On the Product Development Model of Service Innovation in ...

Transcript of On the Product Development Model of Service Innovation in ...

© Kamla-Raj 2014 Anthropologist, 17(3): 713-724 (2014)

On the Product Development Model of Service Innovationin Manufacturing Industry

Min-Wei Hsu1, Tsai-Yun Lo2, Shoujen Bien3, Janson Tsai4 and Wen-Hao Yang5

1The Graduate Institute of Design Science, Tatung University, Department of VisualCommunication Design, Jinwen University of Science and Technology,

No.99, Anzhong Rd., Xindian Dist., New Taipei City 23154, Taiwan.E-mail: [email protected]

2Department and Graduate School of Industrial Design, Tatung University ,40 Zhongshan North Road, 3rd Section Taipei 104, Taiwan

E-mail: [email protected] of Culture Industry and Innovation Design, Jinwen University of Science and

Technology, Taiwan, No.99, Anzhong Rd., Xindian Dist., New Taipei City 23154, TaiwanE-mail: [email protected]

4Department of Visual Communication Design, Jin Wen University, No.99, Anzhong Rd.,Xindian Dist., New Taipei City 23154, Taiwan

E-mail: [email protected] of Culture Industry and Innovation Design, Jinwen University of Science and

Technology, Taiwan, No.99, Anzhong Rd., Xindian Dist., New Taipei City 23154, Taiwan

KEYWORDS Manufacturing Servitization. Service Design. Service Innovation Model. Clustering Model

ABSTRACT The study objects comprise of manufacturers in transition to manufacturing servitization whichTaiwan Government strongly advocates recently. The study conducts in-depth interview with specialized counselingunits in addition to supplementing specific internal data analysis through the discussion on the success cases in theapplication for government counseling. Using qualitative research method, the study expounds the new modeshaping, causes in forming cooperation-strategy model and the association with corporate business model in thedevelopment of product service innovation. The model of service innovation development not yet revealed inprior literatures are now unfolded through the specific flow chart of the operation of product development modelfor the representative manufacturers mentioned in the study, providing an important reference for Asianmanufacturing industries in terms of shortening R&D process time. Students of engineering education can applythe concept of manufacturing servitization to assist them with industrial thinking and connect with in-schoollearning. Such concept can also effectively offer an important discourse for reference during the shifting ofmanufacturing R&D after the students enter the workplace.

INTRODUCTION

The expansion rate for world’s economic tradein 2012 has slowed down, as compared to 2011.The latest estimate of Global Insight Inc. showsthat the 2012 world’s economic growth will slowdown from the 4.14% in 2011 to 3.4%. Additional-ly, the IMF estimated that the 2012 world’s tradevolume expansion rate will drop from the 11.4%in 2011 to 7.0%. In particular, the invigoration ofbooming domestic demand from emerging coun-tries such as mainland China and India remainsthe factors that drive the world’s economicgrowth. On the other hand, industrial countriesshow relatively weakened growing momentumdue to the limitation in sluggish improvement onunemployment, consumption, and the weak paceof investment. Moreover, European sovereign

debt crisis, unemployment of industrial countriesand fluctuations in international raw material pric-es continue to add variables to the recovery ofworld economy (Yang 2010).

Apart from peer domestic competition, prod-ucts made in Taiwan primarily compete with main-land China, followed by overseas Taiwanesecompanies in domestic and export markets. Themassive labor productivity and super minimumwage carried by mainland China pose a gravethreat to Taiwanese industries.

Zhang YJ (2014) suggested that there is noexistence for so-called conventional industry butindustries that are phased out. He mentioned thatany industry not knowing the importance of tech-nology upgrade will not become conventionalindustry living in the past or sunset industrythat gradually becomes part of history. He also

714 MIN-WEI HSU, TSAI-YUN LO, SHOUJEN BIEN ET AL.

stated that the key success for Taiwan indus-tries includes three elements, namely graspinginnovation, R&D and marketing, in addition tocreating differentiation in production of morevalue-added products that will dominate thehigh-end market. Only completely different prod-ucts plus the most sophisticated productionquality will drive foreigners to buy MIT prod-ucts, and therefore the expensive wage of Tai-wan will become a competitive advantage.

