Operating and installation instructions Built-in vacuum ... › pmedia › ZGA › TX3587 ›...

Transcript of Operating and installation instructions Built-in vacuum ... › pmedia › ZGA › TX3587 ›...

Operating and installation instructionsBuilt-in vacuum sealing drawer

To prevent the risk of accidents or damage to the appliance, it isessential to read these instructions before it is installed and used forthe first time.

en-AU, NZ M.-Nr. 10 688 430

Contents

2

Warning and Safety instructions .......................................................................... 3

Caring for the environment ................................................................................ 11

Overview............................................................................................................... 12Overview of the drawer ......................................................................................... 12Accessories supplied ............................................................................................ 13

Controls and display ........................................................................................... 14

Cleaning for the first time ................................................................................... 15

Operation.............................................................................................................. 16Important information on use ................................................................................ 16Useful tips ............................................................................................................. 17Using the vacuum levels ....................................................................................... 18Using the sealing levels......................................................................................... 19Vacuuming and sealing bags ................................................................................ 20

Sealing the bag early........................................................................................ 21Vacuuming preserving jars and jars with twist-off lids .......................................... 22Vacuuming external containers ............................................................................. 24After use ................................................................................................................ 26Cancelling a vacuuming process .......................................................................... 26

Cleaning and care ............................................................................................... 27Cleaning the drawer front and glass lid................................................................. 28Cleaning the vacuum chamber and sealing bar.................................................... 28Cleaning the vacuum adapter ............................................................................... 28Carrying out a drying cycle ................................................................................... 29

Problem solving guide ........................................................................................ 30

Optional accessories .......................................................................................... 35

Safety instructions for installation ..................................................................... 36

Installation notes ................................................................................................. 37

Building-in dimensions ....................................................................................... 38

Installation............................................................................................................ 44

Electrical connection .......................................................................................... 49

After sales service, data plate, warranty........................................................... 50

Warning and Safety instructions

3

Please note that the vacuum sealing drawer is referred to in these operatinginstructions as the drawer.

This drawer complies with all relevant safety requirements.Inappropriate use can, however, lead to personal injury anddamage to property.

To avoid the risk of accidents or damage to the appliance, pleaseread these instructions carefully before installation and using it forthe first time. They contain important notes on installation, safety,use and maintenance.Miele cannot be held liable for damage caused by non-compliancewith these Warning and Safety instructions.

Keep these instructions in a safe place and ensure that new usersare familiar with the content. Pass them on to any future owner.

Warning and Safety instructions

4

Correct application

This drawer is designed for domestic use and for use in similarenvironments by guests in hotel or motel rooms, bed & breakfastsand other typical living quarters. This does not include common/shared facilities or commercial facilities within hotels, motels or bed& breakfasts.

This drawer is not suitable for outdoor use.

The drawer is only to be used to vacuum and seal food in vacuumbags intended for this purpose, to vacuum seal preserving jars, jarswith twist-off lids and vacuum-proof containers made of plastic orstainless steel.Any other use is not permitted.

Never vacuum seal live food (e.g. mussels, seafood).

This appliance is not intended for use by persons (includingchildren) with reduced physical, sensory or mental capabilities, orlack of experience and knowledge, unless they have been givensupervision or instruction concerning its use by a person responsiblefor their safety, and are able to recognise the dangers of misuse.

Warning and Safety instructions

5

Safety with children

Young children must not be allowed to use this appliance.

Older children may only use the drawer when its operation hasbeen clearly explained to them and they are able to use it safely,recognising the dangers of misuse.

Cleaning may only be carried out by older children under thesupervision of an adult.

Please supervise children in the vicinity of the drawer, and do notlet them play with it.

The sealing bar becomes hot during operation. The weld seam ofthe vacuum bag is also heated to a very high temperature during thesealing process. Keep children away from the drawer until thesealing bar and the seam have cooled sufficiently that there is nolonger any danger of burning.

Danger of suffocation! Children may be able to wrap themselves inpacking material or pull it over their head with the risk of suffocation.Keep children away from any packing material.

Warning and Safety instructions

6

Technical safety

Repairs and other work by unqualified persons could bedangerous. Installation, maintenance work and repairs to electricalappliances must only be carried out by a Miele approved servicetechnician.

A damaged drawer can be dangerous. Always check for visiblesigns of damage. Never use a damaged appliance.

Pay attention to any damage or cracks to the glass lid or chamberseal. Damage to the glass lid can cause implosion. Never operatethe drawer if the glass lid and/or the chamber seal is damaged.

The drawer has an integrated vacuum pump which contains oil. Toprevent oil from leaking out, the drawer must be transported andstored in a horizontal position only. Do not tilt the drawer and do notstand it up on its edge. The manufacturer's warranty will be invalidated if oil has leaked outof the appliance because it has not been transported or storedcorrectly.

Reliable and safe operation of the drawer can only be assured if ithas been connected to the mains electrical supply.

The electrical safety of this appliance can only be guaranteedwhen continuity is complete between it and an effective earthingsystem. It is most important that this basic safety requirement ispresent and tested regularly and, where there is any doubt, thehousehold wiring system should be inspected by a qualifiedelectrician.

The connection data (voltage and frequency) on the data plate ofthe drawer must match the mains electricity supply in order to avoidthe risk of damage to the drawer. Compare this data beforeconnecting the appliance. If in doubt, consult a suitably qualifiedelectrician.

Warning and Safety instructions

7

Do not connect the drawer to the mains electrical supply by amulti-socket adapter or extension lead. These are a fire hazard anddo not guarantee the required safety of the appliance.

For safety reasons, this drawer may only be used when it hasbeen built in.

This appliance must not be installed and operated in mobileinstallations (e.g. on a ship).

