p. 16 p. 6 p. 7 FOLIO -...

Transcript of p. 16 p. 6 p. 7 FOLIO -...

FOLIO4 / 2015WE ARE CHEMICALS!

SPECIALISTS FROM EVONIK

THE EMPLOYEE MAGAZINE

With their expert knowledge, they make key contributions to the Group’s success p. 12

Isophorone chemistry Reliable solutions for paints, inks, and coatings p. 8

CoverFormScratch-proof surface for touchpads p. 6

South AmericaStéphanie Facuri on the market for Personal Care p. 7

HRconnect“Implement

and experience change” p. 9

ChlorosilanesIncident Response Team: Always ready to go p. 16

My monthAndrew O’Rourke:

An American in the Ruhr region p. 15

PLEXIGLASVegetables on ice p. 6

PLEXIGLASVegetables

My monthAndrew O’Rourke:

My monthAndrew O’Rourke:

My month

An American in the

2 folio 4 / 2015 CONTENTS

News from the company

Klaus Engel in MalaysiaDuring his Asia tour in July, CEO Engel also accompanied the BVB soccer team as it visited a children’s home in Johor Bahru

CONTENTS4 /2 0 1 5

In order to write a cover story about specialists at Evonik, you would ac-tually have to interview more than 33,000 people. After all, doesn’t every employee have special skills and a special focus? How should we make a selection? A specialty chemicals com-pany needs special knowledge. That’s why it has people whose know-how makes a difference when it comes to developing new products and apply-ing innovative technologies. In his search for specialists, Folio’s Editor in Chief, Christof Endruweit, found experts in many areas of the compa-ny, not just in labs. For example, he talked with finance expert Peichen Zhang from Shanghai as well as with Jonathan Huckle from Frankfurt, who calls himself an IT nerd. You can read about these experts in the cover story, which begins on page 10.

Other reports in this issue also deal with specialists—for example, with the members of the Incident Response Team in Rheinfelden, who always have their suitcases packed and ready so that they can immediately travel to customers who are having prob-lems with the product chlorosilane (page 16). Another article features applications technologist Stéphanie

Journalist meets specialist: Christof Endruweit (right) and Jonathan Huckle

Dear readers,

Facuri from Guarulhos in Brazil, who is an expert on the cosmetics mar-ket in South America (page 7). And there’s also a story about Muhammad Nasiruddin, an employee at the TEGO Innovation Center in Singapore who also happens to be Singapore’s best high-jumper and a participant in the South East Asia Games (page 18). In fact, there’s a specialist either in or behind almost every article in this issue.

Pleasant reading!

The Folio team

Zachary M. Woods is looking forward to

celebrating two Mexican holidays in September

Stéphanie Facuri knows what South American

customers expect from a good cosmetics product

7

18

17

18

10

Andrew O’Rourke from the USA gained many

exciting impressions of Germany as a Ruhr Fellow

15

“The new company structure will make us faster and more agile”Klaus Engel, Chairman of the Executive Board

s h o r t q u o t e

One year after the decision was made to realign Evonik, the Group implemented its new structure as planned on July 1. As a result, the three operating units Nutrition & Care, Resource Efficiency, and Perfor-mance Materials are now supported by Technology & Infrastructure, which is also a separate company. Executive Board Chairman Klaus Engel thanked the em-ployees for the great dedication they showed in implementing the Group’s am-bitious growth plans.

Effective July 1, 2015, Ralph Sven Kaufmann (right) succeeded Patrik Wohlhauser as Evonik’s new Chief Operating Officer. Wohlhauser left the company by mutual agreement on June 30. Su-

pervisory Board Chairman Werner Müller thanked Wohlhauser for his achievements,

which have had a lasting impact on Evonik. Evonik

CEO Klaus Engel added, “With the departure of Patrik Wohlhauser, we lose a competent Executive Board member as well as a respected col-league, with whom we have always worked together very well.” Before joining our company, Kaufmann was Man-aging Partner of SCOPEIN Manage-ment Consultants, which has also ad-vised Evonik on a number of projects.

Evonik Industries has sold its remaining share of 10.3 percent of the housing company Vivawest GmbH to RAG Aktiengesellschaft. The trans-action increased RAG’s share of the largest housing company in North Rhine-Westphalia from 7.9 percent to 18.2 percent. In line with its focus on specialty chemicals, Evonik has thus completely divested itself of its real estate holding. The sale was concluded on June 29, 2015.

A successful start

Kaufmann succeeds Wohlhauser

Evonik sells Vivawest holding to RAG

n e w g r o u p s t r u c t u r e

c h a n g e o n t h e e x e c u t i v e b o a r d

r e a l e s t a t e

Florian Lyon helps the participants of a

trainee program as they be-gin their professional careers

15

Deolinda Scott is impressed by the round

steel framework of the Ópera de Arame in Curitiba

Mechthild Rieping is responsible for the devel-

opment of biological systems in Halle-Künsebeck

Ilona Kraft ensures that chlorosilanes

always meet their high quality requirements

3NEWS folio 4 / 2015

South Africa is a veritable “rainbow” nation. The blacks belong to many different tribes, and there are many people living on the Cape who have Dutch as well as African roots. Durban is the biggest Indian city outside India. The Indians are often merchants, as trading was one of the few professions open to them during the time of apartheid. Our team also consists of blacks, Indians, whites, and people with a variety of eth-nic roots. It therefore goes without saying that we re-spect our colleagues’ various cultures and religions and take them into account. In South Africa, a black person immediately sits down when he enters the office of his or her boss. That would be con-sidered impolite in Germany. Here, on the other hand, it is seen as a sign of mutual re-spect, because it puts both sides on the same level. When we eat together, we make sure that the dishes are “halal” so that Muslim employees can eat them too.

Holger MorhartJohannesburg

After one of my first confer-ences at Evonik, I was surprised to see that the same colleagues who had just held tough and ex-tremely frank discussions at the meeting went to lunch together and casually chatted about their plans for the coming weekend. People in Germany provide feedback and criticism much more readily than in my home country, Finland. But people here don’t take it personally. I agree with this approach, even though I first had to get used to it, because people are more in-direct in Finland. The people’s friendly and welcoming atti-tude made it easy for me to quickly feel at home here. How-ever, I first had problems with the German formal and infor-mal “you,” and who may offer the latter to whom. In Helsinki, by contrast, I addressed even my business professor by his first name. That’s completely normal in Finland and not in the least impolite. However, Finns and Germans are also alike in many things. Both ap-preciate punctuality and objec-tivity and are very reliable.

Riikka PieviläinenEssen

Riikka Pieviläinen began her pro-fessional career in 2013 as a finance trainee at Evonik. She is now a pricing analyst in the Personal Care unit. She lives and works in Essen, where she appreciates the wide variety of leisure activities on offer. Pictured below is the Zeche Zollverein World Heritage Site.

Holger Morhart came to South Africa in 1994 as an ad photographer. He later became a marketing consultant, helped set up the sales organization for PLEXI-GLAS, and is now Managing Director of Evonik Acrylics Africa. On Saturdays he often cheers for his son as he plays crick-et—a popular pastime in South Africa.