Trend in Taiwan’s Manufacturing Servitization

Manufacturing Servitization is the key direc-tion of development for our government and re-lated enterprises, as shown in Figure 1. The man-ufacturing industry must involve service, prod-uct and system to respond to customer demand,with additional consideration of product inno-vation and application through product exten-sion service, product function service, and inte-grated solution.

The study analyzes the predicament facedby the promotion of manufacturing servitizationin transition with the following findings (Fig. 2).

The manufacturing industry is currently ac-customed to taking into consideration of OEM-oriented value proposition strategy with the fol-lowing two findings:

• It is less likely to propose innovative valueproposition and find out profit model fromcustomer demand.

• It is difficult to find out new applicationfields for manufacturing servitization, limit-ing the possible dimension of development.

There is difficulty in developing brandingunder the existing business model, howeverbranding is still the key development for our in-dustries progressing towards servitization. Abranding strategy with resilience such as leas-ing brand is the key focus for the industries todevelop (Liu 2013).

In the process transition for servitization, themanufacturing industry faces with new functions

Fig. 1. Three primary possible development models for Taiwan’s manufacturing servitization

PRODUCT DEVELOPMENT MODEL OF SERVICE INNOVATION 715

Fig. 2. Expected innovation in strategies and operational model

Fig. 3. Service oriented development through new service design concept

716 MIN-WEI HSU, TSAI-YUN LO, SHOUJEN BIEN ET AL.

generation, process change or development ofbusiness division, which corresponds to issuesrelated to organizational reform that offers greatchallenges to the local enterprises.

For enterprises to develop high-end prod-ucts such as complex product system, suchsysopment work. (2) The existing service devel-opment lacks a set of systematic R&D method.(3) Customer demand and viewpoints should becontrolled through different research approach-es, thereby to provide the service value exceedcustomer expectations.

The service development center advocatesfor the mechanism primarily through Service Ex-perience Engineering (S.E.E.) method, as engineto the corporate service innovation by assistingthe leading industries with investment and in-depth definition of service innovation relatedissues, in addition to organizing the service de-velopment center to gradually solve innovationrelated issues and form paradigms of innovation(Hsu 2012).

Promote the Formation Of TechnicalService Value Chain through S.E.E.

In addition to organizing specialized servicedevelopment center, some enterprises already ownsimilar internal service development organization/department that require government assistancein organizing cross and open service innovationalliance to study and analyze the technology ofservice innovation demand in different consum-ers, including: (1) Pre-agglomeration stakehold-ers who contribute to enterprise cooperation. (2)Use approaches to assist industries reaching con-sensus in cooperation with the planning theBluemap for various manufacturing service de-velopment. (3) Conducting gap screening andevaluation on various manufacturing service re-lated themes and value chains. (4) Implementa-tion in industries for the acceleration of imple-menting the process of different innovation man-ufacturing service development (Hsu 2012). Fig-ure 4 shows relevant promotion mechanism.

Fig. 4. Diagram for the promotion mechanism in Taiwan’s manufacturing application and service

PRODUCT DEVELOPMENT MODEL OF SERVICE INNOVATION 717

Literature Review

Development Model of Service InnovationCluster Development Model

Innovative approach originates from inno-vative concepts. Strategy involving service in-novation must first re-review the definition ofservice, in order to break away from the conven-tional cognition and imagery space. Moreover,product oriented logistic thinking in manufac-turing industry has developed a variety of practi-cal strategic models and management tools, whichmerit utilization even for service oriented logisticthinking in service industries. The following is adiscussion on the service types and new servicestrategies with proposal of service-customer ma-trix and added-value-complexity matrix as the think-ing tool for service innovation.

