OT Vsl Retained Earth

-

Upload

tiago-lobo -

Category

Documents

-

view

239 -

download

1

description

Transcript of OT Vsl Retained Earth

-

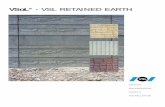

VSOL - VSL RETAINED EARTH

DESIGN &ENGINEERINGSUPPLYINSTALLATIONMONITORING

-

2 V S o L V S L R E T A I N E D E A R T H

Worldwide networkVSL operates through a worldwide network of35 subsidiaries, supported by manufacturingfacilities in Europe and Asia. The Groupprovides technical consultancy and servicesthrough its 4,100 employees, including morethan 1,000 engineers and technicians. It covers the full range of work from projectplanning (including development of preliminarydesigns and alternative design proposals) tospecialised construction operations. In thefield, VSL works mainly using its own workforceand equipment.

More than 50 years of engineering experienceVSLs specialist construction systems havebeen used throughout the world since 1956and have earned an excellent reputation forquality and reliability. This has made VSL arecognised leader in specialist constructionmethods and associated engineering works.

Shaping a better lifeFor VSL, sustainable development meansstriking a balance in its business modelbetween the economic profitability of its

VSoL - DELIVERING HIGH-PERFORMANCE

operations and their social and environmentalimpacts. This commitment is formalised intothe VSL Sustainable Development programme,which focuses on safety, use of fewer scarcematerials and less energy as well as reducedproduction of pollution and waste.

VSL guided by a strong QSE cultureVSLs leading position in the industry is basedon a rigorous and committed quality culture.Its Quality, Safety & Environment policyprovides a strong focus for every service that isprovided. Local teams ensure co-ordination ofactions, encourage sharing of experience andpromote best practices, with the aim ofcontinuously improving performance. In VSLsculture, employees are vitally important to thecompetitiveness and prosperity of thecompany. VSL is committed to maintaining thehighest levels of client satisfaction and safetyfor personnel.

The VSL Academy a unique trainingfacility for VSoL wall constructiontechniquesEnsuring the highest levels of competence is akey focus. VSL applies the principles of

Highway A8, Spain - 2005

continuous learning and training, together withthe sharing of best practices throughout thenetwork. Foremen, supervisors and siteengineers benefit from centralised training atthe VSL Academy, where they are taught bestpractice in all aspects of VSoL wall construction.

VSoL - one of VSL Groups leading brandsThe VSoL wall system is recognised as arevolutionary technique in the field of retainedearth wall construction. VSoL, a registered trademark of the VSLGroup, provides customised solutions adapted

A strong QSE culture

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:14 Page2

-

V S o L V S L R E T A I N E D E A R T H 3

VSoL - a comprehensive solutionVSL assists clients and their consultants atall stages of a project from feasibilitystudies to project completion. Preliminarydesigns, cost estimates and constructiondetails as well as detailed designs,drawings and specifications are madeavailable to assist clients in selecting theoptimum solution for their projects.

The VSoL wall system can be tailored tosuit each customers requirements andVSLs services range from the design andsupply of the specialist materials rightthrough to a complete contractualarrangement for the partial or full scope ofwall installation. Services may include: Feasibility studies Design and detailing Precasting Installation and backfilling Monitoring Complete turnkey projects,

from design to complete wall construction

CE SOLUTIONS FOR MORE THAN 30 YEARS

to the clients technical and architecturalrequirements. The specialist know-how of VSLsengineers provides the foundation for thesuccess of the VSoL wall system, whichcombines reliability with ease of construction.

VSoL - a versatile solution for retaining wallsThe VSoL wall system is a cost-effective,high-performance retaining wall system thathas proven its excellence in a wide variety ofapplications. Since its development in the early 1980s, theVSoL wall system has been used extensivelyworldwide to provide cost-effective andaesthetically appealing retaining wall solutionson a wide range of infrastructure projects. TheVSoL wall system combines concrete facingsand soil reinforcement made from welded wiremesh or VStrips, VSLs polymeric strips,installed into compacted fill to form a coherentretained earth block which resists forcesgenerated within and behind the wall. The system is widely used for projects rangingfrom general grade-separation retaining wallsto highway bridge abutments and miningstructures. In addition to its high level of

performance, the VSoL wall system is veryeconomical and is easy and rapid to install, withonly three primary components. The use offactory-produced elements combined withspeedy erection results in a high-quality wallfinish that is achieved with cost savings of up to50% compared to traditional wall systems.

Unlimited applicationsThe VSoL wall system meets projectrequirements for projects in both the privateand public engineering sectors. Owners,engineers and contractors worldwide make useof VSoL for the construction of many types ofstructures, whether temporary or permanent,and various backfill soils and foundationconditions can be accommodated in the design.Straight, curved, tiered, superimposed or back-to-back walls can all be catered for in a widevariety of site conditions. Urban, marine, mountainous and flood-pronesites can all be accommodated thanks to thedesign flexibility of the VSoL wall system.

Mont Saint-Michel, France - 2012

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:15 Page3

-

2. ReinforcementThe reinforcing elements are either steelladders or polymeric VStrips. The reinforcement develops a high soil toreinforcement interaction and pull-outresistance, ensuring stability, excellentalignment and reliable performance. Thereinforcing elements tie the facings into thesoil mass and resist the horizontal soil forcesgenerated both within and behind the wall.

4 V S o L V S L R E T A I N E D E A R T H

1. FacingsFacings are structural elements which retainand confine the backfill material and are tiedto the reinforced fill by the mesh ladders orVStrips. Different types of facings are available to suitproject individual requirements: Concrete finishes of different shapes,

textures and colours Steel mesh facings, which may be filled with

rock for a natural stone finish Vegetated surfaces, incorporating geotextiles

for containment and facing panels whichretain the soil, root systems and irrigationneeded to sustain the vegetation which willgrow to cover the entire wall surface.

VSoL - HOW IT WORKSA VSoL wall combinesgranular backfill materialand reinforcement which can be either steel mesh orpolymeric VStrips. These areinstalled behind facingpanels, which arecustomised for the project.The combination of thesethree primary materials inthe VSoL system creates a durable and very stableretaining wall.