EVONIK WORLDWIDE

When you travel to new places, you start to see things from a different perspective. What at first seems strange

suddenly becomes wonderfully normal. Two Evonik expats talk about their (now) familiar daily experiences

At home abroad

The nonprofit Grace Covenant Community Care organization in Jo-hor Bahru (Malaysia) provides chil-dren from disadvantaged back-grounds with accommodation, education, care, and protection. In addition to donating €2,500, Evonik organized the visit of the BVB play-ers Neven Subotić and Sven Bender as well as of the BVB ambassador Karl-Heinz Riedle and the team mascot, Emma. The children had previously taken part in a chemistry class, where they learned about and experimented with products from Evonik. “By promoting the natural sciences at an early age, we are help-

ing to get young people enthusiastic about science later on in school,” said Engel.

This summer the BVB embarked on an Asia tour that took the team and the delegation not only to Ma-laysia but also to Singapore and Japan. The players were welcomed like pop stars wherever they went, and the team played test matches in sold-out stadiums. The BVB is an im-portant brand partner for Evonik in Asia as well. Borussia Dortmund has millions of fans in this region, and the team operates an official branch office in Singapore, where it shares a building with Evonik.

During the MSE Colloquium, Executive Board member Christian Kullmann presented the Evonik Sales Awards—worth a total of €90,000—for the first time. The award in the “Commercial Success” category went to a team from Active Oxygens in the Resource Ef-ficiency segment. This entry particularly ful-filled the criteria of “Importance for Custom-ers” and “Creativity.” The team impressed the judges with the introduction of a new genera-tion of hydrogen peroxide for the American market. The award in the “Sales Innovation” category was won by a team from the Silanes Business Line in the Resource Efficiency seg-ment. This team developed an innovative con-cept for an American company that creates products out of aerogels. One of the concept’s key elements was a sustainable approach to recycling and to the use of an ethanol flow. The

Evonik Sales Award in the Solving a Sales Problem category was won by a team from the Functional Solutions Business Line in the Performance Materials Seg-ment. The team assisted a major customer who had purchased four biodiesel plants in southern Europe and was experiencing difficulties in the processing of palm oil from Indonesia. Evonik developed a package of alkoxides and cold flow improvers to overcome the challenges and allow year-round production of biodiesel. The award winners were selected from the more than 50 entries by Kullmann and the Marketing & Sales Council at Evonik.

Christian Kullmann honors award winnerse v o n i k s a l e s a w a r d

The first-ever presentation of the Evonik Sales Award

Klaus Engel and the BVB representatives re-ceived a warm welcome

at the children’s home

Phot

ogra

phy

on p

ages

2-3

: Duh

Mac

hado

, Lin

a N

ikel

owsk

i (2)

, Kar

sten

Boo

tman

n, F

rank

Pre

uß (2

), S

tefa

n W

ildhi

rt (2

), A

ndre

as P

ohlm

ann,

Kirs

ten

Neu

man

n, E

voni

k In

dust

ries (

2), B

ox B

ootm

ann,

Shu

tters

tock

(2)

Cove

r pho

togr

aphy

: Ste

fan

Wild

hirt

, Dai

mle

r AG

, Duh

Mac

hado

, Fra

nk P

reuß

(2),

Evo

nik

Indu

strie

s

PLEXIGLAS® is a registered trademark of Evonik Industries AG or its subsidiaries. It is indicated in capital letters throughout the text.

4 folio 4 / 2015 A PICTURE AND ITS STORY

5 folio 4 / 2015

Phot

ogra

phy:

© S

othe

by’s/

akg-

imag

es

Responsibility: The identity of the first users of the phrase “honest traders” has faded into the mists of time. Were they the merchants of the Hanseatic League, whose success was based on their code of re-sponsible business practice? Or was it one of their Italian partners boasting about a successful business relationship? Whoever it was, honesty, integrity, decency, and tolerance became the principles of re-sponsible and sustainable behavior that formed the foundation and the code of honor of both the medi-eval Hanseatic League and the merchant associations of the Italian Renaissance. These principles con-tinued to be a fixed component of successful business relationships over the centuries. Half a millennium later, these principles are still valid, and they form the basis of our business deal-ings. Every Evonik employee is responsible for complying with the applicable laws and regulations as well as our corporate ethical standards in his or her daily work. This sys-tematic observance of the rules—including legal stipulations, corporate guidelines, and Evonik’s voluntary commitments—is known today as compliance. At Evonik, the key rules of conduct, regulations, and prohibitions are enshrined in the Evonik Integrity Code, which applies to all employees throughout the Group. (AF)

The World Bank estimated in 2012 that corruption causes at least $1 trillion

worth of damage annually. Experts fear that because of the large number of

unrecorded cases that figure might be actually closer

to $4 trillion.

1 TRILLIONOver

PRODUCTS + INNOVATIONS

P I

Phot

ogra

phy:

Evo

nik

Indu

strie

s (4)

, Dai

mle

r AG

EVONIK IN

ACTION

Did you know?

6 folio 4 / 2015 PRODUCTS + INNOVATIONS

Without a coating A panel of polymethyl-methacrylate without a coating shows clear signs of wear after an abrasion test

With CoverForm Even after 500,000 swipes of a felt pad, the test component remains free of scratches

Scrolling with cream on your hands, swip-ing with a big ring on your finger or cleaning with abrasive products—these are just a few of the daily attacks to which the displays of smartphones and tablets, as well as infotain-ment systems in cars, are exposed. The touch-pad of COMAND Online, the new infotainment system in various Mercedes-Benz model series, withstands constant stress with ease, thanks to its plastic faceplate made of PLEXIGLAS and an additional coating of scratch-preventing CoverForm. Evonik and the equipment manu-facturer KraussMaffei jointly developed the system solution CoverForm, which involves di-rectly adding polymethylmethacrylate to the coating material during injection molding. That saves many process steps and makes produc-tion faster, more cost-effective, and thus more

suitable for series production. In addition, the close bond between the two components pre-vents undesirable rainbow effects on the dis-play surface. The supplier, Continental, plans to manufacture more than one million faceplates for Daimler by 2016.

The touchpad in Mercedes models is inte-grated into the central console. In addition to the familiar finger movements, the driver can also write on the display, for instance in order to enter a destination into the navigation sys-tem. Every action is confirmed by a perceptible vibration. As a result, the driver can use the system without taking his or her eyes off the road. The slightly curved touchpad can also be used as a comfortable handrest, because the system can recognize whether it’s being touched intentionally or accidentally. (UJ)

The Mercedes touchpad, which is made with CoverForm, received the SPE Automotive Grand Award in the category “Electronic/optical compo-nents” at the 16th SPE Automo-tive Award Night 2015

Scratch-free driving

Sven Schröbel is responsible for developing business operations for CoverForm technology, which Evonik and the equipment man-ufacturer KraussMaffei began to develop in 2006. The two compa-nies quickly attracted interest from Daimler and Continental. “We had already subjected CoverForm to numerous standardized tests, so its material properties had al-ready been demonstrated,” says Schröbel. Other steps followed on the road to series maturity. For example, a special test specimen had to be used in order to demon-strate the process suitability of the technique in addition to the material properties. Continental, Daimler, KraussMaffei, and Evonik jointly developed the first touch-pad with a curved surface for a car. A number of inquiries from other industries, including consumer electronics, household appliances, building services, and watches, led to pilot projects. This innovation recently received two important awards from the Society of Plastic Engineers (SPE).

Ready for series production

HARVESTING AT -50°CThe researchers at Great Wall Station in the Antarctic are raising fresh vegetables in a greenhouse made of PLEXIGLAS Alltop, which is marketed as ACRYLITE in the Americas. This material lets an especially large amount of light through and stands up effortlessly to extreme cold and strong winds.

