oo top - intel-trade.hr

Transcript of oo top - intel-trade.hr

501

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

Cooling capacity: 21 to 85 kWHeating capacity: 21 to 89 kW

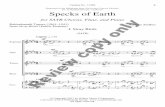

ROOF TOP SPACE PF units are compact, horizontal and autonomous air-to-air packaged units, designed for outdoor installation. They are equipped with propeller fans and EC electronic plug fans, air coils, tandem hermetic scroll compressors and electronic microprocessor control, with components optimised to run with R410A refrigerant.

These units are designed for air conditioning large commercial or industrial premises. They can be quickly installed and function reliably. The broad range of options means that most operating requirements can be met.Each unit is tested and trialled in the factory.

Space RPF seriesCompact, horizontal air-to-air roof top refrigeration units.

Space IPF seriesCompact, horizontal reversible air-to-air roof top heat pumps.

(1) With condensation pressure monitoring activated, operation down to -10ºC.

(2) If the outdoor temperature is periodically less than 5ºC WB, it is recommended that an auxiliary heater is installed.

Description

series

range

operating limits

Class A EER and COP in HEE version as per UNE-EN-14511-2013More sizes availablePlug fan with HEE EC motor and tandem compressors as standard

Air intake conditions Refrigeration Heating

Indoor coil

Minimum 14ºC WB 10ºCMaximum 22ºC WB 27ºC

Outdoor coil

Minimum 12ºC (1) -12ºC WB (2)Maximum 48ºC 15ºC WB

1 refrigerating circuit 2 compressors

90T 120T 160T 180T90HEE 120HEE 160HEE 180HEE

2 refrigerating circuits 4 compressors

-- 240T 320T 360T200HEE 240HEE 320HEE 360HEE

Cooling only

Heat recovery

410A

Air filtration Free cooling DehumidificationCooling and heating

HEE version

502 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE PF 90 - 360

Casing■ Casing made of galvanised sheet steel panels with polyester

paint in RAL 7035 white. Thermal insulation (9 mm thick), with M1 fire classification as standard.

■ Free-standing frame and access panels for the electrical cabinet, compressors, fans, etc.

Outdoor circuit■ EC electronic propeller fan(s) which adapt their rotation

speed to the installation's requirements, thereby reducing consumption of electricity and the sound level at partial load, and improving the unit's average seasonal efficiency.

■ Copper tube coil and aluminium blades.

Indoor circuit■ EC supply air plug fans with variable speed

control and flow rate controller. In tertiary sector installations, a high percentage of the annual air conditioning energy consumption comes from the use of fans for transporting air. Using fans which are more efficient has a direct impact on reducing consumption. EC plug fans with direct drive and variable speed offer the following advantages:- Elimination of friction losses during transmission thanks to the

direct drive, with no belts requiring maintenance.- Greater aeraulic efficiency of the fans (reactive blades with an

optimised profile), running at very high operating pressures.- Greatly increased motor efficiency. Permanent magnet EC

motors activated using electronic switching integrated into the motor itself (improvement on the IE3 motor).

- Variable speed to ensure a constant supply air flow rate, independent of the filter fouling level and which is able to adapt to pressure drops in the network.

- Electronic variable speed control with very low consumption compared to a conventional frequency inverter. The efficiency of the motor remains high at both high and low air flows

- Measuring the flow rate through a calibrated section at the fan intake and a differential pressure sensor allows the control to handle the flow rate reliably and precisely in both CAV and VAV systems.

- The soft start of the fan is adapted for textile ducts and limits the starting current.

- With constant air volume, management of 3 different setpoints for flow rate (hot, cold, neutral).

- With variable air volume and with the tandem option, there is a reduction in air flow at partial load.

■ Reusable air filters, mounted in a frame.■ Copper tube coil and aluminium blades.■ Condensate drain pan.■ Thermostatic expansion valve with external equaliser.

Refrigerating circuit■ Tandem hermetic scroll compressors

which improve the management of stages and comfort and the unit's energy efficiency under partial loads. Reduction in defrost cycles. Fitted on anti-vibration mounts. Direction of rotation and phase balance control.

■ Crankcase heaters.■ Four-way reversal valve (heat pump units).■ Acid-resistant filter dryer(s).

- Architecture of refrigerating section:

• 1 air volume: models 90 to 180 • 2 air volumes: models 200 to

360 (alternating defrost).

Plug fans with EC motor

Optional MO thermal and acoustic insulation

Intelligent defrosting of outdoor coils

EC electronic propeller fans with a low sound level

Assemblies with mixing boxes and free cooling management

High efficiency refrigerating circuits for R410A

Indoor air quality is achieved through combinations of gravimetric and opacimetric filters

Option of refrigerating recovery, adapted for air change requirements (high EER and COP)

Comfort/heating options: electrical heaters, hot water coil, gas burner...

Unit components

ExcEEdsErP 2015

503

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

Protections■ High and low pressure switches.■ Compressor discharge temperature control. ■ Check valve integrated into the compressor discharge.■ Main door switch.■ Thermal-magnetic protection for the compressor and fan

motor supply line.■ Automatic switch for the control circuit.

Electrical cabinet■ Complete electrical cabinet, fully wired. Insulated vertical

unit cover to prevent condensation. IP55 protection.■ Mechanical ventilation controlled by the electrical cabinet to

regulate the temperature and protect the components.■ Transformer for power supply without neutral.■ Main earth connection.■ Compressor and fan motor switches.

