Optimal Location and Tuning of Power System Stabilizers · Electrical and Computer Engineering ......

Transcript of Optimal Location and Tuning of Power System Stabilizers · Electrical and Computer Engineering ......

Optimal Location and Tuning of Power System Stabilizers

Joana Margarida Ribeiro de Oliveira

Thesis to obtain the Master of Science Degree in

Electrical and Computer Engineering

Supervisor(s): Prof. Dr. José Manuel Dias Ferreira de Jesus

Examination Committee

Chairperson: Prof. Dr. Rui Manuel Gameiro de CastroSupervisor: Prof. Dr. José Manuel Dias Ferreira de Jesus

Member of the Committee: Prof. Dr. João Manuel Lage de Miranda Lemos

July 2016

Acknowledgments

This is the perfect opportunity to express my gratefulness to my Mom and Dad, who have always and

unconditionally been so supportive. Their selflessness has not passed unnoticed to me.

The guidance of my tutor Professor Jose Jesus was of paramount importance. He was always very

receptive and would make me feel enlightened after each meeting.

I would also like to mention the availability and attention of Professor Pai, Professor Sauer, Professor

Chow and Prasenjit Dey, with whom I’ve intensely exchanged insights and materials in the course of this

work.

A warm thank you to my friends who have been very present throughout my entire academic journey.

iii

Resumo

O objectivo desta tese e estender as funcionalidades de um programa desenvolvido em MATLAB e

usado para a analise de pequenas perturbacoes de sistemas de energia. A tese complementa o pro-

grama com a opcao ”PSS Inclusion Study” que permite estudar o impacto de instalar estabilizadores de

sistemas de energia (ESE) numa dada rede. Para alem disso, sao tambem estabelecidos criterios para

a melhor localizacao do ESE na rede e para a melhor regulacao dos parametros do ESE.

Uma das principais conclusoes retiradas deste trabalho e que instalar um ESE nao e necessaria-

mente condicao suficiente para uma melhor estabilidade do sistema. Na verdade, a eficacia do ESE

e determinada pela escolha adequada da sua localizacao e dos seus parametros, sendo estes dois

aspectos o grande foco da tese.

Foram implementadas duas abordagens para determinar a localizacao optima do ESE, sendo que

apenas uma revela resultados consistentemente viaveis.

A regulacao do ganho do ESE e efectuada no domınio do tempo, emulando um teste experimental

conhecido por “gain margin test”. A regulacao das constantes de tempo do ESE e efectuada no domınio

da frequencia com o auxılio de diagramas de Bode.

Sao apresentados tres sistemas onde a metodologia e testada e validada, explorando ainda outros

factores que influenciam a estabilidade, nomeadamente a elasticidade das cargas. Em cada um dos

tres casos, a estabilidade do sistema era limitada pela existencia de oscilacoes electromecanicas. Ao

amortizar estas oscilacoes, o ESE permite que o sistema suporte mais carga sem que isso o leve a

instabilidade. Desta forma a capacidade de transmissao de energia do sistema e melhorada.

Palavras-chave: Analise Dinamica, Estabilidade em Pequenas Perturbacoes, Estabilizador

de Sistemas de Energia, MATLAB.

v

Abstract

The goal of the thesis is to extend the functionalities of an existing MATLAB-based power system small

signal analysis program (MaSSA), with the introduction of a “PSS Inclusion Study”, which simulates

the impact of including speed-input Power System Stabilizers (PSS) in a power system. Furthermore,

criteria for the optimal PSS location and for the optimal PSS tuning are established.

A major conclusion withdrawn from this work is that installing a PSS is not a sufficient condition for

improved system stability, meaning that a PSS is only as good as its tuning and location. Hence, much

of the focus of the thesis is on these two aspects.

Two approaches for determining the optimal location are implemented but only one proved to be

consistently reliable.

The tuning of the PSS gain is performed in time domain, by emulating the well-known gain margin

field test. The tuning of the PSS time constants is performed in frequency domain, recurring to the use

of Bode diagrams.

Three power systems are used to successfully validate the methodology and, in doing so, further

aspects that influence the system’s performance, such as the effect of load elasticity and the effect

of tie lines, are explored. The stability of each one of the three presented examples was limited by

the existence of electromechanical oscillations. Installing a PSS provided the necessary damping to

the oscillations of concern, enabling the system to endure heavier loading conditions and in this way

extending the power system’s transfer capability.

Keywords: Dynamic Analysis, MATLAB, Power System Stabilizer, Small Signal Stability.

vii

Contents

Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Resumo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Abstract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Introduction 1

1.1 Motivation [1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Problem Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Literature Review 5

2.1 Motivation: Power System Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Classification of Power System Stability . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Rotor Angle Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3 Electromechanical Oscillations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Excitation Control of Synchronous Machines . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Heffron-Phillips Representation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Synchronizing and Damping Torques . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.3 Voltage Regulator Effect on Machine Stability . . . . . . . . . . . . . . . . . . . . . 13

2.3 Power System Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.1 Performance Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3.2 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3.3 Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 Methodology 21

3.1 Small Signal Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.1 Differential-Algebraic Power System Model . . . . . . . . . . . . . . . . . . . . . . 21

3.1.2 PSS Linearized Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ix

3.1.3 PSS Modular Integration in the DAE . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 PSS Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.1 Criterion: Power Transfer Capability . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2.2 Optimum PSS Location Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 PSS Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.1 Instrumental Transfer Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.3.2 Criterion: Phase Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.3 Criterion: Instability Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.4 PSS Inclusion Study . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5 Contributed Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4 Validation: 3-Machine 9-Bus Network 37

4.1 Analysis Before PSS Inclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2 Analysis After PSS Inclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.3 PSS Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.4 PSS Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5 Results 53

5.1 Two-Area System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.2 10-machine 39-bus System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2.1 AVR Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.2.2 PSS Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Conclusions 67

6.1 Achievements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2 Future Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Bibliography 71

A Dynamic Models 73

A.1 Synchronous Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

A.2 Excitation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

A.3 Turbine-Governor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

B WSCC 3-machine 9-bus System 78

C GENDEC Machine Model 80

C.1 Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

C.2 Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

D Two-Area System 81

E New England 10-machine 39-bus System 83

x

List of Tables

4.1 Eigenvalues of the 3-machine 9-bus system before PSS inclusion. . . . . . . . . . . . . . 40

4.2 Participation factors of the states associated with mode λ1,2. . . . . . . . . . . . . . . . . 40

4.3 Participation factors of the states associated with mode λ4,5. . . . . . . . . . . . . . . . . 40

4.4 Chosen PSS parameters for the 3-machine 9-bus system. . . . . . . . . . . . . . . . . . . 42

4.5 Eigenvalues of the 3-machine 9-bus system after PSS inclusion in machine 1. . . . . . . . 42

4.6 Eigenvalues of the 3-machine 9-bus system after PSS inclusion in machine 2. . . . . . . . 42

4.7 Eigenvalues of the 3-machine 9-bus system after PSS inclusion in machine 3. . . . . . . . 43

4.8 Active power at load bus 5 at which the 3-machine 9-bus system becomes unstable. . . . 45

4.9 Improvement of the 3-machine 9-bus system’s power transfer capability by PSS inclusion. 45

4.10 Participation factors of the states associated with mode λM11,2 for PSS installed at machine 1. 46

4.11 Participation factors of the states associated with mode λM14,5 for PSS installed at machine 1. 46

4.12 Participation factors of the states associated with mode λM24,5 for PSS installed at machine 2. 46

4.13 Participation factors of the states associated with mode λM28,9 for PSS installed at machine 2. 46

4.14 Participation factors of the states associated with mode λM33,4 for PSS installed at machine 3. 46

4.15 Participation factors of the states associated with mode λM36,7 for PSS installed at machine 3. 47

4.16 OPLI computed for each machine of the 3-machine 9-bus system. . . . . . . . . . . . . . 47

4.17 Washout filter behaviour for steady-state condition of the 3-machine 9-bus system. . . . . 48

4.18 Improvement of the system’s power transfer capability by PSS inclusion with for KPSS = 13. 51

5.1 Eigenvalues of the two-area system before PSS inclusion. . . . . . . . . . . . . . . . . . . 54

5.2 Participation factors of the states associated with mode λ3,4 of the two-area system. . . . 55

5.3 Chosen PSS parameters for the two-area system. . . . . . . . . . . . . . . . . . . . . . . 55

5.4 Active power at load bus 10 at which the two-area system becomes unstable. . . . . . . . 55

5.5 Improvement of the two-area system’s power transfer capability by PSS inclusion. . . . . 55

5.6 Eigenvalues of the two-area system after PSS inclusion in machine 3. . . . . . . . . . . . 56

5.7 Partial derivatives contributed by each type of load model. . . . . . . . . . . . . . . . . . . 56

5.8 Active power at load bus 10 at which the two-area system becomes unstable for different

load elasticities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.9 Eigenvalues for different tie lines scenarios before PSS inclusion. . . . . . . . . . . . . . . 57