Evonik has developed a system for touchpads in Mercedes models

p o r t r a i t

PLEXIGLAS® and ACRYLITE® are registered trademarks of Evonik Industries AG or its subsidiaries. They are indicated in capital letters throughout the text.

7PRODUCTS + INNOVATIONS folio 4 / 2015

WHAT: Expanded oil additives plantWHERE: SingaporeSEGMENT: Resource EfficiencyPRODUCTS: Oil additivesAPPLICATION: Improved efficiency of engines and

transmissions as well as of hydraulic fluids, resulting in improved fuel and energy efficiency

EMPLOYEES: 12 additional employeesMARKETS: Asia

New in… Singapore

esh global meeting: At the ESH Global Meeting in Essen, Evonik’s Chief Human Resources Offi-cer Thomas Wessel and Thomas Jostmann (photo), Head of Corporate Environment, Safety, Health and Quality (ESHQ), emphasized the importance of having a uniform corporate culture in the areas of environment, safety, health, and quality in the new corporate structure. For the first time, the meeting featured speakers from outside the Group: Johan Rood from AkzoNobel and Jürgen Herrmann, formerly at BP Deutschland. Rood and Herrmann offered insights into other companies’ approaches to ESH management. One of the focal points is on process safety and risk management. The 55 participants of the meeting engaged in an intense discussion of the necessary common standards within segments, regions, and service units.

Ms. Facuri, you want to fulfill the wishes of your customers in this region. What does that mean in concrete terms?I’ll give you an example. In Europe, most consumers use shower gels. In Brazil, peo-ple prefer to work up a lather with a bar of soap. That’s why we’ve developed a special recipe for such soaps for a local producer. These soaps are sold all over South Ameri-ca. In order to have this kind of success, you have to know what customers expect from the end product and also how much they want to spend for it. Price is an important factor for customers in South America.

Is South America a region where only inexpensive products are sold?No, people’s expectations are rising. There’s also a trend toward highly effective products, and in these cases we have to take into account special requirements such as the climate. We’ve developed a formula-tion for body lotion that releases moisture after it has been applied. It nourishes and refreshes the skin at the same time. One of the biggest Brazilian cosmetics companies is now using this technology.

How is the market developing?For years now, the middle class in South America has been growing, and the cos-metics market has grown along with it. For us Brazilians, hair is an important factor. Brazil is a trendsetter in many areas, such as hair straightening. Brazilians also wash their hair more often than people in other countries, so they need more hair care. That’s why South Americans prefer creamy conditioners. We are currently setting up a hair laboratory in Brazil in order to develop new formulations that are even more mar-ket-specific.

Who are your customers?Our direct customers are multinational cosmetics companies, larger regional com-panies, and also small firms. We help our customers develop formulations and we of-fer training courses. There is still very little research in the area of cosmetics at South American universities, and our customers expect quick solutions. As soon as people see a cosmetics product in one of the pop-ular soap operas on TV, they want to buy it right away. (UJ)

5 minutes with…Stéphanie Facuri

Evonik Industries has acquired the Monarch Cat-alyst company in Dombivli (India). As a result, the Group has expanded its portfolio in the area of pe-troleum and fat hydrogenation catalysts and strengthened its market position for activated metal catalysts and precious metal catalysts in India and the entire Asian market. Monarch Catalyst, which has approximately 300 employees, will be renamed Evonik Catalysts India Pvt. Ltd. and will combine all of Evonik’s catalyst activities in India. The pro-duction plant is located near Mumbai.

Catalysts from Indiaa c q u i s i t i o n

Stéphanie Facuri heads the application tech-nology laboratory of Personal Care in Guarul-hos near São Paulo (Brazil). When cosmetic formulations are developed at the lab, she always has an eye on the needs of customers in the South America region.

Phot

ogra

phy:

Evo

nik

Indu

strie

s (3)

| I

llust

ratio

n: L

yndo

n H

ayes

/Dut

ch U

ncle

You can find further information about cosmetics topics on the intranet in the

Nutrition & Care segment.

C

CC

C

CC

CC

O

H

HH

H

H

H H

H

H

H

H

H

H

H

8 folio 4 / 2015 PRODUCTS + INNOVATIONS

SERIES: MILESTONES OF CHEMISTRY

IsophoroneEvonik is a pioneer in the field of isophorone chemistry and is still the only company in the world to cover the entire isophorone value chain. The VESTA brand family includes isophorone, diamines, diisocyanates, and polyisocyanates. They are used, among other things, in coatings, in flooring, and increasingly in composites. Evonik produces isophorone in Germany, the USA, and, since last year, in China.

Isophorone is a largely colorless liquid that is used, among other things, in the coating, printing ink, and adhesive industries, due to its outstanding solvent properties. It is used in a wide variety of applica-tions, including as a starting material for disinfectants and vitamin E. Sec-ondary products of isophorone are used in car headlights to ensure high temperature resistance and a special look.

Applications:• Plant protection products• Sunscreens• Solvents for printing inks• Headlights

Isophorone diamine (IPD) is used in a wide variety of applications as a cross-linker or hardening agent. As a rule, the addition of even tiny amounts of this material has a big impact. IPD is used in marine coatings as well as in other coat-ings such as those applied to bridges and factory floors, i.e. areas that have to be particularly protected against corrosion or mechanical stress. IPD is also used in high-quality composite materials, such as those used in wind turbine rotor blades or lightweight automotive com-ponents, where it ensures the necessary temperature resistance, mechanical properties, and suitability for the pro-cessing technology used. Applications:• Wind turbine rotor blades• Floor coatings• Marine coatings • Composite materials for pipes

History

Isophorone diisocyanate (IPDI) is the next stage of refinement—one that fulfills all of the preconditions for the production of lightweight and weather-resistant polyurethane. In cars, IPDI is used in “spray skins,” for example. Spray skins include coatings for the dashboard and other plastic parts. In addition to high resistance, such components now need to look and feel good, properties that IPDI noticeably improves. Applications:• Urethane acrylates and polyurethane emulsions for coatings

and adhesives• Elastomers for sealants and in the automotive sector

The secondary products of IPDI are referred to as derivatives. These are crosslinkers for various types of polyurethane coating—either powder, water-based or solvent-based. IPDI derivatives make such coatings very resistant to weathering and chemicals. Powder coatings are especially efficient to apply and give bicycle frames, for example, a high-quality appearance. Such coatings are also used to decorate window profiles with a special production process (transfer printing).

Applications:• Coil coatings• Can coatings• Automotive refinishing coatings• Powder coatings

You can find more information at www.evonik.com/crosslinkers

1962Acetone chemistry at the Hibernia nitrogen plant in Herne, Germany is launched in 1962, when the first isophorone facili-ty is put into operation.

1988Production capacity is more than doubled in Herne in 1988, when the second isophorone production line is put into operation.

1992In 1992 Evonik expands isophorone production be-yond Germany for the first time by installing its third isophorone production line at the plant in Mobile, Alabama (USA). The facil-ity in Mobile mainly serves customers in North and South America.

2007The fourth production line (located in Herne) goes into operation in 2007. This facility has six times the capacity of the first production line.

2014The fifth production fa-cility goes into operation in Shanghai (China). It focuses on the Asian market.

