P ENN S TATE 1 8 5 5 High Flexibility Rotorcraft Driveshafts using Flexible Matrix Composites and...

-

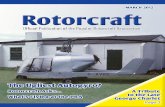

Upload

harold-terry -

Category

Documents

-

view

215 -

download

0

Transcript of P ENN S TATE 1 8 5 5 High Flexibility Rotorcraft Driveshafts using Flexible Matrix Composites and...

PENNSTATE

1 8 5 5

High Flexibility Rotorcraft Driveshafts using Flexible Matrix Composites and Active Bearing Control

Principal InvestigatorsKon-Well Wang, Ph.D.

Diefenderfer Chaired Professor in Mechanical EngineeringCharles Bakis, Ph.D.

Professor of Engineering Science and MechanicsEdward Smith, Ph.D.

Professor of Aerospace Engineering

Graduate Student supported by RCOEBryan Mayrides (M.S. student)

Other Team MembersHans DeSmidt (Ph.D. student)

Ying Shan (Ph.D. student)

PS 2.2

PENNSTATE

1 8 5 5

Issues of Current Driveline Systems – Problem Statement and Technical Barriers

Current Drivelines• Segmented shafting with significant

# of flex couplings/bearings for misalignment compensation

• Passive dampers needed for supercritical speed shafts

High Maintenance and Cost• Component (bearings, couplings, dampers) wear

• Shaft balancing and alignment

• Strict shaft eccentricity tolerances

Issues applicable to both helicopter and tiltrotor

Couplings Bearings

PENNSTATE

1 8 5 5Program Goal and Ideas

To address the issues with current systems and overcome the technical barriers for achieving a simple, high performance, low vibration, low cost, and low maintenance driveline of rotary-wing aircraft Reduce number of mechanical contact components Reduce maintenance need Suppress vibration and ensure stability

IDEAS ?Develop and utilize newly emerging materials and active control technologies -- a combination of

Flexible matrix composite (FMC) materials and Active magnetic bearings (AMB)

PENNSTATE

1 8 5 5Ideas

Flexible matrix composite (FMC) materials with tailored ply orientations for shafting• Soft in flexure and stiff in torsion – to accommodate

for large misalignment and effectively transmit power • Without multi-segment shafting and large # of

bearings/couplings -- reduce cost and maintenance need

New

AMBsFMC shaft

Current

Couplings Bearings

PENNSTATE

1 8 5 5

Ideas (cont.)

Active magnetic bearings for low maintenance and vibration control

While highly flexible composite driveshaft systems have many advantages, their vibration behavior could be issues that need to be addressed before realizing the idea

Penn State researchers have explored the feasibility of active vibration control of tailrotor-drivetrain structure via active magnetic bearings (AMB) by proper controller design, the AMB actuator could be a good candidate for helicopter driveline control (size, weight, power) [DeSmidt, Wang, and Smith, Proc of 54th AHS Forum, 1998]

» Non-contact -- no frictional wear

» Large frequency range -- ideal for active vibration control in rotorcraft setting

» Light backup roller bearings (only contact with active failure) for fail-safe purpose

Stator

Airgap

Electro-Magnetic Coil

Shaft

PENNSTATE

1 8 5 52004 Review Comments and Actions Assess Potential Payoffs

We have examined payoffs for supercritical driveline in previous studies; this year we expanded the study to show potential payoffs (weight and component reductions) for subcritical drivelines via system design

Assess Cost Benefit Qualitatively, reducing components/maintenance = reducing cost; To quantify cost benefit requires development on specific drive system

with manufacturers and users (future RITA project) Examine Practicality of Magnetic Bearing

Have achieved another successful demonstration of AMB controller for FMC shafting with uncertainties

In the process of examining AMB design (weight, size, power) in rotorcraft setting via NASA Glenn design code (On-going effort)

Have generated new ideas of hybrid active-passive failsafe devices as future basic research topics

Address Failure Modes Thorough study beyond scope of current program – Have generated

ideas/plan to examine this issue as a future basic research topic

PENNSTATE

1 8 5 5Research Issues and Task Objectives

Materials and Composite Issues

Structural Mechanics and Dynamics Issues

Systems and Controls Issues

PENNSTATE

1 8 5 5Research Issues and Task Objectives Materials and Composite Issues

Rationale: Traditional barrier to higher strain operation of fiber composites

is matrix cracking Flexible, low-modulus matrix can potentially avoid cracking

Technical Objectives: Select a trial flexible matrix system (carbon/polyurethane) Develop filament winding process Characterize stiffness & damping behavior and validate models

over range of temperatures, frequencies, and strains Build lab-scale shafts for experimental validation of self-

heating, structural dynamics, and to investigate fatigue behavior

0 090

Matrix Cracking

FMC

0 090 90

RMC

0 090 9090 90

Matrix Cracking

PENNSTATE

1 8 5 5Materials and Composite Sub-Task

Achievements 2001-2003/04 Developed wet filament winding technique for trial flexible matrix

composite shafts (carbon/polyurethane) Developed test apparatus & method for characterizing frequency and

temperature dependent damping & stiffness of FMC laminas and laminates

Developed & validated models for frequency and temperature dependent damping & stiffness of FMC laminas and laminates