5.10 Eigenvalues for different tie lines scenarios with PSS installed at machine 3. . . . . . . . . 58

xiii

5.11 Active power at load bus 10 at which the two-area system becomes unstable for different

tie lines scenarios. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.12 Area 1 transfers 153.28 MW to area 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.13 Area 1 transfers 106.14 MW to area 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.14 Area 1 transfers 56.14 MW to area 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.15 Area 1 transfers 6.14 MW to area 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.16 No power transfer between areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.17 10-Machine 39-bus system’s stability limits for different excitation systems models. . . . . 62

5.18 P instabilityL12of the 10-machine 39-bus system for the original values of KA. . . . . . . . . . 63

5.19 P instabilityL12of the 10-machine 39-bus system when KA is increased to 100 for every gen-

erating unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.20 P instabilityL12of the 10-machine 39-bus system when KA is increased to 200 for every gen-

erating unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.21 10-machine 39-bus system’s swing modes before PSS inclusion. . . . . . . . . . . . . . . 64

5.22 10-machine 39-bus system’s chosen PSS parameters. . . . . . . . . . . . . . . . . . . . . 64

5.23 10-machine 39-bus system’s swing modes after PSS inclusion at machine 5. . . . . . . . 64

5.24 Effect of including multiple PSS on the 10-machine 39-bus system’s stability. . . . . . . . 65

B.1 WSCC 3-machine 9-bus system power-flow. . . . . . . . . . . . . . . . . . . . . . . . . . . 79

B.2 WSCC 3-machine 9-bus system machine data. . . . . . . . . . . . . . . . . . . . . . . . . 79

B.3 WSCC 3-machine 9-bus system excitation data. . . . . . . . . . . . . . . . . . . . . . . . 79

D.1 Two-area system power-flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

D.2 Two-area system machine data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

D.3 Two-area system excitation data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

D.4 Two-area system transmission line data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

E.1 New England 10-machine 39-bus system machine data. . . . . . . . . . . . . . . . . . . . 83

E.2 New England 10-machine 39-bus system excitation data. . . . . . . . . . . . . . . . . . . 83

E.3 New England 10-machine 39-bus system power-flow. . . . . . . . . . . . . . . . . . . . . 85

E.4 New England 10-machine 39-bus system transmission line data. . . . . . . . . . . . . . . 86

xiv

List of Figures

1.1 MaSSA’s ”Type of Analysis” window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Flowchart of MaSSA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Flowchart of ”Dynamic Analysis”. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Classification of power system stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Single generator supplying an infinite bus through an external impedance. . . . . . . . . . 9

2.3 Linearized small perturbation block diagram of a SMIB. . . . . . . . . . . . . . . . . . . . 10

2.4 Representation of change in electrical torque on the ∆δ-∆ω plane. . . . . . . . . . . . . . 12

2.5 Inclusion of a speed-based PSS block in the Heffron-Phillips diagram. . . . . . . . . . . . 15

2.6 Illustrastion of the applied torques on machine shaft with a speed-based PSS included. . 15

2.7 Block model of a linearized representation of a typical PSS. . . . . . . . . . . . . . . . . . 16

3.1 Zero-Pole map of a lead-lag compensator that leads. . . . . . . . . . . . . . . . . . . . . . 32

3.2 Inserting a leading compensator in the Control System Designer App. . . . . . . . . . . . 33

3.3 Editing the compensator with the Control System Designer App. . . . . . . . . . . . . . . 34

3.4 Flowchart of PSS Inclusion Study. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1 MaSSA’s new ”Type of Analysis” window. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2 MaSSA’s ”PSS Parameters” window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3 Choosing which load buses to increment when performing a dynamic analysis in MaSSA. 38

4.4 MaSSA’s ”Type of load and Operating Point” window. . . . . . . . . . . . . . . . . . . . . . 39

4.5 MaSSA’s ”PSS Inclusion Study Results” window. . . . . . . . . . . . . . . . . . . . . . . . 39

4.6 Time responses of δ and ω for a step in Vref2, with no PSS included in the network. . . . 41

4.7 Chosen PSS for the 3-Machine 9-Bus Network. . . . . . . . . . . . . . . . . . . . . . . . . 41

4.8 Time responses of δ and ω for a step in Vref1, with PSS included in machine 1. . . . . . . 43

4.9 Time responses of δ and ω for a step in Vref2, with PSS included in machine 2. . . . . . . 44

4.10 Time responses of δ and ω for a step in Vref3, with PSS included in machine 3. . . . . . . 44

4.11 Bode diagram of GGEP (s), GPSS(s) and GGEP (s)GPSS(s). . . . . . . . . . . . . . . . . . 48

4.12 Using the Control System Designer to tune the 9-bus 3-machine PSS. . . . . . . . . . . . 49

4.13 Gain margin test at machine 2 for KPSS = 50. . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.14 Gain margin test at machine 2 for KPSS = 30. . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.15 Gain margin test at machine 2 for KPSS = 40. . . . . . . . . . . . . . . . . . . . . . . . . . 51

xv

4.16 Gain margin test at machine 2 for KPSS = 41. . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1 Two-area system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

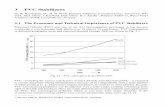

5.2 Incremented active power at load bus 10 that leads to instability for different power trans-

fers between areas. There is no PSS installed. . . . . . . . . . . . . . . . . . . . . . . . . 60

5.3 Incremented active power at load bus 10 that leads to instability for different power trans-

fers between areas. A PSS is installed at machine 3. . . . . . . . . . . . . . . . . . . . . . 60

5.4 IEEET1 excitation system block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.5 ST excitation system block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.6 Root-locus of the ST excitation system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.7 Root-locus of the IEEET1 excitation system. . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A.1 Block diagram representation of the GENROE model. . . . . . . . . . . . . . . . . . . . . 74

A.2 Block diagram representation of the GENSAL model. . . . . . . . . . . . . . . . . . . . . . 75

A.3 Block diagram representation of the IEEET1 model. . . . . . . . . . . . . . . . . . . . . . 76

A.4 Block diagram representation of the ST model. . . . . . . . . . . . . . . . . . . . . . . . . 76

A.5 Block diagram representation of the TGOV1 model. . . . . . . . . . . . . . . . . . . . . . . 76

A.6 Block diagram representation of the HYGOV model. . . . . . . . . . . . . . . . . . . . . . 77

A.7 Block diagram representation of the GAST model. . . . . . . . . . . . . . . . . . . . . . . 77

B.1 WSCC 3-machine 9-bus system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

E.1 10-machine 39-bus system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

