C Assignment Help,C Programming Assignment Help,Help with C Programming Assignment

OSH5002EP Assignment

Transcript of OSH5002EP Assignment

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

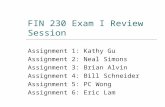

OSH5002EP

LEGISLATIVE CONTEXT IN

OCCUPATIONAL HEALTH AND SAFETY

ASSIGNMENT

Term: March 2011

Class: R13A

Student No.: 03502306

Name: Lee Tat Yan Denny

Word Count: 1832 words

Table of Contents

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

1 Introduction 3

2 Hazard identification of different work process 3

2.1 Excavation 3

2.2 Fall from Height 3

2.3 Fall of Stacking Material 4

2.4 Access and Egress 4

2.5 Electricity Safety 4

2.6 Waterfront Works Safety4

3 Prevention Recommended and Legislation Applicable 4

3.1 Excavation Safety 5

3.2 Access and Egress 6

3.3 Excavator Safety 7

3.4 Electricity Supply Lines Protection 7

3.5 Prevention of Drowning 8

Bibliography 9

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

1 Introduction

On 28th of February 2011 at 1400 hours, a site inspection was conducted at site No.212 (project

no.2011/DSD/1431). The site is located at Sha Tin, the works is to replace 40 meters long pipes for

Drainage Services Department, which pipes installed at 2.7 meters underground and connected to the

water outlet into Shing Mun River Channel (“The River”). The sub-contractor of the project is Kin

Kee Construction Limited, and sub-subcontractor is Shing Kee Construction Limited.

On arrival at the site, the excavation works was completed and part of the pipes was being

installed. The overall setup of the site as follows. The river is on the north side of the site, a

mechanical excavator was employed to excavate the pipe trench and to be used to lift the pipes into

the trench; trench run across from south to north in the middle, and every 10 meters have a 200

millimeters wide concrete block to be used as access point for workers to walk across the trench, a

3,300V lived electrical cable is also located inside the trench; two 20 foot containers are used as site

office on the east side, an overhead power cable is right 1.5 meters above the containers’ roof;

excavated soil placed along west of trench, new pipes placed on soil and prepare for installation.

2 Hazard identification of different work process

During the inspection, some hazards were identified and the likelihood of happening is high to

become risks to personnel on site. Those identified hazards were related to excavation, fall from

height, fall of stacking material, access and egress, electricity safety.

2.1 Excavation

Trench was excavated to the depth of 2.7meters, no setup been made to prevent soil

collapse from both sides. Excavated soil placed right next to the trench may fall and flooded it.

Page 3

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

2.2 Fall from Height

The height from bottom of trench to ground is about 2.7 meters; there was no barrier to

prevent people from falling into the trench.

2.3 Fall of Stacking Material

New pipes which to be installed were placed on excavated soil, it may fall into the trench

when the soil loosen.

2.4 Access and Egress

200 millimeters wide concrete blocks were used for access to cross the trench from one side

to another, it is too narrow and no safety control to prevent people from falling into the trench.

There was no proper setup for worker to access in and out from the trench, only one

handmade ladder was found on site and it is crude and short for use.

2.5 Electricity Safety

A 3,300V lived electrical cable were found inside the trench, there was no warning to

worker being contact with it and get electric shocks.

No safety control was found to prevent the excavator to come into contact with the

overhead electrical wire when it was in operating.

2.6 Waterfront Works Safety

The site was right next to a river, there was no control to prevent of drowning.

3 Prevention Recommended and Legislation Applicable

To prevent accident happening on site, a safe system of work should be provided and

maintained. The following safety precautions should be taken to safeguard the workers on such a

pipe trench excavation site.

Page 4

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

Subcontractor and sub-subcontractor (“Contractors”) should implement appropriate safety

controls to compile with legislative requirement and to provide a safe workplace to workers.

