Omega Report by Shivani Soni

-

Upload

ritu-choudhary -

Category

Documents

-

view

55 -

download

0

description

Transcript of Omega Report by Shivani Soni

APRACTICAL TRAININGSEMINAR REPORTONOMEGA ELECTRONICS, JAIPUR

SESSION 2012-2013Submitted for the partial fulfillment for the award of the degree ofBACHELOR OF TECHNOLOGYOFRAJASTHAN TECHNICAL UNIVERSITY, KOTA

SUBMITTED BY:SHIVANI SONI09ELREC0567th SEM (ECE)

---------------------------------------------------------------------------------------------------------------Department of Electronics & Communication EngineeringLORDS INSTITUTE OF ENGINEERING AND TECHNOLOGY FOR WOMEN

Page | 1

PREFACE

With growing developments in the field of mechtronics , mathematicalmodeling robotics has come long way from an iron piece that moves a fewinches to machines capable of jumping from high buildings detecting mines,performing various operations and troubleshooting various operations.Robotics means the study and application of robot technology. The goal ofrobotics is to mimic natural world as closely as possible. The main elementsin the robot are the moving elements and the sensors.This paper deals with the evolution of robots, the elements of robotics, thelimitation of robots, and the various applications of robots. In theapplication part this paper expects to cover in detail robot surgery androbonauts (the robots used in space), .It also deals with the introductionto interfacing.

Page | 2

ACKNOWLEDGEMENT

I sincerely thank my seminar coordinator Mr. Rakesh Sharma (Head of Department, E.C.E.) Lords Institute Of Engineering and Technology for Women, Alwar who went out of way toprovide me every possible facility and support me in presenting seminar smoothly and successfully. It was her able guidance and support, whichresulted in the successful presentation of my seminar within the specifiedtime. Their unflinching help and encouragement was a constant course ofinspiration to me.

I would also like to express my deep sense of gratitude to the ManagingDirector Omega Electronics and all its employees for extending their helpand painstakingly helping us throughout our training period. I would alsolike to thank all the members of the training and placement cell for helpingus.

A seminar owes its success from commencement to completion, to peopleinvolved with seminar at various stages. I avail this opportunity to conveymy sincere thanks to all individuals who have helped and assisted me incarrying and bringing out this seminar.

Last, but not the least, the co-operation and help received from teachersand friends is gratefully acknowledged.

Page | 3

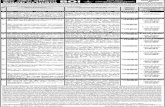

CONTENTS

1. Brief history of Omega Electronics …………………………………………2. Introduction to basic electronics .……………….........……………………. 2.1 Diodes…………………………………………………………………. 2.2 Transistor……………………………………………………………… 2.3 Field effect transistor………………………………………………......3. Soldering…………………………………………………………………….4. Switches ……………………………………………………………………5. Introduction to Robotics ……………………………………………………6. Anatomy of robot…………………………………………………………..7. Gear system…………………………………………………………………..8. Sensors ………………………………………………………………………9. Control System ………………………………………………………....10. Actuators …………………………………………………………….......11. Power Supply…………………………………………………………….12. Physical Interfacing Devices……………………………………………13. Conclusion……………………………………………………………….14. Bibliography………………………………………………………….…

Page | 4

LIST OF FIGURES

Page | 5

1. BRIEF HISTORY OF OMEGA

Mr. Y. P. Agarwal, an eminent & qualified Electronic professional, foundedOMEGA ELECTRONICS in the year 1962. Heading the company as Chief Executive,he is continuing his expert guidance and OMEGA is achieving new horizons ofsuccess under his supervision. Attributing to his foresight, OMEGA iscurrently one of the organizations in the country, which enjoys an all Indiapatronage and coverage. An ISO certified Company 9001:2000, situated inMalviya Nagar RICO Industrial Area, Jaipur, (Rajasthan)

Omega manufactures electronic educational training equipments andinstruments to assist educators in various technical fields such astelecommunications, microprocessors, power electronics, processinstrumentation.Omega Teaching Aids & Equipments bring technical theory to life, teachingthe latest technology and helping trainees to develop valuable troubleshooting skills.

INDUSTRIAL TRAINING AT OMEGA:

Industrial Training at Omega means exposure to Practical learning envinment, Production, Processes, Policies, Layouts, Responsibilities, Discipline, Deadlines, Time & Stress Management, Sales, Marketing, Purchase, Tender etc. All these facets can be learned in an Industry, which has all departments. Training at Omega is gaining popularity in South East Asia RegionDescriptionWe are the proponents of this unique concept in South East Asia Region for imparting hands on experience, practical edge, vocational training & DIY concept. From last 4 years in total 1110 students, teachers, lecturers from 65 different colleges have benefited from these training programmes.

Basic info

Started September 1962

Location Omega Electronics, 28 E and F,, Jaipur City, Rajasthan, India 302017

Awards In last 5 years 1500 Teacher/ Student have done their training at Omega.

Products Omega is the pioneer and leader in World Didac market with more than 1300 products in its portfolio. Exhaustive range includes Antenna Trainers, GPS Trainer, Radar Trainer, RFID Trainer, Instrumentation Trainers, Communication Trainers, LAN Trainer, VLSI Trainers, Microprocessor, Microcontroller & Interfaces Trainers, Consumer Electronics Demonstration Trainers, Test and Measuring Instruments, Microwave Test Benches, Educational Wall Charts, Robotics Kits, Decade Boxes (R,L,C), Analog Electronics Lab, Digital Electronics Lab, Power Electronics Lab, Breadboards, Power Project Board, Circuit Lab Trainers, Physics Systems

Page | 6

Training, Fibre Optics Trainers, Power Supplies. Apart from this range of Training System, we undertake customised development based on customer's feedback, application and required quantity. Our training systems address technology for Master Unit & Optional Modules, Independent Built In Power Supplies and Breadboard based educational Lab equipment.

2. INTRODUCTION TO BASIC ELECTRONICS

Page | 7

In basic electronics we had a review on concepts of various basic electronicdevices like diodes, transistors. FETs, their construction, V-Icharacteristics, working, kit display and application in electronics.

DIODES

In electronics, a diode is a two-terminal electronic component. Asemiconductor diode, the most common type today, is a crystalline piece ofsemiconductor material connected to two electrical terminals. A vacuum tubediode (now little used except in some high-power technologies) is a vacuumtube with two electrodes: a plate and a cathode.The most common function of a diode is to allow an electric current to passin one direction (called the diode's forward direction), while blockingcurrent in the opposite direction (the reverse direction). Thus, the diodecan be thought of as an electronic version of a check valve. Thisunidirectional behavior is called rectification, and is used to convertalternating current to direct current, and to extract modulation from radiosignals in radio receives.However, diodes can have more complicated behavior than this simple on-offaction. Semiconductor diodes do not begin conducting electricity until acertain threshold voltage is present in the forward direction (a state inwhich the diode is said to be forward biased). The voltage drop across aforward biased diode varies only a little with the current, and is afunction of temperature; this effect can be used as a temperature sensor orvoltage reference.Semiconductor diodes have non-linear electrical characteristics, which canbe tailored by varying the construction of their P-N junction. These areexploited in special purpose diodes that perform many different functions.For example, diodes are used to regulate voltage (Zenger diodes), to protectcircuits from high voltage surges (Avalanche diodes), to electronically tuneradio and TV receivers (varactor diodes), to generate radio frequencyoscillations (tunnel diodes, Gunn diodes, IMPATT diodes), and to producelight (light emitting diodes). Tunnel diodes exhibit negative resistance,which makes them useful in some types of circuits.Diodes were the first semiconductor electronic devices. The discovery ofcrystals' rectifying abilities was made by German physicist Ferdinand Braunin 1874. The first semiconductor diodes, called cat's whisker diodes,developed around 1906, were made of mineral crystals such as galena. Todaymost diodes are made of silicon, but other semiconductors such as germaniumare sometimes used.

