Ooitech Customized Solar Panel Production Equipment Introduction OT20141217

-

Upload

akash9112006 -

Category

Documents

-

view

24 -

download

13

description

Transcript of Ooitech Customized Solar Panel Production Equipment Introduction OT20141217

Ver_OT-17-Dec-14

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

WUHAN OOITECH

Crystalline Solar Panel Production Equipment Introduction

Made by: Margret Cao

Wuhan Ooi Photoelectric Technology Co.,Ltd

Website:http://www.ooitech.com Tel:+86-27-81779060 Fax:+86-27-81779060

Address: Buliding 2 NO.13 Yangqiaohu Road, East Lake High-tech Development Zone, Wuhan of China

Technical Information is confidential, shall not be disclosed without Wuhan Ooitech permission to third parties

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 2 of 65 -

Contents

Contents ......................................................................................................................................... 2

1. Project Name:Crystalline Solar Panel Encapsulation Line .................................................... 4

1.1. Project Capacity: Customized 5MW 10MW 20MW 50MW 100MW .............................. 4

1.2. Solar Panel Production Process ..................................................................................... 4

2. Production Process General Explanation.................................................................................. 5

2.1. Main Equipment ............................................................................................................... 5

2.2. 5MW Crystal solar panel Equipment List ................................................................... 8

2.3. 10MW Crystal solar panel Equipment List ................................................................. 8

2.4. 20MW 30MW 50MW 100MW Crystal Solar Panel Equipment List .......................... 9

3. Production Machine Catalogue ................................................................................................ 10

3.1. Solar Panel Laminator ................................................................................................... 10

3.1.1. Semiautomatic Solar Panel Laminator ................................................................ 11

3.1.2. Single Full Automatic Laminator ......................................................................... 17

3.2. Solar Cell Laser Scribing Machine ................................................................................ 22

3.2.1. Solar Cell Fiber Laser Scribing Machine ............................................................ 22

3.2.2. Diode Pump Solar Cell Laser Scribing Machine ................................................ 25

3.3. Solar Cell Tester ............................................................................................................. 29

3.4. Solar Panel Tester Solar Simulator ............................................................................... 31

3.5. EL Defect Tester ............................................................................................................. 33

3.5.1. Electroluminescence Module Defect Tester Offline ........................................... 33

3.5.2. Full Automatic EL Defect Tester .......................................................................... 37

3.6. Solar Panel Framing Machine ....................................................................................... 41

3.7. PV Ribbon Cutting Machine .......................................................................................... 43

3.8. Manual Soldering station ............................................................................................... 44

3.9. Manual EVA/TPT Cutting Station .................................................................................. 45

3.10. Visual Inspection Station.............................................................................................. 46

3.11. Lay-up Station ............................................................................................................... 47

3.12. Solar Module Carrier .................................................................................................... 48

3.13. Ready Material Carrier................................................................................................. 49

3.14. String Cell Carrier ......................................................................................................... 50

3.15. EVA/TPT Carrier........................................................................................................... 51

3.16. Working Table ............................................................................................................... 52

3.16.1. Solar Cell Sorting Worktable ............................................................................. 52

3.16.2. Trimming Worktable .......................................................................................... 52

3.16.3. Glue up/Cleaning/Juction box/Package Worktable ......................................... 52

3.17 Solar Cell Stroage Station............................................................................................. 53

3.18. String Welding Template .............................................................................................. 53

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 3 of 65 -

3.18.1. 125 string welding template .............................................................................. 53

3.18.2. 156 string welding template .............................................................................. 53

4. Working Picture ......................................................................................................................... 54

4.1. Single Welding and String Welding ............................................................................... 54

4.2. Layup .............................................................................................................................. 54

4.3. Visual inspection ............................................................................................................ 55

4.4. Solar panel laminator ..................................................................................................... 55

4.5. Framming........................................................................................................................ 57

4.6 Glue UP the Aluminum frame ......................................................................................... 57

4.7 Glue up the junction box ................................................................................................. 57

5. Factory Layout .......................................................................................................................... 58

5.1. Semi auto production line .............................................................................................. 58

5.2. Full auto production line................................................................................................. 58

6. Factory Building Requirement: ................................................................................................. 59

7. Our Customer............................................................................................................................ 59

8. Machine Working Video ............................................................................................................ 60

9. Company ................................................................................................................................... 61

10. Solar Raw Material ................................................................................................................. 64

10.1. Solar Raw Material List ................................................................................................ 64

10.2. Solar Cell Price Reference .......................................................................................... 64

10.3. Back Sheet Price Reference ....................................................................................... 64

10.4. Solar EVA Price Reference.......................................................................................... 64

11. Contact Us ............................................................................................................................... 65

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 4 of 65 -

1. Project Name:Crystalline Solar Panel Encapsulation Line

1.1. Project Capacity: Customized 5MW 10MW 20MW 50MW 100MW

1.2. Solar Panel Production Process

(Process flow chart can be adjusted as the actual ones.)

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 5 of 65 -

2. Production Process General Explanation

2.1. Main Equipment

Unit Name Machine Picture Working Content Remark

Solar Cell Tester

Test the solar cell IV features.

Solar Cell Laser

Cutting Machine

Cut the solar cell into small pieces. If produced the small

solar panel below 100w, it will need this machine.

EVA/TPT cutting

machine

Cutting EVA / TPT into the desired size according to the design

Manual Lay Up unit

Complete the EVA/TPT layup and bus-bar welding Lay up the glass, EVA,String

cell, EVA,TPT into the worktable cell strings arranged by drawing, and the two leads of each battery string entire series into a circuit, and fixed.