Never open the casing of the drawer.Touching or tampering with electrical connections or componentsand mechanical parts is highly dangerous to the user and can causeoperational faults.

Do not operate the drawer with wet hands or if you are in contactwith water.

The manufacturer's warranty will be invalidated if the appliance isnot repaired by a Miele approved service technician.

Faulty components must only be replaced by genuine Miele spareparts. The manufacturer can only guarantee the safety of theappliance when Miele replacement parts are used.

If the plug has been removed or the connection cable is notsupplied with a plug, the drawer must be connected to the mainssupply by a suitably qualified electrician.

If the connection cable is damaged, it must be replaced with aspecial connection cable of type H 05 RR F (rubber insulated),available from Miele, in order to avoid a hazard.

If power is interrupted during vacuum sealing, the vacuum in thechamber is retained and the glass lid cannot be opened. Do notunder any circumstances try to force the glass lid open or use toolsto open it. You will be able to open the lid when power has beenrestored.

Warning and Safety instructions

8

During installation, maintenance and repair work, the drawer mustbe disconnected from the mains electricity supply. It is onlycompletely isolated from the electricity supply when:

– the mains circuit breaker is switched off, or

– it is switched off at the wall socket and the plug is withdrawn fromthe socket. Do not pull the mains connection cable but the mainsplug to disconnect your appliance from the mains electricitysupply.

Warning and Safety instructions

9

Correct use

Danger of burning! The sealing bar becomes hot during operation.The weld seam of the vacuum sealing bag is also heated to a veryhigh temperature during the sealing process. Do not touch thesealing bar or the seam immediately after the vacuum sealingprocess.

Fire hazard! Do not store any easily flammable substances andmaterials in the vicinity of the drawer.

The telescopic runners can support a maximum load of 15 kg.Overloading or leaning or sitting on the drawer will damage thetelescopic runners.

Damage to the glass lid can cause implosion. Do not place anyobjects on the glass lid. Ensure that the glass lid cannot sustain damage from falling objects.

Do not use the drawer or the glass lid as a working surface, achopping surface or as a shelf.

The drawer must be built in so that it can be pulled out completelyand there is sufficient room to open the glass lid. This ensures thatyou can see into the vacuum chamber and avoid touching thesealing bar and weld seam and burning yourself.

When vacuuming liquids, bubbles can form at lower temperatures,creating the impression that the liquid is boiling. Steam can escapewhich can cause the drawer to malfunction. For this reason only vacuum seal food (liquid or solid) when it hascooled. Follow the vacuuming process carefully and if necessary sealthe bag early.

Liquid getting into the drawer and into the vacuum pump airintake valve can result in damage to the vacuum pump.

Moisture in food or drinks can cause corrosion damage in thedrawer. Do not use the drawer to store food or drinks.

Warning and Safety instructions

10

Never insert the tubes attached to the drawer into any bodyorifices.

If the drawer is installed behind a furniture panel (e.g. a door),ensure that the door is never closed whilst the drawer is in use. Heatand moisture can build up behind a closed furniture panel and causesubsequent damage to the drawer, the housing unit and the floor. Donot close the door until the sealing bar and the drawer have cooleddown completely.

Vacuum sealing preserving jars and jars with twist-off lids in the closedvacuum sealing chamber:

Danger of injury! Damage and cracks in jars / twist-off lids cancause implosion. Only vacuum jars and lids which are in perfect condition.

Danger of injury! The high pressure during the vacuuming processcauses the vacuum chamber and the glass lid on the drawer todistort slightly. Do not let preserving jars or jars with twist-off lidstouch the drawer's glass lid during the vacuuming process as thiscan cause damage to the protective coating on the glass lid andcause it to implode. Only vacuum seal preserving jars and jars with twist-off lids up to amaximum height of 8 cm in order to maintain a safety gap of at least1 cm between the lid of the jar and the glass lid of the drawer.

Cleaning and care

Do not use a steam cleaning appliance to clean the drawer. The steam could reach electrical components and cause a shortcircuit.

Caring for the environment

11

Disposal of the packingmaterialThe transport and protective packaginghas been selected from materials whichare environmentally friendly fordisposal, and can normally be recycled.

Recycling the packaging reduces theuse of raw materials in themanufacturing process and alsoreduces the amount of waste in landfillsites. Ensure that any plasticwrappings, bags etc. are disposed ofsafely and kept out of the reach ofbabies and young children. Danger ofsuffocation.

Disposing of your oldapplianceElectrical and electronic appliancesoften contain valuable materials. Theyalso contain specific materials,compounds and components, whichwere essential for their correct functionand safety. These could be hazardousto human health and to the environmentif disposed of with your domestic wasteor if handled incorrectly. Please do not,therefore, dispose of your old appliancewith your household waste.

Please dispose of it at your localcommunity waste collection / recyclingcentre for electrical and electronicappliances. You are also responsible fordeleting any personal data that may bestored on the appliance prior todisposal. Please ensure that your oldappliance poses no risk to childrenwhile being stored prior to disposal.

Overview

12

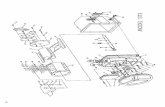

Overview of the drawer

a Air filter cover (see "Installation")

b Glass lid with chamber sealPush down on the little black triangleto close the glass lid.

c Sealing bar in the vacuum chamberand counterpressure bar on theinside of the glass lid

d Push2open mechanismThe drawer can be opened andclosed by pressing lightly in themiddle of the drawer front.

e Control panel

f Vacuum pump air intake valve /Vacuum adapter connection

g Vacuum chamber

Overview

13

Accessories suppliedThe accessories supplied with yourappliance, as well as a range of optionalones, are available to order from Miele(see "Optional accessories").

The vacuum sealing bags suppliedare not suitable for use in pressuresteam ovens (DGD xxxx).