Current–voltage characteristic:-A semiconductor diode’s behavior in a circuit is given by itscurrent–voltage characteristic, or I–V graph (see graph below). The shape ofthe curve is determined by the transport of charge carriers through theso-called depletion layer or depletion region that exists at the p-njunction between differing semiconductors. When a p-n junction is firstcreated, conduction band (mobile) electrons from the N-doped region diffuseinto the P-doped region where there is a large population of holes (vacantplaces for electrons) with which the electrons “recombine”. When a mobile

Page | 8

electron recombines with a hole, both hole and electron vanish, leavingbehind an immobile positively charged donor (dopant) on the N-side andnegatively charged acceptor (dopant) on the P-side. The region around thep-n junction becomes depleted of charge carriers and thus behaves as aninsulator.

Fig 1: V-I characteristic of diodeHowever, the width of the depletion region (called the depletion width)cannot grow without limit. For each electron-hole pair that recombines, apositively charged dopant ion is left behind in the N-doped region, and anegatively charged dopant ion is left behind in the P-doped region. Asrecombination proceeds more ions are created, an increasing electric fielddevelops through the depletion zone which acts to slow and then finally stoprecombination. At this point, there is a “built-in” potential across thedepletion zone.If an external voltage is placed across the diode with the same polarity asthe built-in potential, the depletion zone continues to act as an insulator,preventing any significant electric current flow (unless electron/hole pairsare actively being created in the junction by, for instance, light. seephotodiode). This is the reverse bias phenomenon. However, if the polarityof the external voltage opposes the built-in potential, recombination canonce again proceed, resulting in substantial electric current through thep-n junction (i.e. substantial numbers of electrons and holes recombine atthe junction). For silicon diodes, the built-in potential is approximately0.7 V (0.3 V for Germanium and 0.2 V for Schottky). Thus, if an externalcurrent is passed through the diode, about 0.7 V will be developed acrossthe diode such that the P-doped region is positive with respect to theN-doped region and the diode is said to be “turned on” as it has a forwardbias

Page | 9

Normal (p-n) diodes, which operate as described above, are usually made ofdoped silicon or, more rarely, germanium. Before the development of modernsilicon power rectifier diodes, cuprous oxide and later selenium was used;its low efficiency gave it a much higher forward voltage drop (typically 1.4to 1.7 V per “cell”, with multiple cells stacked to increase the peakinverse voltage rating in high voltage rectifiers), and required a largeheat sink (often an extension of the diode’s metal substrate), much largerthan a silicon diode of the same current ratings would require. The vastmajority of all diodes are the p-n diodes found in CMOS integrated circuits,which include two diodes per pin and many other internal diodes.

TRANSISTOR

A transistor is a semiconductor device used to amplify and switch electronicsignals. It is composed of a semiconductor material with at least threeterminals for connection to an external circuit. A voltage or currentapplied to one pair of the transistor's terminals changes the currentflowing through another pair of terminals. Because the controlled (output)power can be much more than the controlling (input) power, a transistor canamplify a signal. Today, some transistors are packaged individually, butmany more are found embedded in integrated circuits.The transistor is the fundamental building block of modern electronicdevices, and is ubiquitous in modern electronic systems. Following itsrelease in the early 1950s the transistor revolutionized the field ofelectronics, and paved the way for smaller and cheaper radios, calculators,and computers, among other thing.

The transistor is the key active component in practically all modernelectronics. Many consider it to be one of the greatest inventions of the20th century. Its importance in today's society rests on its ability to bemass produced using a highly automated process (semiconductor devicefabrication) that achieves astonishingly low per-transistor costs.Although several companies each produce over a billion individually packaged(known as discrete) transistors every year, the vast majority of transistorsnow are produced in integrated circuits (often shortened to IC, microchipsor simply chips), along with diodes, resistors, capacitors and otherelectronic components, to produce complete electronic circuits. A logic gateconsists of up to about twenty transistors whereas an advancedmicroprocessor, as of 2011, can use as many as 3 billion transistors(MOSFETs). “About 60 million transistors were built this year [2002] ... for[each] man, woman, and child on Earth."

Page | 10

Fig.2: (a) Symbol of transistor. (b) Different types of transistors

The transistor's low cost, flexibility, and reliability have made it aubiquitous device. Transistorized mechatronic circuits have replacedelectromechanical devices in controlling appliances and machinery. It isoften easier and cheaper to use a standard microcontroller and write acomputer program to carry out a control function than to design anequivalent mechanical control function.

FIELD EFFECT TRANSISTOR

The field-effect transistor (FET) is a transistor that relies on an electricfield to control the shape and hence the conductivity of a channel of onetype of charge carrier in a semiconductor material. FETs are sometimescalled uni polar transistors to contrast their single-carrier-type operationwith the dual-carrier-type operation of bipolar (junction) transistors(BJT). The concept of the FET predates the BJT, though it was not physicallyimplemented until after BJTs due to the limitations of semiconductormaterials and the relative ease of manufacturing BJTs compared to FETs atthe time

Fig.3: Field effect transistor

FET operation:-The FET controls the flow of electrons (or electron holes) from the sourceto drain by affecting the size and shape of a "conductive channel" createdand influenced by voltage (or lack of voltage) applied across the gate andsource terminals (For ease of discussion, this assumes body and source areconnected). This conductive channel is the "stream" through which electronsflow from source to drain.In an n-channel depletion-mode device, a negative gate-to-source voltagecauses a depletion region to expand in width and encroach on the channelfrom the sides, narrowing the channel. If the depletion region expands tocompletely close the channel, the resistance of the channel from source todrain becomes large, and the FET is effectively turned off like a switch.Likewise a positive gate-to-source voltage increases the channel size andallows electrons to flow easily.Conversely, in an n-channel enhancement-mode device, a positivegate-to-source voltage is necessary to create a conductive channel, sinceone does not exist naturally within the transistor. The positive voltage

Page | 11

attracts free-floating electrons within the body towards the gate, forming aconductive channel. But first, enough electrons must be attracted near thegate to counter the dopant ions added to the body of the FET; this forms aregion free of mobile carriers called a depletion region, and the phenomenonis referred to as the threshold voltage of the FET. Further gate-to-sourcevoltage increase will attract even more electrons towards the gate which areable to create a conductive channel from source to drain; this process iscalled inversion.