VSoL wall with VStrip reinforcement

Concrete panel facing

Stone facing

Green wall facing

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:15 Page4

-

V S o L V S L R E T A I N E D E A R T H 5

3. Reinforced fillThe reinforced fill material in a VSoL wall ischosen to meet both system requirements andproject specifications. Such requirements covergradation, shear strength, permeability, pHand electrochemical properties.VSoL walls are typically built using granularmaterial with less than 15% fines (< 80m)and a maximum particle size of 150mm,although fills outside this specification can beassessed on a project-by-project basis. VSoL walls are often built using fill materialssourced on the site, making the wall an evenmore cost-efficient and environmentallyfriendly solution.

Simple and rapid installationThe simplicity of the installation method coupled withrapid reinforcement connections ensures cost-effectivewall construction. VSoL walls are easily constructed: 1. Casting of mass concrete levelling pads, generally

measuring 300mm x 150mm and un-reinforced;2. Erection and alignment of the first row of half-height

and full-height facings; 3. Installation of joint and drainage materials;4. Fill placement and compaction up to the level of the

first layer of reinforcement in 300mm steps; 5. Installation of reinforcement and the connections to

the facings; 6. Placing and compaction of additional layers of fill up

to the top of the half-height facings; 7. Installation of the second row of facings; 8. Repetition of steps 3-7 until the full wall height is

completed; 9. Installation of copings and crash barriers at the top

of the wall to suit project requirements.

Depending on the wall geometry and site conditions,construction is normally undertaken using a four-mancrew working with a small crane or truck-mounted craneand conventional earthmoving and compaction plant.Installation is generally carried out entirely from the rearof the wall, which permits ease of construction onrestricted sites.

VSoL wall construction can proceed rapidly, withproductivity usually dictated by the schedule of filldelivery and placement. Wall erection rates varydepending on the project size, access and fill materialdelivery timetable.

VSoL wall with steel mesh reinforcement

Polymeric reinforcement

Steel mesh reinforcement

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:15 Page5

-

6 V S o L V S L R E T A I N E D E A R T H

VSoL - ECONOMICAL, VERSATILE, AEST

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:15 Page6

-

V S o L V S L R E T A I N E D E A R T H 7

STHETICALLY PLEASING

An economical wall solutionVSoL walls require reduced quantities ofsteel reinforcement and concrete comparedwith traditional wall systems and generallyallow the reuse of local materials for thebackfill. The simple and rapid installationcarried out using conventional equipmentmakes this solution very cost-effective.Typically, savings range between 20% and50% depending on the wall heights, siteconditions and local prices.

Low maintenance The wall design is carried out in accordancewith project specifications and can give adesign life of up to 120 years. Concretefacings are very durable and require littlemaintenance, the steel reinforcement isdesigned to allow for the anticipatedsacrificial loss over the walls life and thepolymeric strips are fully tested in a range ofenvironments to provide long-term durability.

Highly versatileVSoL walls are extensively used to replaceconventional retaining wall structures formany applications including roads andhighways, railways, industrial and protectivestructures, transportation facilities, bridgeabutments and many more.

Suitable for temporary useVSoL walls can be used as temporarystructures for many different applications.Uses also include temporary grading of aproject site to accommodate differentconstruction phases. VSoL walls can supportvery heavy loads at any stage of constructionand can remain buried once work iscomplete or can be dismantled quickly andefficiently. The advantages of VSoL walls are numerousand include a very fast turnaround for designand construction, cost-efficiency, suitabilityfor a large variety of applications and easeof dismantling, with all materials recyclable.

Seismic performanceVSoL walls are strong, yet flexible enough toresist the high forces and movements arisingfrom seismic activities. During anearthquake, the seismic forces are dissipatedby friction between the reinforcement andthe fill. Inherent ductility and resilience,coupled with the proven seismic performanceof VSoL walls, justify their high degree ofadoption in seismically active regions.

Aesthetics without compromiseWith a wide range of styles, facing shapes,sizes and finishes, the VSoL wall can meetall architectural challenges. Facing finishescan be designed to blend easily with theenvironment or, where desired, to create aprominent artistic landmark.

Ideal for very poor ground conditionsVSoL walls are internally stable reinforcedsoil structures and so are moreaccommodating to settlement than mostother forms of wall construction. The use offlexible reinforcement connections andsettlement-tolerant facing details means thatVSoL walls can be built on sites with poorerfoundation soils than conventional walls,without affecting the structural integrity andperformance of the finished structure.

Construction without disruptionVSoL walls can be built entirely from behindthe facing, which ensures that constructiondoes not interfere with access, traffic or anyobstacles in front of the wall.

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:15 Page7

-

8 V S o L V S L R E T A I N E D E A R T H

TWO OPTIONS FOR REINFORCING ELEME

In recent years, the VSoL wall system has beendeveloped to include the use of VStrips asreinforcement. The reinforced VSoL polymeric wall system usesVStrips or friction ties made from high-strengthpolyester yarns extruded into a durablepolyethylene sheath which provides physical andchemical protection to the reinforcement.The use of VStrips increases the versatility of theVSoL wall system, as the polymeric friction ties

To ensure full load transfer between facingsand fill reinforcement in the VSoL Polymericwall system, VSL developed an innovativesolution to connect VStrip reinforcement toconcrete facings. The VStrip connection issimply a U-shaped internal slot at the rear ofthe concrete facing, formed by a reusablevoid former during concreting which theVStrip is inserted through during installation.

Rolled-up polymericstrip reinforcement

Simple installationVstrips come in rolls of 100m-150m and witha choice of strength capacities: 30kN, 50kN,70kN and 100kN. The polymeric strip isunrolled in the field and passed through aconnection at the facing panel, from where itforms a V shape in the fill with two lengthsextending to the back of the reinforced fillblock. A light tensioning is then applied tothe strip lengths to remove the slack andprovide a constant tension throughout thewall. Fill is then placed on top of thereinforcement in layers of typically 300mmand then compacted.