Developed model and test method to investigate self-heating behavior of rotating misaligned FMC shafts

Summary of Accomplishments in 2004/05: Refined and experimentally validated self-heating model of rotating

misaligned FMC shafts

PENNSTATE

1 8 5 5

Input to the temperature model: frequency and temperature dependent lamina properties of FMC material; misalignment strain; shaft speed

The misalignment strain and rotation speed can be controlled. The stand can spin FMC shafts at up to 1.25% misalignment strain, and at speed up to 2500 RPM

Internal Self-Heating Model and Experimental Validation Method for Misaligned Rotating FMC Shafts

Shaft Self-Heating Model

x

y

or

a

b

M

z

P

Convection into air (T) due to rotation

r

a b

Insulated

T0Tn

T1 Ti-1 Tn-1Ti Ti+1

r/2 r/2

r

Ti, '''iq

Zoom In

2.5 HP DC Motor

Bearing

IR T/C

FMC Shaft

IR Tachometer

5 ft

Misaligned Rotating Shaft Test Stand for Model Validation and Fatigue Characterization

PENNSTATE

1 8 5 5

Shaft Speed (RPM)

0 500 1000 1500 2000 2500 3000T

empe

ratu

re In

crea

se,

T (

o C)

0

10

20

30

40

Shaft Speed (RPM)

0 500 1000 1500 2000 2500 3000T

empe

ratu

re In

crea

se,

T (

o C)

0

10

20

30

40

0.25%, RMC0.25%, FMC

0.75%, RMC

0.75%, FMC

Shaft Speed (RPM)

0 500 1000 1500 2000 2500 3000

Te

mp

era

ture

Incr

ea

se,

T (

oC

)

0

5

10

15

20

25

0.25%

0.50%

0.75%

0.95%

1.15%

Model Results and Experimental Validation

(±45) deg. FMC

Model capable of predicting self heating behavior of FMC materials and providing guidance for design and control of FMC shaft

Model capable of predicting self heating behavior of FMC materials and providing guidance for design and control of FMC shaft

Self-heating of FMC shaft is insignificant compared to RMC Self-heating of FMC shaft is insignificant compared to RMC

PENNSTATE

1 8 5 5Effect of Temperature on Shaft Properties

Laminate design affects temperature sensitivity of shaft Tool developed can predict temperature effect on shaft

properties provide design and control guidance

Laminate design affects temperature sensitivity of shaft Tool developed can predict temperature effect on shaft

properties provide design and control guidance

Applied Frequency, f (Hz)

0 20 40 60 80 100

Long

itudi

nal M

odul

us, E

x (G

Pa)

30

31

32

33

34

23oC

80oC

Shaft Longitudinal Modulus

[+60/-60/+25/-25]s

Applied Frequency, f (Hz)

0 20 40 60 80 100

Long

itudi

nal M

odul

us,

Ex

(GP

a)

0.0

0.2

0.4

0.6

0.8

1.0

23oC

80oC

[+45/-45/+45/-45]s

PENNSTATE

1 8 5 5Research Issues and Task Objectives

Materials and Composite Issues

Structural Mechanics and Dynamics Issues

• Develop analysis tools for driveshaft dynamic loads/ deformation characterization (e.g., strain level, buckling, stability, damping effect on temperature & property variation)

• FMC materials selection and structural tailoring/optimization to satisfy design desires (e.g., maximum allowable misalignment, minimum weight, and minimum internal damping)

Systems and Controls Issues

PENNSTATE

1 8 5 5

Structural Mechanics and Dynamics Sub-Task

Summary of Previous Work (2001-2003/04)• FE model and analysis tools have been developed to

analyze driveline static and dynamic characteristics (deformation,stress level,natural frequency, etc.)

• Utilizing the model and tools developed,

Performed study to provide information regarding parameter effects on system (durability, stability, etc.)