3. SOLDERING

Soldering is a process in which two or more metal items are joined togetherby melting and flowing a filler metal into the joint, the filler metalhaving a lower melting point than the work piece. Soldering differs fromwelding in that the work pieces are not melted. There are three forms ofsoldering, each requiring higher temperatures and each producing anincreasingly stronger joint strength: soft soldering, which originally useda tin-lead alloy as the filler metal, silver soldering, which uses an alloycontaining silver, and brazing which uses a brass alloy for the filler. Thealloy of the filler metal for each type of soldering can be adjusted tomodify the melting temperature of the filler. Soldering appears to be a hotglue process, but it differs from gluing significantly in that the fillermetals alloy with the work piece at the junction to form a gas- andliquid-tight bond.

Page | 12

(b):-bad joint

Fig.4 (a):-good joint

Soft soldering is characterized by having a melting point of the fillermetal below approximately 400 °C (752 °F), whereas silver soldering andbrazing use higher temperatures, typically requiring a flame or carbon arctorch to achieve the melting of the filler. Soft solder filler metals aretypically alloys (often containing lead) that have liquids temperaturesbelow 350°C.In the soldering process, heat is applied to the parts to bejoined, causing the solder to melt and to bond to the work pieces in analloying process called wetting. In stranded wire, the solder is drawn upinto the wire by capillary action in a process called wicking. Capillaryaction also takes place when the work pieces are very close together ortouching. The joint strength is dependent on the filler metal used, wheresoft solder is the weakest and the brass alloy used for brazing is thestrongest. Soldering, which uses metal to join metal in a molecular bond haselectrical conductivity and is water- and gas-tight. There is evidence thatsoldering was employed up to 5000 years ago in MesopotamiaApplications of soldering:-Soldering was historically used to make jewelry items, cooking ware andtools. Currently, the two most common uses of soldering are in plumbing andin electronics where it is used to connect electrical wiring and to connectelectronic components to printed circuit boards (PCBs). It providesreasonably permanent but reversible connections between copper pipes inplumbing systems as well as joints in sheet metal objects such as food cans,roof flashing, rain gutters, and automobile radiators. Jewelry components,machine tools and some refrigeration and plumbing components are oftenassembled and repaired by the higher temperature silver soldering process.Small mechanical parts are often soldered or brazed as well. Soldering isalso used to join lead came and copper foil in stained glass work. It canalso be used as a semi-permanent patch for a leak in a container or cookingvessel.Types of soldering:-1. Soft soldering.2. Silver soldering3. Blazing soldering

Required Items for soldering:-• Soldering iron

Page | 13

• Filler metal• Flux

Solders:-Soldering filler materials are available in many different alloys fordiffering applications. In electronics assembly, the eutectic alloy of 63%tin and 37% lead (or 60/40, which is almost identical in performance to theeutectic) has been the alloy of choice. Other alloys are used for plumbing,mechanical assembly, and other applications.

Fig.5 (a): Solder iron (b.): Filler metal used in soldering

Common solder alloys are mixtures of tin and lead, respectively:• 63/37: melts at 183 °C (361 °F) (eutectic: the only mixture that melts ata point, instead of over a range)• 60/40: melts between 183–190 °C (361–374 °F)• 50/50: melts between 185–215 °C (365–419 °F)

Flux:-The purpose of flux is to facilitate the soldering process. The obstacle toa successful solder joint is an impurity at the site of the union, e.g.dirt, oils or oxidation. The impurities can be removed by mechanicalcleaning or by chemical means, but the elevated temperatures required tomelt the filler metal (the solder) encourages the work piece (and thesolder) to re-oxidize. This effect is accelerated as the solderingtemperatures increase and can completely prevent the solder from joining tothe work piece. One of the earliest forms of flux was charcoal, which acts

Page | 14

as a reducing agent and helps prevent oxidation during the solderingprocess. Some fluxes go beyond the simple prevention of oxidation and alsoprovide some form of chemical cleaning (corrosion).For many years, the most common type of flux used in electronics (softsoldering) was rosin-based, using the rosin from selected pine trees. It wasideal in that it was non-corrosive and non-conductive at normal temperaturesbut became mildly reactive (corrosive) at the elevated solderingtemperatures. Plumbing and automotive applications, among others, typicallyuse an acid-based (muriatic acid) flux which provides

cleaning of the joint. These fluxes cannot be used in electronics becausethey are conductive and because they will eventually dissolve the smalldiameter wires. Many fluxes also act as a wetting agent in the solderingprocess, reducing the surface tension of the molten solder and causing it toflow and wet the work pieces more easily."Hard soldering" or "silver soldering" (performed with high-temperaturesolder containing up to 40% silver) is also often considered a form ofbrazing, since it involves filler materials with melting points in thevicinity of, or in excess of, 450 °C. Although the term "silver soldering"is used much more often than "silver brazing", it may be technicallyincorrect depending on the exact melting point of the filler in use. Insilver soldering ("hard soldering"), the goal is generally to give abeautiful, structurally sound joint, especially in the field of jewelry.Thus, the temperatures involved, and the usual use of a torch rather than aniron, would seem to indicate that the process should be referred to as"brazing" rather than "soldering", but the endurance of the "soldering"appellation serves to indicate the arbitrary nature of the distinction (andthe level of confusion) between the two processes.Induction soldering is a process which is similar to brazing. The source ofheat in induction soldering is induction heating by high-frequency ACcurrent in a surrounding copper coil. This induces currents in the partbeing soldered, heat then being generated by resistive heating. The copperrings can be made to fit the part needed to be soldered for precision in thework piece. Induction soldering is a process in which a filler metal(solder) is placed between the facing surfaces of (to be joined) metals. Thefiller metal in this process is melted at a fairly low temperature. Fluxesare commonly used in induction soldering. This is a process which isparticularly suitable for soldering continuously. The process is usuallydone with coils that wrap around a cylinder/pipe that needs to be soldered.Some metals are easier to solder than others. Copper, silver, and gold areeasy. Iron, mild steel and nickel are found to be more difficult. Because oftheir thin, strong oxide films, stainless steel and aluminum are even moredifficult. Titanium, magnesium, cast iron, some high-carbon steels,ceramics, and graphite can be soldered but it involves a process similar tojoining carbides. They are first plated with a suitable metallic elementthat induces interfacial bonding

4. SWITCHES

Page | 15

In electronics, a switch is an electrical component that can break anelectrical circuit, interrupting the current or diverting it from oneconductor to another.The most familiar form of switch is a manually operated electromechanicaldevice with one or more sets of electrical contacts. Each set of contactscan be in one of two states: either 'closed' meaning the contacts aretouching and electricity can flow between them, or 'open', meaning thecontacts are separated and the switch is nonconducting. The mechanismactuating the transition between these two states (open or closed) can beeither a "toggle" (flip switch for continuous "on" or "off") or "momentary"(push-for "on" or push-for "off") type.