The key factor to commercialize service lieson the follows: 1. Discovery of service lesson. 2.Proposal to solve service lessons. 3. Establish-ment of appeals in service value, followed by 4.Mobilization of service resources. 5. Executionof service commercialization. These five factorsare regarded as the procedures and guidelinesto service commercialization, which control canbe advanced and strengthened through the en-hancement of imagination and creativity as wellas the application of service science.

Project-Based “Clustering Model” Generat-ed from Clustering Innovation Concept (Gertler2003) . The term, agglomeration, originates fromthe term, population in biology, which is used toexplain and describe the phenomenon of homoand hetero biological clustering that co-exist andare interdependent in a specific area or habit (Bienand Hsu 2013). The concept of industry clustersand emergence of analytical model transform theindustrial economic analysis previously empha-sizing on the market structure, corporate gover-nance, and enhancement of organization opera-tion efficiency into a comprehensive thinkingapproach that take into consideration of spatialsegmentation, relationship with suppliers, exter-nal environment and industry upstream and low-er/downstream. Such transformation implies anew emergence of national regional and urbaneconomies (Granovetter 1985; Yang 2010; Wu2010).

The so-called cluster refers to some specificrelated industries that gradually evolve into an

interactive connection with economic benefits,whereas an independent and profit-sharing rela-tionship with yet intense competition is devel-oped in suppliers within the cluster (Bien andHsu 2013) on the other hand divided clusteringzone into vertical and horizontal integration,whereas the former refers to the relationship be-tween customers and suppliers and is attributedto the upstream supply chain. The later refers tocompetitors with production complementaritiesor alternative products, which scope includesservice and financial companies, as well as therelated industries. Such classification is also ap-plicable to the average public and private-sec-tors institutes. Porter build the foundation forthe definition of cluster and the Bluemap for thedevelopment of future organization, however, itwas only until in recent years, the benefits in-duced by such concept of organization typesstart to gain popularity in discussion.

Arikan (2009) divided the interdependencebetween clustering suppliers as: upstream/down-stream supply/demand relationship, peer coop-eration and competition, and common pool re-sources. Anderson (1994) suggested that thecombination of clustering suppliers not only re-fers to geological combination but the consis-tent ideas in conceptual combination and con-struct of vision. Such driving force will urge thesuppliers to cooperate closely. Feser and Berg-man (2000) combined the two concepts and fur-ther defined cluster as an official input-outputrelationship, buyer-supplier relationship, geo-graphic concentration, industry related organi-zation and a combination with “Coopetition.”Suppliers within the cluster not only have com-mon pool resources but can generate industrysynergies and maintain production efficiencywith flexibility on that specific cluster throughinteraction and exchange.

To cope with globalized competition environ-ment and to control the business opportunitiesfor Taiwan ECFA, the Small and Medium Enter-prise Administration, Ministry of Economic Af-fairs, R.O.C. launched the “Small and MediumEnterprise Agglomeration Innovation Integrat-ed Service Project” in 2008. Such program com-bines the service energies from the IndustrialTechnology Research Institute (ITRI), Institutefor Information Industry (III), and the Metal In-dustries Research and Development Center(MIRDC) to provide comprehensive counselingon small and medium enterprise technology R&D,

718 MIN-WEI HSU, TSAI-YUN LO, SHOUJEN BIEN ET AL.

innovation operation, and marketing expansion,using agglomeration and cooperation model toaccomplish enterprise upgrade and transforma-tion. In sum of aforementioned literature, indus-try clustering is regarded as an agglomerationeconomy constituted by a series of upstream,midstream, downstream, and other enterprisesor institutes. These industries include services,finance, manufacturing, or other industries withapplicable scope including public and private-sector agencies. Agglomeration often extends thetentacles upward (suppler integration) or down-ward (consumer integration), or horizontal inte-gration to the complementary suppliers now.Strategy-cooperation synergies are createdthrough the structure of integrated values, andtherefore extending the clustered service designprocedures in the design field.