Advantages Well suited solution for very aggressive

environments Easy storage and site logistics Simple installation

VStrip: the VSL polymeric strip

Connection to concrete facings: an innovative and patented solution

extend the range of projects for which thesystem can provide an effective and economicalsolution.

Aggressive environmentOne of the major advantages of using theVStrips is that the use of polymeric componentsensures long-term durability of the structure inaggressive environments.

Detail view

Installation of friction ties to facings

The VStrip connection has been testedextensively by VSL to prove its efficiency and tooptimize the associated panel reinforcementdetails. The VStrip connection does not requireany additional cast-in items and rebarrequirements for the connection are part of theoverall reinforcement requirement for the facing.By adopting this approach, the VStrip connectionprovides the most economical and practicalconnection solution which is fully proven bytesting and trials. The innovative VStripconnection concept has been patented by VSL.

Castings of VSoL facingswith VStrip connection

VStrip connection

Advantages Very economical No connection components to install

on site Rapid installation

Pull out capacity testing of VStrip connection

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:15 Page8

-

V S o L V S L R E T A I N E D E A R T H 9

MENTS

The VSoL steel systems reinforcing meshladders develop the greatest soil-to-reinforcement interaction and pull-out resistanceof any reinforced retaining wall system.VSoL steel mesh ladders are composed oflongitudinal and transverse wires weldedtogether. The ladders are generally galvanisedto enhance durability. Black mesh ladders can be used for applications involvingtemporary walls.The transverse wires are welded to thelongitudinal ones in a way which guaranteesoptimum load transfer.The connection between the mesh ladder andthe clevis in VSoL wall facing is simple andvery effective, facilitating rapid andeconomical installation.

The performance of a VSoL wall isbased on the soil-reinforcementinteraction mechanism, which isenhanced by the unique geometry ofthe mesh reinforcing ladder. The interaction is achieved in two ways.The bearing action of the soil particleson the transverse wire develops a highresistance to extraction and ladderpull-out from the soil mass. Thisserves as a major advantage of theVSoL steel system compared to othersoil reinforcement techniques. In the wall, the transverse wires areloaded by the soil and transmit the soilforces into the longitudinal wires,which are in tension.

Soil resistance against the transversewires is the dominant interactionmechanism, compared to frictionalforces against the longitudinal wires.Approximately 80% of the ladderspull-out resistance is generated bybearing on the transverse wirescompared with 20% from friction onthe longitudinal wires.Extensive testing has been carried outto compare VSoL mesh ladders withother reinforcing systems. Tests havedemonstrated that the use of threetransverse wires generates a five-foldincrease in the ultimate pull-outresistance, compared to reinforcementsystems that use strip reinforcements.

Simple installationThe simplicity and performance of the pinned connection is a key feature of the VSoL steel system,enabling rapid installation on site. During installation, the mesh end-loops interlock with similarloops in the facings clevis connectors and a full-strength joint is achieved using a connection pin.Slack between the clevis and mesh is removed using plastic wedges inserted between the concretefacing and the reinforcing ladder end-loop.

Advantages Highest interaction between soil and

reinforcement Minimum labour for installation Simple installation

VSoL steel mesh ladder: proven performance

Interaction between soil and steel meshladder reinforcement

Steel mesh ladder delivery to site

Facing to mesh connection

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60

Pull

out f

orce

(kN)

Displacements (mm)

Sand and gravels =37

Standard VSoL ladder

5 longitudinal wire ladders

2 longitudinal high friction strips

6.10m wall

Standard VSoL ladder

5 longitudinal wire ladders

2 longitudinal high friction strips

10.70m wall

Soil bearing forcesagainst transverse wires

F

F

Friction forces againstlongitudinal wires

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page9

-

10 V S o L V S L R E T A I N E D E A R T H

A COST-EFFICIENT SOLUTION

Bridge abutmentsVSoL walls frequently serve as bridgeabutments which directly support the bankseat and the bridge deck where groundconditions permit. This avoids the need fordeep foundations and costly abutment supportstructures. Where piled bridge supports arerequired, VSoL walls can be incorporated intothe design to provide abutment face and wingwalls, with the bridge support columns locatedeither in front of the VSoL panel facing orbehind it within the block of reinforced fill.

Retaining wallsFor projects such as highways and railwayswhere the retaining walls need to bear heavyloads, the VSoL wall solution can providesavings of up to 50% compared to the costs of conventional walls. This is particularly thecase when the structure is founded on poorsoil, which would otherwise require deepfoundations or ground treatment to enableconventional construction methods to be used.

VSoL structures provide flexible solutions suitable for use on soils with low bearingcapacity and can often avoid the need for deep foundations or ground treatment.VSoL walls represent efficient alternatives to conventional structures.

BACKFILL

REINFORCED FILL

VSoL REINFORCEMENTVSoL FACING

VSoL FACINGVSoL REINFORCEMENT

>

Savings 40 to 60%

BACKFILLBACKFILLREINFORCED FILL

VSoL FACING

VSoL REINFORCEMENT

>

Savings up to 20%

BACKFILL

REINFORCED FILL

EXCAVATION AREA

VSoL FACING

VSoL REINFORCEMENT

VSoL FACING

VSoL REINFORCEMENT

>

Savings 20 to 50%

BACKFILL

REINFORCED FILL

VSoL FACING

VSoL REINFORCEMENT

>

Savings 20 to 40%

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page10

-

V S o L V S L R E T A I N E D E A R T H 11

A RELIABLE SOLUTION VSoL systems can effectively be used as riskmitigation and protection measures against naturaldisasters or industrial hazards. Such applicationsinclude protection against landslides, avalanches,floods, fire and blast and particularly earthquakes.