In electronics engineering, an ideal switch describes a switch that:• has no current limit during its ON state• has infinite resistance during its OFF state• has no voltage drop across the switch during its ON state• has no voltage limit during its OFF state• has zero rise time and fall time during state changes• switches only once without "bouncing" between on and off positionsA switch may be directly manipulated by a human as a control signal to asystem, such as a computer keyboard button, or to control power flow in acircuit, such as a light switch. Automatically operated switches can be usedto control the motions of machines, for example, to indicate that a garagedoor has reached its full open position or that a machine tool is in aposition to accept another work piece. Switches may be operated by processvariables such as pressure, temperature, flow, current, voltage, and force,acting as sensors in a process and used to automatically control a system.For example, a thermostat is a temperature-operated switch used to control aheating process. A switch that is operated by another electrical circuit iscalled a relay. Large switches may be remotely operated by a motor drivemechanism. Some switches are used to isolate electric power from a system,providing a visible point of isolation that can be pad-locked if necessaryto prevent accidental operation of a machine during maintenance, or toprevent electric shock.Types of switches:1. SPST (Single Pole Single Through)2. SPDT (Single Pole Double Through)3. DPST (Double Pole Single Through)4. DPDT (Double Pole Double Through)Standard Switches

Type of Switch Circuit Symbol ExampleON-OFFSingle Pole, Single Throw = SPSTA simple on-off switch. This type can be used to switch the power supply toa circuit.When used with mains electricity this type of switch must be in the livewire, but it is better to use a DPST switch to isolate both live andneutral.SPST toggle switch

Page | 16

(ON)-OFFPush-to-make = SPST MomentaryA push-to-make switch returns to its normally open (off) position when yourelease the button, this is shown by the brackets around ON. This is thestandard doorbell switch.Push-to-make switchON-(OFF)Push-to-break = SPST MomentaryA push-to-break switch returns to its normally closed (on) position when yourelease the button.Push-to-break switch

ON-ONSingle Pole, Double Throw = SPDTThis switch can be on in both positions, switching on a separate device ineach case. It is often called a changeover switch. For example, a SPDTswitch can be used to switch on a red lamp in one position and a green lampin the other position.A SPDT toggle switch may be used as a simple on-off switch by connecting toCOM and one of the A or B terminals shown in the diagram. A and B areinterchangeable so switches are usually not labelled.

ON-OFF-ONSPDT Centre OffA special version of the standard SPDT switch. It has a third switchingposition in the centre which is off. Momentary (ON)-OFF-(ON) versions arealso available where the switch returns to the central off position whenreleased.

Dual ON-OFFDouble Pole, Single Throw = DPSTA pair of on-off switches which operate together (shown by the dotted linein the circuit symbol).A DPST switch is often used to switch mains electricity because it canisolate both the live and neutral connections.

Dual ON-ONDouble Pole, Double Throw = DPDTA pair of on-on switches which operate together (shown by the dotted line inthe circuit symbol).A DPDT switch can be wired up as a reversing switch for a motor as shown inthe diagram.

ON-OFF-ONDPDT Centre OffA special version of the standard SPDT switch. It has a third switchingposition in the centre which is off. This can be very useful for motorcontrol because you have forward, off and reverse positions. Momentary(ON)-OFF-(ON) versions are also available where the switch returns to the

Page | 17

central off position when released.

5. INTRODUCTION TO ROBOTICS

Robotics is that branch which involves with the study and applications ofRobots. The goal of Robotics is to mimic natural world as closely aspossible. Robotics is a relatively new field of engineering (aboutapproximately 50 years old) and is finding many applications in differentareas.With growing developments in the field of mechtronics and mathematicmodeling, Robotics has come a long way. From an iron piece that could moveonly a few inches, there are now machines capable of jumping from high risebuildings, detecting landmines, performing complicated operations, andtroubleshooting. The word robot was introduced to the public by the Czechwriter Karel Čapek in his play R.U.R. (Rossum's Universal Robots), publishedin 1920.The word robotics is used to collectively define a field in engineering thatcovers the mimicking of various human characteristicsSound concepts in manyengineering disciplines is needed for working in this particular field.There are various definitions for the term Robot. Some of them areForce through intelligence.1. An automatic device that performs functions normally ascribed to humansor a machine in the form of a human.2. A robot is a reprogrammable multifunctional manipulator designed to movematerial, Parts, tools or specialized devices through variable programmedmotions for the Performance of a variety of tasks.

Robotics compared to other branches is a relatively new field ofengineering. It is a multi disciplinary field. The various branches involvedin the development of Robotics are:

Mechanical Engineering: Deals with the mechanisms of Robots and their structure.Electrical Engineering: Deals with the sensing and controlling of Robots.Computer Engineering: Deals with the motion planning and perception of Robots.

Though the branch of Robotics is new, the development of Robots started inthe year 1250 when the first Robot was developed. In the period from 1250 to1950 the Robots were developed for fun rather than for applicationsModel Based Robots: These Robots use exact models for the work they areentitled to do. They are not provided with any sensors. Hence, they are notrequired to act on external stimuli.

E.g.: A Robot which used for lifting heavy loads are model based as therewill always be a maximum load specified and the robot need not sense theload also there is no other course of action.Sensor Based Robots: These Robots are provided with sensors that have tochange the course of action based on the stimuli it receives. These Robots

Page | 18

are generally used for lower level works.

E.g.: A Robot, which is used for maintenance of a furnace depending upon itstemperature. In the above case, there are various courses of action for theRobot and the Robot has to choose a course of action depending upon theinput stimuli received.The present scenario of Robotics is unimaginable from just some stipulatedmotions to performing various complex operations and space visits, Robotshave found their application in all fields.

Advantages of Robots:1. Robotics and automation can, in many situation, increase productivity,safety, efficiency, quality.2. Robots can work in hazardous environments3. Robots need no environmental comfort4. Robots work continuously without any humanity needs and illnesses5. Robots have repeatable precision at all times6. Robots can be much more accurate than humans; they may have mili or microinch accuracy.7. Robots and their sensors can have capabilities beyond that of humans8. Robots can process multiple stimuli or tasks simultaneously, humans canonly one.9. Robots replace human workers who can create economic problems

Disadvantages of Robots:1. Robots lack capability to respond in emergencies, this can cause2. Inappropriate and wrong responses3. A lack of decision-making power4. A loss of power5. Damage to the robot and other devices6. Human injuries7. Robots may have limited capabilities in8. Degrees of Freedom9. Dexterity 10. Vision systems12. Real-time Response13. Robots are costly, due to Initial cost of equipment15. Installation Costs16. Need for peripherals17. Need for training18. Need for Programming

6. ANATOMY OF ROBOT

The basic components of a robot system are :1. The locomotion system (Mechanical link)2. Actuators and transmissions3. Sensors4. Controllers5. User interface

Page | 19

6. Power conversion unit

LOCOMOTION SYSTEM:As the name suggests a mobile robot must have a system to make it move. Thissystem gives our machine the ability to move forward, backward and taketurns. It may also provide for climbing up and down.The concept of locomotion invariably needs rotational motion e.g. a wheeldriven by some power source. This involves conversion of electrical energyinto mechanical energy, which we can easily achieve using electrical motors.The issue is to control these motors to give the required speed and torqueA simple equation: Power is the product of Torque and Angular velocityP = ζ.ω This implies that if we want more torque (pulling capacity) from thesame motor we may have to sacrifice speed and vice versaThe dc motors (tape motors) available have very high speed of rotation whichis generally not needed. But what they lack is torque output. For reductionin speed and increase in pulling capacity we use pulley or gear systems.These are governed by: ω1 X r1 = ω2 X r2Wheeled Locomotion Systems1. Differential drive2. Ackerman drive (Car type)3. Skid steer drive4. Articulated drive5. Synchronous drive6. Pivot drive