CIATrtc electronic controlThe CIATrtc control consists of a µPC MEDIUM control board, a pGD1 terminal (local control console) for maintenance and system start-up, and sensors.The control board uses an RS485 field-bus to manage additional components.A communication card (optional) allows the control board to be connected to a centralised management system (CMS).It also manages the local connection between units on a pLAN network (μPC MEDIUM Local Area Network), allowing data and information to be exchanged between the units, for a maximum of 15 units.

Main functions:■ Operating mode selection: COOLING/HEATING.■ Setpoint selection.■ Continuous monitoring of operating parameters.■ Display of values measured by the sensors.■ Compressor time delays.■ Antifreeze protection (heat pump units).■ All-season operation using evaporation and condensation

pressure monitoring.■ Control of the supply air temperature.■ Setpoint compensation based on the outdoor temperature.■ Hourly and weekly time schedule.

■ Fire protection.■ Diagnostic of faults and general alarms.■ Electronic EC outdoor fans with variable speed control.■ EC supply air plug fans with CAV or VAV control.

Optional functions:This control is used to manage additional components, such as:■ External air damper for the renewal of fresh air according to

the temperature of the mixed air (constant) or the air quality sensor (variable).

■ Mixing box for thermal, enthalpic or thermo-enthalpic free cooling.

■ Refrigerating recovery circuit for the renewal of air.■ Auxiliary electric heater: two-stage with on/off control, or

single-stage with proportional control.■ Auxiliary hot water coil with three-way valve with proportional

control.■ Gas burner with proportional control.■ Humidifier with on/off or proportional control.■ Air flow rate controller (for centrifugal fans).■ Filter fouling level detector.■ Smoke detection unit.■ Refrigerant leak detector.■ Air quality sensor to measure CO2 levels and volatile

organic compounds (VOC).■ Electrical energy meter.

pGD1 standard local maintenance terminal (local control console):The terminal installed in the box is used to:■ Carry out initial programming of the unit at system start-up.■ Modify the operating parameters.■ Select the operating mode.■ Adjust the setpoint.■ Display the variables controlled

and the sensor values.■ Display the alarms on the screen.

The terminal can also be directly connected and remotely controlled via a telephone cable from up to 50 m away. For greater distances, please check the options.

Simplified TCO user terminal (local control console) in place of the pGD1 (optional):The TCO terminal installed in the electrics box is used to:■ Switch the unit on/off.■ Adjust the setpoint.■ Select the operating mode: COOLING/HEATING.■ Display the installation's temperatures and humidity,

outdoor temperature, supply air temperature, CO2 sensor and the outdoor air damper opening status.

■ Display the alarm codes.

504 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

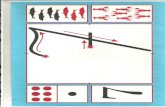

SPACE PF 90 - 360OptionsConfiguration options(Depending on the circulation of the indoor air; cross-section view)

All recirculated air standard assembly■ M0 assemblies: Position of the supply air and/or return air in

the air handling circuit changed.

Assemblies with free cooling and mixing box■ MS assemblies: Outdoor air intake with damper, combined

with the return damper (two-way mixing box).

■ ME assemblies: Air extraction propeller fan (three-way mixing box).

■ MA assemblies: Lower return air propeller fan (three-way mixing box).

■ MC0 assemblies: Lower return air EC plug fan (three-way mixing box).

■ MRC0 assemblies: Lower return air EC plug fan (three-way mixing box) + refrigerating recovery circuit.

■ MC1 assemblies: EC centrifugal return air fan or plug fan in the upper box (three-way mixing box).

■ MRC1 assemblies: EC centrifugal return air fan or plug fan inside the upper casing (three-way mixing box) + refrigerating recovery circuit.

All of the assemblies are also available with a centrifugal fan or supply air fan instead of the EC plug fan.

Assembly KeyMwxy I = Supply air

Supply air (0: standard, 1: option, 2: option) R = Return airReturn air (0: standard, 1: option, 2: option) N = Fresh air intakeType of assembly E = Air extraction

I

M011

R

I M012

R

R

I

M001

R

I M002

R

M000

I

R

I

M010

I

M021 RRM020

I

I M022 R

N

MS00

RI R

I

MS01

N

R

I MS02

N

I

MS10

R

N

I

MS11

R

N

I MS12

R

N

R

N

MS20

I

I

MS21 R

N

I MS22 R

N

ME00

RI

N

E

ME01

I

R

N

E

ME02

R

N

E

I

R

N

E

MA00

I

MA01

R

I

N

E

MA02

R

N

E

I

R

N

E

MC00

I

MC02

R

N

E

IMC01

R

I

N

E

R

N

E

MRC00

I

MRC01

R

I

N

E

MRC02

R

N

E

I

N

E

MC10

R

I

MC11

N

ER

I

N

E

MRC10

R

I

MRC11

N

ER

I

505

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

Options for outdoor environmentsTemperature■ Thermal and acoustic insulation (50 mm thick), with

Euroclass A2-s1, d0 (MO) fire classification. Casing losses:

■ Electrical heaters to protect the components of the electrical cabinet. Compulsory if the outdoor temperature is below -8ºC WB. For temperatures below -16ºC WB, a reinforced heater will be compulsory.

■ Compressor with protection against low temperatures (additional crankcase heater): required if the outdoor temperature is below -8ºC WB.

■ Dampers with springs for automatic closure in the case of a power outage.

■ Electrical heater for antifreeze protection for the mixing box dampers: required if the outdoor temperature is below -12ºC WB.