Open the multimeter can get the current

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 6 of 65 -

Visual Inspection

Visual inspect the dirts for the materials by the mirrors

Solar panel laminator

Laminate the TPT EVA, soar cell, glass together

EL Defect

Tester

uses electroluminescence (EL) phenomena for identifying

micro-cracks,broken finger wires and other invisible defects in solar modules.

Frame machine

Complete component frame riveting

Glue up

Fill the adhesive to aluminum alloy before framing and after framing

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 7 of 65 -

Outlet box processing

Complete the installation process of adapter here

Solar Panel Tester

Electrical performance test

like power, current etc and record and divided into different class

Label Unit

The test finished module are identified by label.

Withstand Voltage

Insulation Meter

Test the panel withstand voltage insulation

Cleaning unit

Complete the component of the surface cleaning

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 8 of 65 -

2.2. 5MW Crystal solar panel Equipment List

S/N Description QTY Remark

1 Semi Auto laminator 1

2 Solar Cell Laser Cutting Machine 1

3 Solar Cell Tester 1

4 Solar Panel Tester 1

5 Solar Panel EL Defect Tester 1 optional

6 Semi Automatic Solar Panel Framing Machine 1

7 PV ribbon cutting machine 1 optional

8 Welding Station 4

9 Lay up station 2

10 Manual EVA/TPT cutter 1

11 Inspection Station 1

12 work table 6 optional

13 Glass/Module Carrier 4

14 Ready material Carrier 4

15 String Cell Carrier 4

16 Solar Cell Carrier 2 optional

17 EVA/TPT Carrier 1

18 String Tray 20

19 150W Lead Free Soldering Station(Electric iron) 16 optional

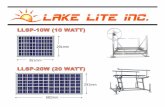

2.3. 10MW Crystal solar panel Equipment List

S/N Description QTY Remark

1 Semi Auto laminator 2

Or Full Auto laminator 1

2 Solar Cell Laser Cutting Machine 1

3 Solar Cell Tester 1

4 Solar Panel Tester 1

5 Solar Panel EL Defect Tester 1 optional

6 Semi Automatic Solar Panel Framing Machine 1

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 9 of 65 -

7 PV ribbon cutting machine 1 optional

8 Welding Station 8

9 Lay up station 2

10 Manual EVA/TPT cutter 1

11 Inspection Station 1

12 work table 6 optional

13 Glass/Module Carrier 8

14 Ready material carrier 10

15 String Cell Carrier 8

16 Solar Cell Carrier 2 optional

17 EVA/TPT Carrier 2

18 String Tray 8

19 150W Lead Free Soldering Station(Electric iron) 28 optional

2.4. 20MW 30MW 50MW 100MW Crystal Solar Panel Equipment List

Welcome to contact via Email:[email protected]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 10 of 65 -

3. Production Machine Catalogue

3.1. Solar Panel Laminator

Semi-Automatic Solar Panel Laminator

Single Full Automatic Solar Panel Laminator

Parameter Laminated

Size Outline Size

(MM) NW (T)

Power (KW) Pump Annual Output

Model Max Working Speed

Semi-automatic solar panel laminator

OCY2211

2200×1100 2560×1460

×1270 3.2 27 4.4-17.3 30 L/S 2.4MW 1 PCS of

module (156 cell 72 pcs)

OCY2222

2200×2200 2560×2830

×1270 4.8 33 6~19 30 L/S 4.8MW 2 PCS of

module (156 cell 72 pcs)

Single full automatic solar panel laminator

OCY3622

3600×2200

13000×3200 ×1800

10 73 32 70 L/S 9.6MW 3 PCS of module

(156 cell 72 pcs)

4 PCS of module

(156 cell 60 pcs)

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 11 of 65 -

3.1.1. Semiautomatic Solar Panel Laminator

[ Technical Parameter ]

Parameter

Laminated Size Outline Size

(MM) NW (T)

Power (KW) Pump Annual Output

Model Max Working Speed

OCY2211 2200×1100

1 PCS of module

(156 cell 72 pcs)

2560×1460 ×1270

3.2 27 4.4-17.3 30 L/S 2.4MW

OCY2222 2200×2200

2 PCS of module

(156 cell 72 pcs)

2560×2830

×1270 4.8 33 6~19 30 L/S 4.8MW

Heating Mode Oil Heating Power Supply AC380V Triphase

five Wires

Control mode: manual/ automatic Working Vacuum 100mpa

Laminating Time 6-8mins (excluding

curing time) Temperature

Control

Intelligent PID Temperature

Control

Temperature Precision

±2℃ Environmental Temperature

0℃-50℃

Temperature Range 30℃-180℃ Temperature Uniformity

±2℃

Module Height 25mm Air Supply required 0.6-0.8MPa

Vacuuming time 2-6Min Compressed air

flow required 50L/Min

[ Machine Function ]

The solar panel laminator is most important process in the solar panel production line.

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 12 of 65 -

It use to bond multiple layers of materials (EVA, Glass, Backsheet, Solar cell) together by

heating vacuum in laminator chamber.

[ Performance features ]

1. Intelligent temperature control system,

Make the temperature more uniform and more easily set and control the temperature.

2.Laminating pressure adjustable

Can adjust the pressure accord to the production process requirement, makes good quality

solar panel.

3. 24 hours continuous working in high temperature.

4. The advanced touch screen operation panel

Easy operation, quickly respond, more stable performance and reduce the failure rate.

5. Humanity system operation process

The equipment is equipped with many detection switches. In the normal production,

operators will only be required to put the modules on the heating platform and press the

cover switch.

The equipment will be automatically laminating, cure and open cover automatically and wait

for operator to start the next procedure.

[ Safety assurance ]

1. With hydraulic safety lock

Equipment accident power off or open cover in a position, the cover will automatically lock in

the current position, not falling. Ensure the safety of operator.