VB 1828 Vacuum sealing bags

50 bags for storage and Sous videcooking of liquid and solid food180 x 280 mm (W x H), D = 90 µ

VB 2435 Vacuum sealing bags

50 bags for storage and Sous videcooking of liquid and solid food240 x 350 mm (W x H), D = 90 µ

Vacuum adapter

1 adapter for vacuum sealing externalcontainers

Miele Sous vide recipe book

A selection of the best recipes from theMiele test kitchen.

Controls and display

14

Sensors controlsThe sensors react to touch. Every touch on the sensors is confirmed by an audibletone.

Sensor Function

For switching the appliance on and off

For setting the vacuum level

For setting the sealing level / For sealing the vacuum bag early

For setting the vacuum level for external containers

For starting the vacuuming process for external containers

For cancelling the vacuuming / sealing process or for cancelling thedrying cycle

For carrying out the drying cycle

Note: this sensor only lights up if drying should or must be carriedout (see "Cleaning and care - Carrying out a drying cycle").

Indicators

Display Description

Vacuum / Sealing level indicators

Warning (see "Problem solving guide")

Cleaning for the first time

15

Please stick the extra data plate forthe appliance supplied with thisdocumentation in the space providedin the "After sales service, data plate,warranty" section of this booklet.Alternatively, the additional label canbe stuck near the appliance if theappliance markings are not visibleafter installation.

Remove any protective foil and salesstickers.

Stickers carrying safety or installationinformation and the data plate mustnot be removed.

Cleaning the drawer for thefirst time Take all accessories out of the

drawer.

Take care not to damage theglass lid and the chamber seal.Do not clean with any abrasive oracidic cleaning agents or sharppointed objects.

Clean the drawer inside and out witha clean sponge and a solution of hotwater and washing-up liquid or aclean, damp microfibre cloth.

After cleaning, wipe the surfaces dryusing a soft cloth.

Operation

16

Important information on use– Only vacuum seal food.

– Only use food that is fresh and ingood condition.

– Ensure hygienic conditions and thatfood has not been out of therefrigerator too long, e.g. duringtransportation.

– Only vacuum seal food in suitablevacuum sealing bags, preserving jarsand jars with twist-off lids (screw-topjars) or in vacuum-proof externalcontainers.

We recommend that you use thevacuum sealing bags supplied (see"Optional accessories"). These arecold stable and boil-proof andtherefore are suitable for storage in therefrigerator or freezer and for Sousvide cooking of solid and liquid food.

– Vacuum seal only food that hascooled.

– Allow pre-cooked and grilled food tocool down at least to roomtemperature (approx. 20 °C) beforevacuum sealing it. Food that is not normally stored inthe refrigerator, e.g. dried pasta ormuesli can also be vacuum sealed atroom temperature.

– If rinsing food with cold water, dry itbefore vacuum sealing to preventwater from collecting in the vacuumbag or container.

– Only vacuum seal food in bags of amaximum size of 250 x 350 mm(sealed edge bags) or 240 x 350 mm(tubular bags).

– Use boil-proof bags if you want tocook food Sous vide after vacuumsealing it.

– Select a suitable bag size for the sizeof the food. If the vacuum bag is toobig, too much air can remain inside.The bag can be cut to fit the size ofthe food.

– If you want to vacuum seal severaltypes of food in one bag, place thefood evenly side-by-side in the bag.

– Fill the vacuum bag to a maximum of²/₃ with solid food or ¹/₃ with liquid.

– For a perfect weld seam, make surethat the edge of the bag is dry andgrease-free in the area of the seam.

– Position the open edge of the bagparallel to the sealing bar so that theedge protrudes over the sealing barby approx. 2 cm.

– Take care not to cover the vacuumpump air intake valve with the bag.

– Vacuum sealing bags are for singleuse only.

– Place food that is suitable for coolingin the refrigerator or freezer aftervacuum sealing it.

– When vacuum sealing food inpreserving jars and jars with twist-offlids, make sure that the jars and thelids are clean.

Operation

17

Preserving jars and jars with twist-offlids must only be vacuum sealed inthe closed vacuum chamber.

– To guarantee the minimum gap of1 cm to the glass lid of the drawer,the jars must not be taller than 8 cm.Before vacuum sealing, make surethat jars do not exceed the maximumpermitted height.

Useful tips– Freeze liquids before vacuum sealing

them. You can then fill the bags ²/₃full.

– Fold the edges of the vacuum sealingbag outwards for filling. This will giveyou clean, perfect weld seams.

– To prevent small bags from slippingdown into the vacuum chamber, achopping board can be placed in thebottom of the chamber.

– If you are unsure whether food suchas berries or potato chips will lose itsshape during vacuum sealing, startwith the lowest vacuum level.

Operation

18

Using the vacuum levelsThere are 3 levels for vacuum sealing.

The higher the vacuum level selected, the greater the vacuum.

Vacuumlevel

Use for

Packaging, portioning and storing

Suitable for:

– food that is prone to squashing, e.g. lettuce, berries or chips;

– preserving jars and jars with twist-off lids (screw cap lids) withliquid contents e.g. stock or pickled vegetables.

Marinating, tenderising, Sous vide cooking and freezing

Suitable for:

– food that is prone to squashing, e.g. tender fish fillets;

– sauces and food with a high liquid content (≥ 50 g), e.g. ragout,curry;

– preserving jars and jars with twist-off lids (screw cap lids) withmore solid or dry contents e.g. jam, pesto or cake.

Sous vide cooking, freezing and storage

Suitable for:

– meat and more solid food, e.g. potatoes, carrots;

– hard cheese (storage);

– food with a low liquid content (≤ 50 g), such as meat seasonedwith a herb oil.