F.1 Combinations of models implemented in MaSSA. . . . . . . . . . . . . . . . . . . . . . . . 88

xvi

Nomenclature

∆ Prefix that indicates small deviation

δ Rotor angle

λ′ Critical swing mode after PSS inclusion

λ0 Critical swing mode before PSS inclusion

ν Normalized rotor angular velocity

ω Rotor angular velocity

ωm Frequency at which the phase of the lead-lag compensator is maximum

ωs Frequency base of the system, in radians

φm Maximum phase of the lead-lag compensator

ρ Swing-loop participation ratio

θ Bus voltage angle

ξ Damping Ratio

A,B,C,D11, D12, D21, JLF Reduced DAE coefficient matrices, after ∆Ig elimination

A1, B1, B2, E1, C1, D1, D2, C2, D3, D4, D5, D6, D7 DAE coefficient matrices

Ass State matrix of the state-space representation

Asys State matrix of the reduced DAE, after ∆ya and ∆yb elimination

Bss Input matrix of the state-space representation

Css Output matrix of the state-space representation

D Coefficient of mechanical damping

Dss Feedthrough matrix of the state-space representation

E′d d-axis electromotive force due to flux linkage in q-axis

E′q q-axis electromotive force due to flux linkage in d-axis

xvii

Efd Field voltage

fbase Frequency base of the system, in Hertz

GAV R(s) Transfer function of the AVR

GGEP (s) Transfer function of GEP

GPSS(s) Transfer function of the PSS

GP (s) Transfer function of the phase compensation stage

GW (s) Transfer function of the washout filter

H Inertia constant

Id d-axis stator current component

Ig Vector of d-q currents of the stator

Iq q-axis stator current component

JAE Algebraic Jacobian matrix

JLF Power-Flow Jacobian matrix

K1,K2,K3,K4,K5,K6 Constants of the Heffron-Phillips model

KA Gain of the AVR amplifier, also referred to as gain of the AVR

KE Exciter gain

KF Rate-Feedback loop gain

KPSS Gain of the PSS

M Inertia coefficient defined as 2Hωs

pki Participation factor of state variable k on mode i

Re SMIB’s external resistance

RF Rate-Feedback

Rs Stator resistance

Sbase Power base of the system

SE Saturation

T ′d d-axis transient open-circuit time constant

T ′q q-axis transient open-circuit time constant

T lowere Electrical torque contributed by the lower torque-angle loop of the Heffron-Phillips model

xviii

TMD Mechanical damping torque

T stabe Electrical stabilizing torque contributed by the PSS

Tuppere Electrical torque contributed by the upper torque-angle loop of the Heffron-Phillips model

T1, T2, T3, T4 Time constants of the lead-lag blocks

TA Time constant of the AVR amplifier, also referred to as time constant of the AVR

TD Electrical damping torque coefficient

TE Exciter time constant

Te Electrical torque

TF Rate-Feedback loop time constant

TM Mechanical torque

TS Electrical synchronizing torque coefficient

TW Time constant of the washout filter

u Control variables vector of the DAE

uss Input variables vector of the state-space representation

V Bus voltage magnitude

Vg Vector of voltages of generating buses

Vl Vector of voltages of load buses

Vref Voltage reference of the AVR

VR Exciter input voltage

Vs State variable that represents the corrective stabilizing voltage produced by the PSS

x State variables vector of the DAE

X ′d d-axis transient reactance

X ′q q-axis transient reactance

Xd d-axis synchronous reactance

Xe SMIB’s external reactance

xp1 State variable contributed by the washout filter

xp2 State variable contributed by a two-stage phase compensation

Xq q-axis synchronous reactance

xix

xss State variables vector of state-space representation

y State variables vector of the DAE

ya Vector of algebraic variables that are not part of the power-flow

yb Vector of algebraic variables that are part of the Power-flow

yss Output variables vector of the state-space representation

Subscripts

0 steady-state value

xx

Glossary

AVR Automatic voltage regulator

DAE Differential Algebraic Equations model

ESE Estabilizador de Sistemas de Energia

GAST Gas turbine-governor

GENDEC Flux-decay round rotor synchronous machine

model

GENRED Two-axis round rotor synchronous machine

model

GENROE Round rotor synchronous machine model with

exponential saturation

GENSAL Salient pole synchronous machine model

GEP Generator, Exciter and Power system

GSC Gain Scheduling Controllers

HVDC Right Half Complex Plane

HYGOV Hydro turbine-governor

IEEET1 IEEE Type 1 DC excitation system model

MRAC Model Reference Adaptive Control

MaSSA MATLAB-based Small Signal Analysis program

OPLI Optimum PSS Location Index

PQ Load bus

PSS Power System Stabilizer

PV Generator bus

RHCP Right Half Complex Plane

SMIB Single Machine Infinite Bus

STR Self-Tuning Regulators

ST Static excitation system model

TGOV1 Steam turbine-governor

WSCC Western System Coordinating Council

xxi

Chapter 1

Introduction

1.1 Motivation [1]

As power systems evolved and changed throughout the time, so has the focus of stability of power

systems.

Early 20th century stability problems were associated with remote generating stations feeding into

metropolitan load centres over long-distance transmission lines. The stability problem was then largely

influenced by the strength of the transmission system and manifested itself mostly through monotonic

instability instances.

As power systems evolved over the years, independent systems are interconnected for economical

and reliability advantages but adversely making stability studies more complex.

In the mid of the 20th century, significant benefits in stability come when most of the generating

units start being equipped with continuously-acting voltage regulators, virtually eliminating steady-state

monotonic instability problems.

As this newly equipped machines became more numerous it was apparent that the voltage regulator

action had a detrimental effect upon stability, giving rise to oscillations of small magnitude and low fre-

quency which often persisted for long periods of time. And so, oscillatory instability becomes a concern.

Such oscillations are undesirable because they reduce stability margins by limiting power transfer on

transmission lines and, in some cases, inducing stress in the mechanical shaft.

Better analytical and computational tools, in particular the rise of the digital computer, allowed for

longer simulations and a more detailed modelling of dynamic elements like synchronous machine, volt-

age regulator and other controls. Accompanying this technological trend there has been a tendency of

power systems to exhibit oscillatory instability.

Besides the voltage regulator, other sources of oscillatory instability are:

• large groups of closely coupled machines connected by weak links (as a consequence of growth

in interconnections) with heavy power transfers;

• increased use of new technologies;

1

• change in the composition and characteristics of loads.

Power System Stabilizers were developed as a complementary control system that offsets the re-

ductions on stability margins by providing damping to the small magnitude low frequency injurious os-

cillations. Its application and design has been the subject of much attention in the past decades and is

extremely relevant nowadays, as power systems frequently operate close to their stability limits.

1.2 Background

This dissertation is a continuation of a research work on power system small signal analysis that has

been developed by several graduate students throughout some years. For a complete background refer

to [2, 3, 4, 5].

The collective contribution of each author culminates in a MATLAB code, referred to as MaSSA, that

analyses the small-disturbance stability of power networks that are computed from data files containing

information about the network’s topology, power-flow and static elements (*.raw data files) as well as the

network’s dynamic elements (*.dyr data files).

Small signal analysis implies that the disturbances to which the power system is subjected are suf-

ficiently small so that linearization of the system’s equations is permissible. Accordingly, the imposed

disturbance on the system adopted in MaSSA comes in the form of small power increments at an arbi-

trary load bus.

To test the system’s stability, MaSSA presents the user with the option to perform either a ”Static

Analysis” or a ”Dynamic Analysis”, as illustrated in Figure 2.1. In either case, the system is evaluated

for the nominal operation situation and then re-evaluated each time the load, at a chosen bus, is incre-

mented by 1 MW , until instability is detected. Figure 1.2 is the flowchart of MaSSA.

Figure 1.1: MaSSA’s ”Type of Analysis” window.

The ”Static Analysis” approach mathematically describes the system by equations based exclusively

on the power flow and considers that the system becomes unstable when the power-flow diverges.

The ”Dynamic Analysis” approach mathematically describes the system not just by its power-flow

but takes the network’s dynamic elements into account as well. In this case, the system is considered

unstable when an eigenvalue of the state-space system matrix crosses to the right-half-complex-plane

(RHCP).