Differential drive:

Page | 20

This is the most commonly used form of locomotion system used in mobilerobots as it’s the simplest and easiest to implement.It has a free movingwheel in the front accompanied with a left and right wheel. The two wheelsare separately powered when the wheels move in the same direction themachine moves in that direction. Turning is achieved by making the wheelsoppose each other’s motion, thus generating a couple

Fig.6: Differential drive in different working modes• In-place (zero turning radius) rotation is done by turning the drivewheels at the same rate in the opposite direction• Arbitrary motion paths can be implemented by dynamically modifying theangular velocity and/or direction of the drive wheels• Total of two motors are required, both of them are responsible fortranslation and rotational motion• Simplicity and ease of use makes it the most preferred system by beginners• Independent drives make it difficult for straight line motion. Thedifferences in motors and frictional profile of the two wheels cause them tomove with slight turning effect

Page | 21

• The above drawback must be countered with appropriate feedback system.Suitable for human controlled remote robots

Ackerman Drive:This is the car type drive and the most common in real world but not inrobot world. It is characterized by a pair of driving wheels and a separatepair of steering wheels. The translation and rotation are independent ofeach other. However, translation and rotation are interlinked hence thissystem faces severe path planning problem.

Fig.7: Ackerman Drive in working modes

Articulated Drive: In this mechanism, the machine chassis (body) is deformedto achieve rotation in contrast to the steering wheels in car type drive.

Page | 22

Fig.8: Articulated Drive In working modes

Two actuators (motors) are needed. One to drive the wheels and the other tochange the pivot angle. This system shares most of its features with the cartype mechanism, this is too an example of Non – Holonomic System.

Pivot Drive:The unique type of Locomotion system. It is composed of a four wheeledchassis and a platform that can be raised or lowered.

Fig.9: Pivot DriveThe wheels are driven by a motor for translation motion in a straight linefor rotation one motor is needed to lower/raise the platform & another torotate the chassis around the platform. This system can guarantee perfectstraight line motion as well as accurate in-place turns to a desiredheading.

Page | 23

7. GEAR SYSTEMGears are the most common form of torque increment devices, found in almostall mechanical machines. The concept of reducing the rotation speed toincrease torque is known as ‘Gear Reduction’. A high-speed motor with lowtorque is used to drive heavier loads at lower speeds. They have much moreefficiency than pulleys. The maximum torque capability is not limited byfriction but material strength.A gear or more correctly a "gear wheel" is a rotating machine part havingcut teeth, or cogs, which mesh with another toothed part in order totransmit torque. Two or more gears working in tandem are called atransmission and can produce a mechanical advantage through a gear ratio andthus may be considered a simple machine. Geared devices can change thespeed, magnitude, and direction of a power source. The most common situationis for a gear to mesh with another gear; however, a gear can also mesh anon-rotating toothed part, called a rack, thereby producing translationinstead of rotation.

Uses of Gear Systems:Gear Reduction’ to increase torque / decrease speed of rotation.Alter thedirection of rotation axis.Synchronization to two axes.Reversal of directionof rotation.Types of Gears:1. Spur Gears2. Helical Gears3. Bevel Gears4. Worm Gears5. Rack and Pinion Gears

Spur Gears:Very common kind of Gear Used primarily for gear reduction. Reduction ratiois the ratio of teeth in the driver gear and the driven gear.

Fig12. Spur gears

Helical Gears:These gears have better grip on each other than the spur gears can also be

Page | 24

used for changing the axis direction.

(a)

(b)

(c)

Fig13 (a), (b), (c): Helical gears.

Bevel Gears:Mostly used for altering the direction of the rotation axis the gearreduction can be achieved by different number of teeth in the gears

Page | 25

(a)

(b)

Fig14 (a) (b):-bevel gears

Worm Wheel Mechanism:Used for very high gear reduction, The wheel is driven by the wormScrew. One rotation of the worm causes wheel to advance one tooth.A gearbox designed using a worm and worm-wheel will be considerably smaller than one made from plain spur gears and has its drive axes at 90° to each other. With a single start worm, for each 360° turn of the worm, the worm-gear advances only one tooth of the gear. Therefore, regardless of the worm's size (sensible engineering limits notwithstanding), the gear ratio is the "size of the worm gear - to - 1". Given a single start worm, a 20 tooth worm gear will reduce the speed by the ratio of 20:1. With spur gears, a gear of 12 teeth (the smallest size permissible, if designed to good

Page | 26

engineering practices) would have to be matched with a 240 tooth gear to achieve the same ratio of 20:1. Therefore, if the diametrical pitch (DP) of each gear was the same, then, in terms of the physical size of the 240 tooth gear to that of the 20 tooth gear, the worm arrangement is considerably smaller in volume.

Fig.15: Worm wheel gear

Rack & Pinion Mechanism:They are used for converting rotational Motion into linear motion. The rack and pinion arrangement is commonly found in the steering mechanism of cars or other wheeled, steered vehicles. This arrangement provides a lesser mechanical advantage than other mechanisms such as recirculating ball, but much less backlash and greater feedback, or steering "feel". The use of a variable rack (still using a normal pinion) was invented by Arthur Ernest Bishop, so as to improve vehicle response and steering "feel" especially at high speeds, and that has been fitted to many new vehicles, after he created a specialized version of a net-shape warm press forging process to manufacture the racks to their final form, thus eliminating any subsequent need to machine the gear teeth.

For every pair of conjugate involute profile, there is a basic rack. This basic rack is the profile of the conjugate gear of infinite pitch radius.

A generating rack is a rack outline used to indicate tooth details and dimensions for the design of a generating tool, such as a hob or a gear shaper cutter.

Page | 27

Fig.16: Rack & pinion gear

8. SENSORS

A sensor is a device that measures a physical quantity and converts it intoa signal, which can be read by an observer or by an instrument. For example,a mercury-in-glass thermometer converts the measured temperature intoexpansion and contraction of a liquid, which can be read on a calibratedglass tube. A thermocouple converts temperature to an output voltage, whichcan be read by a voltmeter. For accuracy, most sensors are calibratedagainst known standards. In other words, we can say that sensor is a device,which

Page | 28

receives and responds to a signal.

Fig.17: Thermocouple sensorSensors are used in everyday objects such as touch-sensitive elevatorbuttons (tactile sensor) and lamps, which dim or brighten by touching thebase. There are also innumerable applications for sensors of which mostpeople are never aware.Applications include cars, machines, aerospace, medicine, manufacturing, androbotics.

Types of Sensors:1. LDR (Light Dependent Resistor)2. Thermistor3. IR Sensor

LDR (Light Dependent Register):This is an electronic device that works on the principal of light when thelight fall on then it becomes in working otherwise it becomes in off statein robotics the light dependent register is used as a sensor.