Service Design

Service design is a process involving 4 D’s,namely discovery, definition, development, anddelivery, which is related to the understandingof customers, organization and market, and de-velopment and idea as well as the transforma-tion into feasible solutions for execution. Ser-vice design involves the undergoing service lifecycle by providing sustained development. Theservice could refer to continuous and timelychanges.

Service design does not refer to a new spe-cialized designing profession but a new multi-disciplinary professional knowledge platform.What it really means is that service design doesnot refer to a short-term plan for launching theservice to market but a sustained process thatintegrates new service practices into organiza-tion through work camps and projects. In fact,service design can adapt to organization anddemand to transform into corporate structure andprogress (Deng 2009).

Hence, service deign aims to plan and buildup useful, usable, desirable, satisfying, effective,and highly efficient service experience, whichhelps crossing all points of contact and time shift-ing to understand consumers, market, commonpool resources, and in-depth understanding ofcustomer expectation, demand and experience.Service design also contributes to launchingopportunities, generating ideas, solving prob-lems, and creating executable solutions by pro-viding meaningful specification, guidelines and

strategies. Moreover, service design generatesideas, develops solutions and creates concepts,using principles of evaluation to validate theoptimal concepts and solutions, in addition todiscovering explanations and sharing interpre-tation, complex structure and methods of pro-cess. Using prototypes to test the results, ser-vice design executes solutions through planningand procedural maps.

Service design creates and builds customerinterface to ingeniously connect the details ofall service itineraries. The user of methods andtools sustain consistency, satisfaction, useful-ness, and feasibility in service experience thatconform to successful branding and commercial-ization. For the companies, service design offerspossibilities of value-added creation, differenti-ation from competitors, effective utilization ofresources, and connection with customersthrough more desirable methods. On the otherhand, for customers, service design could repre-sent the improvement on daily life and supply ofquality experience (Bien and Hsu 2012).

Service design connects customer desire andorganizational desire, which acts as a intermedi-ary that understands how to establish the rela-tionship between customers and organizations.

Service Design Combines Disciplines ofDifferent Professional Knowledge

Design has developed into a strategy thatconnects with multi-disciplinary fields. Hence,many designers are experts from different fields,including research, technology or communica-tion, join to work together.

Service design usually involves internal andexternal customers, whereas different people inone institute must also be treated as customers.Service design assures the collective participa-tion in one project with the perception of a cus-tomer, while different methods and tool use canguarantee excellent internal and external serviceexperience.

Design (including communication) has longbeen the intermediary/translator between indus-try and people, technology and application, andsupply and demand. It can be said that marketdistributors, engineers other people could notfacilitate the service design of multiple profes-sional field, who would likely be addressed asthe service marketing. However, a design ser-vice field offers a very unique task that requiresdifferent tools and techniques.

PRODUCT DEVELOPMENT MODEL OF SERVICE INNOVATION 719

Organizations need to take into considerationof trust, concept of increasing ownership trans-fer and experience when designing and develop-ing new services. Although the change of pay-ment method does not affect product design, itis one major change in service.

Service contact refers to the interaction oc-curred between the customers and providers ofservice organization during the service experi-ence process. It is also the key point and themain link in customer service experience. Theservice providers become the “representative”of service organization in contact with custom-ers during the process.

The behaviors of contact engaged by ser-vice providers are the composition of serviceproducts provided by the service organization,while customers also need the assistance fromthe service provider to complete the primary partof service experience.

This process of contact then becomes thekey quality of service products evaluated bycustomers. In western countries, the moment ofcontact between customers and service provid-er is known as the “moment of truth,” namely themoment of interaction discloses the truth of ser-vice, whereas the strength and weakness of ser-vice quality are determined at this moment.