2

Figure 1.2: Flowchart of MaSSA.

Often happens that the power system becomes unstable before the power-flow diverges and so it

is of paramount importance to complement a static stability analysis with a dynamic stability analysis.

Figure 1.3 is the flowchart of ”Dynamic Analysis”.

Figure 1.3: Flowchart of ”Dynamic Analysis”.

The dynamic elements inventory of MaSSA consists of: three synchronous machine models (GEN-

ROE, GENRED and GENSAL); two excitation system models (IEEET1 and ST) and three turbine-

governor models (TGOV1, HYGOV and GAST). Appendix A describes these models.

3

1.3 Objectives

The mission of this thesis is to complement MaSSA with a ”PSS Inclusion Study” option that allows the

user to simulate the impact of including PSS’s in a given network.

This added ”PSS Inclusion Study” option is equipped with tools like Root-locus and Bode diagrams

which help to draw insights about the most adequate PSS parameters. With continuous adjustments on

the PSS location and parameters, ultimately the user can conclude about the optimal PSS location and

tuning for a certain network.

To accomplish this, the work is partitioned into three main objectives:

• Include the PSS dynamics in MaSSA.

• Establish the criteria for optimal PSS location.

• Establish the criteria for optimal PSS tuning.

1.4 Problem Statement

Throughout the elaboration of this dissertation it is important to bear in mind the following principles:

• The PSS is a dynamic element and so it should not affect the static behaviour of a network. In the

light of this, to understand the impact that the PSS has on the stability of a power system, MaSSA’s

”Dynamic Analysis” functionality should be able to accommodate the PSS dynamics. Introducing a

PSS will have no implications in the ”Static Analysis” of the network because, unlike the inclusion

of FACTS introduced by [5], it does not change the network’s topology.

• To install a PSS is not a sufficient condition for improved system stability. In fact, a PSS is only

as good as its tuning and location. A PSS installed in a machine that is not the main responsible

for instability will have no significant effect in improving stability margins. Likewise, a poorly tuned

PSS may even be detrimental to the system performance. Much of the focus of the developed

work is on this issue.

4

Chapter 2

Literature Review

This chapter is dedicated to describing some fundamentals of the Power System Stabilizer.

Firstly, the reason that motivates its installation - power system stability - is discussed. Then, because

the PSS acts by means of the automatic voltage regulator (AVR), a review on linearized excitation control

of synchronous machine is made. Finally, the PSS function and structure are detailed and its possible

input signals compared.

2.1 Motivation: Power System Stability

Even though power system stability has always been a much debated and studied issue, it continues to

be a valid concern and an open topic of discussion nowadays.

Historically, most of the attention was towards transient stability but with the growth in interconnec-

tions, the use of new technologies and controls, the increased operation in highly stressed conditions

and the renewable energy integration different forms of system instability have emerged.

Power system stability can be defined as “the ability of an electric power system, for a given initial

operating condition, to regain a state of operating equilibrium after being subjected to a physical dis-

turbance, with most system variables bounded so that practically the entire system remains intact.”[6]

This definition applies to the power system as a whole but often cases of isolated machines that lose

stability (i.e. lose synchronism) without cascading instability of the main system are also of interest to

the stability study.

Following a disturbance, the system may be stable or unstable. If the disturbed system is stable then

the state of equilibrium is regained, which can be the original pre-disturbance state of operation or it

can be a whole new state of operation, if topological changes were required, like isolation by protective

relays. If the disturbed system is unstable it will result in a run-away or run-down situation (for example,

a progressive increase in angular separation of generator rotors) possibly leading to cascading outages

and a shut-down of portions of the power system.

5

2.1.1 Classification of Power System Stability

A proposed power system stability classification [6] is presented in Figure 2.1, in which stability is cate-

gorized depending on:

• The physical nature of the resulting mode of instability, that is, the main system variable in which in-

stability can be observed. Concerning this, one can refer to rotor angle stability, frequency stability

or voltage stability.

• The size of the disturbance, that is, large disturbances such as a short circuit, or small disturbances

such as load changes.

• The devices, processes and the time span that must be taken into consideration in order to assess

instability. Here one distinguishes between short term instability and long term instability.

Figure 2.1: Classification of power system stability,reprinted from [6].

It is important to remark that the presented forms of instability don’t necessarily occur separately.

In fact, it is likely that one form of instability may give rise to another form. For example, a possible

outcome of voltage instability is loss of load in an area or tripping of transmission lines, leading to

cascading outages which can in its turn result in loss of synchronism of some generators, i.e., rotor

angle instability.

2.1.2 Rotor Angle Stability

Because the scope of this work is to analyse the contribution of PSS to the stability of power systems,

rotor angle stability is here detailed.

When synchronous machines are interconnected, their stator voltages and currents must have the

same frequency and the rotor mechanical speed of each machine is synchronized to this frequency.

Hence, the rotors of all interconnected synchronous machines must be in synchronism [1].

6

Rotor angle stability may be referred as “the ability of synchronous machines of an interconnected

power system to remain in synchronism after being subjected to a disturbance. It depends on the ability

to maintain/restore equilibrium between electrical torque and mechanical torque of each synchronous

machine in the system. Instability that may result occurs in the form of increasing angular swings of

some generators leading to their loss of synchronism with other generators.”[6]

Thus, here stability is a matter of equilibrium between torques. In steady-state, there is equilibrium

between the input mechanical torque and the output electrical torque of each machine, and so speed

remains constant. In case of a disturbance this equilibrium is upset, resulting in acceleration (or decel-

eration) of the rotors. The resulting angular difference between machines transfers part of the load of

the slow machine to the fast one. This power transfer between machines is a non-linear function of the

angle separation between their rotors and so, from here on two scenarios can happen: either the speed

difference is reduced and therefore the angular separation is also reduced; or the angular separation is

further increased increasing the speed difference and ultimately leading to instability.

In any case, system stability depends on whether or not these deviations in rotor’s angle result

in sufficient restoring torques. The change in electrical torque of a synchronous machine following a

perturbation, ∆Te, can be decomposed in two components [1], as shown in equation 2.1.

∆Te = TS∆δ + TD∆ω (2.1)

Where:

• Synchronizing torque component, TS∆δ: is the component of torque change that is in phase with

rotor angle perturbation. Lack of sufficient synchronizing torque will result in aperiodic or non-

oscillatory instability, which manifests itself through an aperiodic drift in rotor angle.

• Damping torque component, TD∆ω: is the component of torque change that is in phase with the

speed perturbation. Lack of sufficient damping torque will result in oscillatory instability, which

manifests itself through rotor oscillations of increasing amplitude, the so called electromechanical

oscillations.

System stability depends on the existence of both components of torque for each of the synchronous

machines.

The aperiodic instability problem has been largely eliminated by use of continuously acting genera-

tor voltage regulators and so small-disturbance rotor angle stability problem is usually associated with

insufficient damping of oscillations.

Rotor angle stability is classified as short term and can be sub-categorized in:

• Small-disturbance rotor angle stability when referring to the system’s ability to maintain synchro-

nism under small disturbances, i.e. disturbances that allow the linearization of the system’s equa-

tions.

• Large-disturbance rotor angle stability (also known as transient stability) when referring to the

system’s ability to maintain synchronism when subjected to a severe disturbance, for which the

7

system response involves large excursions of the generator rotor angle.

2.1.3 Electromechanical Oscillations

Nowadays, small-disturbance rotor angle stability problems are mainly due to insufficient damping torque,

giving rise to electromechanical oscillations.

Electromechanical oscillations are classified according to the interactions between power system

components that originates them. They are of the following types [7, 8, 9, 10]:

• Inter-area Modes

With a typical frequency range of 0.2 to 0.5 Hz, inter-area modes result when an aggregate of

machines in one area is swinging relative to an aggregate of machines in another area.