Isophorone (3,5,5-trimeth-yl-2-cyclohexene-1-one) is used as a solvent and as an intermediate for synthesis purposes. Isophorone also occurs naturally in cran-berries.

VESTA® is a registered trademark of Evonik Industries AG or its subsidiaries. It is indicated in capital letters throughout the text.

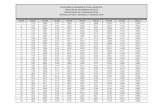

9HUMAN RESOURCES folio 4 / 2015

Around 100 managers and specialists from all over the world came together in Essen for this year’s

HRconnect. One of the key topics addressed at the conference was the continuous process of change

at the company. These key figures from 2014 help illustrate the great diversity of the HR unit’s

challenges

“BECOME FASTER, MORE ENTREPRENEUR-IAL, AND MORE COMPETITIVE” Chief Human Resources Officer Thomas Wessel thanked the employees for their achievements in recent years, particularly with regard to the further development of the HR organization. “For me, continuity and change are two sides of the same coin,” he said. “Through our structural and func-tional realignment, we have laid the foundations for meeting the challenges ahead and created

the basis for a continuous change process in the human resources work at Evonik. Let us become even faster, more entrepreneurial, and more com-petitive in the future. Let us drive, implement, and experience change even more strongly, and work even closer to people.”

The participants at HRconnect 2015 engaged in an ongoing dialogue. Many of them were taking part in the HR conference for the first time and

were able to directly contribute their experiences from the operational businesses and the regions. The second day of the event in particular showed the extent of the substantial and diverse challenges facing human resources work at Evonik in connec-tion with the organization of the segments and the growth projects. Wessel appealed to the partic-ipants not to let up in their efforts but “to go the extra mile to make Evonik and your HR community successful.” (SVS)

CONTINUITY AND CHANGE

23,829

41.6years

Average age of the employees:

52years

The longest time anyone has worked for the Group is

6,000(new staff, internal movement, departures)

Employee movements worldwide:

trainees in Germany, 359 were hired after completing their programs

432Of

percent work part-time (8 percent in Germany)

6Around

Average number of years at the Group:

years15.1

Number of employees in Asia—planned by 2019

750Net workforce

increase:

employees were permanently employed outside their home countries in 2014

408

different nationali-ties are represented

in the Group

90Around

Gra

phic:

C3

Visu

al L

ab |

Pho

togr

aphy

: Kirs

ten

Neu

man

n (2

)

applications were received by the Recruiting Center in Germany in 2014. That’s more than 65 applications per day

10 folio 4 / 2015 COVER STORY

Mechthild RiepingBiotechnological Research Animal Nutrition

Mechthild Rieping (left) is a specialist who knows she can’t do her work without the help of other specialists. “As a molecular biologist, I can’t accomplish anything alone,” she admits. In her work she cooper-ates with engineers who build the apparatus she needs and with bio-informatics specialists who can master the growing flood of data. “I’ve

always been fascinated by applied science,” Rieping says. Specifically, she’s inter-ested in finding out how bacteria strains that have been created in the lab behave in the big tank and how combining technical and molecular biology methods can help to develop new kinds of products and new application properties. Today she is responsible for characterizing and developing biological systems that generate the desired products inside fermenters. She’s also responsible for supporting proj-ects that make healthy and resource-conserving animal husbandry possible—for example, the development of new diagnostic methods to detect diseases. “I’m happy when I can once again really dive into the science,” Rieping says.

Senada Schaack CAPE & Automation

On the display is a virtual stirred tank reactor in which rotating stirrers are making a red mass swirl around. The animation is the result of flow

simulation, and it shows how optimiz-ing stirring processes can increase the capacity of a tank reactor. This is a typ-ical task for the CAPE & Automation department of the Process Technol-ogy & Engineering Service Unit, and a typical job for Senada Schaack. Her area of specialization is simulation, or process and flow simulation, to be ex-act. “In process simulation we assess an entire production line, and in flow simulation we assess individual ap-paratus in great detail,” she explains. These virtual trials provide important analyses and data for the develop-ment, construction, and optimization of production lines, without the need to conduct elaborate test series in the production facilities. “We’ve been able to simulate fluid processes—in other words, processes involving liquids and gases—very effectively for quite a while now,” Schaack con-tinues. “We now have expanded and improved our methods to such an extent that we can also include solid matter apparatus in our apparatus simulations.” For Schaack and her colleagues, this is a big step in their campaign to increase the acceptance of simulations at Evonik—and to make simulations’ contribution to value cre-ation even more visible.

WHO’S THINKING FURTHER AHEAD?The world is full of specialists. Animals that have adapted to their surroundings. Plants that have adjusted themselves to the seasons and the local climate. And people—individuals who possess significant knowledge and skills in a specific field. Not everyone has abilities like these

The specialists

Specialists are typical of societies where there is an extensive division of labor. That’s because the amount

of knowledge in individual specialist ar-eas has grown so huge that today there is practically no demand for polymaths such as Alexander von Humboldt and Johann Wolfgang von Goethe.

One characteristic of modern societies is that they are becoming increasingly differentiated. The Olympic Games of the modern era were launched in Athens in 1896 with 43 competitions in nine differ-ent disciplines. At the London Olympics in 2012, athletes competed for the gold, silver, and bronze medals in 302 com-petitions in 26 disciplines. In the world’s megacities, there’s a restaurant for every taste. Physicians can choose between numerous areas of specialization, jurists can practice in particular areas of the law. There are specialists everywhere you look.

As a rule, individualists with special-ized knowledge can make a contribution only if they are connected with their sur-roundings. They must be able to use their knowledge to help create something that is meaningful. The specialists at Evonik share their knowledge, cooperate with other specialists, and look beyond the boundaries of their special fields. They are curious. Above all, they don’t simply “do their own thing, no matter what others are saying.” Instead, they always try to make sure that their specialist knowledge will be useful for someone. Otherwise, their special skills would deteriorate into an eccentric hobby. “Our goal is to make

sure that our products and solutions bring success to our customers,” says Techni-cal Service Manager Eckhard Just from Rheinfelden.

The specialist knowledge at Evonik is definitely not static. Indeed, it’s closely related to another one of the Group’s ar-eas of expertise: self-renewal. “Special knowledge is a temporary thing. In view of dynamic markets, we have to evolve on an ongoing basis,” says Dorit Wolf, who heads the Research and Development Fixed-bed Catalysts department in the Catalysts Business Line.

Evonik has over 33,000 employees. Are all of them specialists? The author Michael Matthiass believes the answer to this question can only be yes. “Every in-dividual knows something that few others know, thinks something few others think, and can do something few others can do,” he writes in Evonik Magazine. That’s an encouraging thought. Our specializations might not make us Olympic gold medal-ists or Nobel Prize laureates, but they can enable us to make contributions in our re-spective fields. “Being a specialist is noth-ing special,” says Matthiass. “It’s the most normal thing in the world.” (CHE)

You can read more about specialists in Evonik Magazine 3/2014, which you can

find on the intranet under „Communication“/„Publications“/

„Evonik-Magazine“

11COVER STORY folio 4 / 2015

Eckhard Just Technical Service Manager

During his 28 years at Evonik, Eckhard Just has been involved in quite a few developments at the organofunctional silanes unit in Rheinfelden. He has played a major role in many prod-uct developments and process improvements. That is demon-strated by several patents (“it must be 15 or so”) and an opti-

mized production process that saves Evonik about €390,000 annually. As a Technical Service Manager, Just cooperates closely with customers and travels throughout Europe, the USA, and sometimes China. At the moment, he is a member of the working group Applied Technology Sila-nes for Coatings, which is developing a product to prevent the growth of algae and barnacles on ship hulls. The product will reduce the ships’ wa-ter resistance and, as a result, decrease their fuel consumption. Just came up with some of his ideas during his leisure time. “I’m always thinking about how we can do something even better,” he says.