■ Hot water coil circuit with antifreeze protection according to the water temperature: required if the outdoor temperature is below -20ºC WB (includes an accelerator pump).

Corrosion■ Coils (outdoor, indoor and/or auxiliary) with copper tubes

and copper blades.■ INERA® coils (outdoor, indoor and/or auxiliary) made from

copper tubing and aluminium alloy blades, exclusive to CIAT, highly efficient and extremely resistant to corrosion.

■ Coils (outdoor indoor and/or auxiliary) made from copper tubing and aluminium blades, with polyurethane coating, or a coil with full Blygold protection.

■ Condensate drain pan in stainless steel for the indoor circuit.

Humidity■ Droplet eliminator on the indoor

air coil. Recommended if high levels of air humidity are expected or when the air flow rate is high.

■ Droplet eliminator on the outdoor air intake.

■ Tropicalised electrical cabinet.■ Tropicalised fans and motors

(please contact us).

Comfort/heating options■ Auxiliary hot water coil with three-way valve. With this option,

the unit still includes an antifreeze thermostat as a backup.■ Auxiliary electrical heaters, with two stages and on/off

control.

Note: the extra heater is not available with upper supply air and a centrifugal fan (optional) on models 90 to 180. With centrifugal supply air fan (optional) the air flow rate controller must be selected. The plug fan (standard) has this controller built-in.

■ Natural gas or propane burner with modulating actuator. Available for all assembly versions, except upper and lower supply air. With this option, it is recommended that the differential pressure switch is used to detect fouled filters.

Note: with the centrifugal fan (optional) the air flow rate controller, which stops the burner in the event of a fire, must be selected.

Conditions Winter

Indoor 20ºC 50% RH

Outdoor -20ºC 94% RH

9 mm NBR (std) 1790 W 2.0% HC

50 mm mineral wool 437 W 0.4% HC

Conditions Summer

Indoor 27ºC 50% RH

Outdoor 35ºC 40% RH

9 mm NBR (std) 615 W 1.00% HC

50 mm mineral wool 151 W 0.24% HC

Indoor separator

506 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE PF 90 - 360Energy saving optionsFree cooling managementRunning the unit in free cooling mode allows it to make best use of outdoor air conditions when these are more favourable than the return air conditions. This allows the cooling capacity to be reduced.

Note: the free cooling function is never activated at the same time as the recovery circuit.

The percentage of outdoor air can vary between 0% and 100%.

Three options are available for free cooling management:■ Thermal, by comparing the temperatures.■ Enthalpic, by comparing the enthalpies.■ Thermo-enthalpic, by comparing the enthalpies and correcting

for temperature. This is the optimum solution as it takes the variability of the climate into account.

Active thermodynamic recovery■ A dedicated recovery thermodynamic circuit, with independent

control, adapted for air change requirements to improve the COP and EER of the whole unit.

■ EC plug fan or centrifugal fan (MRC0 or MRC1 assemblies).■ Air circuit composed of copper tube coils and aluminium

blades.■ Thermostatic expansion valve with external equaliser.■ Hermetic scroll compressor with acoustic insulation, fitted on

anti-vibration mounts.■ Crankcase heater.■ Four-way reversal valve (heat pump units).■ Acid-resistant dehumidifier filter.■ Condensate drain pan.

Safety options■ Soft start for supply air fans and/or

return air centrifugal fans (optional), increasing the warm-up time, mainly intended for installations with textile ducts. Required for motors of 15 kW and above.

■ Differential pressure switch to detect fouled filters.■ Differential pressure switch for checking the

air flow, for centrifugal fan (optional). ■ Smoke detection unit compliant with the

NF S 61-961 standard.■ Refrigerant leak detector with measuring

sensor.

Spe

cific

hum

idity

W (g

/kg

dry

air)

Spe

cific

hum

idity

W (g

/kg

dry

air)

Spe

cific

hum

idity

W (g

/kg

dry

air)

Dry temperature Td (°C)

Saves more energy

Dry temperature Td (°C)

Dry temperature Td (°C)

Thermal free cooling

Enthalpic free cooling

With thermo-enthalpic

free cooling

Thermo-enthalpic free cooling

Return air

Exhaust

Recovery on exhaust air

Main circuitSupply air

Fresh air

Reversible recovery

circuit

507

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

Comfort/indoor air quality options■ G4 refillable gravimetric filter.■ Low pressure drop G4 filter.■ G4 gravimetric filters + folded F6 to F9 opacimetric filters.■ Low pressure drop G4 filter + low pressure drop folded F7

to F9 opacimetric filters.■ A double layer of folded opacimetric filters (F+F standard or

F+F low pressure drop).

■ Environmental air quality sensor for measuring CO2 levels and/or volatile organic compounds (VOCs). Return on investment in under 1 year.

Installation options■ Two-speed outdoor propeller fan(s) with direct coupling to

the motor. Class F sealed motor, IP54 with internal heat protection. Dynamically-balanced propellers and external protective grille.

■ Centrifugal belt- and pulley-driven supply air and return air fans. Electric motor with tensioner, class F, IP55 and internal heat protection. One, two or three dual-inlet impellers, with forward-curved blades on the wheel. Maintenance-free, lubricated ball socket. High power version available as an option.

■ Overpressure control with MC0 and MC1 assemblies.■ A single compressor on each circuit to replace the tandem.■ Condensate drain pan for the outdoor circuit made from

galvanised steel (consult the dimensional drawing). This option is not available on models 240 to 360 if they are to be transported by sea in a shipping container.

