Ops management lecture 1 introduction

-

Upload

jillmitchell8778 -

Category

Business

-

view

2.849 -

download

3

description

Transcript of Ops management lecture 1 introduction

Operations management“TO FAIL TO PLAN IS TO PLAN TO FAIL”

Anonymous

Email: [email protected] Background BSc(Hons) Chemical Engineering Chartered/Professional Engineer MBA – Bristol Business School, UK Currently studying for a PhD in Entrepreneurship at Pretoria

University 25 years+ industry experience, specifically brewing , food &

packaging industry 12 years+ small business management experience, UK &

RSA:- setting up and running businesses

Jill Mitchell

Understand and identify the role of the operations function in manufacturing and service environments

Relate the role of the operations function to the contribution which operations bring to the competitiveness of the business

Identify the different stakeholders which any operation has to consider

Understand the effects of operations on business performance

Understand the basic operation systems within the manufacturing and services environments

Course aims

Understand the challenges within OPS MAN environment Understand the role and task of an OPS MAN in relation to that of their

functional peers Understand the scope, design and management of manufacturing and

service organisations Evaluate the elements and implementation of lean and efficient operations Evaluate and apply techniques and business processes of operational

planning and control systems Understand the difference in resource scheduling problems between

manufacturing and service environments Understand the fundamental differences between alternative ops man

approaches and their application Evaluate alternative operational planning and control approaches

Skills development

Two assignments

1 40% weighting due 24th April 2012

2 60% weighting due 26th June 2012

assessment

Theory & practical10 hoursLearning Units 1-6No short or long questions(sentences & paragraphs)Essay ResponseMarks: 100

Assignment 1

Theory & practical10 hoursLearning Units 7-13No short or long questions(sentences & paragraphs)Essay ResponseMarks: 100

Assignment 2

P17 of manual

Additional reading

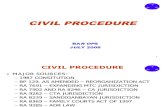

EARLY CONCEPTS – 1776 TO 1880Industrial RevolutionAgricultural subsistence ->factory ad mass productionSpecialisation of labour (Smith & Babbage)Standardised parts (Whitney)

SCIENTIFIC MANAGEMENT – 1880 TO 1910Loading & scheduling charts (Gantt)Time & motion studies (Gilbreth)Process analysis/process optimisation(Taylor)

History of om

ERA OF MASS PRODUCTION – 1910 TO 1980Use of assembly line (Ford)Statistical sampling in quality control(Shewhart)Economic order quantity (EOQ) models (Harris)Linear programming, PERT and critical path (Du Pont)Materials requirement planning (MRP)Pareto analysis, cost of quality, quality trilogy (Juran)Total quality control (Feigenbaum/Ishikawa)

ERA OF LEAN PRODUCTION – 1980 TO 1995JIT/CAD evolved (Toyota)Electronic data interchange (EID)Empowerment of employeesTotal quality management (TQM)

History of om

ERA OF MASS CUSTOMISATION – 1995 TO PRESENTGlobalisationInternet – EcommerceEnterprise resource planning (ERP) – SAP,BAAN,

Q-MusicSupply chain management (SCM)Finite scheduling

History of om

Manufacturing Services Scheduling Inventory control Manufacturing Plant maintenance Productivity, efficiency, customer

service………..

SCOPE

The day to day management of processes Management of the strategic role

The process that makes things happen The management of the needs of the customer and

what the market requires

SCOPE

Must take into account the strategic and tactical plans

Ops Planning DecisionsHow much inventory to carryQuantity of raw materials to purchaseHow much overtime to workControl DecisionsBudget controlProductivity of factory