Operation

19

Using the sealing levelsThere are 3 levels for sealing vacuum bags.

The sealing level to select depends on the material thickness of the bag: thestronger the bag, the higher the sealing level.

Level 3 is recommended for the vacuum sealing bags supplied.

Useful tip: The sealing bar will get progressively hot when carrying out a numberof consecutive vacuuming processes. You can use a lower sealing level aftersealing a few bags.

Operation

20

Danger of injury!Damage to the glass lid can causeimplosion.Do not under any circumstances usethe drawer if the glass lid isdamaged.

Soiling and liquid must not beallowed to get on the sensors.Otherwise the sensors will fail toreact or switch on or offunintentionally.

Avoid damaging the drawer!Liquid getting into the vacuum pumpair intake valve during a vacuumingprocess can result in damage to thevacuum pump.Fill the vacuum sealing bag withliquid to a maximum of ¹/₃.

Vacuuming and sealing bags Fill the vacuum bag.

Open the drawer and the glass lid.

Place the vacuum sealing bag in thevacuum chamber so that the openend of the bag lies across the sealingbar. Ensure that the edge of the bagis positioned centrally and crease freeon the sealing bar.

Switch the drawer on with the sensor.

The and sensors will light up.

Touch the sensor repeatedly untilthe segment for the required vacuumlevel lights up.

Touch the sensor repeatedly untilthe segment for the required sealinglevel lights up.

Close the glass lid and press it downlightly.

The vacuuming process will start.

The following occurrences during thevacuuming process are normal and donot indicate a functional or appliancefault:

– the bag inflates, before envelopingthe food being vacuum sealed,

– bubbles form in the liquid, creatingthe impression that it is boiling.

If the amount of bubbles beingformed during the vacuumingprocess increases alarmingly and itlooks like liquid might run out of thebag, you can seal the bag early (see"Sealing the bag early").

Operation

21

After the vacuuming process

An acoustic tone will sound.

Open the glass lid.

Danger of burning!The sealing bar and weld seam arehot.Do not touch the sealing bar or theweld seam immediately after thevacuuming process.

Remove the vacuum sealing bag fromthe vacuum chamber.

Before starting a new vacuumingprocess, check that the vacuumchamber and the sealing bar areclean and dry.Remove any soiling or liquid residuesif necessary.

Sealing the bag early

You can end the vacuuming processbefore reaching the selected vacuuminglevel and seal the bag early.

Touch the sensor.

The vacuum process stops. After a fewseconds the bag will be sealed.

Successful sealing of the bag is onlypossible when there is a minimumvacuum (vacuum level 1) in thechamber. Touch the sensor again if therequired vacuum level has not yetbeen reached. For technical reasons, afew seconds will elapse before thebag is sealed.

Operation

22

Danger of injury!Damage and cracks in jars / twist-offlids can cause implosion.Only vacuum jars and lids which arein perfect condition.Only vacuum jars on vacuum level 1or 2.

Danger of injury!Take care not to damage the glasslid.Only vacuum seal jars up to amaximum height of 8 cm in order tomaintain a safety gap of at least1 cm between the lid of the jar andthe glass lid of the drawer.

Vacuuming preserving jars andjars with twist-off lids Close the jar with its appropriate lid

and rubber seal or with the twist-offlid.

Open the drawer and the glass lid.

Place the jar in the vacuum chamber.

Switch the drawer on with the sensor.

The and sensors will light up.

Touch the sensor repeatedly untilthe segment for vacuum level 1 or 2lights up.

Touch the sensor repeatedly untilthe segment for sealing level 1 lightsup.

Close the glass lid and press it downlightly.

The vacuuming process will start.

Operation

23

After the vacuuming process

An acoustic tone will sound.

Open the glass lid.

Danger of burning!The sealing bar is hot.Do not touch the sealing barimmediately after the vacuumingprocess.

Remove the jar from the vacuumchamber.

Before starting a new vacuumingprocess, ensure that the vacuumchamber is clean and dry.Remove any soiling or liquid residuesif necessary.

Operation

24

Danger of injury!External glass containers canimplode during vacuuming.Only use vacuum-proof containersmade of plastic or stainless steel.

We recommend caso® container setsif you wish to use externalcontainers. These containers can beconnected to the drawer using thevacuum adapter supplied.

Vacuuming external containersThe process for vacuuming a containerfrom the caso® vacuum container set isdescribed below.

Prepare the vacuum adapter: Detach the container lid connector(smaller diameter) from thecontainer set connecting tube.

Attach the connector to the end ofthe vacuum adapter tube . For asecure grip, make sure that the endof the tube is pushed at least 0.5 cmover the opening on the connector.

Fill the container to a maximum of3 cm below the rim.

Place the lid on the container andpress it down.

Open the drawer and the glass lid.

Operation

25

Place the vacuum adapter over thevacuum pump air intake valve .

Attach the connector to thecontainer lid. Make sure that theclosure of the lid is turned to"seal" (closed).

Switch the drawer on with the sensor.

The and sensors will light up.

Touch the sensor.

The and sensors go out. The and sensors will light up.

Touch the sensor repeatedly untilthe segment for the required vacuumlevel lights up.

Touch the sensor.

The vacuuming process will start.

Leave the glass lid open for theentire duration of the vacuumingprocess.

If an excessive amount of bubblesform you can cancel the vacuumingprocess by pressing the sensor(see "Cancelling the vacuumingprocess").

After the vacuuming process

An acoustic tone will sound.

Detach the connector from thecontainer lid. Make sure that theclosure of the lid is still turned to"seal" (closed).

Remove the vacuum adapter from thevacuum pump air intake valve.

Before starting a new vacuumingprocess, check that the vacuumadapter, the tube and the vacuumchamber are clean and dry.Remove any soiling or liquid residuesif necessary.