2. Set the emergency button switch

When unexpected emergence happen,press the emergency button, the machine will cut off

the working power supply, the cover will remain the old position. Ensure remove the

accidents and working process.

3. The alarm system:

The machine install 8 sets alarm device, it will alarm in the following situation, ensure the

accuracy and normal working state, improve quality.

Oil shortage

Heating over temperature

Vacuuming fault

Open cover in under pressure situation

Vacuum pump fault

Heating fault

temperature measurement module fault

Illegal operation

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 13 of 65 -

4. With emergency open cover device

When falling power off accidentn,it can open the cover to remove the components for

processing.

5. Low voltage control in the equipment control circuit

Easy for charged repair, and improve the safety.

[ Structure features ]

1. The steering structure of touch screen.

Leading technology, pretty appearance, compact structure, and convenient operation.

2. The seal ring is placed overhead to extend the service life.

3. Power arm balancing and lifting structure makes the opening and closing of

upper room more stable and safer.

4. Anti-fold structure of the rubber plate could extend the service life of the

rubber plate.

5. Use finishing thick steel plate as heating platform. In the lower part of this

platform a full closed oil circulation system is adopted which ensures the

uniformity and controllability of temperature when packaging the components.

[ Application features ]

It can be one-time laminating and curing and three times laminating and curing

are workable. The equipment of module production has high compatibility.

[ Main Parts ]

1.PLC: Japan Imported Mitsubishi brand

2. Electric parts:Schneider

3. Touch Screen:Kunlun-state 10-inch

4. AirTAC cylinders

5. Vacuum Pressure Switch: Japan brand SMC

6. Vacuum Pump: China famous brand Sichuan Huaxin

[ Main Parts Picture ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 14 of 65 -

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 15 of 65 -

[ Machine More Picture ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 16 of 65 -

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 17 of 65 -

3.1.2. Single Full Automatic Laminator

(Bottom Temperature Cloth automatically recycled moves)

[ Technical Parameters ]

Parameter Laminated

Size

Outline Size (M)

NW (T)

Power (KW) Vacuum Pump Annual

Output Model Max Working

Speed

(L/S)

OCY3622

3600×2200

12.2×3.24

×1.8M 10 73 32 70 9.6MW 3 PCS of

module (156 cell 72 pcs)

4 PCS of module

(156 cell 60 pcs)

Operate Mode Manual/Full

Automatic Heating Mode Oil Heating

Lamination area 3600×2200mm Power Supply AC380V

Three phase five Wires

Laminate Height 25mm Temperature

Control Intelligent PID

Temperature Control

Laminating Time

4-8Minutes

(Including the solidify

time )

Temperature Uniformity

±2℃

Temperature Precision

±2℃ Vacuum time 2~6Min

Temperature Range

30℃-180℃ Vacuum Degree 20-200Pa

Air Supply 0.6~0.8MPa Compressed air 400L /Min

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 18 of 65 -

flow required

[ Main Parts ]

1.PLC:Germany SIMENS

2. Electric parts: Schneider

3. Touch Screen:Kunlun-state 10-inch

4. Cylinders:AirTAC

5. Vacuum Pressure Switch: Japan brand SMC

6. Vacuum Pump: China famous brand Sichuan Huaxin

[ Security guarantees Features ]

1.With hydraulic safety lock

Equipment accident power off or open cover in a position, the cover will automatically lock in

the current position, not falling. Ensure the safety of operator.

2.Set the emergency button switch

When unexpected emergence happen,press the emergency button, the machine will cut off

the working power supply, the cover will remain the old position. Ensure remove the accidents

and working process.

3.The alarm system:

The machine install 8 sets alarm device, it will alarm in the following situation, ensure the

accuracy and normal working state, improve quality.

Oil shortage

Heating over temperature

Vacuuming fault

Open cover in under pressure situation

Vacuum pump fault

Heating fault

temperature measurement module fault

Illegal operation

4.With emergency open cover device

When falling power off accidentn,it can open the cover to remove the components for

processing.

5.low voltage control in the equipment control circuit

Easy for charged repair, and improve the safety.

6.With photoelectric switch and safety grating, improve the staff's safety and reduce the

failure rate.

[ Structure Features ]

Major Structure :Loading + Laminating + Unloading+ Vacuum Pump+ Heating Station

1. Loading Section

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 19 of 65 -

It adopts rubber conveyor belt, speed motor drive, frequency converters control speed,

The operator also can set inching distance by pressing the button.

2. Laminating Section

The heating plate with double-face milling is perforation plate. The planeness can

reach to ± 250um/ ㎡ . It adopts heating transfer oil circulation system. The

temperature uniformity can reach to ± 1.5℃.

use chain transmission, speed motor drive, frequency converters control,

photoelectric switch position.

Mechanical lock the cover when upper cover lift in a position,it can ensure the safety

operation.

3. Unloading Section

It adopts the stainless steel roll shaft transmission. The roll shaft is drive by speed cut

motor, photoelectrical sensor install at the end of unloading section to protect modules

from sliding down. Cooling fans can be installed under the roll shafts.

4. Vacuum System

The vacuum valve sensors are all adopt imported components. Ultimate vacuum

realizes 30Pa. Vacuum chamber could fast achieve below 120Pa from atmospheric

conditions within 120 seconds.

5. Control System

Control Mode:Operation of semi-auto, auto and manual. It may realize module in

and out and laminate automatically or manually.

Integrated Control Technology:

Integrate vacuum technology, pneumatic transmission technology, PID self-tuning

technology, programmable control and relay control system into one, which can

meet complicated technological requirement of laminating and solidifying

mono crystalline and polycrystalline silicon modules

This system could record the characteristic curves of major parameters, such as

the vacuum degree and the heating plate temperature.