EXCELLENT PERFORMANCE UNDER EXTREME SEISMIC CONDITIONSVSoL walls have very good resistance to the dynamic forces generated during major seismic events. US Federal Highway Administration guidelines state: Due to their flexibility, MSE [mechanicallystabilised earth] wall and slope structures are quite resistant to dynamic forces developed during aseismic event, as confirmed by the excellent performance in several recent earthquakes. The 1989 California earthquake of magnitude 7.1 on the Richter scale and more recently the one in2010 in Chile of magnitude 8.8 demonstrated very good examples of this performance. VSoL wallsup to 19m high were seen to perform very well under seismic loading. The good behavioural responseof MSE and VSoL structures during the earthquakes stems from their flexibility, ductility andcomposite performance. The VSoL wall systems use of galvanised steel mesh ladders asreinforcement gives passive soil resistance on the transverse bars, which means that wall ductility ismuch better than for systems which use steel strips.

SEA WALL PROTECTION

Dibba Harbour & Beaches Phase 2 project, UAE - 2012 VSL was awarded a design and site assistancecontract for VSoL walls at a marine channelproviding access for small boats to luxury villa plots.The length of the channel is 600m and it features6m-high VSoL walls on both sides of the canal. The projects requirements were: 1. For the VSoL panels to match the quay wall

appearance; 2. To use VStrips to eliminate any problems arising from the sea water; 3. To accommodate designs for boat mooring platforms with stairs; 4. To accommodate the required drainage behind the wall.

MINING APPLICATIONSVSoL structures are ideallysuited to many industrialapplications due to theircapacity to withstandvibrations, impact,explosions, flooding andheavy loading. They offer many advantagesto the mining industry andare widely used to createtemporary roads and elevated platforms to storematerials. Benefits include speed and ease ofconstruction, resilience, resistance, performance andthe ability to be used in building high walls. VSoL

walls are also easy to remove, which can be animportant factor as these types of structures aregenerally only for temporary use.

Chilean earthquakeThe 2010 Chilean earthquake was at the time thesixth largest seismic event ever recorded by aseismograph and it proved the excellent behaviour ofmore than 28,500m2 of VSoL walls in thesurrounding area. VSoL walls and abutments weresubjected to high ground accelerations and largedeformations of the foundation soil, yet theirgeometry remained unchanged after the earthquake.

TEMPORARY WALLS TO SUPPORT VERY HEAVY LOADSFlamanville nuclear EPR facility VSoL walls are particularly suitable for applicationsrequiring the temporary support of heavy loads asused at the new EPR (European Pressurised Reactor)nuclear facility in Flamanville, France. Construction of working platforms on the congestedsite and particular challenges with regard to time andspace required the construction of a number oftemporary retaining walls. Initially the walls were tobe built using conventional prefabricated concretemethods. However VSL was awarded the contract forwall construction based on an alternative VSoL wallsolution which enables the tight programme to bemet.On this site, the worlds largest and most powerfulmobile hydraulic crane, the Liebherr LTM 11200 witha capacity of 1200t, has been operating on top of theVSoL walls for the installation of critical EPRcomponents.

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page11

-

12 V S o L V S L R E T A I N E D E A R T H

A WIDE CHOICE OF FINISHES: SIZE, SHA

The VSoL wall systems concrete facings canaccommodate many shapes, patterns andtextures. In addition, the concrete can becoloured to match the natural surroundings orany specific architectural requirements.Raised relief, sandblasted, exposed aggregateand conventional smooth facings representjust a few of the standard VSoL facingfinishes which are available. Other facingsystems, such as full height facings, wiremesh and green finishes are also availablefor both permanent and temporary structures.

Concrete facings

Precast concrete facings are the mostcommon. Panels may incorporate specialcolours, textures or patterns to enhance theappearance of the structure.

Wire mesh facings

Structures with wire mesh facings are oftenemployed to provide temporary support forroads and bridges, although many permanentwalls have also been built in this way. Thewalls use a large mesh size and spacing,making the wire facing systems the fastest,easiest and most economical to install. Blackmesh is typically used for temporary wallapplications, while hot-dip galvanised steelmesh is preferred for permanent walls.

Green wall facings

Environmental and landscaping requirementshave led engineers and architects to look fornovel methods of constructing retaining wallsand slopes. This has led to the addition ofgreen facings to the VSoL wall system rangeto provide a very economical solution forvegetated steep slopes and walls.

Artistic finishes A wide variety of custom architectural finishescan be incorporated into the concrete facingthrough the use of form liners. Many kinds ofstriking repetitive motifs and designs can becreated to enhance and give character toVSoL wall structures and their surroundings.Mural patterns can easily be achieved on full-height facings, with a fully customised patternon each facing allowing an original work of artto be created on every wall.

Three types of facings

Large choice of facings

Stone masonry

Smooth ribbed

Sandblasted exposed aggregate

Individual geometrical shapes

Smooth and patterned

Masonry Raised relief

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page12

-

V S o L V S L R E T A I N E D E A R T H 13

HAPE, COLOUR Shape Square or rectangular concrete facings are most commonlyused in the VSoL wall system as they offer fabrication andconstruction benefits. However, many projects are built usinghexagonal and T-shaped facings. The standard facing sizes used are typically in the range of1.5m x 1.5m to 2.5m x 2.5m.Special facing sizes make it possible to create VSoL walls ofalmost any geometry.

Different facingshapes available

Hexagonal

Rectangular

Square

Full height facing

Cruciform

Full height facingsFull-height facings are available for special finishes or forartistic patterns. Walls with facings up to 14m high havealready been built.

T-shape

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page13

-

14 V S o L V S L R E T A I N E D E A R T H

VSOL - A WIDE VARIETY OF APPLICATIThe VSoL wall system has revolutionised construction and can be applied tonumerous types of retaining structures for various applications.