■ Protective grille for the outdoor coil.■ Hail guard protective grille for the outdoor coil.■ Quarter-turn compression bolts on the access panels for the

filters and/or fans.■ Hinges + quarter-turn compression bolts on the access

panels for the filters and/or fans.■ Pre-assembled standardised frames made from galvanised

sheet steel with thermal insulation. Adjustable height (for dimensions, see Space 2).

■ Adaptation frames for the replacement of existing units.

■ Rubber anti-vibration mounts.

Packaging options■ SEI4C seaworthy packaging.■ Skids for transport in a closed container (except for MC1 and

MRC1 assemblies).

Service options■ System start-up and 1-year warranty extension, including

parts, labour and movement.■ System start-up and 2-year warranty extension, including

parts, labour and movement.

Electrical cabinet options■ Power supply with neutral.■ Marking of the electrical cables.■ Marking of the components in the electrical

cabinet.■ Electric energy meter to monitor the

installation's electricity consumption.

Control system

Opacimetric filters

Gravimetric filters

508 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE PF 90 - 360Control/communication options■ Local TCO terminal to replace the pGD1 terminal.■ Remote control kit for up to 200 m from the pGD1 terminal

(pGD1 terminal + 2 TCONN cards).

■ Return and outdoor air relative humidity sensors: required for enthalpic or thermo-enthalpic free cooling.

■ Room air temperature sensors: if the unit requires the outdoor air relative humidity sensor (optional), the room air sensor cannot be installed in the card (standard), and must instead be connected using a Field-bus.

■ Room air enthalpy sensor: required in units with gas burner + enthalpic or thermo-enthalpic free cooling.

CommunicationsThe CIATrtc control allows communication to be established with a centralised management system using a specific CMS card for one of the following communication protocols:■ RS485 serial cards for communication using the Carel,

ModBus, LonWorks®, BACnetTM MSTP and Konnex protocols.

■ The pCOWEB Ethernet card for communication with a network using the ModBus TCP/IP, BACnetTM Ethernet, TCP/IP, SNMP V1-2-3, FTP and HTTP protocols.

Supervision solutionsCIAT has developed different supervision solutions based on the dimensions of the installation.■ pCO WebThis is the solution for managing and supervising a single unit if this incorporates the Ethernet pCO Web card.■ PLANTWATCH PRO This is a solution designed for the supervision of small- and medium-sized installations, capable of managing up to 10 units. Adapted for technical environments. Includes: a 5.7” touchscreen, a buzzer for notifications and 2 USB ports for downloading reports, loading templates and applying service packs. For this option, each unit requires a Carel / ModBus RS485 card.

■ PLANTWATCH PRO2This is the solution for managing and supervising air conditioning installations up to 300 units. It offers advanced monitoring and maintenance functions, and allows zones and groups to be created to simplify management of the installation. This solution also allows energy measurements to be integrated to monitor the installation's electricity consumption.PlantVisor PRO2 is available in two versions: - Box: formed by the CPU and, as an option, a monitor and

keyboard. - Touchscreen: comprising the CPU and touchscreen in a

single device.For this option, each unit requires a Carel / ModBus RS485 card.

These systems are used to manage the installation remotely. All the information on the system can be accessed via a simple internet connection. The online interface, the same one used by the local PlantVisor user, enables monitoring and complete configuration of the installation, from the office or anywhere else the user happens to be. To control multiple sites remotely, PlantVisor PRO2 offers special tools dedicated to centralised management, such as RemotePRO and RemoteValue.

pCO Web (1 unit)

PlantWatch PRO2 (300 units)

PlantWatch PRO (10 units)

509

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE 3 PF 90HEE 90T 120HEE 120T 160HEE 160T 180HEE 180T

Refrigeration capacities

Cooling capacity (1) (kW) 21.2 23.1 25.2 30.1 33.4 38.1 42.5 46.3

Power input (3) (kW) 7.1 8.2 8.4 10.7 11.1 13.6 14.1 16.5

Energy efficiency rating (EER) 3.01 2.81 3.01 2.81 3.01 2.81 3.01 2.81

Heating capacities

Heating capacity (2) (kW) 21.7 24.0 25.7 31.1 34.5 39.3 42.8 46.7

Power input (3) (kW) 6.4 7.5 7.5 9.7 10.1 12.2 12.5 14.6

COP 3.41 3.21 3.41 3.21 3.41 3.21 3.41 3.21

Outdoor circuit fan

Nominal air flow rate (m3/h) 8 000 13 000 17 000

Available static pressure (mmWC) 4

Type EC electronic propeller fan

Number / Diameter (mm) 1 / 630 1 / 800

Motor output (kW) 0.9 2.2

Power input (kW) 0.5 0.5 1.5 1.5 1.4 1.4 1.6 1.6

Speed (rpm) 1 000 980

Indoor circuit supply air fan

Nominal air flow rate (m3/h) 4 000 6 000 8 700 9 000

Available static pressure (mmWC) 12 12 12 15 15 15 15 15

Air flow rangemin (m3/h) 3 200 3 200 4 800 4 800 6 900 6 900 7 200 7 200

max (m3/h) 4 800 4 800 7 200 7 200 10 400 10 400 10 100 10 100

Type EC motor plug fan

Number / Diameter (mm) 1 / 500 2 / 500

Motor output (kW) 2.68 2 x 2.68

Power input (kW) 0.5 0.5 0.9 1.0 1.4 1.4 1.6 1.6

Speed (rpm) 1 700 2 / 1 700

Compressor

Type Scroll

Number of compressors 2

Number of stages 2

Number of circuits 1

Oil type Copeland 3MAF (32 cST). Danfoss POE 160SZ. ICI Emkarate RL 32 CF. Mobil EAL Arctic 22CC