The chain transmission structure can realize the module in-out automatically.

It adopts SIEMENS PLC to connect with computer which meets the requirement of

modern industrial automation control.

There are independent control buttons on loading and unloading sections to make

modules in-out easily. The operator also can set inching distance by pressing the

button.

The operation platform adopts high quality and sensitive touch screen with friendly

interface and convenient operation. Various technical parameters which are

showing on one window are easy to understand and monitor. Also on touch screen,

it can store many different recipes for production reference.

Automatic memory function of technical parameters could record main operation

process, provide data for module quality analysis. The system with laminated

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 20 of 65 -

times statistical function is convenient for checking working times and output of

modules. It also can be regarded as reference for maintaining and replacing the

consumable spare parts.

Upper and lower vacuum venting manually, when power off accidentally, upper

cover can be open by manual.

[ Performance characteristics ]

1. Intelligent temperature control system,

Make the temperature more uniform and more easily set and control the temperature.

2. Laminating pressure adjustable

Can adjust the pressure accord to the production process requirement, makes good quality

solar panel.

3. 24 hours continuous working in high temperature.

4. The advanced touch screen operation panel

Easy operation, quickly respond, more stable performance and reduce the failure rate.

6. Humanity system operation process

The machine is equipped with several detection switch, in normal production, the operator

only need to put the module component in heating platform, press close lid switch, the

device will automatically laminate, curing, automatically open, waiting for the next working

procedure.

7. Adopt fully humanized system operation process

The whole device is equipped with several detection switch, in normal production work, the

operator only put component input on the platform, press the input switch, the device will

automatically enter the component to a host of encapsulation, curing, automatically the

output to the specified location waiting for operator on to the next working procedure of

processing, and automatic work on to the next cycle.

[ Machine Picture ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 21 of 65 -

[ Package & Delievery ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 22 of 65 -

3.2. Solar Cell Laser Scribing Machine

3.2.1. Solar Cell Fiber Laser Scribing Machine

Model Number: OLS-20F

The Whole Set:

1) 1PCS Fiber laser scribing machine

2) 1PCS Exhaust Fan

3) 1PCS LCD display with Computer(Laser mark software installed)

Choose Different parts to get different price.

Configuration 1 Configuration 2

1. 20w China Raycus Fiber laser 2. Japan Servo motor 3. Import Linear Rail

4. 350*350mm XY Moving worktable

1. 20w China MAX Fiber laser 2. Leadshine stepper motor 3. Import Linear Rail

4. 350*350mm XY Moving worktable

[ Machine Function ]

scribing or cutting the Solar Cells and Silicon Wafers in solar PV industry, including the mono-si

(mono crystalline silicon) and poly-si (poly crystalline silicon)solar cells and silicon wafer.

[ Machine Features ]

1. Using the Germany IPG FIBER laser or China Raycus Fiber laser or Max fiber laser

service time over 100,000hours.

Stronger adaptability to enviroment

better beam quality and higher speed than Diode Pump and YAG Krypton type.

No need to replace the laser module and Krypton lamp.

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 23 of 65 -

2. Work table: X-Y movable

Solar cell can be automatic absoption

3. Air cooling, compact structure, small size

4. Higher conversion efficency,

lower operating cost, save power consumption, cost and shorter maintenance time;

5. Laser Pulse width is more narrow,

Higher peak power, faster scribing cutting speed

6.Long time uninterrupted continuous maintenance-free operation,

no consumable wearing parts to replace

7. Stepper motor or servo motor different cost.

[ Technical Parameters ]

Model OLS-10F OLS-20F

Laser wavelength 1064nm

Laser power 10W/20W

Scribing width 30μm

Scribing speed 160mm/s 200mm/s

Scribing accuracy ±10μm

Working area 350x350mm (13.8in*13.8in)

Temperature control precision 0.5°C

Working power 220V/50Hz/1kvA

Working table negative pressure absorbing and dust

elimination

Cooling method Forced air cooling

[ Main Parts ]

Fiber Laser Raycus brand or Max Brand

Laser Head

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 24 of 65 -

Linear Rails and motors Operate button

[ Application ]

[ Customer ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 25 of 65 -

3.2.2. Diode Pump Solar Cell Laser Scribing Machine

Model: OLS-50D

[ Function ]

scribing or cutting the Solar Cells and Silicon Wafers in solar PV industry, including the mono-si

(mono crystalline silicon) and poly-si (poly crystalline silicon)solar cells and silicon wafer.

[ Product Features ]

1. Using the Diode Side Pump or Semiconductor side pump laser

service time over 12,000hours.

better beam quality and higher speed than YAG Krypton type.

No need to replace the Krypton lamp

Technical Parameters

Model OLS-50D

Laser wavelength 1064nm

Laser power 50W

Scribing width 50μm

Scribing speed 120mm/s

Scribing accuracy ±10μm

Working area 350x350mm (13.8in*13.8in)

Temperature control precision 0.5°C

Working power 380V(220V)/50Hz/3kvA

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 26 of 65 -

Working table negative pressure absorbing and dust elimination

Cooling method Unified rotative homothermal water cooling

2. Import UK acousto optic modulator, high qualiy

3. Work table: X-Y movable

Solar cell can be automatic absoption, no need to use foot pedal 350*350mm size

4.Unified constant water chiller: stable and reliable for long period running

5. higher integration, better beam quality and higher speed, but lower processing

cost and shorter maintenance time;

6. no exterior connect

7. Easy to instal and move the equipment;

8. Improved and new generation machine, Updated 5.0 software;

[ Main Parts ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 27 of 65 -

[ Application ]

[ Different Side Picture ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 28 of 65 -

[ Customer ]

[Package]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 29 of 65 -

3.3. Solar Cell Tester

MODEL:OSCT-A MODEL:OSCT-B

[ Machine Function ]

Use to test the electrical performance of Mono-Si or Poly-Si solar cell pieces and record the

results in files.