System parameters were tailored to achieve satisfactory system performance for supercritical driveline

PENNSTATE

1 8 5 5

Structural Mechanics and Dynamics Sub-Task

Summary of Current Work (2004/05)• Examined feasibility of designing FMC driveshafts for

subcritical applications Maintain advantages of current supercritical driveline (light

weight, fewer bearings) but without the shortcomings (high vibration, whirl instability, and external damper requirements)

• Performed optimization study where shaft parameters were tailored to find minimum weight and/or component driveline that meets performance requirements

• Examined applications for model/analysis tool Reducing weight in subcritical driveline (Blackhawk,

Chinook) Design a driveline for a minimum number of components

PENNSTATE

1 8 5 5

Inputs• Helicopter properties (shaft geometry, speed, power)• Applied loads (torque, misalignment, imbalance)• Design variables (ply sequence, ply angles, # bearings, outer diameter)

Inputs used to iteratively calculate temperature dependent laminate properties and steady state temperature• Accounts for self-heating (misaligned rotation) and considers atmospheric

heating and rotor downwash cooling Laminate properties (at steady state temperature) to calculate

performance indices• Critical speed ratio (ensures subcritical)• Tsai Wu strength factor (measure of strength)• Torsional buckling safety factor• Torsional yield safety factor

Driveline with minimum weight/components is “optimum” design

Design Approach/Model Outline

PENNSTATE

1 8 5 5

Minimum Weight Design Study Results - Blackhawk

Blackhawk: current driveline specifications• 5 segments• 4 midspan flex couplings, 4 midspan bearings• Driveline mass = 31.3 kg (69 lbs)

Blackhawk: optimum FMC driveline specifications• 1 segment with [60/-60/-25/25]S layup

• 0 midspan couplings, 3 midspan bearings • Driveline mass = 21.6 kg (47.6 lbs)

Conventional – AlloyNew - FMC

Input Torque 734 Nm

(reduction of 5 components)

(reduction of 29.5%)

PENNSTATE

1 8 5 5

Minimum Weight Design Study Results - Chinook

Chinook: current driveline specifications• 7 segments• 6 midspan flex couplings, 6 midspan bearings• Driveline mass = 60.4 kg (133 lbs)

Chinook: optimum FMC driveline specifications• 1 segment with [50/-50/-20/20]S layup

• 0 midspan couplings, 5 midspan bearings• Driveline mass = 44.4 kg (97.9 lbs)

Input Torque 4067 Nm

Conventional - Alloy New - FMC

Conclusion: Designers go from subcritical to supercritical to reduce weight, but weight savings (even component reduction) can also be realized by using FMC drivelines

while maintaining subcritical operation

(reduction of 25.5%)

(reduction of 7 components)

PENNSTATE

1 8 5 5

Minimum Component Design Study

Model & analysis tool applied to re-design driveline for minimum components (reduce maintenance needs) instead of minimum weight

Can we still achieve weight savings when minimizing driveline components?

One example: Blackhawk with --s layup

Current Min Weight Min Comp

Lay-up - [60/-60/-25/25]S [70/-70/-10/10]S

OD (m) 0.0889 0.101 0.14

# Midspan Couplings 4 0 0

# Bearings 4 3 2

Weight (kg) 31.3 21.6 23.8

Observations: Always eliminate all midspan couplings for FMC designs

(both methods) The number of bearing components can be further reduced

even with subcritical speed requirement Weight still saved for this case as compared to current

design

PENNSTATE

1 8 5 5

Materials and Composite Issues

Structural Mechanics and Dynamics Issues

Systems and Controls Issues Effective vibration and stability control methodology

Vibration suppression -- Shaft imbalance with uncertain magnitude and distribution

Stability issues for supercritical shafting -- whirl instability due to shaft internal damping

Adaptive control to compensate for operating condition uncertainty and shaft property variations

Actuator/system design in rotorcraft setting (size, weight, power)

Research Issues and Task Objectives

PENNSTATE

1 8 5 5

Systems and Controls Sub-Task- Achievement Summary

Achievements (2001- 2003/04)

• Preliminary study to identify issues and feasibility of AMB actuators/control in rotorcraft setting

• Developed state equation and uncertainty function formulation for the AMB-FMC driveshaft system

• Synthesized hybrid robust feedback/adaptive feed-forward control law for AMB driveline system and developed robust controller design methodology

• Analytically and experimentally evaluated and validated closed-loop controller performance on AMB-driveline testrig (on conventional segmented Alloy shaft)

PENNSTATE

1 8 5 5

Summary of New Achievements (2004/05)

• Developed H/Synchronous Adaptive Feed-Forward controller for AMB/FMC driveline system Suppress imbalance vibration

Suppress whirl instability (if supercritical)

Account for FMC shaft stiffness and damping uncertainties due to operating temperature variations