The basic diagram of LDR is shown below:-

Page | 29

Fig.18: (a).Basic view of LDR

(b).Symbol of LDR (c).LDRThermistor:A thermistor is a type of resistor whose resistance varies significantlywith temperature, more so than in standard resistors. The word is aportmanteau of thermal and resistor. Thermistors are widely used as inrushcurrent limiters, temperature sensors, self-resetting over currentprotectors, and self-regulating heating elements.Thermistors differ from resistance temperature detectors (RTD) in that thematerial used in a Thermistor is generally a ceramic or polymer, while RTDsuse pure metals. The temperature response is also different; RTDs are usefulover larger temperature ranges, while thermistors typically achieve a higherprecision within a limited temperature range [usually −90 °C to 130 °C].

Page | 30

Fig.19: Thermistor symbolAssuming, as a first-order approximation, that the relationship betweenresistance and temperature is linear, then:

WhereΔR = change in resistanceΔT = change in temperaturek = first-order temperature coefficient of resistanceIR Sensor:These are the infrared sensor and they are generally used in robotics.

9. Control system

A control system is a device or set of devices to manage, command, direct orregulate the behavior of other devices or systems.There are two common classes of control systems, with many variations andcombinations: logic or sequential controls, and feedback or linear controls.There is also fuzzy logic, which attempts to combine some of the designsimplicity of logic with the utility of linear control. Some devices orsystems are inherently not controllable.The term "control system" may be applied to the essentially manual controlsthat allow an operator, for example, to close and open a hydraulic press,perhaps including logic so that it cannot be moved unless safety guards arein place.

Fig.21: Control SystemAn automatic sequential control system may trigger a series of mechanicalactuators in the correct sequence to perform a task. For example variouselectric and pneumatic transducers may fold and glue a cardboard box, fill

Page | 31

it with product and then seal it in an automatic packaging machine.In the case of linear feedback systems, a control loop, including sensors,control algorithms and actuators, is arranged in such a fashion as to try toregulate a variable at a set point or reference value. An example of thismay increase the fuel supply to a furnace when a measured temperature drops.PID controllers are common and effective in cases such as this. Controlsystems that include some sensing of the results they are trying to achieveare making use of feedback and so can, to some extent, adapt to varyingcircumstances. Open-loop control systems do not make use of feedback, andrun only in pre-arranged ways.

10. Actuators

An actuator is a mechanical device for moving or controlling a mechanism orsystem. It is operated by a source of energy, usually in the form of anelectric current, hydraulic fluid pressure or pneumatic pressure, andconverts that energy into some kind of motion.Examples and applications:-Mechanical actuators operate by conversion of rotary motion into linearmotion, or vice versa. Conversion is commonly made via a few simple types ofmechanism including:

Screw: Screw jack, ball screw and roller screw actuators all operate on theprinciple of the simple machine known as the screw. By rotating theactuator's nut, the screw shaft moves in a line. By moving the screw shaft,the nut rotates.

Page | 32

Wheel and axle: Hoist, winch, rack and pinion, chain drive, belt drive,rigid chain and rigid belt actuators operate on the principle of the wheeland axle. By rotating a wheel/axle (e.g. drum, gear, pulley or shaft) alinear member (e.g. cable, rack, chain or belt) moves. By moving the linearmember, the wheel/axle rotates.In engineering, actuators are frequently used as mechanisms to introducemotion, or to clamp an object so as to prevent motion. In electronicengineering, actuators are a subdivision of transducers. They are deviceswhich transform an input signal (mainly an electrical signal) into motion.

Specific examples include: electrical motors, pneumatic actuators, hydraulicactuators, linear actuators, comb drive, piezoelectric actuators andamplified piezoelectric actuators, thermal bimorphs, micro mirror devicesand electro active polymers.

Motors:Motors are mostly used when circular motions are needed, but can also beused for linear applications by transforming circular to linear motion witha bolt and screw transducer. On the other hand, some actuators areintrinsically linear, such as piezoelectric actuators.

AC Motors : Not used much in robotics

Stepper Motors : For controlled rotation

DC Motors : Finds extensive general use

Servo Motors : DC motor with in built feedback & error compensation

Stepper motor :

—Used for measured rotation

—Can be held at a particular position of the shaft

—Ideal for many autonomous robots requiring higher precision

Page | 33

Working of stepper motor

0100 1000 0010 0001

single coil ecxcitation

Double coil excitation

Differences b/w single and double coil excitation

Single coil double coil

consumes less power consumes double power

less torque generated more torque generated

settling time is more settling time is less

Page | 34

Problems with stepper motor:

Very low torque to weight ratio

Torque decreases with increase in the stepping frequency

For sufficiently high stepping speed the stepper motor may skip steps due to overshoot

DC motor :

As the name suggests, a motor which uses a DC (Direct Current) power

Can run in both directions Speed Controllable

DC characterstics

Free running torque & current are ideally zero

Increased load implies, increased torque, current drawn & power consumption Power supplied by a motor is the product of output shaft’s rotational velocity

& torque

DC Motors are high–speed, low-torque devices

Using gears, the high speed of the motor is traded off into torque

11. Power supply

A power supply is a device that supplies electrical energy to one or moreelectric loads. The term is most commonly applied to devices that convertone form of electrical energy to another, though it may also refer todevices that convert another form of energy (e.g., mechanical, chemical,solar) to electrical energy. A regulated power supply is one that controlsthe output voltage or current to a specific value; the controlled value isheld nearly constant despite variations in either load current or thevoltage supplied by the power supply's energy source.Every power supply must obtain the energy it supplies to its load, as wellas any energy it consumes while performing that task, from an energy source.Depending on its design, a power supply may obtain energy from:• Electrical energy transmission systems. Common examples of this includepower supplies that convert AC line voltage to DC voltage.• Energy storage devices such as batteries and fuel cells.• Electromechanical systems such as generators and alternators.

Page | 35

• Solar power.A power supply may be implemented as a discrete, stand-alone device or as anintegral device that is hardwired to its load. In the latter case, forexample, low voltage DC power supplies are commonly integrated with theirloads in devices such as computers and household electronics.

Commonly specified power supply attributes include:• The amount of voltage and current it can supply to its load.• How stable its output voltage or current is under varying line and loadconditions.• How long it can supply energy without refueling or recharging (applies topower supplies that employ portable energy sources)

Power supplies types:Power supplies for electronic devices can be broadly divided intoline-frequency (or "conventional") and switching power supplies. Theline-frequency supply is usually a relatively simple design, but it becomesincreasingly bulky and heavy for high-current equipment due to the need forlarge mains-frequency transformers and heat-sinked electronic regulationcircuitry. Conventional line-frequency power supplies are sometimes called"linear," but that is a misnomer because the conversion from AC voltage toDC is inherently non-linear when the rectifiers feed into capacitivereservoirs. Linear voltage regulators produce regulated output voltage bymeans of an active voltage divider that consumes energy, thus makingefficiency low. A switched-mode supply of the same rating as aline-frequency supply will be smaller, is usually more efficient, but willbe more complex.