This complex phenomenon involves many parts of the system with highly non-linear dynamic be-

haviour. The damping characteristic of the inter-area mode is dictated by the tie line strength, the

nature of the loads and the power-flow through the interconnection.

The operation of the system in the presence of a lightly damped inter-area mode is very difficult.

• Local Modes

With a typical frequency range of 0.5 to 1.8 Hz, local modes result when a single machine is

swinging relative to the rest of the system.

They are usually a consequence of remote machines connected to a large system through weak,

essentially radial transmission lines and are more pronounced when high response excitation sys-

tems are used.

These are the most commonly encountered modes of oscillation.

• Intra-plant Modes

With a typical frequency range of 1.5 to 3 Hz, intra-plant modes result when machines on the same

power generation plant oscillate relative to each other and are observable only within and near by

the generating plant.

They are usually a consequence of interaction between controls and so, even though they will be

affected by its presence, it is undesirable for a PSS to respond to these oscillations.

• Torsional Modes

With a typical frequency range of 10 to 46 Hz, torsional modes are associated with the turbine-

generator shaft system rotational (mechanical) components.

Instability of these modes may be caused by interaction with excitation controls and speed gover-

nors controls.

• Control Modes

These control modes are associated with the controls of generating unit and other equipment.

Poorly tuned AVR, speed governors and Static VAr Compensators (SVC) are the usual cause of

these modes. Their frequency of oscillation is not fixed and depends on the used controllers.

8

Power systems stabilizer’s are used to damp local mode and inter-area mode oscillations.

It’s not unusual for a machine to participate in both local and inter-area modes, so the PSS must

therefore be able to accommodate both. Since a single machine or power plant is dominant in local

modes, installing a PSS in that machine can have a very large impact on damping the oscillation. By

contrast, a single machine experiences only a portion of the total magnitude of oscillation in the inter-area

mode. Therefore, a PSS applied to that machine can only contribute to the damping of the inter-area

mode in proportion to the power generation capacity of the machine relative to the total capacity of the

area of which it is a part [7].

2.2 Excitation Control of Synchronous Machines

The stability of synchronous machines under small perturbations is often studied recurring to the sce-

nario of a single machine connected to an infinite bus (SMIB) through external impedance, as pictured

in Figure 2.2.

Figure 2.2: Single generator supplying an infinite bus through an external impedance (SMIB), adaptedfrom [11].

This approach allows an easier understanding on how excitation systems affect the overall system

stability and helps to draw insights on the stabilizing requirements for such system. Once the stabilizing

requirements are settled, a stabilizing solution can be designed. This is extremely well accomplished

in the celebrated article ”Concepts of Synchronous Machine Stability as Affected by Excitation Control”

[12] by DeMello and Concordia.

It will be seen that: the excitation control system improves synchronizing torque and worsens damp-

ing torque; the stabilizing requirement is to provide additional damping torque; the stabilizing solution is

a PSS.

2.2.1 Heffron-Phillips Representation

Figure 2.3 is a block diagram representation in frequency domain of a linearized single machine con-

nected to an infinite bus through an external impedance made popular by Heffron and Phillips in [13]

and from here on referred to as the Heffron-Phillips model.

The Heffron-Phillips model has been extensively used for studying small oscillations in power sys-

tems because it provides a clear physical picture of this phenomenon. The analysis of a SMIB can be

extended to multimachine systems and is instrumental in understanding the requirements for stabiliza-

tion of a perturbed machine, ergo the requirements for a PSS.

9

Figure 2.3: Linearized small perturbation block diagram of a SMIB.

The relations in the block diagram apply to a flux-decay machine (described in Appendix C) with

a field circuit in the d-axis without amortisseur effects and incorporates an AVR represented in Figure

2.3 by the block GAV R. The coefficient H is the machine’s inertia constant and D is the coefficient

that represents mechanical damping due to shaft motion. The constants K1 to K6, derived in [13], are

functions of the machine and system parameters as well as operating point. Their derivation is not

presented here but their physical nature and expressions are listed in equations 2.2 to 2.7.

• K1: Influence of rotor angle on the electric torque with constant flux linkages in the direct axis.

K1 =∆Te∆δ

∣∣∣∣E′q

(2.2)

• K2: Influence of q-axis electromotive force on the electric torque with constant rotor angle.

K2 =∆Te∆E′q

∣∣∣∣δ (2.3)

• K3: Factor between the d-axis synchronous reactance and the d-axis transient reactance. Equa-

tion 2.4 assumes null external resistance Re. Constant K3 can be interpreted as the ”machine’s

gain”.

K3 =X ′d +Xe

Xd +Xe(2.4)

• K4: Influence of rotor angle on q-axis electromotive force, i.e demagnetizing effect of a change in

10

rotor angle.

K4 =1

K3

∆E′q∆δ

(2.5)

• K5: Influence of rotor angle on terminal voltage with constant flux linkages in the direct axis.

K5 =∆V

∆δ

∣∣∣∣E′q

(2.6)

• K6: Influence of q-axis electromotive force on terminal voltage with constant rotor angle.

K6 =∆V

∆E′q

∣∣∣∣δ (2.7)

It should be noticed that all quantities in the block diagram are normalized to pu except for rotor angle

deviations ∆δ, which is in radians. The normalization of rotor angle velocity deviations ∆ω is performed

as in equations 2.8 and 2.9, where ωs is called the synchronous speed.

∆ν =∆ω

ωs(2.8)

ωs = 2πfbase (2.9)

The stability phenomenon under analysis is the stability of the torque-angle loop, i.e the behaviour of

the rotor angle and speed following a small disturbance. It is relevant to remember the machine swing

equation (2.10) that relates the applied torques with changes in the machine speed.

2H∆ν = ∆TM −∆Te (2.10)

From Figure 2.3 it can be seen that the total electrical torque ∆Te applied on the generator shaft

results from three contributions:

• ∆TMD : The electrical torque contributed by the torque-speed loop. This speed loop represents the

torque due to mechanical friction of the shaft.

• ∆Tuppere : The electrical torque contributed by the upper torque-angle loop. This upper loop is

known as the electromechanical oscillation loop because it represents the machine’s linearized

rotor motion equation.

• ∆T lowere : The electrical torque contributed by the lower torque-angle loop. This lower loop repre-

sents the dynamics of the field winding of the machine as well as the dynamics of the AVR.

The electrical torque in the Heffron-Phillips model is thus defined as in equation 2.11.

∆Te = ∆TMD + ∆Tuppere + ∆T lowere (2.11)

11

2.2.2 Synchronizing and Damping Torques

In order to have a better insight on how electrical torque oscillations affect the machine stability, in

particular how they affect the rotor angle stability, the change in electrical torque is decomposed into two

components:

• A synchronizing torque component, in phase with the machine rotor angle deviations ∆δ.

• A damping torque component, in phase with the machine rotor speed deviations ∆ω.

As explained in section 2.1.2, machine stability depends on the existence of both these torque com-

ponents. Lack of sufficient synchronizing torque will result in non-oscillatory instability and lack of suffi-

cient damping torque will result in oscillatory instability.

Figure 2.4: Representation of change in electrical torque on the ∆δ-∆ω plane.

Figure 2.4 shows a change in electrical torque ∆Te in the first quadrant of the ∆δ-∆ω plane. In this

quadrant both the synchronizing and damping components will be positive.

In the light of this perspective and recalling the Heffron-Phillips model, the three different electrical

torque contributions are formulated by equations 2.12, 2.13 and 2.14.

∆TMD =D

ωs∆ω (2.12)

∆Tuppere = K1∆δ (2.13)

∆T lowere =−K2[(KAK5 +K4) + sTAK4)]

1K3

+KAK6 + s(TA

K3+ T ′d0) + s2T ′d0TA

∆δ (2.14)

It is immediate to see that the electrical torque contributed by the torque-speed loop ∆TMD is a purely

damping torque because it has no component in phase with the machine rotor angle ∆δ. Likewise, the

electrical torque contributed by the upper torque-angle loop ∆Tuppere is a purely synchronizing torque.

