OSB-Jaw Crusher Brochure Final - osborn.co.za Crusher.pdfThe CSS on the Telsmith Standard Duty Jaw...

Transcript of OSB-Jaw Crusher Brochure Final - osborn.co.za Crusher.pdfThe CSS on the Telsmith Standard Duty Jaw...

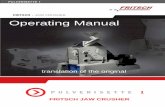

A - SwingstockB - Main frameC - Cheek platesD - Fixed jawE - Swing jawF - Toggle plate & beamG - Tension rod assemblyH - BearingsI - Bearing mountsJ - Eccentric shaftK - Flywheel

• The pitman runs on spherical roller bearings

• Swing jaw pivots with bronze bushes, on a concentric shaft

• Eccentric shaft actuates a vertical pitman connected to a pair of toggle plates, and is not directly exposed to crushing loads

JAW LINERS

BRONZE BUSHSWINGSTOCK

ECCENTRICSHAFT FLYWHEEL

SHIMS

TOGGLE PLATES PITMAN TOGGLE BLOCK

TENSION ROD

C E

D

F

G

A

J

I

H

K

1

Note: Crusher output gradations and tons per hour products may change due to variations in operating conditions and application of the crushing equipment. This information does not constitute an expressed or implied warranty or guarantee, but shows results of test crushing of samples provided by customers. This is guideline information.

NOTES

• All the parameters referred to above must still take into consideration the actual capacity of the crusher at required settings as the cavity has a volumetric constraint. So correct sizing of a crusher is also influenced by the actual capacity required.• In many cases an oversized crusher needs to be selected to handle the lump size whilst the capacity consideration is less important• This is more common in Jaw Crushers• The industry standard of rating various size crushers is based on dry limestone with a loose bulk density of 1,6t/m³ or 100lbs/ft³• Factors affecting these capacities are excessive moisture, clay content, feeding method, feed gradation, bulk density and crushability

COMPILED BY

Single Toggle Jaw Crusher Double Toggle Jaw Crusher

Customer Contact Person

Phone No. Phone No.

Fax.No Date

MATERIAL

Type

Loose Bulk Density kg/m³

Compressive Strength MPa

Abrasiveness High Medium Low

Moisture Content % Max % Min

Shape of Material

DUTY

Capacity mtph

Max.Feed Lump Size mm

Min. Feed Lump Size mm

Feed Analysis Size - mm - mm - mm - mm

% Passing % % % %

Product Size Req’d mm

Application Data

B

CLOSED SIDE SETTING OF CRUSHERPRODUCT SIZE

300 250 200 180 150 130 100 90 75 60 50 40 25 20

-400 100

-350 93

-330 89 100

-300 85 95

-280 78 90 100

-250 70 85 97 100

-230 63 78 91 98 100

-200 56 70 85 91 98

-180 49 60 76 81 92 100

-150 40 50 65 71 82 92 100

-130 31 40 51 60 70 80 95 100 100

-100 22 30 39 46 56 66 82 89 96

-90 20 25 33 39 48 58 73 82 90 100

-75 17 20 27 32 39 49 62 72 83 93 100

-60 14 17 22 26 31 39 52 60 70 81 95 100

-50 11 14 17 20 23 28 41 47 56 65 80 97

-40 9 10 12 15 17 21 28 33 40 48 63 80 100 100

-25 6 7 7 10 11 14 18 22 25 29 43 54 81 98

-20 4 5 5 7 9 11 14 16 19 22 30 38 61 80

-10 2 3 3 5 6 7 10 11 13 14 19 25 41 60

-5 1 2 2 2 3 3 6 6 7 7 8 12 16 20

CLOSED SIDE SETTING & CAPACITY (Depending on material type)

20 25 40 50 75 100 130 150 180 200 250 300

48” x 12” 15 30 55 70 110

Max Lump to to to to to

245mm 30 45 70 100 140

48” x 18” 70 110 150 200

Max Lump to to to to

370mm 100 140 190 260

80” x 60” 600 800 900 1000 1200 1400

Max Lump to to to to to to

1 220mm 680 900 1000 1100 1400 1600

SIZE OF FEED OPENING

Information for reading screen analysisTo illustrate the approximate screen analysis from an Osborn Hadfields Heavy Duty Jaw Crusher, the following results can be read from the relevant table.

Using a 48” x 18” as a typical popular crusher model and set at a 25mm CSS we can read off the screen analysis table that:

• 100% will pass through a 40mm square opening

• 81% will pass through a 25mm square opening

• 61% will pass through a 20mm square opening

• 41% will pass through a 10mm square opening

• 16% will pass through a 5mm square opening

Note: On the Osborn Hadfields and Osborn Telsmith Heavy Duty Jaw Crushers, the CSS is measured from peak to valley.

The CSS on the Telsmith Standard Duty Jaw Crusher is measured from peak to peak.

2

Double Toggle Jaw Crusher Osborn Hadfields Single Toggle - Heavy Duty For material below 500 MPa.

• Optional sizes available to suit feed/setting ratios.