Oil volume (l) 3.1 3.1 3.1 3.1 3.1 3.1 3.1 5.3

Electrical specifications

Network voltage 400 V / 3-ph / 50 Hz (±10%)

Supply 3 wires + earth

Maximum input current

Compressor(s) (A) 12.0 13.6 13.6 20.8 25.9 31.7 31.7 25.4

Outdoor fan(s) (A) 2.0 2.0 3.4 3.4 3.4 3.4 3.4 3.4

Indoor fan (A) 4.2 4.2 4.2 4.2 8.4 8.4 8.4 8.4

Control (A) 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9

Total (A) 19.1 20.7 22.1 29.3 38.6 44.4 44.4 38.1

Refrigerant

Type R410A

Global warming potential (GWP) (4) 2 088

Charge (kg) 6.0 6.0 7.5 7.5 8.5 8.5 10.0 10.0

Environmental impact (tCO2eq) 12.5 12.5 15.7 15.7 17.7 17.7 20.9 20.9

Dimensions

Length (mm) 2 400 2 400

Width (mm) 1 400 1 400

Height (mm) 1 497 1 675

Weight (kg) 574 574 595 595 657 657 697 697

Condensate draining diameter 1 1/4” connection

technical characteristics (Une-en-14511-2013)

(1) Cooling capacity calculated in accordance with the UNE-EN-14511-2013, standard, for indoor temperature conditions of 27ºC, 19ºC WB, and an outdoor temperature of 35ºC.

(2) Heating capacity calculated in accordance with the UNE-EN-14511-2013 standard, for indoor temperature conditions of 20ºC, and an outdoor temperature of 6ºC WB.

(3) Total input power of the compressors and fan motor assemblies under rated conditions, calculated in accordance with the UNE-EN-14511-2013 standard.(4) Global warming potential of one kilogram of a fluorinated greenhouse gas relative to one kilogram of carbon dioxide over a period of 100 years.

510 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE PF 90 - 360technical characteristics (Une-en-14511-2013)

(1) Cooling capacity calculated in accordance with the UNE-EN-14511-2013, standard, for indoor temperature conditions of 27ºC, 19ºC WB, and an outdoor temperature of 35ºC.

(2) Heating capacity calculated in accordance with the UNE-EN-14511-2013 standard, for indoor temperature conditions of 20ºC, and an outdoor temperature of 6ºC WB.

(3) Total input power of the compressors and fan motor assemblies under rated conditions, calculated in accordance with the UNE-EN-14511-2013 standard.(4) Global warming potential of one kilogram of a fluorinated greenhouse gas relative to one kilogram of carbon dioxide over a period of 100 years.

SPACE 3 PF 200HEE 240HEE 240T 320HEE 320T 360HEE 360T

Refrigeration capacities

Cooling capacity (1) (kW) 52.7 58.5 61.3 71.3 74.6 79.9 85.2

Power input (3) (kW) 17.5 19.4 21.8 23.7 26.5 26.5 30.3

Energy efficiency rating (EER) 3.01 3.01 2.81 3.01 2.81 3.01 2.81

Heating capacities

Heating capacity (2) (kW) 55.6 62.5 66.1 74.4 78.7 86.0 88.7

Power input (3) (kW) 16.3 18.3 20.6 21.8 24.5 25.2 27.6

COP 3.41 3.41 3.21 3.41 3.21 3.41 3.21

Outdoor circuit fan

Nominal air flow rate (m3/h) 30 000

Available static pressure (mmWC) 4

Type Electronic propeller fan

Number / Diameter (mm) 2 / 800

Motor output (kW) 2 x 2.2

Power input (kW) 2.2 2.2 2.2 2.5 2.5 2.5 2.5

Speed (rpm) 2 / 980

Indoor circuit supply air fan

Nominal air flow rate (m3/h) 10 000 12 000 14 300 15 900

Available static pressure (mmWC) 20 20 20 20 25 25 25

Air flow rangemin (m3/h) 8 000 9 600 9 600 11 440 11 440 12 720 12 720

max (m3/h) 12 000 14 400 14 400 17160 17 160 19 080 19 080

Type EC motor plug fan

Number / Diameter (mm) 2 / 500

Motor output (kW) 2 x 2.68

Power input (kW) 1.7 2.2 2.2 3.0 3.3 3.7 3.7

Speed (rpm) 2 / 1 700

Compressor

Type Scroll

Number of compressors 4

Number of stages 4

Number of circuits 2

Oil type Copeland 3MAF (32 cST). Danfoss POE 160SZ. ICI Emkarate RL 32 CF. Mobil EAL Arctic 22CC

Oil volume (l) 6.3 6.3 6.3 6.3 6.3 6.3 8.5

Electrical specifications

Network voltage 400 V / 3-ph / 50 Hz (±10%)

