radiator sized properly

4 Sufficient Dyno Testing and Validation Will be completed once fully assembled on dyno

4 Optimized Turbo Size for Application Yes-Chosen using simulation results to avoid surge

4 Meet FSAE Noise Regulations Will be determined once dyno testing begins

3 Quick Throttle Response Simulated, will be validated by dyno testing

3 Easy to Access in Car Yes-CAD shows this3 Compact Design in Car Yes-CAD shows this

3 Fit Within Constraints of Current Chassis Yes-CAD shows this

2 Easy to Drive Will be tested once on car

2 Drivetrain Components Designed for Power Increase Yes, designers have used simulated values as design parameters

2 Design for Intercooler Location (if required) Yes-CFD analysis confirms location is apt

1 Readily Available Replacement Parts Some will have to be manufactured in house

1 Simple Interface with Current Engine Yes – No modifications are required to interface

1 Maximized Use of Composite Material Yes-Plenum, intercooler parts

Important Specifications

Function Specification Unit of Measure Ideal Value Comments/Status

Engine Peak Power Output HP and ft-lbf >= 60HP, 45 ft-lbf 62 HP Peak with 45 ft-lbf (GT-Power Model)

Intake Mass Air Flow g/s >=40 58 g/s Peak (GT-Power Model)

System Overall Weight Increase lbs <=15 Expected powertrain weight increase of <7 lb

Funding Cost To Formula Team $$$ <1000 Funding/sponsorship required

System Compliance With FSAE Rules N/A No Infractions Rules Compliant

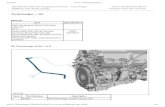

System Architecture

• Induction• Turbocharger• Boost control• Engine• Exhaust system• Mounting

Final Design

Final Simulation Model

•GT-Power is a 1-D engine simulation software•Allows engine flow components to be modeled as 1-D approximations•Very good at simulating flow transients and resonances•Good at modeling Turbocharger system•Must be validated thru testing

Turbo Selection

Comparison of GT0632 VS GT1238. GT12 is close to surge line until 6500 RPM. GT06 is near maximum efficiency until higher engine speeds.

Turbocharger Efficiency

•GT06 turbine operates close to peak efficiency over most of operating range•Compressor is near peak efficiency until higher engine speeds• This is acceptable since boost will be reduced at higher engine speeds anyway

Results From Simulation

Comparisons with Turbocharged (Red) and naturally aspirated powertrain (Blue)

•Top Left: Power•Top Right: Torque•Bottom Left: Manifold air pressure•Bottom Right: BSFC

Transient Data•GT Power allows the simulation of transient flow characteristics•Can be used for simulation validation by making similar measurements on the Dyno•Can also be used to identify performance limitations• Cam profile is not ideal, however stock cams are better than Hotcam alternatives

•PV Diagram Mass Flow Thru Valves Static Pressure in Restrictor

Lap Time Simulation

•Lap Time Simulator used to find scoring potential of possible configurations•Shows that performance gain of turbocharger outweighs fuel efficiency and weight penalties

Turbocharger Modifications

Flange modifications:•Weight savings of 883g•Allowed mounting to single port for single cylinder engine (designed for two cylinder diesel)

Turbocharger-Mounting

• Needs: – positioned and constrained robustly– allow for thermal expansion– isolate from vibration to maximum

degree possible– follow turbocharger specs for proper

lubrication to ensure longevity

• Structural analysis• Modal analysis• Verification through testing

Intercooler

• Size-based off intake flow rate and packaging constraints

• GT Power model simulated effect on overall system– Needs to be verified with test data

• CFD analysis-ensure proper airflow based on full car location

• CFD analysis-shroud design for maximum efficiency

Intercooler-Modification

• Material removal from intercooler core resulted in 192.2g weight reduction

• Additional weight savings with carbon fiber end tanks

Intake/Fuel Delivery

• Intake shape-packaging constraints, desired volume, runner length– Utilized DOE within GT Power for iterative

analysis– Plenum diameter varied 3-8 inches-5.5”

chosen-packaging/performance compromise– Runner varied 5-12 inches-9” chosen-packaged

better than slightly better 12” length• CFD analysis-verify no unusual flow patterns• Cone geometry of injector spray based on data

from Delphi• 2 stage injection system

– Primary (near intake port) improved starting, low speed operation

– Secondary (plenum) maximize atomization at high speeds, minimize wall wetting

Intake/Fuel Delivery Cont’d

Electronic Boost Control

• Needed to allow tuning flexibility-boost varied for different events

• Three-way solenoid in-line between manifold pressure and wastegate diaphragm, vented to atmosphere

• Solenoid controlled via PWM from ECU according to a PID control algorithm to achieve desired boost level

Exhaust

• DOE utilized within GT Power• Header length varied .5-3.5”

– 3.5” best, 2.5” chosen-packaging

• Exhaust length varied .5-8”– Minimal effect on performance

• Header bomb simulated– Minimal effect on

performance-not adopted• Thin walled (.020”)

Commercially Pure Grade 2 Titanium chosen for exhaust– High working temp– Low density

Exhaust Cont’d

Engine

Budget

Purchased Items

Item Cost

GT-0632SZ Honeywell Turbocharger $680.00

Intercooler core material $260.00

Sheet aluminum, intercooler end material $50.00

Exhaust plumbing material $250.00

Intake plenum mold material $40.00

Boost Control Selonoid $100.00

External Engine oil piping, hose, fittings $50.00

Crank Bearings $50.00

Carillo Connecting Rods $484.00

Total: $1,964.00

Testing

• Testing to begin on DC Motor Dynamometer as soon as remaining components are manufactured

• Dyno setup modified to accommodate intake and exhaust systems• Testing/tuning with actual components-delayed start, but save manufacturing

time/cost, more accurate validation, calibration• Measurements will include:

– Torque– Engine Speed– Crank Angle– Cylinder Pressure

• Temp and Press will be measured at:– Intake Before Intercooler– Intake After Intercooler– Intake Plenum– Exhaust Near Exhaust Port– Exhaust After Turbine

• Data logging will be once per degree of crank angle to verify transients

Lessons Learned

• Engine simulation allowed for single iteration of manufacturing-saves time/resources-depends on simulation accuracy

• Simulation results sensitive to input parameters- many initially unverified

• Power generated is knock-limited (no feasible way to simulate)

• Scoring potential trade-off between fuel efficiency and lap time depends on performance of fastest car at competition

Future Work• Finish manufacturing• Complete testing• Verify simulation, change parameters if

necessary to ensure accurate future simulations• Make multiple ECU maps for different events• Install in car• Tune based off driver feedback• Ensure noise level meets regulations• Win at competition