• Assists with finer wear, nip angles and in some cases provides smaller closed-side settings.

Hadfields Single Toggle - Heavy Duty

Current Model Optional Model

4812 4810

Performance Schedule

Screen Analysis

3

Osborn Hadfields Double Toggle - Heavy Duty For material well over 400 MPa and very abrasive material.

Screen Analysis

CLOSED SIDE SETTING OF CRUSHER

200 180 150 130 100 75 50 40

-400

-350 100

-300 97 100

-250 92 95 100

-200 78 89 95 100

-180 68 79 87 96

-150 59 69 77 90 100

-130 44 56 65 77 95 100

-100 32 41 52 63 81 95

-75 21 28 36 46 60 81 100 100

-50 13 18 22 24 38 54 80 88

-40 9 13 16 18 26 38 62 72

-25 6 9 11 12 15 23 38 46

-20 4 5 7 8 11 15 28 32

-10 2 3 4 5 6 9 18 17

-5 1 1 2 3 3 4 6 7

PRODUCT SIZE

Performance Schedule

CLOSED SIDE SETTING & CAPACITY (Depending on material type)

40 50 75 100 130 150 180 200

24” x 13” 15 25 40

Max Lump to to to

265mm 25 35 50

24” x 18” Special Heavy Duty 25 40

Max Lump to to

350mm 35 50

30” x 23” 30 50 70

Max Lump to to to

470mm 45 65 90

36” x 25” 75 90 130 150

Max Lump to to to to

508mm 100 140 150 190

42” x 32” 150 170 220

Max Lump to to to

650mm 200 220 250

48” x 42” 260 300 360

Max Lump to to to

850mm 330 370 420

60” x 52” 400 480 550

Max Lump to to to

1 050mm 450 540 600

SIZE OF FEED OPENING

• Data based on Dry Limestone @ 1.6t/m3. Performance schedule setting is Peak to Valley on Heavy Duty machines.

• Max lump not applicable to small settings. Crushing ratio = Feed size to CSS = 6:1 on mined ore.

• When crushing Ferro Chrome – ignore all information following and consult with Osborn Head Office.

• Optional sizes available to suit feed/setting ratios.

• Assists with finer wear, nip angles and in some cases provides smaller closed-side settings.

Hadfields Double Toggle - Heavy Duty

Current Model Optional Model

2413 2411 & 2409

3023 3020

3625 3623

4842 4836 & 4828

4

SIZE OF FEED OPENING

Performance Schedule

Osborn Telsmith Single Toggle - Heavy Duty For material below 400 MPa.

Screen Analysis

CLOSED SIDE SETTING & CAPACITY (Depending on material type)

CLOSED SIDE SETTING OF CRUSHER

300 250 200 180 150 130 100 90 75 60 50 40 25 20

-400 100

-350 93

-330 89 100

-300 85 95

-280 78 90 100

-250 70 85 97 100

-230 63 78 91 98 100

-200 56 70 85 91 98

-180 49 60 76 81 92 100

-150 40 50 65 71 82 92 100

-130 31 40 51 60 70 80 95 100 100

-100 22 30 39 46 56 66 82 89 96

-90 20 25 33 39 48 58 73 82 90 100

-75 17 20 27 32 39 49 62 72 83 93 100

-60 14 17 22 26 31 39 52 60 70 81 95 100

-50 11 14 17 20 23 28 41 47 56 65 80 97

-40 9 10 12 15 17 21 28 33 40 48 63 80 100 100

-25 6 7 7 10 11 14 18 22 25 29 43 54 81 98

-20 4 5 5 7 9 11 14 16 19 22 30 38 61 80

-10 2 3 3 5 6 7 10 11 13 14 19 25 41 60

-5 1 2 2 2 3 3 6 6 7 7 8 12 16 20

PRODUCT SIZE

10 20 25 40 50 60 75 90 100 130 150 180 200 230 300

15” x 24” 27 35 45 50

Max Lump to to to to

304mm 40 50 65 80

20” x 32” 30 40 50 60 70

Max lump to to to to to

406mm 60 70 90 100 120

30” X 42” 180 220 260 300

Max Lump to to to to

608mm 210 250 290 340

42” X 48” 410 450 500 550 600 700

Max Lump to to to to to to

850mm 460 510 560 610 660 770

50” X 60” 580 600 640 740 820

Max Lump to to to to to

1 015mm 640 680 720 810 890

• Data based on Dry Limestone @ 1.6t/m3. Performance schedule setting is Peak to Valley on Heavy Duty machines.

• Max lump not applicable to small settings.Crushing ratio = Feed size to CSS = 6:1 on mined ore.

• Optional sizes available to suit feed/setting ratios.

• Assists with finer wear, nip angles and in some cases provides smaller closed-side settings.

Telsmith Single Toggle - Heavy Duty

Current Model Optional Model

4248 3848

5060 4760

3042 2842

5

Performance Schedule

Osborn Telsmith Single Toggle - Standard Duty For material below 280 MPa.