12

Equation 2.14 is the electrical torque contributed by the lower torque-angle loop and was taken from

the famous article by deMello and Concordia [12]. It assumes the use of a flux-decay machine model

and a static AVR with gain KA and time constant TA. Nevertheless, the conclusions here presented are

generalized to other types of machine and AVR models.

Because ∆T lowere is a function of the complex variable s defined in equation 2.17, it will have both

damping and synchronizing components. Consider equation 2.15 as a version of equation 2.14 in which

the torque contribution from the lower loop is decomposed in its synchronizing component T lowerS and

damping component T lowerD .

∆T lowere = T lowerS ∆δ + T lowerD ∆ω (2.15)

Recalling that ∆δ and ∆ω relate with one another in frequency domain as shown in equation 2.16,

then the torque contributed by the lower loop is rewritten as in equation 2.19 by substituting 2.18 in 2.15.

∆ω = s∆δ (2.16)

s = σ + jω (2.17)

∆ω = σ∆δ + jω∆δ (2.18)

∆T lowere = (T lowerS + σT lowerD + jωT lowerD )∆δ (2.19)

In this way it is possible to express the torque just in relation to ∆δ. The same could be done to

express it just in relation to ∆ω.

So, in frequency domain, the damping and synchronizing components of the torque contributed by

the lower torque-angle loop can be obtained as shown in equation 2.20, taken from [14]. T lowerD = Imag[∆T lower

e

∆δ ] 1ω

T lowerS = Real[∆T lower

e

∆δ ]− T lowerD σ(2.20)

2.2.3 Voltage Regulator Effect on Machine Stability

As mentioned in the introduction section, the installation of AVR in generating units significantly con-

tributes to improve monotonic stability at the cost of worsening oscillatory stability. Rephrasing, the AVR

significantly contributes to improving synchronizing torque at the cost of worsening damping torque.

The synchronizing torque component from the lower loop T lowerS is summed with the synchronizing

torque component from the upper loop K1. The steady-state stability criterion is that this sum should

be greater than zero. The AVR improves monotonic stability because it reduces a steady-state negative

component of synchronizing torque originated by the armature in the lower loop. This reduction in neg-

ative synchronizing torque is proportional to the gain of the AVR KA. Hence, the overall synchronizing

torque T lowerS increases with the inclusion of the AVR and this increase is proportional to KA.

On the other hand, the positive damping component of torque due to the armature from the lower

loop is correspondingly reduced and so the overall damping torque T lowerD is also reduced, narrowing

13

the system’s stability margins. Further, this reduction in damping is proportional to the gain of the AVR,

imposing limitations on the value of KA.

Thus, there is a conflicting problem: an AVR is a major help in providing synchronizing torque and

curing that part of the stability problem. However, in doing so, it destroys the natural damping of the

machine which is small to start with. Furthermore, the AVR does not perform at its best potential because

of the limitations imposed on KA.

The solution is to provide extra damping through transient manipulation of the voltage reference of

the AVR, Vref , by means of an auxiliary stabilizing function. This stabilizing function is the PSS.

2.3 Power System Stabilizer

Besides its basic function, some fundamental components of a typical PSS are here described [15, 11].

Since the focus is on small signal stability, some components usually present is a PSS circuit such

as PSS output limits (as well as AVR output limits) and torsional filters are not implemented in MaSSA,

even though they exist in real power systems.

2.3.1 Performance Objectives

”The basic function of a power system stabilizer is to extend stability limits by modulating generator

excitation to provide damping to the oscillations of synchronous machine rotors relative to one another.”

[16]

Such oscillations correspond to the aforementioned electromechanical local modes of oscillation

together with inter-area modes of oscillation. Combining the typical frequencies of these two modes

yields an approximate frequency range for which the PSS has to operate of 0.2 Hz to 2 Hz.

Providing damping translates into increasing damping torque, i.e. increasing the component of elec-

trical torque that is in phase with rotor speed deviations ∆ω.

Modulating generator excitation consists, in the PSS case, on superposing on the voltage error signal

of the AVR an auxiliary and transient stabilizing signal. Such signal can be derived from rotor speed,

terminal frequency or electric power.

As emphasized by Larsen in [7], it is important to remember that the objective of adding PSS is to

extend power transfer limits by stabilizing system oscillations and that adding damping is not an end in

itself, but a means to extending power transfer limits.

Figure 2.5 pictures how a rotor speed based PSS, represented by the block GPSS , is incorporated in

the Heffron-Phillips block diagram model of a SMIB with AVR control. The blue path shows how an input

signal derived from rotor speed deviations ∆ω is converted into a correcting stabilizing signal ∆Vs that

is fed to the AVR, ultimately influencing the produced torque ∆T lowere that is applied on the shaft.

Because the focus is on damping torque, which is in phase with ∆ω, it is convenient to conceive the

Heffron-Phillips model of Figure 2.5 as represented in Figure 2.6, valid for a speed-based PSS.

In this representation, the under loop is a torque-speed loop through which the PSS acts on the

14

Figure 2.5: Inclusion of a speed-based PSS block in the Heffron-Phillips diagram.

Figure 2.6: Illustration of the applied torques on machine shaft with a speed-based PSS included.

generator, the exciter and the power (GEP) system. The torque resulting from this loop is thus the

electrical torque produced solely by the PSS via modulation of the AVR. It is therefore referred to as

stabilizing torque ∆T stabe and the loop is called the stabilizing loop, represented in blue. All other sources

of electrical torque are represented by ∆T othere .

From Figure 2.6 it can be seen that the transfer functions of GEP and of a speed-based PSS are as

in equations 2.21 and 2.22, respectively.

GGEP (s) =∆T stabe

∆Vs(2.21)

GPSS(s) =∆Vs∆ν

(2.22)

15

Finally, the contribution of torque due to the stabilizer path, i.e the torque contributed solely by the

PSS is as in equation 2.23.

∆T stabe = GPSS(s)GGEP (s)∆ν (2.23)

In order for ∆T stabe to be a pure damping torque it must be in phase with speed deviations, i.e.

it must be in phase with ∆ν. This means that GPSS(s)GGEP (s) can not introduce any phase and

should therefore be a pure gain. The conclusion is that a PSS using rotor speed deviations as input

signal must compensate for the phase lag introduced by GGEP (s) to produce a component of damping

torque in phase with speed deviations. In doing so, it will damp undesired electromechanical oscillations,

extending the system’s stability margins.

2.3.2 Structure

A linearized representation in frequency domain of a typical PSS is presented in Figure 2.7.

Because it is a linearized representation, normally present components associated with transient

stability like output limits are not considered.

Figure 2.7: Block model of a linearized representation of a typical PSS.

Phase Compensation Stage: GP (s)

Examining equation 2.23 and recalling that the goal of the PSS is to provide damping torque, one can

say that an ideal speed-input PSS should perfectly compensate for the phase lag introduced by GEP,

making the transfer function ∆T stabe

∆ν a pure gain. In this condition ∆T stabe would be in the ∆ω axis of

the ∆δ-∆ω plane of Figure 2.4. The eigenvalues associated with the damped oscillation would move

towards the left-half-complex-plane (LHCP) with no change in frequency.

Such an ideal PSS would be a purely lead system requiring pure differentiation, which is not possible

to implement. Thus, a realistic PSS will be a lead-lag system with both integrators and differentiators.

When the transfer function ∆T stabe

∆ν has some phase-lag, the produced torque will be in the first quad-

rant of Figure 2.4 with positive damping and synchronizing contributions. In response, the damping and

frequency of the damped oscillation will both increase, in particular, when the phase-lag is 45◦ the damp-

ing and frequency will increase at the same rate. If the phase-lag is 90◦ then no change in damping will

take place but the frequency of the oscillation will increase.