Karl-Josef FölschOperational Excellence (OPEX)

All of the experts at OPEX have many years of experience and are ideally qualified to advise the business units on how to improve the productivity of their processes and increase their competitiveness. One of these experts is Karl-Josef Fölsch, who has a doctorate in chemistry with a specialization in polymer

chemistry. He has worked at Evonik for the past 27 years and at OPEX since 2009. “We’re always looking for new approaches,” Fölsch says, adding that the search has become very challenging today. “The various units have es-tablished a lot of good processes, sometimes with our support. One example of that is the continuous improvement process,” he says. But the specialists at OPEX are still finding new and better ways to do things by using sophisti-cated methods such as ESysTO, in which the availability of production facil-ities plays a big role, complexity optimization in order to focus on the most profitable activities, and Environmental Technology Excellence (a method of improving the flows of exhaust air, wastewater, and refuse). “The important thing in the process is the dialogue with the units,” says Fölsch.Ph

otog

raph

y: S

tefa

n W

ildhi

rt (2

), M

arku

s Sch

mid

t, Li

na N

ikel

owsk

i

12 folio 4 / 2015 COVER STORY

Peter Albers Electron Microscopy/Surface Analytics Centre of Excellence

Catalysts are Peter Albers’ area of specialization. He’s been dealing with them ever since his first workday at Evonik in 1986. Today he heads the Electron Microscopy/Surface Analytics Centre of Excellence, which is part of Evonik’s Analytics department. He’s still working on the characterization of catalysts, but the range of his responsibilities is now much broader. At the center, highly complex analytic devices provide important information for characterizing

work materials, raw materials, chemicals and products, and for testing their properties. “We are the only industrial group that has this special know-how,” says Albers. Here too, he emphasizes the key role played by teamwork and cooperation. “Only cooperative projects between the business lines and a central function can generate this know-how and expand and refine it across our various business locations in line with the needs of individual products,” he says. Albers always thinks in terms of the future. Where do we stand today, and what methods will we need in two or three years? Albers looks for answers to such questions, and in the process he keeps track of current developments at Evonik and outside the Group. “We have to stay curious about new things,” he says.

Peichen Zhang Regional Controlling Greater China

How can challenges be met most effectively? Peichen Zhang, who heads Regional Controlling for the Greater China region, believes the answer is a combination of knowledge and curiosity. Zhang gained her professional knowledge at one of China’s big-gest banks and at the Corporate Treasury unit of a multinational

company. She believes that professional development means facing new challenges and constantly enhancing your expertise in your individual area of specialization. “Nobody can accomplish things alone,” she says. Teamwork is essential. When she joined Evonik in 2009 as the head of the Finance Great-er China unit, her greatest challenge as she built up and managed the Finance team in Shanghai was to establish an integrated management structure. “The successful support we’re giving to the operating units and their big projects in this region shows that we’ve mastered this challenge,” she says confi-dently. “Even though we sometimes have difficulties, I enjoy my work every single day.” That’s because she enjoys working together with her colleagues to reach shared goals.

Dorit Wolf R & D Fixed-bed Catalysts

Catalysts help man-ufacturers to utilize raw materials more

efficiently and expand the capacity of their

production facilities. Catalysts are used in the synthesis of pharmaceu-ticals, fine and industrial chemicals,

and the components of polymer-ization catalysts. Dorit Wolf heads

the Research and Development Fixed-bed Catalysts department in

the Catalysts Business Line. She has her own clear definition of special-ization. “Our field is very complex,

and it therefore requires lots of expert knowledge,” she says. “We

have to translate this knowledge for our customers and communi-cate it to them.” She expects the

approximately 25 colleagues in her department to share this attitude. “Developing process catalysts is a project-related business in which

research, production, business de-velopment, and sales are closely in-

terlinked,” she explains. “In addition to possessing professional expertise,

our colleagues have to be able to work on solutions within a team.”

The wide product range and the ever shorter innovation cycles also

mean that specialists have to engage in continuous self-renewal. “The

young university graduates that we employ bring fresh knowledge into the department. That’s also true of our involvement in the catalyst re-

search community,” says Wolf.

13COVER STORY folio 4 / 2015

Rainer Spittka Technical Service Pre-Coated Metal

When you meet a person who has been working with polyesters for over 20 years, you’re tempted to ask whether the job doesn’t sometimes get boring. Rainer Spittka doesn’t hesitate for a second before saying “no.” Spittka started out with polyesters for composites, then moved on to polyesters for adhesives, and for the past 14 years his focus has been on polyesters for coatings. In the area of coatings for metal pack-

aging, “polyesters are currently booming—and the boom is connected with a challenging and exciting system transformation,” he says. He also points out that his customers from the coatings industry are very demanding. They require healthy, i.e. non-toxic, solutions for their coatings that can stand up to all the steps of the sterilization process. “Our product has to be explained. That’s why technical consultation is a key part of our work,” Spittka says. To provide these consultations, he cooperates closely with the lab group headed by Sabrina Gingter. Future knowledge transfer has already been taken care of, as Spittka has been sharing his specialist knowledge with his colleague Harald Jung for the past four years. The two polyester professionals are already sharing responsibility for their products’ worldwide markets.

Jonathan Huckle SAP & Database Hosting

Jonathan Huckle, who comes from Wales, could be called an IT veteran. He’s been working in this field for 30 years now, and he has been at Evonik

since 2004. He is currently working in the Global IT & Processes service unit. He has gathered a lot of experience in this area, but his current job is the one he likes best: database administration. Among other things, he manages the systems produced by Oracle. “I’ve been working with Oracle systems since 1991,” he says. The challenge of his job consists of managing complexity. Evonik works with three different database systems: Oracle, Hana, and Sybase. Evonik uses approxi-mately 220 databases from Oracle alone, about 150 of them for SAP applications. “In spite of the complexity, there’s a lot of routine involved. But of course I learn new things very often,” Huckle says. Regular advanced training, seminars, training sessions with new database versions, and constant dialogue with colleagues all help him to continually refresh and expand his knowledge. “When problems crop up, we have to find the causes very quickly—and they can be very complex,” he says. It’s good to be able to rely not only on your own know-how but also on that of your colleagues.

Heiko Luft Global Automation Technology

Heiko Luft is the spe-cialist’s specialist. The

focus of his work is the optimization of pro-

cesses. He worked for many years in the area of process

technology, and since 2012 he has been the Head of Global Automa-tion Technology Management in the Acrylic Monomers Business

Line. “The objective is to bring pro-duction facilities to an optimal state

and keep them there,” he says. In other words, the aim is to make the best possible use of space and time. This is clearly not a desk job. Some-

times Luft moves his office to the measuring station in order to “suck

up knowledge,” as he likes to put it. He defines his work as combining

the know-how of the experts at production plants and facilities with

his own knowledge of automation processes and implementing this

combined knowledge in daily oper-ations. At the moment he is focus-

ing on methacrylates, and his scope is worldwide. For example, he is

trying to improve the yield in Weit-erstadt, optimize the sulfuric acid plants in Worms and Wesseling,

and optimize fractionation columns in Shanghai (China). “Our work is never static,” Luft says. “We’re

always initiating new changes.”

