Optimisation of the Primary Purification Steps of a VLP production process

-

Upload

kaye-cameron -

Category

Documents

-

view

16 -

download

1

description

Transcript of Optimisation of the Primary Purification Steps of a VLP production process

Optimisation of the Primary PurificationSteps of a VLP production process

Olotu Ogonah

Benjamin Blaha

Tarit Mukhopadhyay

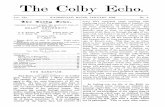

VLP Process Flow Chart – early phases

Fermentation and RNA removal

Homogenisation

Concentration/DiafiltrationHF TFF: NMWC 100kDA

Cell harvestingCentrifugation

ClarificationCentrifugation/Normal flow filtration 0.45, and 0.2 m

2

1

3

4

5

GSK Stevenage

Identification of the Critical Process Parameters (CPP): parameters that impact process performance.

Homogenisation

• The Lab40 is a validated scale down model to the Manufacturing scale– Use process knowledge and expertise to suggest critical

process parameters (CPP): parameter which impact process behaviour (response) or critical product quality attributes (CQA).

– Will confirm through model building.• In these experiments the responses evaluated will be selected for

their potential impact on process efficiency and scalability; i.e. soluble vlp recovered and DNA concentration.

Homogenisation screening experiment design – model building.

• MODDE software used to enhance the design of screening experiments.

• These experiments will identify parameters which have a statistically significant impact on process efficiency.

• Model VLP → GFP insert.• GFP concentration will be used for a

surrogate for VLP/core concentration.

• Parameter range

• Responses: GFP concentration and DNA concentration.

• Create a model which describes process behaviour.

Name Abbr. Units Settings PrecisionHomogenisation pass pass# 2, 3, 4 0.05

pH pH 7.5, 8, 8.5 0.1

pressure bar bar 300 to 1000 10

detergent Tri % 0.1 to 1 0.1% solids %_sol 3 to 15 0.2

# Homog. pass pH Pressure bar

Detergent %

% solids (w/w)

GFP yield flur. Units

DNA mg/l

4 7.5 650.0 0.1 3.0 4159.9 24.14 8.0 300.0 1.0 15.0 1586.6 29.03 8.0 650.0 0.6 9.0 3993.3 37.03 8.0 650.0 0.6 9.0 4453.3 46.13 8.5 1000.0 0.1 3.0 14426.6 43.44 8.5 650.0 0.1 15.0 3973.3 59.62 8.5 650.0 0.6 15.0 3499.9 52.24 8.0 1000.0 0.6 3.0 12013.3 46.93 8.0 1000.0 0.1 15.0 6186.6 107.43 8.5 300.0 0.6 15.0 2066.6 23.53 7.5 650.0 1.0 15.0 1586.6 31.54 7.5 1000.0 0.6 15.0 3853.3 122.44 8.5 300.0 1.0 3.0 9199.9 31.32 8.0 300.0 0.1 15.0 959.9 16.42 7.5 1000.0 1.0 15.0 2753.3 102.93 8.0 650.0 0.6 9.0 3726.6 54.62 8.5 1000.0 1.0 3.0 14213.3 43.23 8.0 650.0 1.0 3.0 7106.6 24.53 7.5 300.0 0.6 3.0 953.3 7.72 7.5 300.0 0.1 3.0 226.6 5.32 8.0 650.0 0.6 3.0 4979.9 18.02 8.5 300.0 0.1 3.0 2208.4 4 8.5 300.0 0.1 3.0 4568.4 4 7.5 300.0 0.1 15.0 938.9 3 8.0 650.0 0.6 9.0 2815.7 3 8.0 650.0 0.6 9.0 2959.1 2 7.5 1000.0 0.1 3.0 4907.7 2 8.5 1000.0 0.1 15.0 5951.7 2 7.5 300.0 0.1 15.0 758.7 4 8.5 1000.0 1.0 15.0 9099.1 2 8.5 300.0 1.0 15.0 2049.7 4 7.5 1000.0 1.0 3.0 8303.1 2 7.5 300.0 1.0 3.0 948.8 3 8.0 650.0 0.6 9.0 3078.4

Actual vs predicted plots (DNA and GFP)

Graphical presentation of model terms: The scale and centred coefficients can be used to evaluate the significance of the model terms.

Impact of homogenisation pass # on GFP yield

• Re-evaluation of initial fermentation data reveal low vlp yield was an artefact of the homogenisation conditions used.

• Reducing loading from 15%→ 6% solids increases soluble VLP → ~ 55%)

3 passes

4 passes

• 3% load →1.74 X (V/V) than 15% loading.

• 3% load →8.75 X (g/g) than 15% loading.