Operations planning & control decisions

Board of Directors

FinanceAccounts Payable

Accounts ReceivableInvestments

Loans

Operations ProductionLogistics

ProcurementProduct Design

MarketingSales PromotionMarket Research

AdvertisingCustomer Satisfaction

FUUNCTION RELATIONSHIP

Film

Operations at Emirates

1. MONEY – Finance available to produce goods or services

8 M’s of Operations Management

1. MONEY – Finance available to produce goods or services

2. MANPOWER – Selection, mentoring, training and rewarding of workforce

8 M’s of Operations Management

1. MONEY – Finance available to produce goods or services

2. MANPOWER – Selection, mentoring, training and rewarding of workforce

3. MATERIALS – Obtaining, storage and quality of all materials required for manufacturing goods or rendering a service

8 M’s of Operations Management

1. MONEY – Finance available to produce goods or services

2. MANPOWER – Selection, mentoring, training and rewarding of workforce

3. MATERIALS – Obtaining, storage and quality of all materials required for manufacturing goods or rendering a service

4. METHODS – Design of processes for optimisation and manufacture or deliver the service

8 M’s of Operations Management

1. MONEY – Finance available to produce goods or services

2. MANPOWER – Selection, mentoring, training and rewarding of workforce

3. MATERIALS – Obtaining, storage and quality of all materials required for manufacturing goods or rendering a service

4. METHODS – Design of processes for optimisation and manufacture or deliver the service

5. MANAGEMENT – Manage in roles of planning, organising, leading and controlling

8 M’s of Operations Management

1. MONEY – Finance available to produce goods or services2. MANPOWER – Selection, mentoring, training and

rewarding of workforce3. MATERIALS – Obtaining, storage and quality of all

materials required for manufacturing goods or rendering a service

4. METHODS – Design of processes for optimisation and manufacture or deliver the service

5. MANAGEMENT – Manage in roles of planning, organising, leading and controlling

6. MACHINES - Plant must be reliable and well maintained

8 M’s of Operations Management

1. MONEY – Finance available to produce goods or services2. MANPOWER – Selection, mentoring, training and rewarding

of workforce3. MATERIALS – Obtaining, storage and quality of all

materials required for manufacturing goods or rendering a service

4. METHODS – Design of processes for optimisation and manufacture or deliver the service

5. MANAGEMENT – Manage in roles of planning, organising, leading and controlling

6. MACHINES - Plant must be reliable and well maintained7. MESSAGES – Communication between departments,

management and employees

8 M’s of Operations Management

1. MONEY – Finance available to produce goods or services2. MANPOWER – Selection, mentoring, training and rewarding of

workforce3. MATERIALS – Obtaining, storage and quality of all materials

required for manufacturing goods or rendering a service4. METHODS – Design of processes for optimisation and

manufacture or deliver the service5. MANAGEMENT – Manage in roles of planning, organising,

leading and controlling6. MACHINES - Plant must be reliable and well maintained7. MESSAGES – Communication between departments,

management and employees8. MARKETS - Need to be aware of markets and market

requirements

8 M’s of Operations Management

GROUPS 20 MINUTES Imagine you are the managing director of a manufacturing company that manufactures dogfood. Write a profile of an operations manager you require for your factory

CLASS EXERCISE

OPERATIONS

FINANCE

HUMAN RESOURCE

S

SALES & MARKETIN

G

ITPURCHASING

ENGINEERING

QUALITY

RELATIONSHIP WITH OTHER DEPARTMENTS

INPUTSMoney

ManpowerMaterialsMethods

Management

MachinesMessagesMarkets

OUTPUTSFinished goods and

servicesTRANSFORMAT

ION

VALUE ADDED

FEEDBACK

TRANSFORMATION

SERVICES GOODSIntangible TangibleProvided by service organisations Produced by manufacturersImpossible to store Easy to storeCannot be transported Can be transportedConsume & produce simultaneously Delay between production &

consumptionLose value rapidly Maintain value much longerLikely to be unique Less likely to be uniqueHigh customer/provider interaction Little/no contactCustomers participate in service Little/no participationService near customer Centralised away from customerVery labour intensive Mostly automatedDifficult to measure quality Easier to measure qualityServer determines quality Does not depend on one personCannot measure output accurately Easier to measure output

GOODS VS SERVICES

GOODS SERVICES SCALE

High product contentMedium product content

Low product content

No product content

Laptop sales

Restaurant

Medical Services

Lecturing

GOODS

SERVICES

PRIMARY – Sourcing of raw material from natural sources eg. Mining, fishing, forestry

SECONDARY – Utilises the materials from primary functions in the manufacture of goods. All manufacturing operations fall into this category

TERTIARY –Rendering of services only eg. Doctor, attorney etc

MODES OF OM

DECENTRALISED – Local manager determines needs and therefore delivery date and time. Planning carried out only for this facility. ADVANTAGE: Reduced need for communication & control. DISADVANTAGE: Inventory levels hard to control, customer service?

CENTRALISED – All systems managed from a central point. All scheduling, purchasing, planning determined by Head Office. Management of inventory to ensure equitable distribution of raw materials. ADVANTAGE: Synchronisation of orders, production schedules etc. DISADVANTAGE: Ability to react quickly to local situations

OM STRUCTURES

GROUPS 20 MINUTES1. Provide examples of operations

managers and discuss the jobs of each2. What are the 8 M’s involved in this

lecture and how do they fit into the transformation process

3. Name examples of companies that provide goods and services or a combination of both

GROUP EXERCISE