Concurrent optimal design of control parameters and AMB locations to maximize closed-loop robustness

• Analytically and experimentally evaluated AMB/FMC driveline closed-loop performance on testrig Stability and vibration suppression performance and robustness

Multiple operating conditions (various shaft speeds, load torques, and operating temperatures)

Systems and Controls Sub-Task

PENNSTATE

1 8 5 5

AMB-FMC Driveline System with Hybrid H /Adaptive Control

ud

y

uFBRobust HFeedbackController+

uAVC y

SynchronousAdaptive Feed-

Forward VibrationControl

T

AMB-FMCDriveline

Hybrid H/AVC Control Law Robust H feedback - Levitates

driveline & ensures stability Adaptive feed-forward - Adapts

to suppress driveline vibration

ShaftNon-Contact

Active Magnetic Bearing

AMB-FMC Driveline SystemShaft Imbalance

AerodynamicLoads

AMB1

LoadTorque

AMB2AMB3

One-Piece FMC shaft with rigid couplings supported by Active Magnetic Bearings (AMB)

Driveline subjected to shaft imbalance, misalignment, torque & ambient temperature variations

PENNSTATE

1 8 5 5

AMB-FMC Driveline SystemClosed-Loop Robustness & Performance

Due to FMC stiffness and damping temperature sensitivity, H/AVC designed to be robust to variations about nominal temperature

Closed-loop system has significant temp. robustness [ -20°F < T < 190°F]

0 1000 2000 3000 4000 5000 60000

50

100

150

200

250

Shaft Speed, RPM

Nominal OperatingTemperature: Tn = 85 °F

Closed-LoopRobustnessMargin, °F

Max Allowable Shaft TemperatureDeviation about Nominal Temperature

|T |max

Limited sensor information requiredOnly uses collocated AMB

sensorsNo knowledge of shaft imbalance

or operating temperature required

0 50 100 150 200

0 50 100 150 200

0 50 100 150 200

time, sec

-225

0

225

-225

0

225

-225

0

225

Shaft VibrationAMB1

AMB2

AMB3D

isp

lace

men

t,

m

Activate AVC

Test Results

PENNSTATE

1 8 5 5Plan for rest of 2005

Structural Mechanics and Dynamics Issues Use structural dynamics model to select an “optimum”

matrix material Incorporate a safety factor in the model to design against

fatigue failure

Materials and Composite Issues Evaluation of FMC fatigue behavior

Systems and Controls Issues Evaluate design issues (size, weight, power) of AMB actuator in

rotorcraft setting via NASA Glenn AMB code Compare weight/size with conventional bearing system

PENNSTATE

1 8 5 5

The feasibility and advantages of utilizing FMC and AMB technologies to improve current rotorcraft driveline systems have been demonstrated for both super- and sub-critical drivelines

Tools have been developed which can be utilized for specific driveline system development applications Manufacturing and characterization processesAnalytical and experimental methodsDesign and control algorithms

Overall Project Accomplishments & Conclusions

We have shown, while maintaining torque transmitting capability

FMC shafting Eliminates segments and flexible couplings/bearings –

reduces components and maintenance needs Reduces strict requirements for alignment Reduces weight

AMBs Eliminate contact bearings – reduce maintenance Reduce vibration level with robust performance w.r.t.

uncertainties (temperature, operating conditions, etc.) Reduce strict requirements for balancing, alignment,

and tolerance

PENNSTATE

1 8 5 5Overall Project Future Directions

Application and development work (RITA type projects) The analytical and experimental tools developed can be

utilized for the development and evaluation of specific future drivelines with FMC shafting and/or AMB technology

Basic research possibilities FMCs with materials enhancement (environment, fatigue,

failure modes, etc.) for advanced rotorcraft applications Active-passive hybrid non-contact bearings – Enhance

driveline fail-safety and stability while retaining merits of AMBs

Distributed auto-balancing techniques – Enhance vibration reduction of driveline without active action

PENNSTATE

1 8 5 5

Publications

Shan, Y., and Bakis, C.E., “Static and Dynamic Characterization of a Flexible Matrix Composite Material,” Proc. 58th American Helicopter Society Annual Forum, Montreal, Quebec, June 2002.

Shan, Y., and Bakis, C.E., “Frequency and Temperature Dependent Damping Behavior of Flexible Matrix Composite Tubes,” 35th International SAMPE Technical Conference, Dayton, OH, Sept. 28 –Oct. 2, 2003.

Shin, E., Wang, K.W., and Smith, E.C., “Characterization of Flexible Matrix Composite Rotorcraft Driveshafts,” Proc. 59th American Helicopter Society Annual Forum, Phoenix, AZ, May 2003.