3.1 Excavation Safety

According to CAP.59I Construction Sites (Safety) Regulations Reg.39 Safety of

Excavations stated that the contractor who carrying excavating or earthworking operations at a

construction site is responsible to made structure of suitable timber or other suitable material to

be prevent workmen employed on the site from being endangered by a fall or displacement of

earth, rock, or other material adjacent to or forming the side of the excavation or earthwork.

Every part of the excavation or earthwork where workmen are employed to be examined by a

competent person at least once in every period of 7 days after the commencement of the

excavation or earthwork until it is completed or abandoned.

Contractors should take immediate action to install shoring in the trench. Assign

competent person to examine the trench and issue Form 4 every 7 days.

According to CAP.59I Construction Sites (Safety) Regulations Reg.40 Fencing of

excavations stated that when a workman or other person lawfully on the site is liable to fall a

distance of more than 2 metres into or down the side of the excavation, shaft, pit or opening in

the ground, those places shall be erected with a suitable barrier as close as is reasonably

practicable to the edge; or securely covered.

Contractors should erect with a suitable barrier as close as is reasonably practicable to the

edge, the best practice for barrier should be installed with guard-rails and toe-boards. The height

of a top guard-rail shall be between 900mm and 1150mm above the ground. The height of an

intermediate guard-rail shall be between 450mm and 600mm above the ground. The height of a

toe-board shall be not less than 200mm.

According to CAP.59I Construction Sites (Safety) Regulations Reg.41 Safe Guarding the

Edges of Excavations stated that no material shall be placed or stacked close to the edge of the

Page 5

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

excavation, shaft, pit, or opening in the ground so as to endanger any person who is working in

it. No load or plant shall be placed or moved near the edge of the excavation, shaft, pit or

opening in the ground if it is likely to cause the side of those places to collapse and thereby

endanger any person.

Contractors should arrange location on site which away from trench as far as possible for

storage of excavated soil. If it is not practicable due to the size of site, contractors should

arrange to deliver soil to an off-site location. New pipes which to be installed should arrange to

store in location which away from trench and properly stack.

According to CAP.59I Construction Sites (Safety) Regulations Reg.41A Requirements for

Emergency Escape stated that where there is reason to apprehend danger from rising water or

from an irruption of water or material to persons employed in an excavation, shaft, tunnel, pit or

opening in the ground, adequate means shall be provided, so far as practicable, to enable such

person to reach positions of safety in the event of emergency.

Contractors should arrange ladders to be placed in trench every 10 meters for access and

emergency escape. Securely fasten the ladder to avoid slipping. Place the ladder on a 1:4 ratio

of setback distance to height. The top of the ladder should be 1 meter above the support point.

Draw up emergency procedure guide workers to handle emergency situation, and provide

necessary equipment on site in related to handle emergency, such as water pumps to take away

water from trench.

3.2 Access and Egress

According to CAP.59I Construction Sites (Safety) Regulations Reg.38A Duty of

Contractor Responsible for Construction Site to Ensure Safety of Places of Work Sect.2 stated

that the contractor responsible for any construction site shall ensure that, so far as is reasonably

practicable, suitable and adequate safe access to and egress from every place of work on the site

is provided and properly maintained.

Page 6

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

Contractors should erect proper access paths for workers to cross the trench. Minimum

width of access path is 400 millimeters, and 600 millimeters for use of transportation of

material. Proper guard-rails and toe-boards erect along sides of access path.

3.3 Excavator Safety

According to CAP.59J Factories and Industrial Undertakings (Lifting Appliances and

Lifting Gear) Regulations Reg.8 Precautions to be taken where lifting appliance has travelling

or slewing motion stated that every stage, gantry, or similar place where a lifting appliance

having a travelling or slewing motion is in use, the owner of the appliance shall ensure that an

unobstructed passageway, not less than 600 millimetres wide, is maintained between any part of

the appliance liable so to move and any nearby guard rail, fence or other fixture.