Temporary retaining structuresTemporary wall Paris, France - 2012

Bridge abutmentsCarretera AS-112 Tramo Moreda Corigos, Spain - 2006

Public facilitiesCoimbra pediatric hospital, Portugal - 2012

Highways and roadsSouthern Expressway Muscat, Oman - 2010(Record height wall of 65m)

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page14

-

V S o L V S L R E T A I N E D E A R T H 15

ATIONSRailways

High speed train line Madrid-Zaragoza-Barcelona-French border:Mollet del Valles-Montornes del Valles - 2009

Industrial and protective structuresRT Sulfuros, Chile - 2009

Arch structuresPeninsula link Melbourne, Australia - 2012

Water retentionFlamanville nuclear power plant, France - 2012

Green wallsMont Saint-Michel, France - 2012

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page15

-

16 V S o L V S L R E T A I N E D E A R T H

TESTING AND DURABILITY

Optimised designA research programme was carried out in 1997to increase understanding of the performance ofVSoL soil reinforcing mesh ladders. VSLundertook the work in conjunction with theFrench Laboratoire Central des Ponts etChausses (L.C.P.C.) and the Service dEtudesTechniques des Routes et Autoroutes (S.E.T.R.A.). Accelerated corrosion testing was carried out aspart of the detailed study of the durability ofboth black and galvanised VSoL mesh ladders.The tests involved the immersion of testspecimens in saline liquids to simulateconditions that could causes corrosion of themesh. Complementary tests were alsoundertaken using acid solutions to extend theresults of the study. The tests confirmed that corrosion occursuniformly around the circular cross-section of thesteel wire of the VSoL wall mesh ladder. This isin contrast to rectangular steel strips, where thecorrosion develops more intensely on the uppersurface than on the underside of the strip.

Performance of the welded jointsStrength tests were carried out on samples ofsteel mesh ladder after they had experiencedprolonged exposure to the aggressive testenvironments. The tests proved that the weldsof the steel mesh ladder had suffered onlylimited corrosion in relation to the longitudinaland transverse wire sections. It was proventhat the welds are no weaker than the laddersnormal circular steel wire sections aftercorrosion has occurred.Accelerated corrosion tests on samples ofblack steel wire that were dipped in acid for aperiod representing a service life of 100 yearsshowed a retained strength as expected by theFrench design code. In addition, the effects onthe welded sections were similar to those ofthe normal black wire sections. Hence, thesacrificial loss as specified in internationaldesign standards can be applied to the entireVSoL steel mesh ladder and no additionalcorrosion allowance is required at the welds.

VSoL VStrips are made from polyester yarn,extruded inside a polyethylene shell which isdesigned to enhance the friction with thesurrounding soil and ensure high durability ofthe strip. It is a non-metallic component andas such is not subject to corrosion, makingthis component very durable.

VSoL Steel mesh ladder

VSoL VStrip

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

0 10 20 30 40 60 70 80 9050 100

R tc

;d //

SSof

Service LLife ((years)

2N 12

2N 10

45*5

40*4

Steel mesh ladder

Steel strip

0.95

1.00

1.05

1.10

1.15

1.20

1.25

1.30

0 10 20 30 40 50 60 70 80 90 100

Ult

imat

e Te

nsile

Str

engt

h R

esis

tanc

e R

atio

(ste

el m

esh

ladd

er/s

teel

str

ip)

Service LLife ((years)

Steel mesh ladder 210 / Steel strip 40*4

Steel mesh ladder 212 / Steel strip 45*5

The sizing of VSoL steel mesh ladders takes into account the potential for sacrificial loss of steel overthe design life of the structure in accordance with all international design codes applicable to VSoL

wall applications.

Rtc;d : Ultimate Pull-out Resistance (at maximum traction point c)So : Initial Steel Cross of a Longitudinal Wirefr : Ultimate Tensile Strength

Conformity with design codes The retained strength and steel loss of theVSoL mesh ladder specimens tested forVSoL wall applications was found to be inaccordance with the anticipated sacrificialloss as per international design standards.

The VSoL wall system has been continuously improved since its development inCalifornia in the 1980s.

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page16

-

V S o L V S L R E T A I N E D E A R T H 17

QUALITY ASSURANCE

Steel mesh ladder end-loop capacity test

Testing of VStripconnections

Clevis connector pull-out test

VSoL steel mesh ladderlaboratory pull-out test

VSoL steel mesh ladderin-situ pull-out test

All VSoL wall components are tested and checked in accordance with VSLs quality assuranceprogrammes. The use of standard components designed and manufactured in accordance withnational standards minimises the need for project-specific testing, while offering the security of atried and tested system.

Backfill testingReinforced fill is placed and compacted toreach a maximum density as per the projectspecification. Density testing can be used to verify the compacted fill density in every fill layer.

Concrete facings are designed in accordancewith project specifications and local designstandards.Conforming to the relevant codes for the facingpanel design gives assurance of wall facingdurability.

VSoL concrete facings

Proven system and componentsKey features of the steel system are the pinned connection to the facings and the ability of thereinforcing mesh ladders to develop high pull-out resistance in the soil at low strains. Extensivetesting of the mesh ladders with a variety of reinforced fills has clearly demonstrated the superiorinteraction of VSoL wall mesh with typical project fill.

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page17

-

18 V S o L V S L R E T A I N E D E A R T H

CONTRIBUTING TO SUSTAINABLE SOLUTIOMaterial savingsMaterial savings in concrete and steel incomparison to traditional wall systems canrange from 20% to 60%, depending on the wallheight and the loads applied. VSoL walls takeadvantage of the soil strength and weightbehind the wall and make them contribute tothe overall structural stability.

Very resilient structuresVSoL walls have excellent resistance to severeearthquake loading, with many VSoL wallsremaining standing after major seismic eventswhen adjacent conventional structures havecollapsed.

Becoming part of the landscapeVSoL walls can accommodate a wide varietyof finishes, with concrete, stone and vegetatedfinishes available to match the surroundingenvironment and thus enhance the locallandscape.

Ease to dismantle and 100%recyclableVSoL walls are easy to build and similarlyeasy to dismantle. They do not produce largeamounts of unusable waste materials. The fillmaterials can be reused directly or in otherwalls, while facing elements can be reused orrecycled into aggregate for walls, road-base orother construction materials.

Up to 60% reduction of CO2footprint, and aboveThe combination of thin facings and site-wonbackfill as primary structural elements makesVSoL walls very efficient in terms of materialuse. This dramatically reduces the need forconcrete and rebar and therefore reduces theoverall CO2 footprint of the construction project.