DeSmidt, H.A., Wang, K.W., Smith, E.C., and Provenza, A.J., “Stability Control of Driveline System with Internal Damping and Non-Constant Velocity Couplings,” Proc. ISCORMA-2 Conference, Gdansk, Poland, Aug. 2003.

PENNSTATE

1 8 5 5

Publications (Cont.)

DeSmidt, H.A., Wang, K.W., and Smith, E.C., “Multi-Harmonic Adaptive Vibration Control of AMB-Driveline Systems with Non-Constant Velocity Couplings,” Proc. ASME Design Technical Conference-19th Biennial Conference on Mechanical Vibration and Noise, Chicago, IL, Sept. 2003.

DeSmidt, H.A., Wang, K.W., and Smith, E.C., “Multi-Harmonic Adaptive Vibration Control of Magnetic Bearing-Driveshaft with Auxiliary Feedback: Theory and Experiment,” Proc. 45th AIAA Structures, Structural Dynamics and Materials Conference, Palm Springs, CA, April 2004.

DeSmidt, H.A., Wang, K.W., and Smith, E.C., ”Stability of a Segmented Supercritical Driveline with Non-Constant Velocity Couplings Subjected to Misalignment and Torque,” Journal of Sound and Vibration Vol. 277, No. 4-5, pp. 895-918, 2004.

DeSmidt, H.A., Wang, K.W., and Smith, E.C., “Adaptive Control of Flexible Matrix Composite Rotorcraft Drivelines,” Proc. 60th American Helicopter Society Annual Forum, Baltimore, MD, June 2004.

PENNSTATE

1 8 5 5

Publications (Cont.)

DeSmidt, H.A., Wang, K.W., Smith, E.C., and Provenza, A.J., ”On the Robust Stability of Segmented Driveshafts with Active Magnetic Bearing Control,” Journal of Vibration and Control, Vol. 11 pp.317-329, 2005.

Shan, Y., and Bakis, C.E., “Internal Heating Behavior of Flexible Matrix Composite Driveshafts,” Proc. 61st American Helicopter Society Annual Forum, Grapevine, Texas, 1-3 June 2005.

Mayrides, B., Wang, K.W., and Smith, E.C., “Analysis and Synthesis of Highly Flexible Helicopter Drivelines with Flexible Matrix Composite Shafting,” Proc. 61st American Helicopter Society Annual Forum, Grapevine, Texas, 1-3 June 2005.

DeSmidt, H.A., Wang, K.W., and Smith, E.C., “Multi-Harmonic Adaptive Vibration Control of Misaligned Driveshaft Systems – An Experimental Study,” Proc. of the 12th International Congress on Sound and Vibration, Lisbon, Portugal, July 2005.

PENNSTATE

1 8 5 5

External Interactions, Leveraging and Technology Transfer

Have had discussions with Army NASA Glenn (Bill, Provenza), Bell (Brunken, Riley), Boeing Philadelphia (Robuck, Gabrys), Boeing Mesa (Hansen), Lord Corporation (Potter), and UTRC (Davis) on various aspects of this project

Have worked with Army NASA Glenn on designing and fabricating test fixtures as well as Magnetic Bearing setup and calibration

Have visited Bell and discussed with Brunken and Riley – addressing temperature effect based on their suggestions; have continued discussion since then

Mark Robuck (Boeing Philadelphia) has visited Penn State in 2003 and discussed future collaboration possibilities in joining efforts for government contracts in this area – have continued to follow up

Leveraged upon Army/NASA Glenn GSRP Fellowship, Army DURIP, Weiss Fellowship, and internal funds from the Structural Dynamics and Controls Lab

PENNSTATE

1 8 5 5

Questions?

The End

PENNSTATE

1 8 5 5Schedule and Milestones

Tasks 2001 2002 2004 2005Refinement of driveline model Perform analysis on driveline model to provide info for FMCFMC selection/ synthesisFMC material characterizationStructure tailoring/optimizationAMB control law synthesis and overall system analysisSub-scale shaft/test stand development Initial testing for validation of model and approachRefinement of material systems and processing methods Evaluation of FMC fatigue behavior Adaptive control design and closed-loop stability and performance analysis for FMC/AMB driveline systemConcurrent system integration and analysis; AMB sizing and design for rotorcraft setting Integrated system testing and evaluation

2003

Near TermMid TermLong Term

PENNSTATE

1 8 5 5

Materials and Composite Sub-Task Key Accomplishments and Conclusions

Key Accomplishments Developed manufacturing process for building FMC driveshafts Characterized both static and dynamic properties of FMC driveshaft

material Developed models to predict self-heating behavior of misaligned FMC

shafts from the basic lamina properties Experimentally validated shaft self-heating model Investigating FMC shaft fatigue behavior