Operation

26

After use Touch the sensor to switch the

drawer off.

Clean and dry the drawer and anyaccessories as described in"Cleaning and care".

Do not close the glass lid until thevacuum chamber is completely dry.

Close the drawer.

The last vacuum and sealing levelselected is automatically activated thenext time the drawer is switched on,and this is shown in the display.

Cancelling a vacuumingprocessYou can cancel a vacuuming process atany time, e.g. if you notice during theprocess that the edge of the bag is notpositioned correctly or that the closureon the container lid is not pointing to"seal" (closed).

Please note that when vacuumingbags, if the vacuuming process iscancelled, the bag will not be sealed.

Touch the sensor.

The vacuuming process stops.

Cleaning and care

27

Danger of injury!The steam from a steam cleanercould reach electrical componentsand cause a short circuit.Do not use a steam cleaner to cleanthe drawer.

The use of unsuitable cleaningagents can cause the surfaces todiscolour or alter. Only use cleaningagents designed for domestic use.All surfaces of this appliance aresusceptible to scratching. Scratcheson glass surfaces could cause abreakage in certain circumstances.Remove any residual cleaning agentimmediately.

Allow the sealing bar to cool downbefore cleaning it.

Switch the drawer off to clean it.

The drawer and accessories shouldbe cleaned and dried thoroughly aftereach use.

Do not close the glass lid until thevacuum chamber is completely dry.

Unsuitable cleaning agentsTo avoid damaging the surfaces of yourappliance, do not use:

– cleaning agents containing soda,ammonia, acids or chlorides,

– cleaning agents containing descalingagents,

– abrasive cleaning agents, e.g.powder cleaners and cream cleaners,

– solvent-based cleaning agents,

– stainless steel cleaning agents,

– cleaning agents for ceramiccooktops,

– dishwasher cleaner,

– oven cleaners or sprays,

– hard, abrasive sponges and brushes,e.g. pot scourers,

– sharp metal tools.

Cleaning and care

28

If soiling is left on for any length oftime, it may become impossible toremove.Surfaces may suffer discolouration ordamage.Remove any soiling immediately.

Cleaning the drawer front andglass lid Remove soiling and fingerprints with

a standard domestic glass cleaner orwith a clean, damp microfibre cloth.

After cleaning, wipe the surfaces dryusing a soft cloth.

Cleaning the vacuum chamberand sealing bar

Avoid damaging the drawer!Liquid getting into the vacuum pumpair intake valve can result in damageto the vacuum pump.Take care that water does not getinto the air intake valve.

Useful tip: For easier cleaning of thevacuum chamber and sealing bar thesealing bar can be lifted out.

Remove light soiling immediatelyusing a solution of hot water andwashing-up liquid applied with aclean sponge or use a clean, dampmicrofibre cloth.

Remove any residual cleaning agentwith some clean water.

After cleaning, wipe the surfaces dryusing a soft cloth.

Cleaning the vacuum adapter Clean the vacuum adapter with a

clean sponge and a solution of hotwater and washing-up liquid or aclean, damp microfibre cloth.

Then dry the vacuum adapterthoroughly with a soft cloth.

Do not use the vacuum adapter againuntil it is completely dry.

Cleaning and care

29

Carrying out a drying cycleWhen food is vacuumed, moisture getsinto the oil circulation system in thevacuum pump. To remove the moistureit is necessary to run a drying cycleafter a particular operating period.

The sensor on the control panel ofthe drawer lights up yellow when adrying cycle needs to be carried out.After the first time it lights up you canstill run another 10 vacuumingprocesses. After that, the sensorlights up red and a drying cycle must becarried out. The drawer will lock afterthe last remaining use and cannot beused again until drying has been carriedout.

We recommend carrying out a dryingcycle before the drawer locks out.

The whole drying cycle lasts for amaximum of 20 minutes.

The vacuum chamber must be freefrom objects and liquid residues forthe drying cycle.Clean and dry the vacuum chamberas necessary.

Touch the sensor.

Close the glass lid.

The drying cycle starts. The sensorwill flash yellow throughout the entireprocess.

You can cancel the drying cycle withthe sensor. If a drying cycle iscancelled, it must be repeated afterthe remaining vacuuming processeshave elapsed or when the drawer isswitched on again.

When the drying cycle has finished, abuzzer will sound and the sensorgoes out. You can now use the draweragain as usual.

Problem solving guide

30

With the aid of the following guide, minor problems can be easily correctedwithout contacting Miele. If, after reading this guide, you can't remedy the problemyourself, please call Miele (see back cover for details).Please note, however, that a call-out charge will be applied to unnecessary servicevisits where the problem could have been rectified as described in these operatinginstructions.

Danger of injury! Installation, maintenance and repairs may only be carriedout by a suitably qualified and competent person.Repairs and other work by unqualified persons could be dangerous. Mielecannot be held liable for unauthorised work.Do not attempt to open the casing of the appliance yourself.

Problem Possible cause and remedy

The drawer will notopen.

The safety screws on the back of the drawer have notbeen removed. Call Miele.

The drawer cannot beswitched on.

The appliance is not correctly plugged in andswitched on at the mains socket. Insert the plug and switch on at the socket.

The circuit breaker is defective or has tripped. Reset the circuit breaker in the mains fuse box

(minimum fuse rating - see data plate). If, afterresetting the circuit breaker in the mains fuse boxand switching the appliance back on, theappliance will still not heat up, contact a qualifiedelectrician or Miele.

There was a loud bangduring operation.

The transit device has not been removed and the airfilter has not been fitted. Call Miele.

The drawer hasswitched itself off.

The drawer will switch itself off automatically to saveenergy if no other action is taken within a certain timeframe after switching it on or after the end of avacuuming process. Switch the drawer back on.