HIGH QUALITY AND SAFETY RIGHT FROM THE START22,000m2 and zero accidents on the Anderson RoadProject, Hong KongVSL built 10 VSoL Retained Earth walls totalling22,000m2 for a site formation development at AndersonRoad, Kowloon, to help create level ground for future high-rise residential housing. The VSoL walls used 4m2

rectangular masonry-finish facings and featured sectionsbetween 25m and 36m high. The VSL Hong Kong site teamhad a strong focus on QSE matters and this was rewardedby a zero accident rate, recognised by both monthly andquarterly safety awards from the main contractor.

0

100

200

300

400

500

600

700

800

900

2 3 4 5 6 7 8 9 10 11 12 13

Car

bon

foot

prin

t em

issi

on (t

ons

eq. C

O2)

Wall height (m)

VSoL wall

L-shape wall

Note: CO2 emissions based on a 100m-long wall

Carbon footprint values are for a 100m-long wall comparedto a conventional reinforced concrete cantilever wall.CO2 emissions have been calculated with CarbonEco

developed by VSL. Loading on wall: 10kN/m2 (Live Loads) = 1T/m2

VSoL wall reinforced fill material: all imported from 20km L-shape with fill material:

- walls below 6m height: all local (1km)- walls above (and including) 6m height: 50% local (1km)

and 50% imported from 20km

Comparison of carbon footprints of VSoL walls with L-shape concrete walls

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page18

-

V S o L V S L R E T A I N E D E A R T H 19

TIONS CASE STUDY: VSL-BEBO AN EFFICIENT ALTERNATIVE TO SMALL TO MEDIUMSPAN REINFORCED CONCRETE BRIDGES

This carbon footprint compares a conventionalbridge solution with a solution combining VSL-BEBO precast arches and VSoL reinforced soilwall for an overpass bridge on the Etihad Railproject in Abu Dhabi, UAE.

The alternative design consists in replacing thereinforced concrete footings, the reinforcedconcrete abutment walls and the prestressedprecast concrete beams by VSL-BEBO reinforcedconcrete arches (with the correspondingfoundations and footings) and VSoL reinforcedearth walls.

The VSL-BEBO + VSoL solution presents a reduction of nearly 74% of CO2 emissions. The VSL-BEBO arch solution, combined with the VSoL soil wall system, provides a sustainable and energyefficient alternative to the original bridge design.

VSoL - blending with the naturalsurroundingsThe visual design of the facing of a new Frenchby-pass mimics the local geology, including thenatural rock strata. The facings were madeusing five different carved rock moulds.

The northern end of the new Thonon-les-BainsBypass brought local environmental challenges.It was essential to preserve the local Dranceecosystem while ensuring the overall stability ofthe slopes above the river. The designerssolution uses retained earth walls built with theVSoL system. This met both aims, providing thenecessary support and minimising the impact onthe environment.

The project consisted of a cascade of fourVSoL retaining walls faced with 9,250m ofconcrete facings.

Copy nature

VSoL - natural vegetated greenwalls at Mont St-MichelThe VSoL wall system was chosen for theconstruction of green sea walls as part of therehabilitation of the access area at Mont-SaintMichel, the UNESCO world heritage site inFrance. Access for the new car park had to beprovided through an existing swamp. Buildingthe new sites car park on the swampy groundrequired construction of various green slopes toensure perfect integration with the surroundings.

Become nature

Original design Alternative VSL-BEBO arch design

Creating sustainable solutions togetherThe VSoL solution provides several advantages : Reducing the CO2 footprint up to 60% compared to a conventional wall structure. Reduced maintenance during the life span of the wall structure High resilience to exceptional events such as flooding, earthquake, explosions Matching the landscape, the panels can accommodate any finish, whether concrete,

stone or grass.

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page19

-

20 V S o L V S L R E T A I N E D E A R T H

DESIGN PRINCIPLESA VSoL wall is designed as a reinforced mass large enough to resist loads fromoutside the wall and with enough reinforcement layers of sufficient strength to keepthe reinforced soil mass together.

The VSoL reinforced soil block behaves like alarge gravity wall. The external stability ischecked with respect to sliding on the base ofthe wall, for overturning, bearing failure,foundation settlement and overall stability.

External stability

The VSoL block is subjected to external forces,which are modelled in the design.

Resultant forces taking account of all forcesover the base of the wall:RH = PHRV = G1 + Q + PV

Resultant moment over the base of the wall:M = G1 X1 Q XQ + PH Zp + PV L/2

Resulting eccentricity of the forces over thebase of the wall:e = M / RV

Resulting pressure on supporting ground: = RV / (L- 2e)

Design mechanism

Sliding check Bearing capacity and overturning check

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:16 Page20

-

V S o L V S L R E T A I N E D E A R T H 21

The facing is secured with a full-strength connection to the soil reinforcement inorder to keep the facing units stable and all components properly connected toensure wall stability.

From a mechanical standpoint, the block may be divided into two distinct zones: the active zone the passive zone

Design mechanism

This refers to the strength and stability of thereinforced fill block. At each reinforcement layer,the facing strength, reinforcement strength andreinforcements pull-out strength are checked towithstand the applied design loads and toensure that the reinforcement is fully anchoredin the soil mass.

Internal stability

Pull-out capacity check Tensile capacity check

Active zoneThis zone is in front of thecritical potential failure plane.Its stability is provided by thehorizontal reinforcementanchored back in the resistingzone.

Resisting zoneThis zone lies behind the critical potential failureplane and is a stable reinforced mass, whichresists the destabilising tension forces developed inthe reinforcement by the active zone. The resistingzone provides anchorage for the reinforcement bythe mechanism of the soil/reinforcement bond. Thetensile load in the reinforcement over the lengthwhich is in the resisting zone is not constant. Itreduces towards the inner end of the reinforcement(located opposite from the facing) as load is shedinto the soil. At that inner end of the reinforcementin the resisting zone, the tensile load in thereinforcement is zero.