Service Bluemap

A service bluemap describes the meticulousdetails that can execute and maintain this ser-vice, providing reference as development designfor the manager of business development divi-sion, designers, and software engineers. Suchbluemap can also be used as grounds for man-agers of service department in the execution ofroutine services, helping the manager of servicedepartment to comprehend the qualities and ad-vantages from the usage to brand managementof IT infrastructure.

Bluemap refers to an illustration that trans-forms service concepts and design thinking intoservice system through simple and explicitmeans. Bluemap design is previously a funda-mental method to architecture design, whichmethod is adopted by the service industry tocarry out the design of service system. The con-tent of service bluemap is further divided intothe following according to the degree of sophis-tication (Fig. 5):

(1) Conceptual Bluemap: Overall descriptionof the service system.

(2) Specific Bluemap: Detailed description oncertain part of the service system.

Fig. 5. Simplified service Bluemap diagram

720 MIN-WEI HSU, TSAI-YUN LO, SHOUJEN BIEN ET AL.

Service Experience Model

For product designers, modeling is the mostimportant factor for development products anddetermining the style. Service experience modelreveals the intangible experience that need toquickly convey the experience and function ofservices, so that we can conduct effective eval-uation on service feasibility, in addition to shar-ing its concepts with potential users, peers anddecision makers. A service experience model sup-ported by commercial projects is usually the R&Dstage or consideration set aside for the evalua-tion of one service.

It is often required to attempt and test howthe service concept will be applied in the contextof reality since service does not exist in isolatedprototype, while testing requires the restructur-ing of reality and expected framework to assureintegrity to service experience, similar to the ser-vice that will exist (Deng 2009).

Usually, this implies that service requires theinput of a temporary existence, whereas the us-ers naturally use it under the conditions of real-ity, which sometimes require more efforts to cre-ate the space, ambient and the environment. Oth-er times, the mobiles and actors are required todisguise them into hotlines.

RESEARCH METHODS

The study adopts qualitative research meth-od on suppliers applying for subsidies with re-view and approval from the government agen-cies, which have been executed and completed.The study collected data from the interview withthe person in charge of the internal R&D centerand the discussions on internal organization datato obtain more detailed, in-depth and genuinedata. The study analyzes the data using qualita-tive research method, case study, in-depth inter-view with the experts, expert focus group meet-ing, and oral data analysis to acquire the out-come and generate conclusion.

For sample selection, due to the consider-ation of the composition and interaction for man-ufacturing servitization in product innovationservice development, only companies with smallscale of capital in NTD5,000,000 were selected tocarry out the analytical research. To successful-ly promote the formation of industry upgrade,Taiwan government commissioned National Sci-ence Council for Academic-Industry counseling

application and the CITD from the Ministry ofEconomic Affairs for conventional industry de-velopment program counseling to apply for theimplementation. The suppliers emphasize on thetransformation of conventional manufacturingindustry into modern manufacturing-servitizationproduction model, by assisting the suppliers andR&D and growth with emphasis placed on theformation and building of future industry mod-els. For this reason, the study conducts inter-view with suppliers that have been approved bythe program application, discussing in more de-tails of future manufacturing evolution. Addi-tionally, 16 success counseling cases in line withthe service design model of the issues discussedby the study are selected as target samples, sup-plemented with detailed internal interview anddata to comprehensively present the innovationservice development model of the products asthe key success factor to operation.

Finally, the samples selection includes allpersonnel in contact with internal organizationof the suppliers, who play the key role in thecontact and communication with internal devel-opment units. Moreover, the discussion of theo-ries and practices involve representative objects.