Conclusion FMC shaft material shows significant improvement on strain to failure,

fatigue resistance, and self-heating behavior over the conventional composite materials

Despite the large damping capacity of FMC shaft materials, internal self-heating behavior of FMC shaft under misaligned rotating conditions is much less significant than that of RMC

PENNSTATE

1 8 5 5

Structural Mechanics & Dynamics Sub-Task- Key Accomplishments & Conclusions

Key Accomplishments Developed versatile model and analysis tool to tailor FMC designs to

meet certain performance standards Applied model to supercritical drivelines to prove that FMC shafts can

meet performance requirements Showed possible weight saving advantage of FMC shafting by

optimizing designs for specific subcritical drivelines (Blackhawk, Chinook)

Conclusion – Through selective tailoring of FMC driveshafts, the number of components and system weight can be reduced on helicopter drivelines The single piece subcritical FMC driveline effectively addresses

potential short comings of current drivelinesEliminates mid-span flex couplings – decreases maintenance and

replacement costsReduces overall system weight

PENNSTATE

1 8 5 5

Systems and Controls Sub-Task- Key Accomplishments & Conclusions

Key Accomplishments Developed comprehensive AMB/FMC driveline dynamics analytical model Developed feedback/adaptive feed-forward vibration and stability control strategy

for AMB/FMC driveline which adaptively suppresses imbalance vibrations and is robust w.r.t. shaft temperature variations

Developed frequency scaled AMB/FMC driveline-foundation testrig Experimentally implemented robust feedback/adaptive feed-forward control and

validated AMB/FMC closed-loop performance at multiple operating conditions

Conclusion - Use of AMB with supercritical FMC driveline feasible & beneficial The non-contact and active control aspects of AMB complement the low

maintenance aspects of one-piece rigidly coupled FMC driveline

AMB with H/AVC control effectively addresses potential short comings of supercritical FMC drivelines Suppress supercritical whirl instability due to large FMC damping Suppress relatively large imbalance vibration due to FMC shafting

manufacturing tolerances Accounts for stiffness and damping variation due to temperature sensitivity

PENNSTATE

1 8 5 5

Blackhawk Fixed OD Design Study Results

Current [+1/-1/-2/+2] [+1/-1/-2/+2]s [+1/-1/-2/+2/+3/-3]

Design Metal DC1 DC2 DC3 DC1-3 DC1-2 DC3Classification Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical SubcriticalMaterial Aluminum FMC FMC FMC FMC FMC FMC

Lay-up - [50/-50/-15/15] [60/-60/-30/30] [65/-65/-30/30] [45/-45/-15/15]s [15/-15/-55/55/30/-30] [55/-55/-15/ 15/30/-30]

# of segments 5 1 1 1 1 1 1# of couplings 6 2 2 2 2 2 2# of bearings 4 3 4 4 3 3 3

Outer diameter 0.0889 m 0.0889 m 0.0889 m 0.0889 m 0.0889 m 0.0889 m 0.0889 mWall thickness 2.413 mm 3.881 mm 3.079 mm 3.5 mm 3.775 mm 3.757 mm 3.757 mmEqv. Axial Stiff 75 Gpa 45.1 Gpa 23.5 Gpa 25.9 Gpa 43.2 Gpa 43.2 Gpa 43.2 GpaEqv. Tors. Stiff 27 Gpa 17.7 Gpa 21.6 Gpa 19.3 Gpa 18.1 Gpa 18.2 Gpa 18.2 Gpa

Tsai-Wu S.F. - 3.27 3.82 3.87 3.08 3.28 3.23Buckling torque S.F. 10.49 2.16 4.49 6.45 10.57 5.42 9.15Yield torque S.F. 8.65 8.97 9.84 9.87 8.49 9.33 9.47Critical speed 103.9 Hz 87.7 Hz 95.0 Hz 99.2 Hz 86.0 Hz 86.0 Hz 86.0 HzCritical speed ratio 0.66 0.78 0.72 0.69 0.80 0.80 0.80

Operating strain, xx - 1189 1199 1132 1241 1193 1211Operating strain, yy - 1021 711 508 1487 1066 1082Operating strain, xy - 942 949 946 948 913 926

Shaft mass 13.85 kg 10.95 kg 8.77 kg 9.92 kg 10.66 kg 10.61 kg 11.61 kgTotal system mass 31.25 kg 23.15 kg 24.81 kg 25.96 kg 22.87 kg 22.82 kg 23.82 kg% Mass reduction - 25.92% 20.61% 16.93% 26.83% 26.99% 23.79%