Inter-fermentation analysis: VLPs

S I S I S I S I

MeOH 30°C (Lab40)

Mixed 20°C (Lab40)

MeOH 20°C (Lab40)

MeOH 20°C (Soni.)

Western blots (AB – HepB core protein)

Fluo

resc

ence

6% load

48

21

Impact of # of homogenisation passes on DNA levels

• High DNA contamination.

• Allowable DNA content for final formulated product ~ <10 ng/dose.

• Data suggests need for a DNA removal step.

3 passes

4 passes

The story so far……..• Homogenisation:

– ↑pH, ↑pass#, and ↑pressure increases vlp release.– Low % solids (3%) gives better vlp release (8 fold (wt./wt.) increase) compared to current protocol.– ↑ % Load, ↑homogenisation pass #, and ↑pressure increase total DNA released.– High genomic DNA contamination indicate DNA removal step will be necessary.

• Floculation• Precipitation• AIEX

• Fermentation– 3 batches run under different conditions.– Yields and quality (multiple bands on western) impacted by fermentation conditions.

• Repeating assays with 6% load during homogenisation ( instead of 15%) reinforces impact of homogenisation conditions on yield.

– GFP assay appears to overestimates soluble fraction compared to western. • Assay measure total (free and vlp attached) GFP, hence amplified signal ? • Need assays to distinguish between free and attached antigen (Octet ?). Use as measure of stability?

Next….. TFF Akta Crossflow

What is Tangental Flow Filtration (TFF)?

• TFF - Fluid continuously sweeps the membrane surface, recirculating the feed stream across the membrane.

Advantages• Minimizes clogging membrane pores (fouling) and promotes consistent,

long-term productivity.

• Units can be cleaned, stored, and re-used as needed; i.e. it is very cost effective.

• Suitable for scale-up

• Two types• Cassettes: High shear, High flux → Higher ∆P• Hollow Fibre: Low shear, lower flux than cassettes. Suitable for

fouling feed streams.

0

10

20

30

40

50

60

70

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

Flux vs. TMP

Flux

[ LM

H]

TMP [ bar]

Run 3 - 25 ml/min Run 3 - 35 ml/min Run 3 - 50 ml/min

Hollow Fibre vs Cassettes: Initial Flux vs TMP

10

15

20

25

30

35

40

45

50

55

60

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

Flux vs. TMP

Flux

[ LM

H]

TMP [ bar]

Run 16 - 250 ml/min (8000/s) Run 16 - 125 ml/min (4000/s) Run 16 - 63 ml/min (2000/s)

At large scale systems are run in constant flux mode in linear (non fouling) region of the flux vs TMP curve.

Cassettes• Steep Flux vs TMP curve• System difficult to control at lower TMP

because:– Flux sensitive to perturbations in TMP.– Requires high ∆P and permeate

pressures to maintain low TMP.

Hollow fibres:• Very flat flux vs TMP curve.• Easier to maintain steady state.• Lower pressure required to achieve

acceptable permeate flow. Will tolerate fouling streams.

Summary• Homogenisation:

– ↑pH, ↑pass#, and ↑pressure increases GFP (and by implication vlp) release.– Low % solids (3%) gives better vlp release: 8 fold (wt./wt.) increase over current protocol.– ↑ % Load, ↑homogenisation pass #, and ↑pressure increase total DNA released.– High genomic DNA contamination indicate DNA removal step will be necessary.

• TFF– Cassettes: Sensitivity to perturbations in critical process parameters suggests not suitable for scale up.

– Early data suggests Hollow Fibre preferred route.

• Next Steps• Begin fermentation optimisation• Complete parameter screening/optimisation of TFF step.• Evaluate additional dead end filtration step as a replacement for centrifugation during primary clarification of

homogenate.• Look at DNA removal step• Include Quality assays in evaluation of CPPs.

• OCTET – biacore without the flow! Kinetic and concentration data.• TEM of vlp.

• Define Critical Attributes (CQA) ?

Revised VLP Process Flow Chart – What the future may look like.

Fermentation and RNA removal

Homogenisation

Concentration/DiafiltrationHF TFF: NMWC 100kDA

DNA capture Anion exchange Chromatography

Cell harvestingCentrifugation

ClarificationNormal flow filtration1.2, 0.45, and 0.2 m

2

1

3

4

5

6

GSK Stevenage

END

Identification of the Critical Process Parameters (CPP): parameters that impact process performance.

Summary of model statistics

Impact of Filter Type on ∆P at initial conditions

0.25

0.50

0.75

1.00

1.25

1.50

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

DeltaP vs. TMP

Del

taP

[ b

ar]

TMP [ bar]

Cassett Flow 1 Cassett Flow 2 Cassett Flow 3

Hollow Fibre Run 1 Hollow Fibre Run 2 Hollow fibre run 3

Note: as concentration factor increases P will also increase