Supply 3 wires + earth

Maximum input current

Compressor(s) (A) 36.1 41.6 48.3 55.0 59.2 63.4 62.3

Outdoor fan(s) (A) 6.8 6.8 6.8 6.8 6.8 6.8 6.8

Indoor fan (A) 8.4 8.4 8.4 8.4 8.4 8.4 8.4

Control (A) 1.8 1.8 1.8 1.8 1.8 1.8 1.8

Total (A) 53.1 58.6 65.3 72.0 76.2 80.4 79.3

Refrigerant

Type R410A

Global warming potential (GWP) (4) 2 088

Charge (kg) 11.5 11.5 11.5 15.0 15.0 17.0 17.0

Environmental impact (tCO2eq) 24.0 24.0 24.0 31.3 31.3 35.5 35.5

Dimensions

Length (mm) 2 750 2 750

Width (mm) 2 115 2 115

Height (mm) 1 705 2 005

Weight (kg) 1 029 1 029 1 029 1 062 1 062 1 152 1 152

Condensate draining diameter 1 1/4” connection

511

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

soUnD levels dB(a)Standard unit (for MC1 and MRC1 assemblies, please consult us)Sound power level (LW)Sound pressure level (LP)Measurement conditions: in a free field, measured at a distance of 5 metres, directivity 2 and 1.5 metres from the ground.Note: the sound pressure level depends on the installation conditions, and is therefore only given as a guide. Values obtained in accordance with ISO standard 3744.

electrical connection

specifications for the single compressor per circUit (option)A single compressor to replace the tandem.

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

63 Hz 34.2 43.2 47.2 48.2 48.2 48.2 48.2 49.2125 Hz 47.5 56.5 60.5 61.5 61.5 61.5 61.5 62.5250 Hz 56.3 65.3 69.3 70.3 70.3 70.3 70.3 71.3500 Hz 64.3 73.3 77.3 78.3 78.3 78.3 78.3 79.31000 Hz 70.7 79.7 83.7 84.7 84.7 84.7 84.7 85.72000 Hz 66.1 75.1 79.1 80.1 80.1 80.1 80.1 81.14000 Hz 58.8 67.8 71.8 72.8 72.8 72.8 72.8 73.88000 Hz 47.7 56.7 60.7 61.7 61.7 61.7 61.7 62.7Total LW dB(A) 73.0 82.0 86.0 87.0 87.0 87.0 87.0 88.0Total LP dB(A) 46.4 55.4 59.4 60.4 60.1 60.1 60.1 61.0

Qty SPACE PF 90 to 360

1 Main power supply

400 3-ph (±10%) 3 + E

2

pGD1 terminal connection for remote control (installed on the electrical cabinet as the default option) (1)

standard 6-wire phone cable (RJ12 connector)

3TCO user terminal connection for the remote control (option) (2)

2 wires for the 230 V power supply + 1 shielded cable

for AGW20 / 22 type communication (1 twisted pair +

continuity wire + mesh)

4 Remote on/off (opt.) 2 wires

5 General fault signal (opt.) 2 wires

6 NTC room sensor (std) 2 wires

7 RS485 room sensor (opt.) 5 wires

8 Air quality sensor (opt.) 3 wires

1

2

3

4

5

6

7

8

(1) In this case, the TCO terminal can be installed on the electrical cabinet.(2) It is necessary for the terminal to use the same power supply source as the control board.

SPACE PF 90HEE 90T 120HEE 120T 160HEE 160T 180HEE 180T

Number of compressors / Stages / Circuits 1 / 1 / 1Oil volume (l) 1.6 3.0 3.0 3.3 3.3 3.3 3.3 6.2Maximum input current (A) 15.9 15.3 15.3 20.1 21.1 25.0 25.0 29.1Additional weight (kg) -21 -21 -15 -15 -10 -10 -21 -21

SPACE PF 200HEE -- 240HEE 240T 320HEE 320T 360HEE 360T

Number of compressors / Stages / Circuits 2 / 2 / 2Oil volume (l) 2 x 2.7 -- 2 x 3.3 2 x 3.3 2 x 3.3 2 x 3.3 2 x 3.3 2 x 6.2Maximum input current (A) 2 x 14.2 -- 2 x 20.1 2 x 23.0 2 x 23.0 2 x 25.1 2 x 25.1 2 x 29.1Additional weight (kg) -32 -- -32 -32 -22 -22 -31 -31

512 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE PF 90 - 360options for the oUtDoor circUit■ External condensate pan

options for the inDoor circUit■ Centrifugal supply air fan

■ Two-speed outdoor propeller fan

■ Propeller extraction fan (ME assembly)

■ Propeller return air fan (MA assembly)

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Dimensions Length (mm) 2 474 2 750Width (mm) 1 400 2 263 (1)Height (mm) 1 497 1 675 1 705 2 005

External pan(1) The machine has two built-in pans, one on each side.

(1) On models 160 and 180 with upper supply air, a 3 kW fan motor must be selected.