Contractors should draw up operating procedure to ensure no workers come into safe

distance of excavator or the area being excavate. The safe distance of excavator should be

cordon off with fence. Banksman should be appointed to direct the excavator’s operator to

operate.

3.4 Electricity Supply Lines Protection

According to CAP.406H Electricity Supply Lines (Protection) Regulation Reg.10

Requirements relating to works in vicinity of electricity supply lines stated that a person shall

not carry out or cause or permit another to carry out in the vicinity of an underground electricity

cable any works which are below ground level; or carry out or cause or permit another to carry

out in the vicinity of an overhead electricity line works of any kind, unless before the works are

begun all reasonable steps have been taken to ascertain the existence within the proposed works

site and its vicinity of any such underground electricity cable and its alignment and depth or of

any such overhead electricity line and its alignment, distance from the ground and voltage, as the

case may be. A person who carries out or causes or permits another to carry out in the vicinity of

an underground electricity cable any works which are below ground level; or carries out or

Page 7

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

causes or permits another to carry out in the vicinity of an overhead electricity line works of any

kind, shall ensure that all reasonable measures are taken to prevent the occurrence of an

electrical accident or an interruption to the supply of electricity arising from those works. For the

purposes in relation to works in the vicinity of an underground electricity cable, and without

affecting the generality of that subsection, reasonable steps shall not be regarded as having been

taken unless a competent person has undertaken an investigation for the purpose of ascertaining

the existence within the proposed works site and its vicinity of any such underground electricity

cable and its alignment and depth and has provided a written report of his findings as to those

matters.

Contractors should conduct survey to locate electricity supply lines on site, and put up

marking or sign to warns other about electricity cables underneath. Whenever possible, hand dig

near underground electricity supply lines. Avoid working unnecessarily directly beneath the

overhead lines. Determine the height of any object, including any tools, equipment, apparatus or

vehicles, and maintain a safe working distance between the object and the overhead line as

advised by the electricity supplier. Use suitable physical restraining devices if necessary.

3.5 Prevention of Drowning

According to CAP.59I Construction Sites (Safety) Regulations Reg.52A Prevention of

Drowning stated that where a construction site is situated on, or adjacent to, water into which a

workman is liable to fall with risk of drowning, the contractor responsible for the site shall

provide suitable rescue equipment and keep it in an efficient state; and take measures to arrange

for the prompt rescue of any such person in danger of drowning.

Contractors should provide suitable rescue equipment on site, and erect barrier to prevent

workers from fall into river.

Page 8

OSH5002EP Assignment 03502306 Lee Tat Yan Denny

Bibliography

CAP.59I Construction Sites (Safety) Regulations Reg.39 Safety of Excavations

CAP.59I Construction Sites (Safety) Regulations Reg.40 Fencing of excavations

CAP.59I Construction Sites (Safety) Regulations Reg.41 Safe Guarding the Edges of Excavations

CAP.59I Construction Sites (Safety) Regulations Reg.41A Requirements for Emergency Escape

CAP.59I Construction Sites (Safety) Regulations Reg.38A Duty of Contractor Responsible for

Construction Site to Ensure Safety of Places of Work

CAP.59I Construction Sites (Safety) Regulations Reg.52A Prevention of Drowning

CAP.59J Factories and Industrial Undertakings (Lifting Appliances and Lifting Gear) Regulations

Reg.8 Precautions to be taken where lifting appliance has travelling or slewing motion

CAP.406H Electricity Supply Lines (Protection) Regulation Reg.10 Requirements relating to works

in vicinity of electricity supply lines

Labour Department, “A Guide to the Provisions for Excavations and Miscellaneous Safety”, May

2010.

Labour Department, “Code of Practice on Safe Use of Excavators”, January 2005.

Electrical and Mechanical Services Department, “Advice To Site Personnel When Working Near

Overhead Electricity Lines”, October 2008.

Electrical and Mechanical Services Department, “Advice To Site Personnel When Working Near

Underground Electricity Lines”, October 2008.

Page 9