PENNSTATE

1 8 5 5

Blackhawk Varied OD Design Study Results

Redesigned [+1/-1/-2/+2] [+1/-1/-2/+2]s

Design DC1 DC2 DC3 DC1 DC2 DC3 DC1 DC2 -3Classification Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical SubcriticalMaterial Aluminum Aluminum Aluminum FMC FMC FMC FMC FMCLay-up - - - [55/-55/-20/20] [70/-70 -25/25] [60/-60/-30/30] [60/-60/-25/25]s [55/-55/-20/20]s

# of segments 5 5 5 1 1 1 1 1# of couplings 6 6 6 2 2 2 2 2# of bearings 4 4 4 3 3 4 3 3

Outer diameter 0.097 m 0.097 m 0.095 m 0.094 m 0.102 m 0.085 m 0.101 m 0.098 mWall thickness 1.811 mm 1.811 mm 1.938 mm 2.982 mm 2.993 mm 3.607 mm 2.268 mm 2.590 mmEqv. Axial Stiff 75 Gpa 75 Gpa 75 Gpa 38.5 Gpa 35.4 Gpa 23.5 Gpa 32.0 Gpa 38.5 GpaEqv. Tors. Stiff 27 Gpa 27 Gpa 27 Gpa 18.7 Gpa 14.5 Gpa 21.6 Gpa 19.3 Gpa 18.7 Gpa

Tsai-Wu S.F. - - - 3.09 3.03 3.87 2.90 3.08Buckling torque S.F.5.37 5.37 6.3 2.10 4.12 6.22 5.24 6.35Yield torque S.F. 8.01 8.01 8.18 8.88 9.44 10.13 8.46 8.07Critical speed 113 Hz 113 Hz 110.5 Hz 86.8 Hz 90.5 Hz 90.1 Hz 85.8 Hz 90.9 HzCritical speed ratio 0.61 0.61 0.62 0.79 0.76 0.76 0.80 0.75

Operating strain, xx - - - 1317 1367 1217 1495 1296Operating strain, yy - - - 907 418 722 831 893Operating strain, xy - - - 1006 1093 902 1091 1056

Shaft Mass 11.44 kg 11.44 kg 11.97 kg 9.01 kg 9.83 kg 9.74 kg 7.43 kg 8.20 kgTotal system mass 30.58 kg 30.58 kg 30.68 kg 22.03 kg 24.14 kg 24.95 kg 21.57 kg 21.86 kg% Mass reduction - - - 27.95% 21.05% 18.67% 29.45% 28.73%

PENNSTATE

1 8 5 5

Chinook Fixed OD Design Study Results

Current [+1/-1/-2/+2] [+1/-1/-2/+2]s [+1/-1/-2/+2/+3/-3]

Design Metal DC1 DC2 DC3 DC1-2 DC3 DC1-2 DC3Classification Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical

Material Aluminum FMC FMC FMC FMC FMC FMC FMC

Lay-up - [65/-65/-35/35] [70/-70/-35/35] [5/-5/-55/55] [50/-50/-20/20]s [55/-55/-5/5]s[55/-55/-15/

15/45/-45][45/-45/-5/

5/45/-45]

# of segments 7 1 1 1 1 1 1 1# of couplings 8 2 2 2 2 2 2 2# of bearings 6 6 6 5 5 5 5 6

Outer diameter 0.1143 m 0.1143 m 0.1143 m 0.1143m 0.1143 m 0.1143 m 0.1143 m 0.1143 mWall thickness 3.048 mm 3.976 mm 4.574 mm 6.866 mm 4.254 mm 6.866 mm 4.125 mm 4.358 mmEqv. Axial Stiff 75 GPa 18.2 Gpa 20.2 Gpa 56.5 Gpa 36.1 Gpa 56.5 Gpa 32.2 Gpa 37.8 GpaEqv. Tors. Stiff 27 Gpa 21.2 Gpa 18.7 Gpa 13.3 Gpa 20.0 Gpa 13.3 Gpa 20.5 Gpa 19.6 Gpa

Tsai-Wu S.F. - 2.09 2.12 3.13 2.07 3.01 2.03 3.05Buckling torque S.F. 4.03 2.27 3.37 2.31 3.44 14.43 3.84 3.36Yield torque S.F. 3.26 3.37 3.38 3.44 3.18 3.36 3.11 3.11Critical speed 198.2 Hz 152.2 Hz 158.9 Hz 187.0 Hz 158.1 Hz 187.0 Hz 150.0 Hz 214.6 HzCritical speed ratio 0.58 0.76 0.73 0.62 0.73 0.62 0.77 0.54