Phot

ogra

phy:

Evo

nik

Indu

strie

s, St

efan

Wild

hirt

(2),

Uw

e Fe

uerb

ach

(2),

Fra

nk P

reuß

14 folio 4 / 2015 PEOPLE + EVENTS

New joint venturee v o n i k & d u i s p o r t

The Evonik facility in Lülsdorf still has plenty of unused space—around 50 hectares in all. Evonik Industries and Duisburger Hafen AG (duisport) are planning to create a new joint venture in order to find companies that are willing to move their opera-tions to this location, which has ideal transport connections. The joint ven-ture, which will commence opera-tions later this year, aims to develop the unused space and optimize the lo-cation’s existing logistics. Evonik and duisport will each own 50 percent of the joint venture. The two companies have enjoyed a successful partnership for many years. At the Marl Chemistry Park, the two partners own Umschlag Terminal Marl GmbH & Co. KG, which operates the local container terminal for combined rail transport services.

Young researchers: Boys and girls from more than 760 daycare centers took part in this year’s Evonik “Children’s University,” which is jointly organized by Evonik Industries and the Rheinische Post newspaper. Among other things, the children used baking powder and vinegar to inflate balloons and also employed baking powder to turn red cabbage juice blue. Executive Board Chairman Klaus Engel honored the ten best teams at an awards ceremony in Essen. First prize went to the St. Clemens Cath-olic childcare center in Krefeld. The up-and-coming young scientists received a four-week subscrip-tion to the Rheinische Post, which offered child-appropriate instructions for scientific experiments. The experiments were conducted with everyday items in the daycare centers. The children later did handicrafts and recorded their results.

Evonik Industries is making ex-tensive investments. For example, it has teamed up with AkzoNobel to cre-ate a production joint venture for the construction and operation of a chlo-rine-caustic potash electrolysis facili-ty at the AkzoNobel location in Ibben-büren. The Evonik plant in Lülsdorf will turn the caustic potash into po-tassium carbonate and other materi-als. In another investment, Creavis and the Thai company Rajburi Sugar have created a joint venture for the cost-efficient production of isomalt, a sugar substitute. Evonik has also ac-quired a holding in the Canadian startup Wiivv Wearables, which will begin to use polyamide 12 from Evon-ik this fall in order to make 3D print-ed, biomechanically optimized in-soles. The Group has also invested in JeNaCell GmbH, a specialist for bio-technologically produced nanocellu-lose, which is used to treat burns.

Extensive investmentsg r o w t h

BLEACHING EXPERTCésar Leporini, the person re-sponsible for hydrogen peroxide application technology in South America, is one of the authors of a book about pulp bleaching. It’s the first scientific book devoted to the special characteristics of eucalyptus as a raw material for paper and cellulose production

Phot

ogra

phy:

Evo

nik

Indu

strie

s, Ki

rste

n N

eum

ann,

Joch

en B

alke

PEOPLE + EVENTS

P E

15PEOPLE + EVENTS folio 4 / 2015

Supervisory Board Chairman Werner Müller and Chief Strate-gic Officer Christian Kullmann recently toured the two largest production facilities of Evonik Industries in Asia. Together, the two executives learned about key growth projects at the Multi-User Site China (MUSC) in Shanghai and the Jurong Island facility in Singapore. Müller and Kullmann discussed in detail the development of regional markets and Evonik’s growth po-tential with the management teams of the regions Greater China and SEAANZ (Southeast Asia, Australia, and New Zealand) and their assistants. They also held direct talks with the employees, dined in the plant cafeterias (pictured), and answered questions posed by the workforce at a town hall meeting in Shanghai. Müller and Kullmann were impressed by the recently completed production facilities and by the sales development in the two large Asian regions. Kullmann, who visited the plants in China and Singapore for the first time, expressly thanked the employ-ees there: “I’m very impressed by your achievements. Your ener-gy and your motivation are crucial driving forces for the future development of Evonik.”

g r o w t h r e g i o n s

Müller and Kullmann in Asia

June 1, 2015 Arrival in GermanyI land in Frankfurt in the afternoon and then take a train to Dortmund. I’m welcomed by Laura Hope, who organizes the Ruhr Fellow-ships. My first impressions: For one thing, many Germans speak English, which is great. Second, I see far fewer SUVs on the road than in the USA. And third, people here don’t jaywalk. Laura, the other students, and I eat dinner in Dortmund.June 2, 2015 First German class All of us are still suffering from jet lag when we arrive at our

Andrew O’Rourke comes from Massachusetts, where he is studying at Harvard. As part of the Ruhr Fellowship Program, O’Rourke got to know the engineering profes-sion this summer and worked as an intern in Marl. The Ruhr Fellowship Program was initiated for U.S. college students by Initiativkreis Ruhr GmbH.

Andrew O’Rourke from the USA took part in the Ruhr Fellowship Program

THAT WAS MY MONTH…

What does IPREP stand for?IPREP is the abbreviation of “Internation-al Professional Rotational Enrichment Program,” which we first set up in the summer of 2014 for college graduates with bachelor’s or master’s degrees at the Sales & Marketing, Finance, Supply Chain, and Engineering & Manufacturing units. In Germany we’d call it a trainee program, but this expression isn’t used for such job-entry opportunities in the USA. Like the trainee programs in Germany, IPREP conforms to the global framework of trainee programs at Evonik.

What does the program consist of?Over a period of two years, the trainees take part in three assignments: two nine-month assignments at one of our 25 loca-tions in North America and one six-month assignment at an international location. The trainees can also do a stint at another unit so that they can explore other exciting options for their professional careers—for example as an engineer at the Sales unit.

How are people recruited for this program?We call students’ attention to ourselves at our eight partner universities in North America. We try to win over students who are in their sophomore or junior years at college and recruit them for a three-month internship in our Summer Professional Enrichment Program. Many of the participants later take part in the selection process for IPREP, because Evonik’s international focus makes the company an attractive employer. We’ve also gotten this feedback from the par-ticipants of the new training year, which began in early August.

What happens to the participants when they’ve finished their trainee-ships?We are in constant touch with our HR colleagues at the various segments in order to find out how the candidates might develop in the future. As a result, everyone always knows who is working on which project at which location. For example, the first eight participants are currently working at the locations in Marl and Darmstadt, Germany. Before the participants went there, they attended an intercultural training course that focused specifically on Germany. I’m looking forward to hearing from the participants what they think of this preparation in hindsight. We need such feedback for the program’s further development. (UD)

Florian Lyon works in Parsippany (USA), where he is the University Relations & Early Career Development Manager for the North America region. He coordinates the two-year IPREP program at Evonik in North America. Florian is currently assisting the graduates of the program’s second year as they begin their professional careers

5 minutes with…Florian Lyon

“Ensuring the safety of our chemi-cal production facilities is one of the Group’s top priorities for the protec-tion of people and the environment. Maintaining a high process safety standard is also a precondition for en-suring the high availability of the plants, which makes it financially significant,” Margit Hahn, Head of the Global Process Safety Competence Center (GPSC), told approximately 100 participants at the beginning of the Global Safety Expert Network Meeting in Essen. Thomas Jostmann and Rain-er Kohlen from the corporate division for Environment, Safety, Health and Quality talked about Evonik’s current requirements. In cooperation with the segments, the corporate division and the GPSC have created a concept that specifies globally uniform standards for process safety. As the representa-tive of the segments, Frank Hübner, Head of Production/Technology for Performance Materials, explained the requirements of the operators.