Care should be taken so that there is no overcompensation of the phase characteristic ofGGEP (s). In

such a case, the PSS produced torque ∆T stabe would be in the second quadrant of Figure 2.4, contribut-

16

ing with positive damping but with negative synchronizing torque. In this quadrant shaft acceleration ∆ω

is positive possibly leading to non-oscillatory instability, which is coherent with stating that synchronizing

torque is deteriorated.

Figure 2.7 shows the phase compensation consisting of two first-order lead-lag blocks, but more or

less blocks can be used. In some cases second-order blocks with complex roots have been used [1].

Gain: KPSS

The total gain of the stabilizing loop will be the combination of the PSS gain KPSS and the gain of

GGEP (s). But the characteristics of GGEP (s) vary significantly with operating conditions, in particular

the gain of GGEP (s) increases as the ac system becomes stronger (this effect is amplified with a high

AVR gain KA) and it also increases with generator loading.

Because a PSS tuning that is adequate for a specific system and operating conditions will not per-

form as well when conditions change, an adjustable gain (adaptive gain control) can be very welcome.

However, when a fixed gain stabilizer is sufficient to meet the stability requirements the efforts of adap-

tive control system may not be justified. Quoting Kundur in [17]: “Since we have been able to satisfy

the requirements for a wide range of system conditions with fixed parameters there is little incentive to

consider an adaptive control system.”

The overall gain will determine the amount of damping to be applied and so the eigenvalue associated

with the oscillation will move an amount proportional to KPSS and in a direction determined by the phase

of GGEP (s)GPSS(s) [16].

Washout Filter: GW (s)

The purpose of the washout filter is to ensure that the PSS does not interfere with the normal operation

of the system, that is, with the steady-state system.

The PSS presence should only be noticed when local mode or inter-area mode oscillations arise,

which will activate the PSS to provide the proper damping. Once these oscillations of concern cease,

the PSS is again deactivated and thus the washout filter prevents the PSS from offsetting the steady-

state AVR voltages.

This is accomplished with a high-pass filter with a chosen time constant TW such that the filter is

approximately unitary for the range of frequencies in which it is desired the PSS to perform. That is, for

an oscillation that should be damped sz, the washout filter should be as in equation 2.24.

GW (sz) ≈ 1∠0◦ (2.24)

A subtlety about this component is worth mentioning: a time constant TW tuned for aGW (s) preceded

by KPSS is probably not adequate for the same GW (s) followed by the same KPSS . That is, for a certain

tuning, blocks KPSS and GW (s) are not commutative, as it usually happens in frequency domain. This

is because KPSS ”inflates” the PSS input signal, and so TW is either tuned for the PSS input signal or

tuned for the PSS input signal multiplied by KPSS .

17

Usual values for TW (preceded by KPSS) are in the order of 10 seconds [15].

2.3.3 Input Signal

The choice of input signal affects the PSS phase characteristic and therefore affects as well the tuning

procedure.

There are several theoretical possibilities for input signals, but the following three are, for practical

reasons, the most commonly used [15, 16, 18].

• Shaft speed deviation, ∆ω

Curiously, although being the most popular choice for input signal, it presents many limitations.

It is particularly sensitive to power system noise and torsional interactions, demanding the imple-

mentation of torsional filters, which is an added complication to an an already complicated system.

Perhaps its popularity can be explained because it is so intuitive to think of a speed signal to correct

speed deviations.

• Accelerating power, ∆P

As mentioned before, when a disturbance upsets the torques equilibrium the rotor will acceler-

ate/decelerate. This suggests that rotor acceleration would be the obvious input signal.

Since rotor acceleration is not easily measurable and thus not practical, accelerating power is

used instead because, as Concordia explains in [18], ”electrical active power (measured in the

direction of rotation) is an approximation to electrical torque, which in turn is an approximation to

accelerating torque and thus to acceleration itself”.

A great advantage in using power is its inherent low level of torsional interaction. On the other

hand, a main disadvantage is that the integration resulting from the lead-lag stage causes adverse

effects in case of mechanical power variations.

• AC bus frequency deviation, ∆f

Frequency has a great advantage over speed because it behaves similar to speed for the oscillating

modes of concern but is greatly attenuated for higher-frequency modes, for which the PSS is not

likely to be needed. Thus, the PSS design is simpler because of the smaller range for which it

must function.

Similarly to speed-input signals, frequency based stabilizing signals need torsional filtering and

contain power system noise.

Concordia states that the choice of input signal should depend on what are the critical problems

in each case, for example, frequency input may be more suitable for rather low frequency oscillations

between relatively large areas but that power input is probably better when torsional oscillations are a

problem [18]. Also, some authors have used a combination of signals, leveraging from the advantages

of each signal.

18

In summary, even though the input signal choice influences the tuning and performance of the PSS,

any of the presented options can be used to damp oscillatory instabilities.

19

Chapter 3

Methodology

The ”PSS Inclusion Study” implementation in MaSSA is carried out through three main courses of action:

inclusion of the PSS dynamics in the linearized power system model; choosing the optimal location for

the PSS and choosing the optimal parameters of the PSS.

This chapter elaborates on each one of these processes.

3.1 Small Signal Analysis

Small signal analysis is the study of non-linear systems by approximating them to their linearized model.

This analysis is only valid for small excursions of the system around an equilibrium point and so its use

is appropriate in studying small-disturbance voltage and angle stability.

3.1.1 Differential-Algebraic Power System Model

This subject was extensively discussed in the previous dissertations that this dissertation intends to

complement [2, 3, 4, 5] therefore it is here only briefly reviewed in order to provide a better context of the

developed work.

A power system may be modelled by the non-linear equations 3.1 and 3.2. In this model, x repre-

sents the state variables vector, y the algebraic variables vector and u the control variables vector.

x = f(x, y, u) (3.1)

0 = g(x, y) (3.2)

Equation 3.1 consists of the differential equations of the dynamic elements of the network such as

machines and respective controls. Equation 3.2 consists of the algebraic stator equations (in the polar

form) and the algebraic network equations (in the power-balance form).

Linearizing equations 3.1 and 3.2 around an equilibrium point and rearranging in matrix format yields

21

equations 3.3 to 3.6 which constitute the so called Differential Algebraic Equation model (DAE).

∆x = A1∆x+B1∆Ig +B2∆Vg + E1∆u (3.3)

0 = C1∆x+D1∆Ig +D2∆Vg (3.4)

0 = C2∆x+D3∆Ig +D4∆Vg +D5∆Vl (3.5)

0 = D6∆Vg +D7∆Vl (3.6)

Equation 3.3 represents the differential equations of the dynamic elements of the power system

and equation 3.4 the algebraic equations of the stators. Equations 3.5 and 3.6 represent the network

equations for the generator buses and for the load buses, respectively.

Consider a power system with n buses and m generators. Bus 1 is the slack generator bus, buses 2

to m are the generator buses (referred to as PV buses) and buses m+1 to n are the load buses (referred

to as PQ buses). Then, the algebraic variables vectors are arranged as shown in equations 3.7 to 3.9.

∆Ig = [ ∆Id1 ∆Iq1 ... ∆Idm ∆Iqm ]T (3.7)

∆Vg = [ ∆θ1 ∆V1 ... ∆θm ∆Vm ]T (3.8)

∆Vl = [ ∆θm+1 ∆Vm+1 ... ∆θn ∆Vn ]T (3.9)

Because the machine currents are not of interest in voltage stability and rotor angle stability studies,

∆Ig is eliminated and the DAE set of four equations is reduced to three equations. This procedure will

modify the coefficients matrices and so the reduced DAE is as written in equation 3.10.

∆x

0

0

=

A B

CD11 D12

D21 JLF

∆x

∆ya

∆yb

+

E1

0

0

∆u (3.10)

Vector ∆y is partitioned as in equation 3.11, where ∆yb is the power-flow algebraic variables vector

and ∆ya is the vector of the remainder algebraic variables.