DC power supply

An AC powered unregulated power supply usually uses a transformer to convertthe voltage from the wall outlet (mains) to a different, nowadays usuallylower, voltage. If it is used to produce DC, a rectifier is used to convertalternating voltage to a pulsating direct voltage, followed by a filter,comprising one or more capacitors, resistors, and sometimes inductors, tofilter out (smooth) most of the pulsation. A small remaining unwantedalternating voltage component at mains or twice mains power frequency(depending upon whether half- or full-wave rectification is used)—ripple—isunavoidably superimposed on the direct output voltage.For purposes such as charging batteries the ripple is not a problem, and thesimplest unregulated mains-powered DC power supply circuit consists of atransformer driving a single diode in series with a resistor.

Page | 36

Fig.22: Circuit diagram of dc power supply

Before the introduction of solid-state electronics, equipment used valves(vacuum tubes) which required high voltages; power supplies used step-uptransformers, rectifiers, and filters to generate one or more directvoltages of some hundreds of volts, and a low alternating voltage forfilaments. Only the most advanced equipment used expensive and bulkyregulated power supplies.

12. PHYSICAL INTERFACING DEVICES

An electrical connector is an electro-mechanical device for joiningelectrical circuits as an interface using a mechanical assembly. Theconnection may be temporary, as for portable equipment, require a tool forassembly and removal, or serve as a permanent electrical joint between twowires or devices.There are hundreds of types of electrical connectors. Connectors may jointwo lengths of flexible copper wire or cable, or connect a wire or cable oroptical interface to an electrical terminal.In computing, an electrical connector can also be known as a physicalinterface (compare Physical Layer in OSI model of networking). Cable glands,known as cable connectors in the U.S., connect wires to devices mechanicallyrather than electrically and are distinct from quick-disconnects performingthe latter.

Properties of electrical connectors: An ideal electrical connector would have a low contact resistance and high

insulation value. It would be resistant to vibration, water or other

contaminants, and pressure. It would be easily mated/unmated, unambiguously

preserve the orientation of connected circuits, reliable, carry one ormultiple circuits.

Page | 37

Desirable properties for a connector also include easyidentification, compact size, rugged construction, durability (capable ofmany connect/disconnect cycles), rapid assembly, simple tooling, and lowcost. No single connector has all the ideal properties. The proliferation oftypes is a reflection of the differing importance placed on the designfactors.

Some of the interfacing devices are:1. USB Connector (Universal Serial Bus)2. CAT5 (Category 5)3. VGA Connector (Video Graphics Array)4. BNC Connector (Bayonet Neill–Concelman)5. HDMI (High Definition Multimedia Interface)6. DVI (Digital Visual Interface)

USB Connector (Universal Serial Bus):USB (Universal Serial Bus) is an industry standard developed in themid-1990s that defines the cables, connectors and protocols used forconnection, communication and power supply between computers and electronicdevices.USB was designed to standardise the connection of computer peripherals, suchas keyboards, pointing devices, digital cameras, printers, portable mediaplayers, disk drives and network adapters to personal computers, both tocommunicate and to supply electric power. It has become commonplace on otherdevices, such as smartphones, PDAs and video game consoles. USB haseffectively replaced a variety of earlier interfaces, such as serial andparallel ports, as well as separate power chargers for portable devices.

Micro-B USB 3.0 compatible (cable/male end)

USB 2.0 connector on the side of the specification standard micro USB 3.0 connector

are aligned pin-minute increase in the standard.

No.1: power (VBUS)

No.2: USB 2.0 differential pair (D−)

No.3: USB 2.0 differential pair (D+)

No.4: USB OTG ID for identifying lines

No.5: GND

No.6: USB 3.0 signal transmission line (−)

No.7: USB 3.0 signal transmission line (+)

No.8: GND

No.9: USB 3.0 signal receiving line (−)

No.10: USB 3.0 signal receiving line (+)

Page | 38

Pinouts of

Standard, Mini, and Micro USB plugs. The white areas in these drawings represent

hollow spaces. As the plugs are shown here, the USB logo (with optional letter A or

B) is on the top of the overmold in all cases.[contradiction][23]

Types of USB connectors left to right (ruler in centimeters): Micro-B plug, a non-

USB proprietary plug, Mini-B plug (5-pin, upside down), Standard-A receptacle

(upside down), Standard-A plug, Standard-B plugFig 23: Standard type A plug and receptacle

CAT 5 (CATEGORY 5):Category 5 cables (Cat 5) is a twisted pair cable for carrying signals. Thistype of cable is used in structured cabling for computer networks such asEthernet. It is also used to carry other signals such as telephony andvideo. The cable is commonly connected using punch down blocks and modularconnectors. Most Category 5 cables are unshielded, relying on the twisted

Page | 39

pair design and differential signaling for noise rejection.

TIA/EIA-568-A.1-2001 T568A Wiring

Pin Pair Wire Color

1 3 1 white/green

2 3 2 green

3 2 1 white/orange

4 1 2 blue

5 1 1 white/blue

6 2 2 orange

7 4 1 white/brown

8 4 2 brown

Fig 24: Category 5 patch cable in T568B wiring

VGA Connector (Video Graphics Array):A Video Graphics Array (VGA) connector is a three-row 15-pin DE-15connector. The 15-pin VGA connector is found on many video cards, computer

Page | 40

monitors, and some high definition television sets. On laptop computers orother small devices, a mini-VGA port is sometimes used in place of thefull-sized VGA connector.

A female DE-15 output in a laptop computer.

Type Computer analog video connector

Production history

Designer IBM based on D-subminiature

Designed 1987

Produced 1987 to present

Superseded by DVI (1999)

General specifications

Hot pluggable No

Video signal RGB video signal plus option H and V sync

Pins 15

Connector DE-15

Data

Data signal I²C data channel for DDC information

Pin out

A female DE15 socket (videocard side).

Pin 1 RED Red video

Pin 2 GREEN Green video

Pin 3 BLUE Blue video

Pin 4 ID2/RES formerly Monitor ID bit 2, reserved since E-DDC

Pin 5 GND Ground (HSync)

Page | 41

Pin 6 RED_RTN Red return

Pin 7 GREEN_RTN Green return

Pin 8 BLUE_RTN Blue return

Pin 9 KEY/PWR formerly key, now +5V DC

Pin 10 GND Ground (VSync, DDC)

Pin 11 ID0/RES formerly Monitor ID bit 0, reserved since E-DDC

Pin 12 ID1/SDA formerly Monitor ID bit 1, I²Cdata since DDC2

Pin 13 HSync Horizontal sync

Pin 14 VSync Vertical sync

Pin 15 ID3/SCL formerly Monitor ID bit 3, I²Cclock since DDC2

The image and table detail the 15-pin VESA DDC2/E-DDC connector; the diagram’s pin numbering is that of a female connector functioning as the graphics adapter output. In the male connector, this pin numbering corresponds with themirror image of the cable’s wire-and-solder side.

Fig 25: A VGA Cable

BNC Connector (Bayonet Neill–Concelman):The BNC connector (Bayonet Neill–Concelman) is a common type of RF connectorused for coaxial cable. It is used with radio, television, and otherradio-frequency electronic equipment, test intstruments, video signals, andwas once a popular computer network connector. BNC connectors are made tomatch the characteristic impedance of cable at either 50 ohms or 75 ohms. Itis usually applied for frequencies below 3 GHz and voltages below 500 Volts.