Built to standardsVSL has developed efficient software whichautomates the design of VSoL walls, regardless ofproject geometry. All VSoL wall projects are designed and built inaccordance with the latest standards, including: BS 8006: UK code of practice for strengthenedreinforced soils and other fillsAASHTO: USA specifications for highway bridgesGEO: Hong KongGeoGuide 6AS 4678/RTA R57: AustraliaEUROCODE: Europe EC7NF P94-270: France French national standard

Rankine failure plane:/4 + 1/2

Bilinear failuresurface

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:17 Page21

-

22 V S o L V S L R E T A I N E D E A R T H

VSLS KNOW HOW

Circunvalacin Spilimbergo Crdoba, Argentina - 2010

Airport interexchange, Oman - 2006

Hamilton Road, Australia - 2007

Chtellerault, France - 2012

Access to the port of Ferrol, Spain - 2008

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:17 Page22

-

V S o L V S L R E T A I N E D E A R T H 23

Marao Highway, Portugal - 2012

An Suong, Vietnam - 2005

Thonon-les-Bains, France - 2008

East Link Project,Australia - 2005

Collahuasi Mine, Chile - 2004

Dawson Mine,Australia - 2007

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:17 Page23

-

24 V S o L V S L R E T A I N E D E A R T H

MORE REFERENCES

Castle Peak Road, Hong Kong - 2004

Shatin Heights, Hong Kong - 2006

Mandurah Entrance Road, Australia - 2011

Avenida Circunvalar bridge access, Colombia - 2003

Avenida Pontos Barrassa, Spain - 2010

Variante de Canjayar, Spain - 2006

Kralupy wanany, Czech Republic - 2002

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:17 Page24

-

V S o L V S L R E T A I N E D E A R T H 25

Thonon-les-Bains, France - 2008

Dviation de Lure, France - 2008

Geelong Bypass, Austrlia - 2011

South East Transit, Australia - 1999

Marga-Marga project, Chile - 2001

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:17 Page25

-

26 V S o L V S L R E T A I N E D E A R T H

VSLS RELATED ACTIVITIESBRIDGE CONSTRUCTION VSL provides a full range of technical and constructionservices for bridge construction, including designevaluation, temporary works design, permanent worksdesign and construction engineering, precastingmanagement and bridge construction.

VSL has contributed to some of the most prestigious andcomplex structures around the world, ranging fromconventional precast beam crossings to large span cable-stayed bridges.

As a specialist partner for bridge construction, VSL can bring to the project team a wealth of experience.This experience has been gained from erecting more than100,000 precast bridge deck elements (with a surfacearea of almost five million square metres), constructingmultiple in-situ bridges using VSL form-travellers andincremental launching methods and also being involved inthe construction of over 150 cable-stayed bridgesworldwide.

VSL ENGINEERING Each project presents unique challengesand, in recognition of this, members ofVSLs technical staff work with contractors,owners and engineers to evaluate projectsand determine optimum solutions. VSLengineers have a cultural and professionalresponsibility to design safe, economicaland buildable structures that meet thecurrent and future needs of their ownersand the public. Looking for savings andrecycling opportunities, this issue hasbecome an integral part of VSL TechnicalCentres day-to-day activities.

SEGMENTAL ARCH CONSTRUCTION A SUSTAINABLE AND ENERGY EFFICIENTALTERNATIVE

VSL offers a precast concrete arch system for a variety of structures. The VSL-BEBO Arch system isa pre-engineered system to create arches with spans from 3.5m up to 31m.

The arches are built by assembling precast segments in a staggered symmetrical pattern. Theconstruction of a precast arch structure is simple, rapid and predictable, requiring conventionalequipment and just a small crew. VSoL walls can be combined with VSL-BEBO Arch solutions tocreate cost-effective low-maintenance aesthetically pleasing bridges as well as drainage culvertsthrough walls.

VSL provides design, casting and installation services for the arch projects, using elliptical, circularor flat arch profiles to suit project requirements.

Arch applications include overpasses, bridges, tunnels, culverts and underpasses as well as otherstructures.

Hunter Expressway, Australia - 2012

Penrith Lakes, Australia - 1995

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:17 Page26

-

www.vsl.com

SYSTEMS & TECHNOLOGIESPost-tensioning strand systemsBars & post-tensioning bar systemsStay cable systemsDamping systems (stays & buildings)Ductal ultra-high performance concreteBearings & Joints

REPAIR, STRENGTHENING & PRESERVATION

Repair &Strengthening

InfrastructurePreservation

Infrastructure Protection

Structural diagnostics& Monitoring

36.25

3178.25

Ground anchors

GROUND ENGINEERING

VSoL walls

D-walls & Piles

Groundimprovement

Groundinvestigation

Buildings

Slab on grade

Nuclear Containments

Bridges

Offshore structures

CONSTRUCTION

Formwork & Equipment

LNG & LPGcontainments

Heavy lifting

MONITORINGVSL offers instrumentation and monitoring services for allstructures including VSoL walls.

Monitoring of VSoL walls can be carried out to provideinformation on the magnitude and distribution ofreinforcement tension, soil pressures, vertical and lateralmovements and foundation soil settlements.Instrumentation is installed during construction andmonitoring equipment is set up to record and send dataautomatically to the clients office for analysis.

GROUND ANCHOR SYSTEMS VSL has extensive experience in the supply and installationof ground anchors.

VSL Ground Anchor systems are in use around the world,securing famous structures, large dams and retainingwalls, underpasses, underground structures, wind turbinetowers and much more.

VSL Ground Anchors may be installed as temporary orpermanent solutions in combination with VSoL walls toprovide a complete wall and slope stability solution on aproject.

Centenary Link, Australia - 2006

Plaq VSoL_v2_Heavy Lifting 22/04/13 15:17 Page27

-

Copyright 04/2013, VSL International Ltd. Printed in France patented.

The information set forth in this brochure including technical and engineering data is presentedfor general information only. While every effort has been made to insure its accuracy, thisinformation should not be used or relied upon for any specific application without independentprofessional examination and verification of its accuracy, suitability and applicability. Anyoneusing this material assumes any and all liability resulting from such use. VSL disclaims any andall express or implied warranties of merchantability fitness for any general or particular purposeor freedom from infringement of any patent, trademark, or copyright in regard to the informationor products contained or referred to herein. Nothing herein contained shall be construed asgranting a license, express or implied under any patents.