The sensors are notreacting to touch.

Foreign objects, soiling or liquid residues have gotonto the control panel. Remove the objects and/or clean the control

panel.

Problem solving guide

31

Problem Possible cause and remedy

The vacuuming processtakes longer thanexpected.

The oil in the vacuum pump has become extremelyhot. Leave the drawer to cool for an hour before

starting another vacuuming process. When carrying out a number of consecutive

vacuuming processes, wait a minimum of2 minutes between each process to prevent the oilfrom overheating again.

The vacuum sealing bagwas not sealed early.

The required vacuum (vacuum level 1) for sealing abag was not achieved. Touch the sensor again or repeatedly until the

vacuuming process ends and the bag is sealed.

All sensors have goneout. The glass lid willnot open.

There was an interruption to the power supply duringthe vacuuming process. The vacuum chamber is stillunder pressure so the glass lid cannot be opened.

Do not in any circumstances try to force the glasslid open or use tools to open it.

When the power supply is restored, the glass lidcan be opened again after initialisation (all sensorsand controls light up).

Start the vacuuming process again if necessary.

There is still too muchair in the bag at the endof the vacuumingprocess.

The vacuum level was too low. Start the vacuuming process again with a new bag

and a higher vacuum level.The vacuum sealing bag is too big for the food to bevacuumed. Use a new smaller bag or cut a larger bag to fit the

size of the food. Start the vacuuming process again with a higher

vacuum level if necessary.

After severalconsecutive vacuumingprocesses, the weldseam is faulty/notproperly sealed.

The sealing bar has overheated. Wait a minimum of 2 minutes between individual

vacuuming processes to avoid the sealing baroverheating again.

Problem solving guide

32

Problem Possible cause and remedy

The edge of the bag isnot completely sealed.

The edge of the bag was not positioned centrallyalong the sealing bar or has slipped. Place the edge of the bag centrally along the

sealing bar. Make sure that the edge of the bag isparallel to the sealing bar and protrudes over it byapprox. 2 cm.

The bag is wider than 25 cm. Use vacuum sealing bags with a maximum width

of 25 cm.

The seal was not strongenough and hasopened.

The edge of the bag is dirty (inside and out). For aperfect weld seam the edge of the bag must be dryand grease-free in the area of the seam. Fold the edges of the vacuum sealing bag

outwards for filling. This will give you a clean,perfect weld seam.

The edge of the bag was not positioned smoothly andwithout creases on the sealing bar. Position the bag smoothly and without creases

along the sealing bar.The sealing level was too low. Start the vacuuming process again with a new

vacuum sealing bag and select a higher sealinglevel.

The rubber on the counterpressure bar is not evenlyfitted. Flatten the rubber.

The sealing bar and/or the counterpressure bar isdamaged. Call Miele to have it replaced.

The bag is notmaintaining the vacuumalthough the weld seamis intact.

The vacuum sealing bag has been damaged by sharppointed objects, e.g. pointed pasta shapes or a bone. Start the vacuuming process again with a new

vacuum sealing bag, on a lower vacuum level ifnecessary.

Use an external container if possible.

Problem solving guide

33

Problem Possible cause and remedy

The weld seam isdefective or notproperly sealed in oneor more places.

The sealing bar and/or counterpressure bar are dirtyor there are liquid residues on the sealing bar. Clean and dry the sealing bar and/or

counterpressure bar.The rubber on the counterpressure bar is not evenlyfitted. Flatten the rubber.

The edge of the bag is dirty (inside and out). For aperfect weld seam the edge of the bag must be dryand grease-free in the area of the seam. Fold the edges of the vacuum sealing bag

outwards for filling. This will give you a clean,perfect weld seam.

The edge of the bag was not positioned smoothly andwithout creases on the sealing bar. Position the bag smoothly and without creases

along the sealing bar.

The sensor is lit upeven though a dryingcycle has been carriedout. The drawer cannotbe used.

The drying cycle failed to remove all of the moisturefrom the oil circulation system in the vacuum pump. The drawer is locked and cannot be used for 1 hour. Carry out a further drying cycle after 1 hour (see

"Cleaning and care - Carrying out a drying cycle").Make sure that the vacuum chamber is free ofliquid residues.

The sensor lights upyellow. The vacuum islower than usual.

Moisture from the food vacuuming process has gotinto the oil circulation system in the vacuum pump.This can result in a reduced level of vacuumingperformance. Carry out a drying cycle (see "Cleaning and care -

Carrying out a drying cycle").

The sensor lights upred. A vacuumingprocess cannot bestarted.

Moisture from the food vacuuming process has gotinto the oil circulation system in the vacuum pump. Ifthe sensor lights up red, the drawer is locked forfurther use. Carry out a drying cycle (see "Cleaning and care -

Carrying out a drying cycle").

Problem solving guide

34

Problem Possible cause and remedy

There is a film of oil onthe glass lid and in thedrawer.

The oil in the vacuum pump has become extremelyhot. Clean the drawer and leave it to cool down for

1 hour before starting another vacuuming process. When carrying out a number of consecutive

vacuuming processes, wait a minimum of2 minutes between each process to prevent the oilfrom overheating again.

If the problem occurs again, contact Miele.

The vacuuming processis cancelled after2 minutes. An acoustictone sounds and the symbol lights up red.

The required vacuum could not be achieved. Switch the drawer off and back on again. Start the vacuuming process again, selecting a

different vacuum level if necessary.After intensive use of the drawer the oil in the vacuumpump has severely overheated. Leave the drawer to cool for an hour before

starting another vacuuming process. When carrying out a number of consecutive

vacuuming processes, wait a minimum of2 minutes between each process to prevent the oilfrom overheating again.