[ Machine Features ]

Key components use import abroad brand

A grade spectrum

A grade unevenness degree of irradiance

four-line measurent,14-bit 4-channel high speed synchronous acquisition card

10 parameters display and Measurement Parameter displays in Tabulation and Graphic

way

Pneumatic and buffering contact

Temperature automatically compensating

Voice counts off and prompts, Counting prompt of flash times

24 continuous work

Import Xenon Lamp.

[ Technical Specification ]

MODEL OSCT-A OSCT-B

Lamp spectrum In line with iec60904-9 spectral Irradiance distribution requirement(AM1.5)

Light intensity 700-1200W/Mm2

continuous adjustable range

Light intensity non-uniformity ≤±2% 【A】 ≤±3%

Light intensity instability degree of irradiation(STI)

≤±0.5% 【A】 ≤±2% 【A】

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 30 of 65 -

Light intensity instability degree of irradiation(LTI)

≤±2% ≤±2%

Test results consistency ≤±0.5%【A】 ≤±1%

Single flash time 10ms 10ms

Effective test range 200×200mm /0.1W-5W

Measuring voltage 0-0.8V(resolution 1mV)

Measuring current 0-20A(resolution 1mA)

Test parameters Isc、Voc、Pmax、Vm、Im

FF、EFF、Temp、Rs、Rsh

Power supply AC220V/50HZ/2KVA

Air supply 0.5-0.8Mpa

Weight 160KGS 140KGS

Machine Dimension 800*600*1750mm 800*600*1850mm

[ Machine picture ]

[ Customer ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 31 of 65 -

3.4. Solar Panel Tester Solar Simulator

MODEL:OSMT-A MODEL:OSMT-B

[ Machine Function ]

Use to test the electric performance of Mono-Si or Poly-Si solar modules and record the

results in files.

[ Machine Features ]

four-line measurement,14-bit 4-channel high speed synchronous acquisition card

10 parameters display,Measurement Parameter displays in Tabulation and Graphic way

Temperature automatically compensating

Voice counts off and prompts, Counting prompt of flash times

24 continuous work

import Xenon lamp

[ Technical Features ]

MODEL OSMT-A OSMT-B

Lamp spectrum In line with iec60904-9 spectral Irradiance distribution requirement(AM1.5)

Light intensity 200m_1200W/M

2

continuous adjustable

Light intensity non-uniformity ≤±2% 【A】 ≤±3%

Light intensity instability degree of irradiation(STI)

≤±0.5% 【A】 ≤±2%

Light intensity instability degree

of irradiation(LTI) ≤±2% ≤±2%

Test results consistency ≤±0.5%【A】 ≤±1%

Single flash time 10ms~40ms 10ms

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 32 of 65 -

Effective test range 2000×1100mm /5W-300W

Measuring voltage 0-100V(resolution 1mV)

Measuring current 0-20A(resolution 1mA)

Power Supply AC220V/50HZ/2KVA

Test parameters Isc、Voc、Pmax、Vm、Im

FF、EFF、Temp、Rs、Rsh

Xenon Lamp service time 200,000flash times 100,000flash times

Weight 600kgs 500kgs

[ Factory Picture ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 33 of 65 -

3.5. EL Defect Tester

3.5.1. Electroluminescence Module Defect Tester Offline

[ Machine Function ]

Used in testing the solar module Crack,breakage,Black Spot,Mixed Wafers,Process

Defect,Cold Solder Joint phenomenon

[ Specification ]

Item OEL-S830 OEL-S1600

Capture Mode: Single Camera Single Camera

Run Mode: Offline

Monitor Point: After Laminating

Sample Stage: Super-white Tempered Glass

Sample Size: ≤2000mm*1100mm

Operation Height: 950mm

Camera Type: Cooled CCD

Resolution: 3032*2016 4928*3264

Exposure Time: 1 ~ 60s

Current/Voltage: 10A/60V

Software:

1.Interface for barcode scanning, naming files with barcode names; 2.Defect classification, create image folder and save image

files automatically.

Detection Ability: Crack,Black Spot,Mixed Wafers,Process Defect,Cold

Solder Joint.

Configuration Testing host,computer,software

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 34 of 65 -

[ Machine Advantage ]

Reveals invisible defects such as microcracks, breakage,finger defects, and dark

areas

Improves line yield by identifying defective modules before lamination

Improves quality and reliability of final product

Highest available resolution

Flexible system can be used to test framed or unframed modules, before or after

lamination

[ Judging defect classification ]

Welding spots

Crack Current not

match Cell Process

defect Virtual

welding Cell

contaminate

OK OK OK OK OK OK

[ Machine More Pictures ]

Machine Picture Machine picture

Camero Control Box

We use CCD Camero CCD chips imported

Not SLR camera Japan camera lens

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 35 of 65 -

Japan brand SMC air cylinder Glass with round hold easy to install.