Printed on paperfrom sustainablymanaged forests.

MALAYSIAVSL Engineers (M) Sdn. Bhd.KUALA LUMPURPhone: +603 7981 47 42

PHILIPPINESVSL Philippines Inc.MANDALUYONG CITYPhone: +632 722 1703

SINGAPOREVSL Singapore Pte. Ltd.SINGAPOREPhone: +65 6559 12 22

TAIWANVSL Taiwan Ltd.TAIPEIPhone: +886 2 2759 6819

THAILANDVSL (Thailand) Co. Ltd.BANGKOKPhone: +66 2 679 76 15 - 19

VIETNAMVSL Vietnam Ltd.HANOIPhone: +84 4 3976 5088

HO CHI MINH CITYPhone: +84 8 810 6817

Australia /VSL Australia Pty. Ltd.NEW SOUTH WALESPhone: +61 2 9484 5944

QUEENSLANDPhone: +61 7 3265 64 00

VICTORIAPhone: +61 3 979 503 66

SOUTH AUSTRALIAPhone: +61 8 8252 1900

TASMANIAPhone: +61 3 6249 3044

PERTHPhone: +61 8 9419 1119

Americas /ARGENTINAVSL Sistemas Especiales deConstruccin Argentina SABUENOS AIRESPhone: +54 11 5272 87 52

BOLIVIAPostensados de BoliviaSAN MIGUEL, LA PAZPhone: +591 2 27 70 338

BRAZILVSL Brasil Construo eRecuperao LtdaSO PAULOPhone: +55 113 521 7153/4

CANADACTT Stronghold CanadaTORONTOPhone: +1 416 477 1042

CHILEVSL Sistemas Especiales deConstruccin S.A.SANTIAGOPhone: +56 2 571 67 00

COLOMBIASistemas Especiales deConstruccin S.A.SBOGOTAPhone: +57 1 226 6230

MEXICOVSL Corporation Mexico S.A de C.VMEXICOPhone: +52 55 55 11 20 36

PERUSistemas Especiales de ConstruccinPeru S.A.LIMAPhone: +51 1 349 38 38

VSL PeruLIMAPhone: +51 1 713 98 32

UNITED STATES OF AMERICAVStructural LLCBALTIMORE, MDPhone: +1 410 850 7000

Africa /EGYPTVSL EgyptCAIROPhone: +20 2 344 19 00

SOUTH AFRICAVSL Construction Solutions (Pty) LtdJOHANNESBURGPhone: +27 11 878 6820

TUNISIAVSL TunisiaTUNISPhone: +216 70 72 84 73

Europe /AUSTRIAGrund-Pfahl- und SonderbauGmbHHIMBERGPhone: +43 2235 87 777

CZECH REPUBLICVSL Systemy (CZ) SroPRAGUEPhone: +420 2 51 09 16 80

FRANCEVSL France S.A. (Bouygues TPRF)LABGEPhone: +33 5 33 65 96 59

GERMANYVSL Systems GmbHBERLINPhone: +49 172 313 22 33

NETHERLANDSHeijmans Beton-en Waterbouw B.V.ROSMALENPhone: +31 73 543 66 02

NORWAYSpennarmering Norge ASRUDPhone: +47 98 21 02 31

POLANDVSL Polska Sp. Zo. oWARSZAWAPhone: +48 22849 22 09

Middle East /SULTANATE OF OMANVSL Muscat LLCMUSCATPhone: +971 4 885 7225

UNITED ARAB EMIRATESVSL Middle East LLCDUBAI, UAEPhone: +971 4 885 7225

DOHA, QATARPhone: +974 44 052 444

Asia /BRUNEI VSL Systems (B) Sdn. Bhd.BRUNEI DARUSSALAMPhone: +673 2 380 153 / 381 827

CHINA PRCVSL Engineering Corp., Ltd.(China)HEFEIPhone: +86 551 382 29 18

HONG KONGVSL Hong Kong Ltd.CHAI WANPhone: +852 2590 22 88

INDIAVSL India Private Ltd.CHENNAIPhone: +91 44 4225 11 11

INDONESIAPT VSL IndonesiaJAKARTAPhone: +62 21 570 07 86

JAPANVSL Japan CorporationTOKYOPhone: +81 3 3346 8913

KOREAVSL Korea Co. Ltd.SEOULPhone: +82 2 553 8200

PORTUGALVSL Sistemas Portugal SAPAO DE ARCOSPhone: +351 21 445 83 10

Delegao NorteVILA NOVA DE GAIAPhone: + 351 22 371 18 80

SPAINVSL Construction Systems SABARCELONAPhone: +34 93 289 23 30

SWEDENInternordisk Spnnarmering ABVSTERHANINGEPhone: +46 10 448 11 42

SWITZERLANDVSL (Switzerland) Ltd.SUBINGENPhone: +41 58 456 30 30

SAINT LEGIERPhone: +41 58 456 30 00

TURKEYMega Yapi Construction & Trade Co. LtdANKARAPhone: +90 312 490 90 66

UNITED KINGDOMVSL System (UK) Ltd.LUTONPhone: +44 148 040 4401

Headquarters

VSL International Ltd.Sgestrasse 76CH-3098 KnizSwitzerlandPhone: +41 58 456 30 [email protected]

VSL LOCATIONS

VSL Infrastructure Protection Ltd.LONDONPhone: +44 207 803 3614SINGAPOREPhone: +65 65 59 12 22SYDNEYPhone: +61 2 94 84 5944

Intrafor Hong Kong Ltd.CHAI WAN, HONG KONGPhone: +852 2836 31 12DUBAI, UAEPhone: +971 4 885 7225

FT Laboratories Ltd.PING CHE, HONG KONGPhone: +852 2758 48 61

VSL Offshore Pte Ltd.SINGAPOREPhone: +65 65 59 13 05

Plaq VSoL_v2_Heavy Lifting 22/04/13 16:43 Page28