The vacuuming processis cancelled after5 seconds. An acoustictone sounds and the symbol lights up red.

The glass lid is not sitting evenly. There is an object,e.g. the edge of a bag, or some soiling on the surfaceof the chamber seal. Remove the obstruction and/or the soiling. Close the glass lid and press it down lightly for

approx. 5 seconds.The chamber seal is not fitted correctly. Press the chamber seal in all the way round to

make sure it is fitted evenly.The chamber seal is damaged, e.g. cracks can beseen. Call Miele to have it replaced.

Optional accessories

35

Miele offers a range of usefulaccessories, as well as cleaning andconditioning products for yourappliance.

These products can be ordered fromthe Miele online shop.

They can also be ordered directly fromMiele (see end of this booklet forcontact details).

Vacuum sealing bags

VB 1828 (pack of 50)

For storing and Sous vide cooking ofliquid and solid food180 x 280 mm (W x H), D = 90 µ

VB 2435 (pack of 50)

For storing and Sous vide cooking ofliquid and solid food240 x 350 mm (W x H), D = 90 µ

Cleaning and care products

Original Miele all purpose microfibrecloth

Removes finger marks and light soiling.

Safety instructions for installation

36

Incorrect installation can result in personal injury and damageto property.

Before connecting the drawer to the mains supply, ensure that theconnection data on the data plate (voltage and frequency) matchesthe mains electricity supply.This data must correspond in order to avoid the risk of damage tothe drawer. Consult a qualified electrician if in any doubt.

The socket and on-off switch should be easily accessible after thedrawer has been installed.

The drawer may only be installed in combination with thoseappliances quoted by Miele as being suitable. If the drawer is used incombination with other appliances, the warranty will be invalidated,as trouble-free operation cannot be guaranteed.

The base on which the drawer and the combination appliance arefitted must be fixed in place and must support the weight of bothappliances.

When building in the combination appliance, it is essential tofollow the instructions given in the operating and installationinstructions supplied with the combination appliance.

The drawer must be installed in such a way that

– you can see into the vacuum chamber. This helps to avoidscalding and burns from touching the hot sealing bar or weldseam.

– there is enough space for the drawer to be pulled out fully and foropening the glass lid.

Installation notes

37

When building in the drawer with acombination appliance, thecombination appliance is placed on topof the drawer without the need for aninterim shelf.

All dimensions in this instructionbooklet are given in mm.

Building-in dimensions

38

Installation in a base unit

a Cut-out for ventilation

b Building-in dimension includingmains supply cable plug connectorMains connection cable L = 2200 mm

c Worktop protrusion

* Glass front / ** Metal front

Installation in a tall unit

a Cut-out for ventilation

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

Building-in dimensions

39

EVS with H 2xxx B(P) /H 6xxx B(P)

a Vent cut-out for when appliance isinstalled in combination with apyrolytic oven

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

EVS with H 6xxx BM(BP) /M 61xx / M 62xx

a Vent cut-out for when appliance isinstalled in combination with apyrolytic oven

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

Building-in dimensions

40

EVS with DGM 6800

a Ventilation cut-out required wheninstalled with a steam oven withmicrowave

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

EVS with DG 6x00 / DG 6x0x

a Ventilation cut-out required wheninstalled with a steam oven

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

Building-in dimensions

41

EVS with DGC 6300 / DGC 6400

a Ventilation cut-out required wheninstalled with a steam combinationoven

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

EVS with DGC 6500 /DGC 6600 / DGC 680x

a Ventilation cut-out required wheninstalled with a steam combinationoven

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

For the DGC 6805, cut-outs arerequired for the water inlet and drainhoses (see DGC 6805 installationinstructions).

Building-in dimensions

42

EVS with DGC 6660 / DGC 686x

a Ventilation cut-out required wheninstalled with a steam combinationoven

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

For the DGC 6865, cut-outs arerequired for the water inlet and drainhoses (see DGC 6865 installationinstructions).

EVS with DGD 4635 / DGD 6xx5

a Filler panel AB 45-7 (optionalaccessory)

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

For the pressure steam oven, cut-outsare required for the water inlet anddrain hoses (see installationinstructions for the pressure steamoven).

Building-in dimensions

43

EVS with CVA 6401 / CVA 68xx

a Ventilation cut-out for installation incombination with a coffee machine

b Building-in dimension includingmains supply cable plug connectorMains connection cableL = 2200 mm

* Glass front / ** Metal front

Installation

44

Avoid damaging the drawer!The drawer has an integratedvacuum pump which contains oil.To prevent oil from leaking out, thedrawer must be transported andstored in a horizontal position only.Do not tilt the drawer and do notstand it up on its edge.

Preparing the drawerFor safe transportation, the vacuumpump is provided with a transit devicewhich must be removed beforeinstallation. The air filter supplied mustbe fitted in place of the transit device. There are also 2 safety screws on theback of the drawer to prevent thedrawer from being openedunintentionally during transportationand when it is being removed from thepackaging.

Important!Fit the air filter before building in thedrawer and remove the safetyscrews at the back.Otherwise the drawer cannot beoperated and may have to be takenout of the housing unit.

Keep the transit device and safetyscrews for any future transportation. The transit device can be secured tothe back of the drawer.

Fitting the air filter and removing thesafety screws

Slide the cover to the right andremove it.

Pull the red transit device out, e.g.with universal pliers.

Installation

45

Screw the air filter onto thevacuum pump using a screwdriver.

Secure the transit device to theback of the drawer.

Slide the cover back over theopening to close it.

Remove the safety screws fromthe back of the drawer.

Avoid damaging the drawer!Remove the air filter beforetransporting the drawer and plug thevacuum pump with the transitdevice .

To remove the air filter and fit the transitdevice, carry out these steps in reverseorder.