Top Brand Power Supply

Single CCD Camero 830w Effect

Double CCD Camero 830W Effect

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 36 of 65 -

[ Equipment packing list ]

Dark Room:1

12mm Toughened glass:1

Optical mirror:1

Power Supply:1

Computer: 1

Application software:1

Operation manual:1

Camera: 1 or 2

Electric cabinet: 1

Barcode scanner: 1

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 37 of 65 -

3.5.2. Full Automatic EL Defect Tester

(830w) (1600w)

[ Machine Function ] Used in testing the solar module Crack,breakage,Black Spot,Mixed Wafers,Process

Defect,Cold Solder Joint phenomenon

[ Technical Specification ]

Item OEL-F830 OEL-F1600

Camera Specification

Camero: KADAK Image sensor: CCD

pixel: 830W Resolution 3584*2574mm Image sensor size : 17.96mm*13.52mm Pixel Size: 5.4um*5.4um

Double refrigeration cooling system (inner + outer) camera lens:sony

Camero: Nikon

Image sensor: CMOS Pixel:1620W Resolution: 4928*3264 Image sensor size: 23.6mm*15.6mm

Pixel Size :4.76um*4.76um Shooting download time : 1500ms

Run Mode: online

Monitor Point: Before or After Laminating

Sample Size: ≤2150mm*1150mm

Operation

Height: 950mm

Resolution: 830W 1600W

Test Scope

Test Size 2150X1150mm

Voltage:46—48V

Current:7—8A

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 38 of 65 -

Test environment temperature:-20℃—40℃

Exposure Time: 1 ~ 60s

Test parameter Target、Gain、Time、Gamma、Contrast、Data wide

Current/Voltage

: 10A/60V

Loading system:

Using for transporting module Module will be located on this station

EL Test system Reflection

Unloading system

For transfer of module after test.

Software: 1.Interface for barcode scanning, naming files with barcode names; 2.Defect classification, create image folder and save image files automatically.

Detection

Ability: Crack,Black Spot,Mixed Wafers,Process Defect,Cold Solder Joint.

Configuration Testing host, loading, unloading system,computer, software

Machine Size: Host:2900*1900*1680MM 3300*1900*1250mm

830W CCD Type imaging results equivalent to 1600W CMOS 830W CCD is more clear 1600W CMOS faster speed.

[ Machine Size ]

Size (mm) Weight (KG)

Uploading system 1610*1680*950 150

Test system 2900*1900*1680(830w) 3300*1900*1250(1600w)

600

Unloading system 1610*1680*950 150

[ Machine Advantage ]

Reveals invisible defects such as microcracks, breakage,finger defects, and dark areas Improves line yield by identifying defective modules before lamination Improves quality and reliability of final product

Highest available resolution Flexible system can be used to test framed or unframed modules, before or after lamination

[ Judging defect classification ]

Welding spots

Crack Current not

match Cell Process

defect Virtual

welding Cell

contaminate

OK OK OK OK OK OK

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 39 of 65 -

[ Machine More Pictures ]

Machine Picture Machine picture

Japan Motor Control Box

CCD Camero

CCD chips imported Japan camera lens

Japan brand SMC air cylinder Top Brand Power Supply

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 40 of 65 -

Single CCD Camero 830w Effect

Double CCD Camera 830W Effect

[ Equipment packing list ] Dark Room:1

Power Supply:1

Computer: 1 Application software:1 Operation manual:1

Camera: 1 or 2

Electric cabinet: 1

Barcode scanner: 1

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 41 of 65 -

3.6. Solar Panel Framing Machine

Minimum Max

Framing size 400×400MM 2000×1000MM

[ Specification ]

1. Air cylinder : Airtac Brand

2. solenoid valve: Airtac Brand

3. high-pressure air tube: South Korea imported

4. Maximum framing size: 2000 * 1000mm

5. Minimum framing size: 400 * 400 mm

6. Operating voltage: 220V/50Hz/1Ph

7. Dimensions: 2900 * 1650 * 920mm

[ Features ]

use the air cylinder and steel structure construction,

achieved Aluminum frame extrusion positioning when the module laminated

easy to fixed, fastened the aluminum frame, save time and improve product quality.

with the rotary wheels, may guarantee the module in each direction freedom, and protects

module's surface, operation nimble convenient.

composed of the bidirectional fixed end and the bidirectional activity, may suit for the

module in the wide scope to install the frame to make industry the need, in addition may

satisfy some non-standard packages to enter the luggage frame's work demand.

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 42 of 65 -

[ Machine Picture ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 43 of 65 -

3.7. PV Ribbon Cutting Machine

[ Machine Function ]

The product is designed for the cutting of solar photovoltaic welding strip, mainly used for PV

ribbon, wire, copper, tin and other metal films or other strip materials, featuring high precision

and speed, convenient operation, low operation noise, and exquisite appearance.

Technical Parameter

Model: C350-SL

Power Supply: AC220V 120W

Dimensions: (L) 350 × (W) 250 × (H) 320 (mm)

Weight: 32.0KG

Number of strip processed:1-10PCS

Cutting length: 0.1-999.9 mm

Cutting width :1.0-10.0 mm

Cutting thickness: 0.10-0.40 mm

Cutting accuracy: L × 0.002

Cutting speed: L = 200m, 700PCS/min

Information storage: 10(at the same time cutting 10 pcs, cutting 200 mm long, 70 times a

minute, 700 PCS per minute)

Material: tin plated copper belt or other strip material

[ Machine More Picture ]

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 44 of 65 -

3.8. Manual Soldering station

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 45 of 65 -

[ Main parameter ]

Outer Dimension: 2.2×1.2×1.85M

Three work-place: one series welding , two single welding

Optional:Welding line: 1.2(width)×1.84(high)×length

No conveyor belt

With constant temperature heating and a 125 welding template,156 template.

Features: Used in a variety of single and string welding

Device weight: 331Kg

Application temperature: 40℃~100℃

[ Features ]

The high-quality carbon fiber heating and heating speed is quick, can use a long time.

PID temperature control, the temperature is uniformly and adjust arbitrarily.

Each work controls independent and the craft is strong.

Light illuminate, button indicate is easy to operate.

Safety power supply system, comprehensive efficiency is well.