Space PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Nominal air flow rate (m3/h) 8 000 13 000 17 000 17 000 30 000 30 000 30 000 30 000

Available static pressure (mmWC) 4

Quantity/Diameter (mm) 1 / 630 1 / 800 2 / 800

Capacity (kW) 0.7 / 0.4 2.0 / 1.3 2 x 2.0 / 1.3

Speed (rpm) 875 / 650 895 / 685 895 / 685

Maximum input current (A) 1.3 4.3 4.3 4.3 8.6 8.6 8.6 8.6

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Nominal air flow rate (m3/h) 2 000 3 000 4 350 4 500 5 000 6 000 7 150 7 950

Quantity/Diameter (mm) 1 / 450 2 / 450

Supply voltage 230 V/1 ph/50 Hz

Power (kW) 0.48 2 x 0.48

Speed (rpm) 1 350

Maximum input current (A) 2.1 4.2

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Maximum air flow rate (m3/h) 4 000 6 000 8 700 9 000 10 000 12 000 12 400 12 400

Quantity/Diameter (mm) 2 / 450

Supply voltage 230 V/1 ph/50 Hz

Power (kW) 2 x 0.48

Speed (rpm) 1 350

Maximum input current (A) 4.2

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Rated air flow rate (m3/h) 4 000 6 000 8 700 9 000 10 000 12 000 14 300 15 900

Available static pressure (mmWC) 10.0 10.0 10.0 10.0 12.5 12.5 12.5 12.5

Number/ Number of impellers 1 / 1

Motor output (kW) 0.75 1.1 2.2 À 2.2 À 1.5 2.2 4 5.5

Power input (kW) 0.51 0.92 1.34 1.46 1.08 1.81 2.85 3.54

Speed (rpm) 864 820 707 725 523 592 672 696

Maximum input current (A) 2.1 2.7 5.0 5.0 3.6 5.0 9.0 11.6

Additional weight (kg) -45 -45 -47 -47 -50 -50 -50 -50

513

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

■ Centrifugal return air fan (MC1 assembly)

■ Return air EC plug fan with variable speed control (MC0/MC1 assembly)

■ MRC refrigerating recovery circuit

■ Auxiliary heater2-stage auxiliary electric heaters for assembly and connection within the unit. Not available for models 90 to 180 with upper supply air.

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Rated air flow rate (m3/h) 4 000 6 000 8 700 9 000 10 000 12 000 14 300 15 900

Available static pressure (mmWC) 10.0 10.0 10.0 10.0 12.5 12.5 12.5 12.5

Nominal power input (kW) 0.30 0.70 1.04 1.13 1.13 1.43 2.14 2.76

Number/ Number of impellers 1 / 1

Power (kW) 0.55 1.1 1.5 1.5 1.5 2.2 3 4

Speed (rpm) 585 671 583 593 477 503 547 581

Maximum input current (A) 1.6 2.7 3.6 3.6 3.6 5.0 6.9 9.0

Additional weight (MC1) (kg) -33 -25 -11 -11 -35 -35 -26 -16

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Nominal flow rate (m3/h) 4 000 6 000 8 700 9 000 10 000 12 000 14 300 15 900Plug fan (MRC0/MRC1 assemblies)

Maximum avail. static pressure on the return (mmWC) 96.4 85.9 50.3 44.3 84.8 81.0 69.1 58.3

Centrifugal fan (MRC1 assembly)

Avail. static pressure on the return (mmWC) 10.0 10.0 10.0 10.0 10.0 12.5 12.5 12.5

Additional weight (kg) -33 -25 -11 -11 -35 -35 -26 -16

Recovery compressor characteristics

Type Scroll

Number of compressors / Circuits 1 / 1

Oil type Copeland 3MAF (32 cST). Danfoss POE 160SZ. ICI Emkarate RL 32 CF. Mobil EAL Arctic 22CC

Oil volume (l) 1.1 1.6 3.0

Maximum input current (A) 6.3 9.0 15.3

R410A refrigerantLoad (kg) 2.6 2.7 3.3 3.3 6.1 6.1 6.1 6.2

Environmental impact (tCO2eq) 5.4 5.6 6.9 6.9 12.7 12.7 12.7 12.9

SPACE PF 90HEE 90T

120HEE 120T 160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE 320T 360HEE360T

Rated air flow rate (m3/h) 4 000 6 000 8 700 9 000 10 000 12 000 14 300 15 900

Rated available static pressure (mmWC) 12.0 12.0 15.0 15.0 15.0 20.0 20.0 20.0 25.0 25.0

Nominal power input (kW) 0.31 0.66 0.73 1.42 1.54 1.28 1.76 2.34 2.60 3.20

Maximum available static pressure (mmWC) 98.7 90.1 57.7 52.1 93.9 90.1 79.0 68.9

Quantity x Diameter (mm) 1 x 500 2 x 500

Capacity (kW) 2.68 2 x 2.68

Speed (rpm) 1 700 2 x 1700

Maximum input current (A) 4.2 8.4

SPACE PFTotal power (kW) 12 18 27 36 45

Stage power (kW) 6 + 6 9 + 9 9 + 18 18 + 18 18 + 27

Current (A) (400V / 3-ph / 50Hz)

90HEE / 90T / 120HEE / 120T 17.3 26.0 Unavailable

160HEE / 160T / 180HEE / 180T 17.3 26.0 39.0 Unavailable

200HEE / 240HEE / 240T / 320HEE / 320T Unavailable 26.0 39.0 52.0 Unavailable

360HEE Unavailable 26.0 39.0 52.0 65.0

Module weight (kg) 11 15 19 24 29

514 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE PF 90 - 360■ Auxiliary hot water coil

Note: - with a droplet eliminator on the indoor air coil, it is not possible to fit a hot water coil.- this option still incorporates an antifreeze thermostat as a safety feature.