Installation

46

Building in the drawer

Danger of injury!The drawer is heavy and will tipforwards when open.Installation must be carried out bytwo people.Keep the drawer closed until theanti-tipping mechanism supplied hasbeen fitted to the side walls of thehousing unit.

Check that the base on which thedrawer will sit is clean and level (usea spirit level). This is important forthe appliance to function correctly.

Fitting the anti-tipping mechanism

Measure the distance to the right andleft-hand side walls of the housing(see illustration).

Mark the uppermost position in thelong slot of the anti-tippingmechanism . Make sure that theanti-tipping mechanism is flush withthe base of the housing unit.

Secure the anti-tipping mechanism tothe right and left hand side walls ofthe housing unit with the 4 screwssupplied (4 x 16 mm).

Installation

47

Building in and connecting thedrawer

Check that the air filter is fitted andthe safety screws have been removedfrom the back of the drawer (see"Preparing the drawer").

Connect the mains connection cableto the drawer.

Slide the closed drawer into thehousing unit. When doing so makesure that the mains cable does notget trapped or damaged.

Align the drawer at right angles.

Open the drawer and secure it to theright and left hand side walls of thehousing unit with the 2 wood screwssupplied (3.5 x 25 mm).

Remove the 4 foam adhesive labelsfrom the back of the front panel onthe right and left hand sides.

Connect the drawer to the mainselectricity supply.

When the drawer is first connected, orafter an interruption to the powersupply, all of the sensors andindicators in the display will light upfor approx. 10 seconds for testing(initialisation). As soon as they go out,the drawer is ready for use.

Build in the combination appliance inaccordance with its own specificoperating and installationinstructions.

Installation

48

Aligning the front of the drawerAfter building in the combinationappliance, it may be necessary undercertain circumstances to align the frontof the drawer and adjust the gapbetween the drawer and thecombination appliance. To help you dothis, there are 2 screws behind thedrawer front with which the front is fixedto the drawer housing.

Open the drawer.

Loosen the fixing screws on theright and left of the drawer housing.

Danger of injury!When the fixing screws are removed,the drawer front is only hooked ontothe housing and can easily fall off.Do not remove the fixing screwscompletely.

Push the drawer up or down a little tocorrect the alignment and the gap.

Tighten up the fixing screws.

Electrical connection

49

All electrical work must be carried outby a suitably qualified and competentperson in strict accordance with currentlocal and national safety regulations.Connection should be made via aswitched socket. This will make it easierfor service technicians should theappliance need to be repaired. Theelectrical socket must be easilyaccessible after installation.

Danger of injury!Miele cannot be held liable forunauthorised installation,maintenance and repair work as thiscan be dangerous to users. Miele cannot be held liable fordamage or injury caused by incorrectinstallation, maintenance or repairwork, or by an inadequate or faultyearthing system (e.g. electric shock).If the plug has been removed or theconnection cable is not supplied witha plug, the drawer must beconnected to the mains supply by asuitably qualified electrician.If the appliance is to be hard-wired,an additional means ofdisconnection must be provided forall poles. When switched off, theremust be an all-pole contact gap of atleast 3 mm in the switch (includingswitch, fuses and relays). Connectiondata is shown on the data plate. Itmust match the mains electricalsupply.After installation, ensure that allelectrical components are shieldedand cannot be accessed by users.

Total power outputSee data plate.

Connection and fuse ratingAC 230 V, 50 Hz

The voltage and rated load are given onthe data plate. Please ensure thesematch the household mains supply.

Residual current deviceFor extra safety, it is advisable to installa residual current device (RCD), with atrip current of 30 mA. Do not connectthe appliance via an extension lead.

Replacing the mainsconnection cableIf the mains connection cable needs tobe replaced, it must be replaced with aspecial connection cable, typeH 05 RR F (rubber insulated), availablefrom Miele, in order to avoid a hazard.

After sales service, data plate, warranty

50

After sales serviceIn the event of any faults which you cannot easily remedy, please contact Miele.

See back of this booklet for contact details.

Please quote the model and serial number of your appliance when contactingMiele.

Data plateSpace in which to stick the extra data plate supplied with the appliance. Ensurethat the model number is the same as the one on the back of these operatinginstructions.

WarrantyThe manufacturer's warranty for this appliance is 2 years.

For further information, please refer to your warranty booklet.

www.miele.com.au

Miele Experience Centre and Head Office Melbourne:1 Gilbert Park DriveKnoxfield, VIC 3180

Miele Experience Centre South Melbourne:206-210 Coventry StreetSouth Melbourne, VIC 3205

Miele Experience Centre and Office Sydney:3 Skyline PlaceFrenchs Forest, NSW 2086

Miele Experience Centre and Office Brisbane:39 Harvey Street NorthEagle Farm, QLD 4009

Miele Experience Centre and Office Perth:

83-85 Sir Donald Bradman DriveHilton, SA 5033

205-207 Stirling HighwayClaremont, WA 6010

Miele Experience Centre and Office Adelaide:

Miele Australia Pty. Ltd.

Miele New Zealand Limited

Level 2, 10 College HillFreemans Bay, Auckland 1011

Miele Experience CentreAuckland:8 College HillFreemans Bay, Auckland 1011Telephone:0800 464 353 (0800 4 MIELE)www.miele.co.nz

Miele Global HeadquartersGermanyMiele & Cie. KGCarl-Miele-Straße 2933332 GüterslohFederal Republic of Germany

Head Office:

IRD 98 463 631

ACN 005 635 398ABN 96 005 635 398

Miele Experience Centre Gold Coast:131 Ferry RoadSouthport, QLD 4215

M.-Nr. 10 688 430 / 00en-AU, NZ

EVS 6114 / EVS 6214