Provide with 125 or 156 two kinds of welding template.

Remarks: We can make each kind of different specification according to the customer’s need.

3.9. Manual EVA/TPT Cutting Station

Model: Aluminium

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 46 of 65 -

[ Main parameter ]

Dimension: 3000*1200*800mm

1.with scale ruler

2.Support EVA TPT use of sliding bearings

[ Features ]

Good flexibility, and could be cut alternately or at the same time

The whole plastic coating is milky white, the structure is solid, the work surface is good.

The plate is compression plate, the plate surface have the graduation, easy to use when

the reduction of size.

EVA TPT use of sliding bearings support , flexibility, in the middle with positioning devices

with cutting EVA TPT.

Remarks:

If customers have special requirements for equipments, welcome negotiations by visiting or

sending a letter.

3.10. Visual Inspection Station

[ Main parameter ]

Aluminum Material Structure: 3000*1200*800mm

1.Check the detection of laminated cells is impurities and make sure no breakage

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 47 of 65 -

2.The angle of the mirror can adjust.

3.With specular reflection, can easily and quickly find the detect of the cells

3.11. Lay-up Station

Material:Aluminum Molding

Dimension:2000*1080*850mm

[ Features ]

1. 8 PCS halogen lamp

2. 4 PCS fluorescent

3. 1PCS ammeter

4. 1 voltmeter

5. working surface with tempered glass.

The overall spray the varnish, This can enhance the gathering the light

The bottom install fire-proof plate and has common economy energy floodlight, iodine

Wu light test.

The whole operation is convenient, by the conversion button, can test module electric

current electric voltage(the number type electric voltage electric current the watch Be easy

to read a number).

Have a armored glass.

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 48 of 65 -

The electric current voltage could converse automatically (New technology)

Remarks: If customers have special requirements for equipments, welcome negotiations by

visiting or sending a letter.

3.12. Solar Module Carrier

Steel Structure

Dimension: 1.6×1.0×1.1M

[ Features ]

It can put up 20 PCS 160 Watt solar module in one time .

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 49 of 65 -

With a Rubber pad to speerate module and steel structure, avoide rowing of module

wound and touch damage etc. unexpected situations.

With cardan rolling wheels,heels can rotary flexible,make sure that the trolley arrive the

appointed place.

can be locked in a position,avoide the accident by its proper motion action.

3.13. Ready Material Carrier

The steel products welding and the gum cover is join assembly

[ Main parameter ]

Outer Dimension: 1.2×1.05×1.5M (10Layer )

[ Device characteristics ]

1.Modules does not slide in the elastic deformation of steel。

2. The design of the tote cart base is reasonable,to ensure full of modules does not shake, do

not tilt, and do not tip over。

3.It can be place 10 sets of 1.2 ×1.17 M of module at the same the time.

4.Place module bracket to all have a gum set to partition module and steel structure, avoided

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 50 of 65 -

rowing of module wound and touch Sun etc. surprised circumstance.

5.The lower part has cardan rolling wheels ,and the wheels can rotary flexible,it can make sure

that the tote cart arrive the appointed place smoothly.

6.It can be locked in a position after arriving appointed position and so it promise that it can

avoide the accident loss by its proper motion action.

Remarks:We can make each kind of different specification according to the customer request

of product.

3.14. String Cell Carrier

Function:used in string of welded box Turnover.

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 51 of 65 -

Size: 1600 * 800 * 1300mm

Stainless steel materials, 10 layers *2 side, Total put 20 layers

universal wheels: yes

All welding argon arc welding, after welding Sand, there will not be affect beautiful

3.15. EVA/TPT Carrier

3 Layers

Steel Material and surface with Plastic coating treatment

Size:1.2×1.0×1.3M

With High quality wood board

Remarks:We can make each kind of different specification according to the customer request

of product.

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 52 of 65 -

3.16. Working Table

3.16.1. Solar Cell Sorting Worktable

1. Size:1200*700*1300 mm,One Workpiece,Aluminum Chassis

2. 20mm High density fiber board, Green Surface With Anti-static rubber

3.30w Lighter

3.16.2. Trimming Worktable

Aluminum structure

Size: 2000×1100×900 mm

3.16.3. Glue up/Cleaning/Juction box/Package Worktable

Aluminum structure

Size: 2000×1100×800 mm

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 53 of 65 -

3.17 Solar Cell Stroage Station

The steel structure, the high temperature bears the clamp,accept the treatment of spray paint

plastic.

Outer Dimension:1.7×0.67×1.32M

Device characteristics):

It's easy to storage the battery ,and it is hard to be contact damage .

Remarks:We can make each kind of different specification according to the customer request

of product

3.18. String welding template

3.18.1. 125 string welding template

Size:1600*180*10mm

Aluminum Material,Rivet steel die ,durable,surface oxidized

3.18.2. 156 string welding template

Size1950*180*10mm

Aluminum Material,Rivet steel die ,durable,surface oxidized

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 54 of 65 -

4. Working Picture

4.1. Single Welding and String Welding

(Single Weld) (String Welding)

4.2. Layup

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 55 of 65 -

4.3. Visual inspection

4.4. Solar panel laminator

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 56 of 65 -

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 57 of 65 -

4.5. Framming

4.6 Glue UP the Aluminum frame

4.7 Glue up the junction box

4.8 Clean the Solar panel

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 58 of 65 -

5. Factory Layout

5.1. Semi auto production line

5.2. Full auto production line

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 59 of 65 -

6. Factory Building Requirement:

[Factory Requirement]

Size: 800 to 1500 m2

Door: At least 4000mm, for the laminator enter in and out.