Page | 42

Male 50 ohm BNC connector

Type RF coaxial connector

Production history

Designer Paul Neill, Carl Concelman, & Octavio M. Salati

Designed Patented 1951

Manufacturer Various

General specifications

Diameter Male: 0.570 in (1.45 cm)Female: 0.436 in (1.11 cm)(outer, typical)

Cable Coaxial

Passband Typically 0-3 GHz

Fig 26: Male 50 ohm BNC connector

HDMI (High Definition Multimedia Interface):High-Definition Multimedia Interface (HDMI) is a compact audio/videointerface for transmitting uncompressed digital data. It is a digitalalternative to consumer analog standards, such as radio frequency (RF)coaxial cable, composite video, S-Video, SCART, component video, D-Terminal,or VGA. HDMI connects digital audio/video sources (such as set-top boxes,DVD players, HD DVD players, Blu-ray Disc players, AVCHD camcorders,personal computers (PCs), video game consoles such as the PlayStation 3 andXbox 360, and AV receivers) to compatible digital audio devices, computermonitors, video projectors, tablet computers, and digital televisions.

Page | 43

HDMI (High-Definition Multimedia Interface)

HDMI official logo and standard connector

Type Digital audio/video/data connector

Production history

Designer HDMI Founders (seven companies)

Designed December 2002

Manufacturer HDMI Adopters (over 1,100 companies)

Produced 2003–present

General specifications

Width Type A (13.9 mm), Type C (10.42 mm), Type D (6.4 mm)

Height Type A (4.45 mm), Type C (2.42 mm), Type D (2.8 mm)

Hot pluggable Yes

External Yes

Audio signal LPCM, Dolby Digital, DTS, DVD-Audio, Super Audio CD, Dolby Digital Plus, Dolby TrueHD,DTS-HD High Resolution Audio, DTS-HD Master Audio, MPCM, DSD, DST

Video signal Maximum resolution limited by available bandwidth

Pins 19

Data

Data signal Yes

Bitrate 10.2 Gbit/s (340 MHz)

Protocol TMDS

Pin out

Type A receptacle HDMI

Pin 1 TMDS Data2+

Pin 2 TMDS Data2 Shield

Pin 3 TMDS Data2–

Pin 4 TMDS Data1+

Page | 44

Pin 5 TMDS Data1 Shield

Pin 6 TMDS Data1–

Pin 7 TMDS Data0+

Pin 8 TMDS Data0 Shield

Pin 9 TMDS Data0–

Pin 10 TMDS Clock+

Pin 11 TMDS Clock Shield

Pin 12 TMDS Clock–

Pin 13 CEC

Pin 14 Reserved (HDMI 1.0–1.3c), HEC Data- (Optional, HDMI 1.4+ with Ethernet)

Pin 15 SCL (I²C Serial Clock for DDC)

Pin 16 SDA (I²C Serial Data Line for DDC)

Pin 17 DDC/CEC/HEC Ground

Pin 18 +5 V (max 50 mA)

Pin 19 Hot Plug detect (all versions) and HEC Data+ (optional, HDMI 1.4+ with Ethernet)

Fig 27: HDMI standard connector

DVI (Digital Visual Interface):The Digital Visual Interface (DVI) is a video interface standard coveringthe transmission of video between a source device (such as a personalcomputer) and a display device. The DVI standard has achieved widespreadacceptance in the PC industry, both in desktop PCs and monitors. Mostcontemporary retail desktop PCs and LCD monitors feature a DVI interface,and many other devices (such as projectors and consumer televisions) supportDVI indirectly through HDMI, another video interface standard. Most laptopsstill have legacy VGA and, in some models, HDMI ports, but fewer have DVI.

Digital Visual Interface (DVI)

A male DVI-D (single link) connector.

Type Digital computer video connector

Page | 45

Production history

Designer Digital Display Working Group

Designed April 1999

Produced 1999–present

Superseded by DisplayPort

General specifications

Hot pluggable Yes

External Yes

Video signal Digital video stream:

(Single) WUXGA (1,920 × 1,200) @ 60 Hz

(Dual) Limited by copper bandwidth limitations, DVI source limitations,

and DVI sync limitations.

Analog RGB video (−3 dB at 400 MHz)

Pins 29

Data

Data signal RGB data, clock, and display data channel

Bitrate (Single link) 3.96 Gbit/s

(Dual link) Limited only by copper bandwidth limitations, DVI source

limitations, and DVI sync limitations.

Max. devices 1

Protocol 3 × transition minimized differential signalingdata and clock

Page | 46

Pin out

A female DVI-I socket from the front

Pin 1 TMDS data 2− Digital red− (link 1)

Pin 2 TMDS data 2+ Digital red+ (link 1)

Pin 3 TMDS data 2/4 shield

Pin 4 TMDS data 4− Digital green− (link 2)

Pin 5 TMDS data 4+ Digital green+ (link 2)

Pin 6 DDC clock

Pin 7 DDC data

Pin 8 Analog vertical sync

Pin 9 TMDS data 1− Digital green− (link 1)

Pin 10 TMDS data 1+ Digital green+ (link 1)

Pin 11 TMDS data 1/3 shield

Pin 12 TMDS data 3- Digital blue− (link 2)

Pin 13 TMDS data 3+ Digital blue+ (link 2)

Pin 14 +5 V Power for monitor when in standby

Page | 47

Pin 15 Ground Return for pin 14 and analog sync

Pin 16 Hot plug detect

Pin 17 TMDS data 0− Digital blue− (link 1) and digital sync

Pin 18 TMDS data 0+ Digital blue+ (link 1) and digital sync

Pin 19 TMDS data 0/5 shield

Pin 20 TMDS data 5− Digital red− (link 2)

Pin 21 TMDS data 5+ Digital red+ (link 2)

Pin 22 TMDS clock shield

Pin 23 TMDS clock+ Digital clock+ (links 1 and 2)

Pin 24 TMDS clock− Digital clock− (links 1 and 2)

C1 Analog red

C2 Analog green

C3 Analog blue

C4 Analog horizontal sync

C5 Analog ground Return for R, G, and B signals

Page | 48

Fig 28: A male DVI-D (single link) connector

13. CONCLUSIONRobotics means the study and application of robot technology. The goal ofrobotics is to mimic natural world as closely as possible. The main elementsin the robot are the moving elements and the sensorsEvolution of robots, the elements of robotics, the limitation of robots andthe various applications of robots. In the application part this paperexpects to cover in detail robosurgery and robonauts (the robots used inspace).Thus, learning from basic knowledge of robotics and applying them inassembling a robot helped clearing many quest of knowledge and so manyqueries. The most important part was the concepts of basic electronics tothe circuit diagram, practicing soldering and which helped in developing thegrounds of building a basic robot.Additionally, it helped in boosting confidence for working in higher coreelectronics based industries in the near future.

14. BIBLIOGRAPHY

1. http://www.omegaelectronics.net/profile.asp2. http://electronics.howstuffworks.com/robot.htm3. http://engineering-ed.org/Robotics/documents.4. http://html.alldatasheet.com/html5. http://en.wikipedia.org/

Page | 49

Page | 50