∆y = [ ∆Id1 ∆Iq1 ... ∆Idm ∆Iqm ∆V1 ∆θ1 ... ∆Vm | ∆θ2 ... ∆θn ∆Vm+1 ... ∆Vn ]T = [ ∆yTa | ∆yTb ]T

(3.11)

The sub-matrix JLF is the power-flow Jacobian and the algebraic Jacobian JAE is defined as in

equation 3.12.

JAE =

D11 D12

D21 JLF

(3.12)

Proceeding to the elimination of ∆ya and ∆yb, the DAE is again simplified and rewritten as in equation

3.13. The resulting matrix Asys is the matrix used to compute the associated eigenvalues of the power

22

system that are used for stability studies. It is called the system matrix.

∆x = Asys∆x+ E1∆u (3.13)

Asys = A−BJ−1AEC (3.14)

3.1.2 PSS Linearized Equations

The ”PSS Inclusion Study” was developed considering normalized shaft speed deviation ∆ν as the PSS

input signal. Normalization is here required to be coherent with the DAE formulation, which adopts pu1.

The user has some flexibility in choosing the PSS structure: the phase compensation stage may

consist in one or two first-order lead-lag blocks and the washout filter is optional. A two-stage with

washout filter PSS is presented in Figure 2.7 in section 2.3.2.

Each individual block of the PSS, apart from the gain KPSS , will contribute to power system model

with a differential equation and with a new state variable.

Since the implemented PSS may or may not include a washout filter and may have one or two lead-

lag stages, the additional number of equations and state variables will depend on the chosen structure

of the PSS. For example, the two-stage with washout PSS as shown in Figure 2.7 will contribute with

equations 3.20 to 3.22, introducing three new state variables in the system.

Equations 3.15 to 3.22 constitute the linearized equations for all PSS structure options with normal-

ized input signal ∆ν.

• One-stage phase compensation

∆Vs =KPSS

ωs

T1

T2∆ω +

KPSS

ωs

1

T2∆ω − 1

T2∆Vs (3.15)

• One-stage phase compensation with washout filter

∆Vs = − 1

T2∆Vs +

T1

T2∆xp1 +

1

T2∆xp1 (3.16)

∆xp1 =KPSS

ωs∆ω − 1

TW∆xp1 (3.17)

• Two-stage phase compensation

∆Vs = − 1

T4∆Vs +

T3

T4∆xp2 +

1

T4∆xp2 (3.18)

∆xp2 =KPSS

ωs

T1

T2∆ω +

KPSS

ωs

1

T2∆ω − 1

T2∆xp2 (3.19)

• Two-stage phase compensation with washout filter

∆Vs = − 1

T4∆Vs +

T3

T4∆xp2 +

1

T4∆xp2 (3.20)

1MaSSA adopts Sb = 100MVA as base for power and fb = 60 Hz as base for frequency.

23

∆ ˙xp2 = − 1

T2∆xp2 +

T1

T2∆xp1 +

1

T2∆xp1 (3.21)

∆xp1 =KPSS

ωs∆ω − 1

TW∆xp1 (3.22)

The component ∆ω depends on the chosen machine’s model. For example, if it is a GENRED model

∆ω will result from the linearization of equation A.2 in Appendix A. Substituting the component ∆ω by

its expression allows the formulation of the PSS dynamics in the form of the DAE equation 3.3.

3.1.3 PSS Modular Integration in the DAE

To study the effect of the PSS in the power system, in particular, to understand how it influences the

system modes of oscillation, the PSS equations are integrated in the DAE and a new set of eigenvalues,

corresponding to the new compensated power system, is computed from the new system matrix APSSsys .

Because the PSS is characterized only by differential equations, the only equation of the DAE that is

modified when including the PSS dynamics is equation 3.3. Since including a PSS in a network does

not influence the static behaviour of the system, it is only natural that the algebraic equations of the

DAE remain unchanged, apart from the fact that they are redimensioned to accommodate the new state

variables introduced by the PSS.

Considering that the PSS linearized model is a state-space system of the form of equation 3.24 and

considering that the PSS is to be installed in machine i, the PSS integration in the DAE is done in a

modular-like fashion, by extending the DAE differential equation of the machine i without PSS (equation

3.23) with the differential equation of the PSS (equation 3.24).

∆xi = A1i∆xi +B1i∆Igi +B2i∆Vgi + E1i∆ui (3.23)

∆xPSS = APSS1 ∆xPSS +BPSS1 ∆Ig +BPSS2 ∆Vg + EPSS1 ∆u (3.24)

Furthermore, matrix A1i is modified to incorporate the voltage contribution of the PSS, ∆Vsi, in the

AVR’s dynamics, as can be seen in the AVR’s equations in Appendix A. The resulting adjusted matrix

is A′1i and the new augmented DAE differential equation for the machine i with the installed PSS is

represented by equation 3.25.

This DAE augmentation is done for every machine in which a PSS is installed.

∆xi

∆xPSS

=

A′1i

APSS1

∆xi

∆xPSS

+

B1i

BPSS1

∆Igi +

B2i

BPSS2

∆Vgi +

E1i

EPSS1

∆ui (3.25)

Performing ∆Ig elimination and then ∆ya and ∆yb elimination, the reduced DAE (equation 3.26) with

the new system matrix APSSsys is obtained and from it the new eigenvalues are computed.

∆x = APSSsys ∆x+ EPSS∆u (3.26)

24

3.2 PSS Location

The adopted criterion for optimal PSS location was its ability to improve the system’s power transfer

capability. This is a much more holistic view on system’s stability than the Optimum PSS Location Index

(OPLI) approach which is more focused on the stability of individual eigenvalues.

These two indicators can be used together to conclude on the optimal machine to install the PSS.

3.2.1 Criterion: Power Transfer Capability

Recalling that the oscillations that the PSS is intended to damp are undesirable because they limit the

system’s power transfer capability then the optimal machine to install a PSS will be the machine that

improves the system’s power transfer margins the most.

The ”Dynamic Analysis” of MaSSA tests the system’s stability by subjecting it to a disturbance in the

form of a continuously incremented load active power at an arbitrary load bus until instability is detected

after k increments. The later instability is detected the more power transfer the system can endure and

the better the system’s stability margins are. Installing a PSS in the network should allow heavier loads

before instability is detected.

In a ”Dynamic Analysis” instability is detected at the moment that a system’s eigenvalue, computed

from Asys, crosses to the RHCP. Installing a PSS in the network should pull the system’s eigenvalues

towards the LHCP.

The developed ”PSS Inclusion Study” will run a dynamic analysis of the system without PSS, which

should reach instability after k increments of the perturbed load bus. Then, it will run a dynamic analysis

for each possible scenario of PSS location, that is, it will run a dynamic analysis for the PSS installed

at each machine. If the system has m machines then ”PSS Inclusion Study” will perform m dynamic

analyses, each one detecting instability at a different number of increments.

The optimal machine to install a PSS will be the one that reaches instability for the highest number

of increments, i.e the one that reaches instability for the heaviest load at the perturbed bus.

3.2.2 Optimum PSS Location Index

The Optimum PSS Location Index is a technique proposed in [19] that, in a multimachine power system

scenario, indicates which is the most adequate machine-AVR set to include the PSS.

The OPLI is a measure of how a certain AVR’s behaviour changes with respect to the influence of

the PSS installed in that AVR. This change in the AVR’s response is reflected by the difference of its

transfer function GAV R before and after the inclusion of the PSS, as seen in equation 3.27.

OPLI =

∣∣∣∣GAV R(λ′)−GAV R(λ0)

GPSS(λ′)

∣∣∣∣ (3.27)

The characters λ0 and λ′ are respectively the critical swing mode before and after the inclusion of

the PSS.

25

The AVR transfer function is defined as in equation 3.28 and is obtained by applying the Laplace

transform to the equations of the AVR, presented in Appendix A.

GAV R(s) =∆Efd(s)

∆Vs(s)(3.28)

This is a reasonable approach because the PSS operates through the AVR and because the effect