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Air pressure drop (mmWC) 1.8 3.5 3.6 3.9 2.4 3.5 4.6 4.0

Water 80/60ºC and air intake 20ºC

Heating capacity (kW) 24.6 31.8 44.0 45.0 96.5 104.0 115.4 140.7

Water flow rate (m3/h) 1.1 1.4 2.0 2.0 4.3 4.6 5.1 6.2

Water pressure drop (mmWC) 0.7 1.1 1.0 1.0 1.5 1.7 1.6 3.5

Water 90/70ºC and air intake 20ºC

Heating capacity (kW) 30.4 39.4 54.6 55.7 119.9 129.0 143.3 172.6

Water flow rate (m3/h) 1.4 1.8 2.4 2.5 5.3 5.7 6.4 7.7

Water pressure drop (mmWC) 1.0 1.4 1.2 1.2 1.8 2.0 2.5 5.0

Weight (empty) (kg) 11.1 11.1 15.1 15.4 34.8 34.8 34.8 41.7

■ Droplet eliminator on the indoor air coil It is recommended that a droplet eliminator is installed on the indoor coil from the following air flow rates.

■ Gas burnerFor the burner characteristics, see the documentation for SPACE PF 415 to 1200.The following table indicates the pressure drop (mWC) at the burners available for each model:

A B

C21 KEY

1 Water outlet

2 Water inlet

SPACE PF A (mm)

B (mm)

C (mm)

Ø of hydraulic connections: I/O

90HEE / 90T / 120HEE / 120T 203 190 177 1 1/4”

160HEE / 160T / 180HEE / 180T 203 190 177 1 1/2”

200HEE / 240HEE / 240T / 320HEE / 320T / 360HEE / 360T 295 250 177 2”

Note: the I/O connections for the coil are located within the unit. The connection can be made at the base of the unit, using the flexible sleeves, or via the lateral panel. The diagram above shows the location of the pre-punched holes located on the lateral panel. For connections via the base, consult the diagram for the pre-assembled frames.

Position of the auxiliary coil hydraulic connections (option)

SPACE PF 90HEE 90T

120HEE120T

160HEE160T

180HEE180T

200HEE 240HEE240T

320HEE320T

360HEE360T

Air flow rate (m3/h) 7 280 7 280 10 190 10 190 14 560 14 560 14 560 17 480

Note: - under operating conditions with a high level of dehumidification in the indoor coil (for example on installations close to the seafront), it may be necessary to install an eliminator even if the flow rate is less than that given above.

- with a hot water coil, it is not possible to fit the droplet eliminator.

SPACE PF Nominal air flow rate (m3/h)

Pressure drop (mmWC)

PCH-35 PCH-43 PCH-54 PCH-7290HEE / 90T 4 000 6.3 -- -- --

120HEE / 120T 6 000 11.1 -- -- --160HEE / 160T 8 700 18.7 -- -- --180HEE / 180T 9 000 19.7 -- -- --

200HEE 10 000 -- 11.2 11.2 5.3240HEE / 240T 12 000 -- 16.1 16.1 7.7320HEE / 320T 14 300 -- -- 20.5 9.7360HEE / 360T 15 900 -- -- 23.7 11.1

515

SPAC

E P

F 90

- 3

60

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

minimUm space reqUireD for system start-Up anD maintenance

■ SPACE PF - 90HEE, 90T, 120HEE, 120T, 160HEE, 160T, 180HEE and 180T

■ SPACE PF - 200HEE, 240HEE, 240T, 320HEE, 320T, 360HEE and 360T

516 HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 15.01 A

Roof top

SPACE PF 90 - 360

SPACE PF A B C D E F G H I J M N O P Q R S T U V W Y c d e

90 to 180 2 346 1 371 536 400 2 220 1 214 2 114 1 112 123 2 014 100 114 1 012 114 1 018 1 104 98 84 373 201 399 157 89 98 124

200 to 360 2 696 2 055 536 400 2 570 1 929 2 463 1 827 132 2 363 100 114 1 727 114 1 371 1 104 95 90 617 535 496 191 104 224 87

SPACE PF frame

Weight (kg)

Centre of gravity (mm)

Maximum slope

X Y Z a b

90 to 180 189 1 244 685 228 4º (7%) 4º (7%)

200 to 360 250 1 431 1 025 298 4º (7%) 4º (7%)

KEY

ÀFor assembly of the SPACE PF with lower supply air (Mwx0) (1)

ÁFor assembly of the SPACE PF with lower return air (Mw0y) (1)

Â

Routing for the power supply (Ø 40 mm):90HEE / 90T / 120HEE / 120T / 160HEE / 160T / 180HEE / 180T (mm)Routing for the power supply (Ø 64 mm):200HEE / 240HEE / 240T / 320HEE / 320T / 360HEE / 360T (mm)

ÃRouting area for the optional hot water coil hydraulic connections (optional)

(1) The assemblies available are indicated in the "Configuration options" section

pre-assembleD frames (option)■ SPACE PF frames - 90HEE / 90T / 120HEE / 120T / 160HEE / 160T / 180HEE / 180T / 200HEE /

240HEE / 240T / 320HEE / 320T / 360HEE / 360T (dimensions in mm)

Y

X

d

c

e3

YW

VU

T

SRQ

1

4

2

YW

VU

TD

PN

O

M

A

E

C

G

JI

H

F

B

18mmØ

b

Y

Z

SRQ

X

c

ed

1

3 4

2

a*

SPACE PF - 90HEE / 90T / 120HEE / 120T / 160HEE / 160T / 180HEE / 180T (mm)

SPACE PF: 200HEE / 240HEE / 240T / 320HEE / 320T / 360HEE / 360T (mm)

* To benefit from maximum seal tightness, it is not recommended that the angle ‘a’ is set up on the opposite side.