Operating strain, xx - 1654 1534 1166 1502 1214 1622 1121Operating strain, yy - 769 556 585 1424 608 1210 1116Operating strain, xy - 2575 2565 2446 2583 2545 2533 2527

Shaft Mass 25.65 kg 16.59 kg 18.98 kg 27.89 kg 17.70 kg 27.89 kg 17.19 kg 18.12 kgTotal system mass 60.44 kg 48.7 kg 51.09 kg 54.80 kg 44.61 kg 54.80 kg 44.10 kg 50.23 kg% Mass reduction - 19.42% 15.47% 9.33% 26.19% 9.33% 27.04% 16.89%

PENNSTATE

1 8 5 5

Chinook Varied OD Design Study Results

Redesigned [+1/-1/-2/+2] [+1/-1/-2/+2]s

Design DC1 DC2 DC3 DC1 DC2 DC3 DC1 DC2 DC3Classification Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical Subcritical SubcriticalMaterial Aluminum Aluminum Aluminum FMC FMC FMC FMC FMC FMCLay-up - - - [55/-55/-30/30] [65/-65/-35/35] [5/-5/-50/50] [50/-50/-20/20]s [50/-50/-20/20]s [50/-50/-5/5]s

# of segments 7 7 7 1 1 1 1 1 1# of couplings 8 8 8 2 2 2 2 2 2# of bearings 6 6 6 6 6 5 5 5 5

Outer diameter 0.122 m 0.117 m 0.122 m 0.106 m 0.11 m 0.11 m 0.118 m 0.116 m 0.11 mWall thickness 2.458 mm 2.820 mm 2.458 mm 4.613 mm 4.551 mm 7.152 mm 3.809 mm 4.040 mm 7.152 mmEqv. Axial Stiff 75 Gpa 75 Gpa 75 Gpa 20.5 Gpa 18.2 Gpa 56.4 Gpa 36.1 Gpa 36.1 Gpa 56.4 GpaEqv. Tors. Stiff 27 Gpa 27 Gpa 27 Gpa 23.5 Gpa 21.2 Gpa 14.5 Gpa 20.0 Gpa 20.0 Gpa 14.5 Gpa

Tsai-Wu S.F. - - - 2.22 2.12 3.14 2.04 2.06 3.01Buckling torque S.F. 2.28 3.15 2.28 2.08 3.01 2.08 2.64 3.04 13.25Yield torque S.F. 3.02 3.15 3.02 3.83 3.44 3.32 3.05 3.10 3.29Critical speed 174.1 Hz 166.3 Hz 174.1 Hz 148.4 Hz 145.5 Hz 179.9 Hz 164.0 Hz 160.8 Hz 179.9 HzCritical speed ratio 0.66 0.69 0.66 0.78 0.79 0.64 0.70 0.72 0.64

Operating strain, xx - - - 1542 1704 1144 1490 1495 1195Operating strain, yy - - - 1210 792 817 1413 1417 854Operating strain, xy - - - 2372 2466 2338 2675 2625 2442

Shaft Mass 22.22 kg 24.35 kg 22.22 kg 17.68 kg 18.15 kg 27.81 kg 16.45 kg 17.11 kg 27.81 kgTotal system mass 59.53 kg 60.06 kg 59.53 kg 47.13 kg 48.88 kg 53.57 kg 44.35 kg 44.47 kg 53.57 kg% Mass reduction - - - 20.83% 18.61% 10.01% 25.50% 25.30% 10.01%

PENNSTATE

1 8 5 5

Bias Current Design Level, Amps

Mas

s, k

g

1.2 1.4 1.6 1.8 2

2.5

2.7

2.9

3.1

3.3

3.5

3.7

3.9

4.1

1.0

Fmax = 90 Lbf

Fmax = 70 Lbf

Fmax = 110 Lbf

AMB Mass vs Bias Current

Conventional AH-64 Bearing Mass (3.17 kg)

Shaft

Comprehensive Radial AMB Design Code

Max force (Fmax) and current determined by material magnetic flux saturation and current density/RMS heating limitations

Based on required Fmax for given shaft OD and airgap, code optimizes AMB rotor, stator and pole geometries and coil winding parameters for minimum weight.

AMB mass similar to existing AH-64 contact hanger bearing

OD

L

AMB design for AH-64 (Shaft OD=4.5 in) Max Force, Fmax = 100 Lbs Mass = 3.17 kg (Matches Existing) Bias Current = 1.62 Amps AMB Size, OD = 7.4 in, L = 2.2 in

AMB Design