Tables 1 and 2 refer to the samples of theresearchers’ actual participation in program exe-cution between 2001 and 2013:

Table 1: Eleven cases of academic-industry col-laboration supplier samples approved by Nation-al Science Council

Name of Programs

A Study on Experience Perspective Guided ProductDesign Model, 2003Development of Experience Oriented Office and HomeFurniture, 2004Establish Innovation Experience and BrainstormingApplications on Quality Kitchenware Design Model,2005Global Brand Fashion Design of Taiwan Cultural Boutique– An Example of Cheerful Fashion Goods, 2006Pursuit of Style and Fun – Innovative DesignDevelopment of Fashion Boutique, 2007Development of Fashion and Luxury InnovativeEyeglass Design, 2008Digital Simulation Technology Applied on Cabin Design,2009Research on Chinese-German Cultural Kitchen SystemIntegration, 2010Future Family and Kitchen Interactive Space andRelevant Advanced Green Product Design, 2011A Study on Kitchen Space and Green LightingInnovation Design, 2012Application of Innovation Service In-Depth Model onLock Product Development, 2012

PRODUCT DEVELOPMENT MODEL OF SERVICE INNOVATION 721

ANALYSIS AND DISCUSSION

Seven Indicators of ManufacturingServitization on New Product DevelopmentProcess

Although design is a professional occupa-tion, its effectiveness could not be easily esti-mated through precise data and methodologies.Hence, design service often faces with multiplechallenges in the process of product develop-ment, while how to convince the industries intoagreeing with your service, accepting your pro-fessionalism, and recognizing your work becomeone great challenge for the industries.

Design service not only includes profession-alism in style, color, arrangement and techniquesbut also need to express several points to cus-tomers. Design is an “objective” industry thatcould not be expressed of energies through tech-nology, productivity and sales, therefore apartfrom professional knowledge, the use of non-marketing schemes such as reinforcing custom-er impression on you, stressing your viewpointsand success cases will strengthen customers’value judgment on your design and works.

In the past, design service mostly empha-sized on the deliberation and persistence on workstyles, with gradual transfer from the commercialterritory of the industries to the backend CAD/CAM, printing, molding and other manufactur-ing engineering fields at certain point in time,under the intensely competitive market pressure.However, the researchers stress that there aretwo most important values to design, one is the

innovation trend and the other is the marketingstrategy. Hence, even if the industries intend to“transform,” they need to progress towards thefrontend “market research” or the very backend“marketing” of the industry chain, and conse-quently not only can the design professionalismbe extended but can also more “explicitly” createvalues for customers (Arikan 2009).

The following is the development process of“how to development products under manufac-turing sertivization” with a list of seven thinkingusing industry transformation to strengthen cus-tomer recognition, which is not only used byexisting industries to strengthen the value be-tween manufacturing and services but can alsobe the key indictors applied to product develop-ment process (Bien and Hsu 2013).

Preparing Professional and ExquisiteCompany Introduction and Websites toWin Customer’s First Impression

Introduce your professional services anddesign styles via written forms and websites.Such introduction includes: brands, design meth-ods, success cases, and awarded works. Not allproprietors have design demand at all time andthe best way is to arrange a face-to-face inter-view by leaving a written document as reference.The company introduction needs to be straight-forward and powerful by leaving two to threekey points on the website or the written docu-ments. Focus on the design style, cases andmedia report whenever possible, as the informa-tion will leave impression on the customers.

Table 2: Five Cases of Ministry of Economic Affairs CITD supplier samples

Subsidized or Commissioned institutions Name of Program

Ministry of Economic Affairs Industrial Development Multi-Functional Home SPA Massage SeriesBureau sponsored 2009 “Taiwan Creative Design”counseling for the innovative design of conventionalindustriesIndustrial Development Bureau sponsored 2009 (CITD) Stylish Home Product Design No.: S09800053-099Conventional Industry Technology Development–Product Design CategoryIndustrial Development Bureau sponsored 2009 Future Home Life Aesthetics – Delightful and(CITD) Conventional Industry Technology Practical Product Design No.: S09800053-116Development – Product Design CategoryIndustrial Development Bureau sponsored 2009 Design and Development for Medical Counseling(CITD) Conventional Industry Technology Product Application No.: S09900074-219Development Program – Product DevelopmentIndustrial Development Bureau sponsored 2010 Design and Development of Sports and Leisure(CITD) Conventional Industry Technology Shoes Product Application No.: S09900074-218Development Program – Product Development