Global standards for safe operation

p r o c e s s s a f e t y

Phot

ogra

phy:

Fra

nk P

reuß

, Zha

oWei

, Lin

a N

ikel

owsk

i |

Illus

tratio

n: L

yndo

n H

ayes

/Dut

ch U

ncle

German class. None of us speak German. Our teacher, Matthäus, is understanding and helps us in the following weeks.June 22, 2015 5,000 feet deepTen other American students and I are lucky: We are given the opportunity to visit a work-ing coal mine. We go 5,000 feet underground to see how state-of-the-art RAG mining ma-chines extract the coal. Although it’s hot and dark, I find the pit impressive. The tunnels are spacious and we feel very safe. Due to the ma-chines, there are fewer people down there than I had expected.June 28, 2015 Marl Chemistry ParkFifteen other U.S. students and I travel from Dortmund University to the Marl Chemistry Park. This gives the two of us, Chad Wangsanu-wat and me, the opportunity to take a look at our future workplace. We tour the acrylic plant. July 1, 2015 The first day of my internshipChad and I are welcomed by our boss, Martina Heitzig, who introduces us to the other em-ployees and interns. We are given basic safety instructions and spend the day setting up our re-spective workplaces. In July we will learn about the fields of process design and simulation so that we can try to optimize a fermentation process.

Whether chlorosilanes are transported in 10-kilogram

packages or 20-ton con-tainers, they have to arrive at manufacturers of optical fibers and semiconductors safely and with high purity

ALWAYS READY TO GO

Incident Response Team

The Resource Efficiency segment’s Chlorosilane Product Line has an Incident Response Team that is always on hand if any problems arise during

the transport or unloading of chlorosilanes

17PEOPLE + EVENTS folio 4 / 2015

Harry Winter is on his first day back at work after a vacation with his family in southern

France. Although it’s still early morn-ing, the phone rings, and Winter finds out that he will have to travel to China in three days. The flight and the hotel room have already been booked.

Winter, 50, is the assistant of the site group manager at the Rheinfelden chlorosilane facility and a member of the Incident Response Team, which goes into action whenever a transport container runs into problems at a cus-tomers’ plant or en route.

High level of responsibilityThe team consists of 16 trained em-ployees from Rheinfelden, Wesseling, Antwerp (Belgium), Alabama (USA), and Rizhao (China). The members al-ways have a special suitcase already packed with the team member’s pass-port and visa, credit card, vaccination certificate, protective clothing, helmet, flanges, valves, gaskets, and safety harnesses as well as special tools and spare parts for technical systems.

After arriving in China, Winter drives directly to the customer, where he sees traces of corrosion on the valves. As a precaution, he calls the fire department and tells the local people in charge what he will have to do. “I proceed step by step, even though this takes longer,” says Winter. He does this because he is responsible for the people around him and also has to ensure his own safety.

Winter quickly finds out that the ISO container’s condition doesn’t ful-ly comply with Evonik’s high safety standards. The safety valve and the rupture disc have to be replaced. The container then has to be prepared for transport back to Rheinfelden. “Be-cause our products are used in Asia to make optical fibers and wafers for chip production, they don’t meet the quality

standards even if they only contain as little as one microgram per kilogram of impurities. In such cases, we have to ship them back to Germany,” says site group manager Ilona Kraft. Every container is thoroughly inspected and repaired after it comes back. The con-tainers are also examined by the Ger-man technical inspection association TÜV every five years.

Training customers None of the containers can go on a jour-ney without being inspected first. “Our long-term goal is to enable our custom-ers to judge dangerous situations more accurately themselves,” says the as-signment coordinator, Helmut Droege. After all, the aim is not just to profes-sionally handle suspicious incidents, but to prevent them from occurring in the first place, if possible. (FF)

1 HELMUT DROEGE Assignment coordinator of the Incident Response Team “Because prevention is better than cure, we train our custom-ers and tell them how they can improve the way they empty containers. It really pays off—for both sides.”

2 ILONA KRAFT Site group manager for chlo-rosilanes “We manufacture products that our customers rely on. This in-cludes relying on our shipments and packaging. Even small pack-aging can cause big problems. My mind’s at ease when I know that the employees we send all over the world are very experi-enced and have a high sense of responsibility.”

3 BURKHARD JOHN Process technologist for

functional silanes “Over the past 39 years, I’ve walked through every

inch of the plant. I’m the specialist for process im-

provements, some of which are inspired by our assign-

ments.”4 WOLFGANG HAAS

Application technician for chlorosilanes “If your new car breaks down, you take it to the workshop. We, however, fly to our customers. That’s the difference. We have to get along with people all over the world.”5 HARRY WINTER Assistant of the site group manager for chlorosilanes “I spent 300 days in Japan,

where I put the monosilane facility into operation and shut it

down again. It was great training.”

FIVE TEAM MEMBERS

You can find more information about SIRIDION chlorosilanes

on the Internet at www.siridion.com

“Prevention is better

than cure”Helmut Droege,

assignment coordinator of the Incident Response Team

“Our assignments also provide us with ideas for improving processes” Burkhard John, process technologist, functional silanesPh

otog

raph

y: S

tefa

n W

ildhi

rt (4

), E

voni

k In

dust

ries (

2)

1

3

5

42

Multipurpose suitcase

MaskFilters mercury, particulates, organ-ic gases, and other substances

This suitcase is packed and always ready for use in Harry Winter’s locker in Rheinfelden. It weighs 18 kilograms and is taken along on every assign-ment

Protective clothingThis chlorosilane-resistant suit is worn on every assignment

Spare parts Flanges, valves, gaskets

Special toolsThe combination varies, depending on the task

Safety harnessPrevents falls from great heights

BagsThey are used to dispose of contam-inated clothing and objects

Internet, cloud computing, video telephony: Consumers want to have more and more com-puting and storage capacity without having to spend more money. These demands are inspiring semiconductor manufacturers to develop new solutions. New kinds of molecules enable func-tional layers to be precipitated at much lower temperatures. This reduces the thermal and mechanical strain on the chips during the manufac-turing process. As a result, the chip yield increases. Evonik is actively involved in these developments. For example, it supplies the latest and most pop-ular of these molecules, SIRIDION HCDS. Such chlorosilanes are shipped to customers from Rheinfelden in containers ranging from 1.9-liter packages to 20-foot ISO containers, which can be transported by air, ship or train.

SIRIDION® is a registered trademark of Evonik Industries AG or its subsidiaries. It is indicated in capital letters throughout the text.

18

After setting a sports benchmark last year, Muhammad Nasiruddin, an employee at the TEGO Innovation Center in Singapore, took part in this year’s South East Asian (SEA) Games. In April 2014 he was the best high jumper in the “Under 23” category in Singapore with a jump of 1.99 meters. This April he surpassed this personal benchmark with a 2.03-meter jump and was nominated for the SEA Games in Singapore. At the Games he only placed ninth with a jump of 1.90 meters, but he views that as an incen-tive for the future. “Hard work doesn’t automatically bring you good results. The im-portant thing is to stay on the ball,” he says. In other words, he’s already focusing on the next competition. Nasiruddin began his career as a high jumper at the age of ten. Initially he jumped just for the fun of it, but in high school he intensified his training and started to compete. Since mid-2014 he’s been training almost daily. The Singapore Athletics Association noticed him last March when he topped the two-meter mark. That has spurred him on to train even more intensely.