Floors: hardened ground, Better with epoxy flooring

Total supply: 380V 200A

Air source: 0.7 ~ 0.9m3/min 0.8 ~ 1.0MPa central gas tank

Water: No requirements

Fire: layout requirements in accordance with local fire

Air Conditioning: workshop with central air conditioning, EVA / Cell warehouse equipped with

Constant temperature air conditioning.

Exhaust pipe: vacuum laminating machine need place for exhaust pipes

Plant construction requirements:

(1) the indoor light intensity, temperature, humidity, atmospheric pressure, venting

facility should be able to reach the general assembly of electronic products plant

requirements.

(2) cells, EVA, TPT repository temperature of 25 ℃ ± 2 ℃.

(3) cell scribing, cell sorting, welding; layup, laminated work area need the general purification

plant, and room temperature should be 25 ℃ -30 ℃.

(4) cells sorting and solar panel test station room temperature should be 25 ℃ ± 2 ℃.

According to the above requirements,need to build different room: raw materials warehouse,

ready to plant workshop, solar panel production line (clean room), solar panel repair

room (clean room), finished products room and other accessories.

7. Our Customer

Company Country or region

VJ SOLAR * * India

SUNUSA *** India

Surana *** India

Cosmic Sense *** Germany

United States Green Energy *** USA

EBTICAR SOLAR *** Egypt

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 60 of 65 -

8. Machine Working Video

Follow website could find our machine video:

1. Semi Automatic Laminator operation

http://youtu.be/lponA8bofgE

2. diode laser scribing & break off

http://youtu.be/elcPmuLWgEU

http://youtu.be/m3G6U7SLa58

3. fiber laser scribing machine

http://youtu.be/UjbIkidom0M

4. solar cell tester

http://youtu.be/0-625AHKe_Y

5. EL tester

http://youtu.be/cz3h1jCSjzg

6. online EL

http://youtu.be/TIrJVRfP8MI

7. Solar panel tester and solar simulator

http://youtu.be/FPClazaXuiA

8. Solar panel framing machine

http://youtu.be/_brzdHeMOl8

9. Glass washing machine:

http://youtu.be/hxLgjevSCjs

10. PV Ribbon cutting machine

http://youtu.be/wfs_Z-Fa0JY

11.solar panel making machine-single solar cell welding video

http://youtu.be/ecS-_M51tj0

12. solar panel making machine solar cell String welding

http://youtu.be/OjxBlFOxd7w

13. solar cell lay up and visual inspection

http://youtu.be/v_CfifB0HNg

http://youtu.be/9v0YCJIhZlg

14.Framing and gluing

http://youtu.be/EfDDiD58jJc

http://youtu.be/d6FWAR3zfxY

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 61 of 65 -

9. Company

Wuhan Science and Technology Bureau to our company guide to inspect technological innovation projects.

Wuhan RD Center

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 62 of 65 -

Wuxi Factory

Guide customer visit china solar panel factory

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 63 of 65 -

Certificate

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 64 of 65 -

10. Solar Raw Material

10.1. Solar Raw Material List

Solar Cell

Backsheet

EVA

Low Iron solar Tempera Glass

Junction box

Frame, junction box PV Module sealant

Interconnected Solder Strip

Bus-bar Solder Strip

Aluminum frame and corner

3M adhesive tape

Soldering Flux

10.2. Solar Cell Price Reference

Item High Low Average AvgChg AvgChg %

Multi Cell Price Per Watt 0.44 0.30 0.324 -0.001 -0.31%

156 mm Multi Solar Cell 1.98 1.23 1.381 -0.004 -0.29%

156 mm Mono Solar Cell 2.65 1.66 1.857 -0.01 -0.54%

125 mm Mono Solar Cell 1.61 0.97 1.116 -0.006 -0.53%

Taiwan Poly Cell Per Watt 0.42 0.30 0.324 -0.001 -0.31%

Non (TW or CN) Poly Cell Per Watt Visit here for more detail Cell price information

Unit: USD more Last Update: 2014-12-10

10.3. Back Sheet Price Reference

Company Name Model Total

Thickness Outer(Air)

Layer Mid

Layer Inner(Cell)

Layer Reference

Price

Hangzhou Ventura Photov...

TPT 280±20 PTFE PET PTFE $4.86/m2

UMTechnologies HF-300 300±10 Coating PET Coating $5.18/m2

10.4. Solar EVA Price Reference

Company Name Model Type Thickness Tensile Strengt

h

Light Transmitt

ance

Reference Price

Jiangsu Sveck New Material

SV-15296 Fast Cure 0.3 ~ 1 mm 18.6 MPa

≥91 % $1.44/m2

Hangzhou Fumao PV Material

FM906 Fast Cure 0.2 ~ 1 mm 18 MPa ≥91 % $1.49/m2

Baixing Group B601 Fast Cure -- 26 MPa ≥91 % $1.54/m2

WUHAN OOI PHOTOELECTRIC TECHNOLOGY CO.,LTD

- page 65 of 65 -

Jiangsu Sveck New Material

SV-15290

Standard Cure

0.3 ~ 1 mm 18.6 MPa

≥91 % $1.44/m2

Hangzhou Fumao PV Material

FM906P Fast Cure 0.2 ~ 1 mm 18 MPa ≥91 % $1.54/m2

11. Contact Us

Start to Work with OOITECH,

Built Beautiful Future

contact Margret Cao

Wuhan Ooi Photoelectric Technology Co.,Ltd

Email: [email protected]

Website:http://www.ooitech.com

Mobile: +8618571645990 +8613554255933

TEL: +86-27-81779060 (F)

Skype: margret200789

Wechat: margret2009

WhatsApp: +8618571645990

Address: Buliding 2 NO.13 Yangqiaohu Road, East

Lake High-tech Development Zone, Wuhan of China.