722 MIN-WEI HSU, TSAI-YUN LO, SHOUJEN BIEN ET AL.

Fully Understand Customer Products andMarket, Providing Customers with theOptimal Solutions

Talk with customers using the same languagewhen interviewing them, understand the profes-sional terms of the industry while proposing aset of Design Solution that will meet customerproduction and market expectation, or least letthe customers know that you understand them.For example, what are the domestic and interna-tional competitors of the market and what aretheir product styles and strategies? What is theexpectation of consumer market? How to devel-op potential consumer groups? How do custom-ers create business opportunities through prod-ucts or service innovation? Such issues requirere-study prior to the visit.

Apply Project Management Techniquesto Control Design Quality andEmphasize on Professionalism

Most designing departments offer flexibledesign process and management for the entireproject while sometimes without any rules to fol-low, in the event of meeting customers’ demandin rushing for the deadlines. In the past, somecustomers has played role of designer for on-site design while the designer also agreed. It wasinevitable that the customer became the creativedirector, supervising the work of the designer.As a result, the case failed and the project didnot go into mass production, as one of the big-gest reason being that the product did not dif-ferentiate much from past product creativity.

It is necessary for the designing departmentto develop a set of project management on thecontrol over time and resources for the projects,as all creativities require project management tocontrol and quality while protecting the indus-tries from defeating themselves due to customerpressure. Such project management must bepackaged into maximizing customer interestswhile showing the competency of the designingdepartment.

Work for Special Market Presentationor Awards to Increase Value Recognitionfor Services from the Industries

Special performance and awards on the mar-ket can improve the brand value of industries to

service providers, strengthening customer trust-worthiness in you. In particular, the past achieve-ment of excellent market performance will be mostconvincing. Such records will help customersvalue your design process, viewpoints and out-come. For example, famous ASUS and BENQcompanies from Taiwan have created rich designperformance as a result of reporting on interna-tional awards.

Create Media Exposure, List Media Reports, and Produce Third-Person Word-of-Mouth Marketing

Third-person’s words are always easily ac-cepted by customers when you and your cus-tomer engage in first contact. The media not onlyrepresents the third person but the majority ofthird persons. Hence, manufacturing industryshould learn to express them through media ex-posure, since “service and design” is anotherindustry that needs persuasion. Publicity alsoserves as a powerful mean apart from the prod-ucts, design brand, and designers.

Additionally, word-of-mouth marketing isquite important. Statistics show that the firstcooperation with customers mostly come fromintroduction and design companies should par-ticipate in social events with interactions to ex-pand the sources of business opportunities.

Publish Works with Solid Context

Creativity requires instruction and most cus-tomers hold standards for creativity based onthe product patterns of existing market. Whenthe designing department proposes propositionfor creativity, several illustration and sample dia-gram are not enough while a story with life needsto be invigorated into this proposition. An in-struction far more superior than existing prod-ucts and the interpretation of commercial strate-gy should be provided to help customers enter anew scenario, using story and culture to bringthe manufacturing industries closer to consum-er service orientation.

Strategy Services

Design projects not only offer pattern de-sign and visual design of products but can alsocreate benefits in marketing and production. Forexample, the designing department can introduce

PRODUCT DEVELOPMENT MODEL OF SERVICE INNOVATION 723

new production resources, new technology, spe-cial components or materials, funding, and mar-keting cooperation opportunities for customers.Particularly, the designing department can as-sist the suppliers obtain relevant know-how andresources for some conventional suppliers step-ping into new products and the new market,which not only assure successful mass produc-tion of design but obtain more trustworthinessfrom customers.

In sum, the designing department should fo-cus on creativity capacity as well as strengthen-ing resource management and communicationability in order to design exceptional productsand improve the future production and sales like-lihood of customers.