South East Asian GamesThe SEA Games are held every two years during the years when neither the Olympic Games nor the Asian Games take place. The predecessor event, the South East Asia Peninsular (SEAP) Games, was held for the first time in Bangkok in 1959. At the SEA Games, athletes from Malaysia, Singapore, Myanmar, Brunei, Thailand, the Philippines, East Timor, Laos, Indonesia, Vietnam, and Cambodia compete in 35 different disciplines.

“At the moment I’m completing my second ISAM assignment in the Health Care Business Line in Mexico City. In September I’ll be here for Mexico’s Independence Day, Grito de Do-lores. This day commemorates the ‘Cry of Do-lores’ called out by the priest Miguel Hidalgo on September 16, 1810 in the town of Dolores, which triggered the Mexican War of Inde-pendence. I’ll also still be here for the tradi-tional celebrations on the Día de los Muertos, or Day of the Dead, in the fall. On both of these holidays there are big street parades and typical foods such as enchiladas and tamales. I’m looking forward to seeing the

costumes, the decorations, and the dances performed to the rhythm of tradi-

tional musical instruments.”

What I’m looking for-ward to this month…

Muhammad Nasiruddin aims to fly high

Muhammad Nasiruddin, an Evonik employee in Singapore, competed in the high jump event at the SEA Games

Zachary M. Woods is from the USA and has worked for the Crosslinkers and

Coating Additives Business Lines in the Resource Effi-ciency segment in

Marl, Germany and Hopewell, Virginia

(USA)

Phot

ogra

phy:

Evo

nik

Indu

strie

s, Ka

rste

n Bo

otm

ann

(2),

Dan

nyTo

h, S

tefa

n W

ildhi

rt

BREAKFAST FOR KIDS Six Evonik employees from the Ani-mal Nutrition Business Line in Guate-mala regularly make breakfast for the children at three schools in one of the country’s poorest regions. The em-ployees are also helping to build new school kitchens. The joint program is supported financially by Evonik, its customer Grupo DIP, and Guatemala’s Poultry Breeders Association

--

portant thing is to stay on the ball,” he says. In other words, he’s already focusing on the next competition. Nasiruddin began his career as a high jumper at the age of ten. Initially he jumped just for the fun of it, but in high school he intensified his training and started to compete. Since mid-2014 he’s been training almost daily. The Singapore Athletics Association noticed him last March when he topped the two-meter mark.

The SEA Games are held every two years during the years when neither the Olympic Games nor the Asian Games take place. The predecessor event, the South East Asia Peninsular (SEAP) Games, was held for the first time in Bangkok in 1959. At the SEA Games, athletes from Malaysia, Singapore, Myanmar, Brunei, Thailand,

lores’ called out by the priest Miguel Hidalgo on September 16, 1810 in the town of Dolores, which triggered the Mexican War of Independence. I’ll also still be here for the traditional celebrations on the Día de los Muertos, or Day of the Dead, in the fall. On both of these holidays there are big street parades and typical foods such as enchiladas and tamales. I’m looking forward to seeing the

costumes, the decorations, and the dances performed to the rhythm of tradi

tional musical instruments.”

EVONIK + US

E Ufolio 4 / 2015 EVONIK + US

Lunch in… Buenos Aires. There’s more to Argentinian cui-sine than succulent steaks. Other popular specialties in this country, which has adopted many of the culinary traditions of its immigrants from Spain and Italy, include milanesas (Milan-style breaded veal cutlets), empanadas (filled dump-lings), and various kinds of cake. Maximiliano Langone, Cristina Fanani, Mariana Gomez, and Lorena Morao (left to right) meet every day for lunch at the big table in the com-mon room of Evonik’s administrative center in Buenos Aires. They enjoy eating together and sharing the dishes everyone has cooked at home and brought to work. They also like to spend time together and sometimes meet after work to watch a soccer game or to cheer on the Argentinian soccer team in front of the TV.

Deolinda Scott is responsible for Human Resources at Evonik’s plant in Castro in the state of Paraná in Brazil. Curitiba is the state capital of Paraná.

Italian heritageIn the Santa Felici-dade neighborhood you can find deli-cious Italian food and insights into the history of Italian migration to Brazil. Houses steeped in history, such as Casa Culpi, Casa dos Gerânios, and Casa das Pinturas, still

have well-preserved original frescoes on their walls. The locals still celebrate traditional festivals such as the Chicken, Polenta, and Wine Festival in July.

Bicycles and caipirinhaTry a Brazilian churrasco barbecue

at the Batal Grill in the Bairro do Batel neighborhood and drink a caipirinha at Le Voleur de Vélo, a cool venue with a bicycle motif.

Oscar NiemeyerThe Oscar Niemeyer Museum is spread out over two build-ings designed by

Niemeyer himself: a spacious rectilinear construction from 1967 and an exten-sion built in 2002 that is also known as the “Eye” thanks to its design. The museum provides an exhibition space for artists from Paraná and other parts of Brazil.

Opera in a lakeThe impressive circular steel frame of the Ópera de Arame, designed by the architect Do-mingos Bongestabs, supports transpar-ent polycarbonate façades. The opera house, which can only be reached via a bridge, is surround-

ed by a lake ringed by lush vegetation and waterfalls in the middle of a former quarry. The opera’s open-air stage covers 480 square meters and has excellent acous-tics, thanks in large part to the 30-me-ter-high cliff walls of the quarry.

o n t h e r o a d

WHAT YOU SHOULDN’T MISS IN CURITIBA

19EVONIK + US folio 4 / 2015

Friendly atmosphere, strict customs: At the Degussa headquarters in Frankfurt, there were fixed “lunch groups” that would meet every day at the same time. New employees were invited to join one of the groups, and they had to undergo a probation period. Group members were not allowed to talk about work during the meal; if they did, they had to pay a fine. So did group members who were not punctual. At the end of the year, the collected fines were used to pay for a party. The employees dined at perfectly set tables and were served by waiters. Everyone ate the same meal, served with wine. Those who required a special diet had to provide a doctor’s certificate. In the mid-1980s the company canteen shifted over to a self-serve model. Today employees can choose from a wide selection of food in which healthy nutrition plays a major role.

t h e n & n o w

1931

2015

Phot

ogra

phy:

Evo

nik

Indu

strie

s, Ka

rste

n Bo

otm

ann

folio 4 / 2015 EVONIK COMIC

HARD TIMES

Sports fans’ lives unfold in an orderly rhythm marked by the games of their favorite teams.

This gives them a sense of structure and security. But if this routine is interrupted

for any length of time, a fan’s well-balanced inner life may

be thrown out of kilter.

Tobi Dahmen

drew this comic shortly before going on vacation. He hopes his summer vacation will be more

fun and fulfilling than his current protagonist’s.

No derbies, no fights for a trophy…

…no offensive fouls and no close calls.

“Off-season”—two harmless little words…

…that really make me blue.

Separately, they sound pretty good…

…but together, they’re a disaster.

…and it’s still 0:0 in the friendly game between Podunk and

Waterville…

Thank goodness it won’t last forever…

At last! The off-season’s over!

20