Screen Analysis

CLOSED SIDE SETTING OF CRUSHER

200 180 150 130 100 90 75 60 50 40 25 20

-330 100

-300 95

-280 90 100

-250 85 97

-230 78 91 100 100

-200 70 85 98 98

-180 60 76 92 91 100

-150 50 65 82 81 92 100

-130 40 51 70 69 80 93 100 100

-100 30 39 56 55 66 82 89 96

-90 25 33 48 47 58 73 82 89 100

-75 20 27 39 39 49 62 72 82 93 100

-60 17 22 31 31 39 52 60 68 80 93 100

-50 14 17 23 23 28 41 47 55 65 80 97 100

-40 10 12 17 18 22 28 33 40 49 65 84 90

-25 7 7 11 11 14 18 21 25 28 43 55 68

-20 5 5 9 9 11 14 18 18 23 31 39 50

-10 2 2 6 4 4 8 9 9 11 14 20 29

-5 1 1 3 2 2 4 4 5 6 7 9 12

PRODUCT SIZE

CLOSED SIDE SETTING & CAPACITY (Depending on material type)

25 32 40 50 64 76 90 100 130 152 178 203

25” x 40” 100 130 150 170

Max Lump to to to to

508mm 140 160 180 200

30” x 42” 160 170 190 200 220

Max Lump to to to to to

608mm 200 230 250 280 300

30” x 55” 175 200 230 250

Max Lump to to to to

608mm 270 280 300 340

36” x 48” 260 300 350 400 430

Max Lump to to to to to

731mm 320 360 400 480 550

SIZE OF FEED OPENING

Telsmith Single Toggle - Standard Duty

Current Model Optional Model

3042 2842

3648 3248

• Data based on Dry Limestone @ 1.6t/m3. Performance schedule setting is Peak to Peak on Standard Duty machines.

• Max lump not applicable to small settings. Crushing ratio = Feed size to CSS = 6:1 on mined

ore.

• Optional sizes available to suit feed/setting ratios.

• Assists with finer wear, nip angles and in some cases provides smaller closed-side settings.

A

B

How to determine maximum feed for a 3042 Jaw Crusher

Crusher Gape (smallest dimension of the feed opening)

30” (760 mm)

Maximum Feed

= 30” (760 mm) x 0.8

= 24” (600 mm)

30” 760 mm

600 mm

TOP

Settings in above case is as follows

600 mm Lump ÷ 6 = 100 CSS (F:CSS) 6 : 1

Yield 600 mm Lump ÷ 4 = 150 mm Product Lump (F : P) 4 : 1

When setting below this ratio effective manganese wear increases

This condition will also occur when too large a crusher is used with small feed size.

Only the extreme ends of the liners are used

6

Model kg Mass kW rpm A B Width over flywheels

48” x 12” 11000 75 375 1870 2025 2130

48” x 18” 16800 75 250 2360 1985 2260

80” x 60” 140000 220 140 6220 5400 3840

Osborn Hadfields Single Toggle - Heavy Duty

Model kg Mass kW rpm A B Width over flywheels

24” x 13” 9500 37 330 1670 2520 1580

30” x 23” 19700 55 270 2025 3075 2100

36” x 25” 23600 75 270 2340 3825 2050

42” x 32” 42000 90 225 2385 4390 2410

48” x 42” 71000 110 185 2920 4980 2990

60” x 52” 110 000 160 155 3485 5960 3090

Osborn Hadfields Double Toggle - Heavy Duty

A

B

Telsmith Single Toggle

Hadfields Double Toggle

Model kg Mass kW rpm A B Width over flywheels

15” x 24” 5000 30 325 1805 1625 1540

20” x 32” 11034 55 270 2380 2560 1930

30” x 42” 31700 132 250 3290 3050 2490

42” x 48” 53000 160 220 4340 3655 2890

50” x 60” 112000 220 180 4755 4490 3420

Osborn Telsmith Single Toggle - Heavy Duty

Model kg Mass kW rpm A B Width over flywheels

25” x 40” 16100 90 260 2455 2420 2370

30” x 42” 24100 110 290 3025 3160 2500

30” x 55” 26300 160 280 3025 3160 2830

36” x 48” 34800 160 230 2515 3100 2740

Osborn Telsmith Single Toggle - Standard Duty

Jaw

Cru

sher

/1

01

3/

Rev

2

Companies of the Astec Aggregate and Mining Group

www.osborn.co.za www.telsmith.com www.rockbreaker.com www.kpijci.comwww.astecmobilescreens.com

All rights reserved. Unless otherwise indicated, all materials on these pages are copyrighted by OSBORN. No part of these pages, either text or image may be used for any purpose other than personal use. Therefore, reproduction, modification, storage in a retrieval system or retransmission, in any form or by any means, electronic,

mechanical or otherwise, for reasons other than personal use, is strictly prohibited without prior written permission.

Head Office:57 Jansen Road, Elandsfontein

PO Box 8182Elandsfontein, 1406

JohannesburgSouth Africa

Tel: +27 11 820 7600 Fax: +27 11 388 1136

Call Centre: 0861 OSBORN

E-mail: [email protected] www.osborn.co.za