CONCLUSION

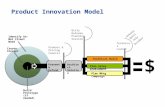

Finally, the paper highlights and integratesthe key for manufacturing industry in transitionto servitization for the designing and R&D de-partments to conduct reverse deduction (Fig.6)through the physical and virtual channel think-ing, so that the process of innovation product

development will face with the new trend of fu-ture manufacturing servitization more effective-ly, as show in the following five conclusions:

The product development unit of the sup-plier (designing department) should serveas cluster communication and coordinationwith definition of role importance.Use service design thinking for manufac-turing servitization as the future trend ofclustering industry development.Successful clustering development is de-termined by the integration efficiency ofvarious internal organization chains.Clustering thinking model contains advan-tages such as value-added creativity, in-novation and savings in transaction costs.The flow chart for the product developmentmodel operation of representative suppli-ers in this study is carefully compared withthe interview of supplier representative tosolve the service innovation developmentmodel that has not been revealed from pastliterature.

Such indicators will provide important refer-ence for the industries with considerably impor-tant shortening of R&D schedule.

Fig. 6. Innovative clustering thinking model for product development process

724 MIN-WEI HSU, TSAI-YUN LO, SHOUJEN BIEN ET AL.

REFERENCESAnderson G 1994. Industry clustering for economic

development, Economic Development Review,12(2): 26-32.

Arikan AT 2009. Interfirm knowledge exchanges andthe knowledge creation capability of clusters. Acad-emy of Management Review, 34(4): 658-676.

Bien SR, Hsu MW 2013. A successful service innova-tion model for shortening the design process. Ad-vanced Materials Research, 834-836.

Bien SR, Hsu MW 2012. Establishment of ImageryExperience and Interaction Theory Applicatioin onthe Service Innovation Strategy System of QualityKitchenware Industries. Cultural and Creative De-sign Brand Marketing International Forum, in Chun-gyu Institute of Technology, Keelung, Taiwan, May25, 2012.

Bien SR, Hsu MW 2013. Application of Service Inno-vation Strategy-Cooperation Model on Cultural Cre-ative Package Design. Style, Design and EducationInternational Academic Forum in Taipei, in JinwenUniversity of Science and Technology, Taipei, Tai-wan, May 31 2013.

Deng CL 2009. Construction and exploration into theorder of branding culture - livelihood supplies devel-opment project. The Industrial Design, 24(3): 23-35

Feser EJ, Bergman EM 2000. National industry clustertemplates: A framework for applied regional clusteranalysis. Regional Studies, 34(1): 1-20.

Gertler MS 2003. Tacit knowledge and the economicgeography of context, or the under finable tacitnessof being (there). Journal of Economic Geography,3(1): 75-99.

Granovetter M 1985. Economic action and social struc-ture: The problem of embeddedness. American Jour-nal of Sociology, 91: 481–510

Hsu MW 2012. Value-added Service Innovation andApplication of System Cabin. Seminar on Commer-cial Management and Innovation Design (SCMID),Far East University, Tainan, Taiwan, May 30 2012.

Liang GJ 2010. Exploration on the process and ap-proach to conventional industry product develop-ment projects. The Industrial Design, 25(1): 114-128

Liu CM, Lin KW, Huang CJ 2013. Effects of productdevelopment on operating performance in textileindustry. Anthropologist, 17(1): 157-163.

Wu YC 2010. Common Wealth Special Edition, Vol-ume 50, Taipei.

Xu MW, Bien SR 2007. April, Introduction to the Out-come of Innovation Experience Brainstorming Ap-plication on Quality Kitchenware Design Model,Taipei Kitchenware, Taipei Kitchen Commerce As-sociation.

Yang M 2010. Insight to the 20 futures. Global ViewMonthly, 289: 35-55.

Zhang JY 2014. Why we need architecture?, Ecologi-cal Civilization and Urbanization, 22(3): 211-224