OCPS CLAY SPRINGS ES SUBMITTAL TRANSMITTAL · miam~~ (3.lilb., iiiii . depar1ment of regulatory and...

Transcript of OCPS CLAY SPRINGS ES SUBMITTAL TRANSMITTAL · miam~~ (3.lilb., iiiii . depar1ment of regulatory and...

SUBMITTAL NUMBER: 035216-01.00

OCPS CLAY SPRINGS ES SUBMITTAL TRANSMITTAL

SUBMITTAL DETAILS:

REVIEWERS:

SUBJECT: LIGHTWEIGHT INSULATING CELLULAR

CONCRETE

DATE RECIEVED: Feb 06, 2015

DISCIPLINE: Architecture

PRIMARY: DEVON TULLY

BYRON LASTRAPES

RHODES+BRITO ARCHITEC

PHN: (407) 648-7288

FAX:

RHODES+BRITO ARCHITEC

PHN: (407) 648-7288

FAX: (407) 648-7289

SECONDARY:

PRIORITY STATUS: 2-STANDARD

REVIEWER DUE DATE: 2/18/2015

SPECIFICATION REF: 03 52 16

DWG REF. NONE

DWG TITLE:

NO OF ITEMS: ITEM DESCRIPTI

REVIEW STATUS:

COMMENTS:

CONTRACTOR/CM:

: WILLIAMS COMPANY: BRAD KUBIN 2301 SILVER STAR RD. ORLANDO, FL, 32809 (407) 295-2530 FAX:(407) 297-0459

REVIEWED

RETURNED ITEMS:

DATE RETURNED TO CM: 2/6/2015

BUILDING REFERENCE:

1 Product Literature(s)

PAGE 1 OF 1RHODES + BRITO ARCHITECTS INC. : 605 E. ROBINSON STREET, SUITE 750 : ORLANDO, FL. : 32801 : 407.648.7288 : FAX.648.7289

cc:

OWNER : CALVIN WOOLFOLK 6501 MAGIC WAY, BLDG. 200 ORLANDO, FL, 32809 (407) 317-3700

FAX:(407) 317-3768

R+B FILE: : 13017-0001.X6

SUBMITTAL NUMBER: 03521601.00

OCPS CLAY SPRINGS ES SUBMITTAL ASSIGNMENT MEMO

SUBMITTAL DETAILS: REVIEWERS:

SUBJECT: LIGHTWEIGHT INSULATING

CELLULAR CONCRETE

DATE RFI RECIEVED: Feb 06, 2015

DISCIPLINE: Architecture

PRIMARY: DEVON TULLY

BYRON LASTRAPES

RHODES+BRITO ARCHITECTS INC.

PHN: (407) 648-7288FAX:

RHODES+BRITO ARCHITECTS INC.

PHN: (407) 648-7288

FAX: (407) 648-7289

SECONDARY:

PRIORITY STATUS: 2-STANDARD

REVIEWER DUE DATE: 2/18/2015

SPECIFICATION REF: 03 52 16

DWG REF. NONE

DWG TITLE:

REVIEW STATUS:

THIS SUBMITTAL IS ISSUED TO YOU FOR YOUR REVIEW. PLEASE RESPOND AND RETURN...WITH THIS COMPLETED SAM TRANSMITTAL...TO MICHELE BUDAY-URDANETA NO LATER THAN: 2/18/2015. PLEASE COMPLETE REVIEW STATUS AT RIGHT

SUBMITTAL CONTENTS:

NO OF ITEMS: ITEM DESCRIPTION

(please print)THIS SUBMITTAL WAS REVIEWED BY :

RE-SUBMIT WITH ITEMS

NOT REVIEWED

REJECTED

REVISE AND RESUBMIT

FURNISHED AS MARKED

REVIEWED

COMMENTS:

1 PRODUCT LITERATURE(S)

cc:

OWNER : CALVIN WOOLFOLK

6501 MAGIC WAY, BLDG. 200

ORLANDO, FL, 32809

R+B FILE: : 13017-0001.X6CONTR/CM: : WILLIAMS COMPANY

: BRAD KUBIN

2301 SILVER STAR RD.

Submittal Approval Form

PROJECT: CLAY SPRINGS ELEMENTARY SCHOOL

DATE: _ __________________ ______

SUBCONTRACTOR NAME: __

SUBCONTRATOR ADDRESS: ______________________________ ____

NUMBER AND TITLE OF SPECIFICATION SECTION:

Contractor’s Submittal Stamp Architect/ Engineer’s Submittal Stamp

Cellucrete Corp

03 52 16 - Lightweight Insulating Cellular Concrete - Mix Designs

2/6/15

2/6/15

Florida Building Code Online

https://www.floridabuilding.org/pr/pr_app_dtl.aspx?param=wGEVXQwtDqua%2flMZ8n5CNWtNvVI07hd5DDK%2fOl1g%2br4%3d[11/28/2014 4:44:21 PM]

BCIS Home Log In User Registration Hot Topics Submit Surcharge Stats & Facts Publications FBC Staff BCIS Site Map Links Search

Product Approval USER: Public User

Product Approval Menu > Product or Application Search > Application List > Application Detail

FL # FL2037-R3Application Type RevisionCode Version 2010Application Status Approved

*Approved by DBPR. Approvals by DBPR shall be reviewed and ratified by the POC and/or the Commission if necessary.

CommentsArchived

Product Manufacturer Celcore IncorporatedAddress/Phone/Email 3148 US Hwy 70 West

Black Mountain, NC 28711(828) [email protected]

Authorized Signature William Mac Donald

Technical Representative William R. Mac DonaldAddress/Phone/Email 3148 US Hwy 70 West

Black Mountain, NC [email protected]

Quality Assurance Representative William Mac DonaldAddress/Phone/Email 3148 US Hwy 70 West

Black Mountain, NC 28711(828) [email protected]

Category RoofingSubcategory Roofing Insulation

Compliance Method Evaluation Report from a Product Evaluation Entity Evaluation Entity Miami-Dade BCCO - EVLQuality Assurance Entity Miami-Dade BCCO - QUAQuality Assurance Contract Expiration Date 10/19/2018Validated By Miami-Dade BCCO - VAL

Certificate of Independence

Referenced Standard and Year (of Standard) Standard Year

FM 4454 1998TAS 114 1995

Equivalence of Product Standards Certified By

Florida Building Code Online

https://www.floridabuilding.org/pr/pr_app_dtl.aspx?param=wGEVXQwtDqua%2flMZ8n5CNWtNvVI07hd5DDK%2fOl1g%2br4%3d[11/28/2014 4:44:21 PM]

Sections from the Code

Product Approval Method Method 1 Option C

Date Submitted 10/08/2013Date Validated 10/11/2013Date Pending FBC ApprovalDate Approved 10/16/2013

Summary of Products

FL # Model, Number or Name Description

2037.1 Celcore Foam Concentrate Foam Concentrate for making Cellular Insulating Concrete

Limits of Use Approved for use in HVHZ: Yes Approved for use outside HVHZ: Yes Impact Resistant: N/A Design Pressure: +0/-262.5 Other:

Installation Instructions FL2037_R3_II_13030702.pdf Verified By: Miami-Dade BCCO - EVL Created by Independent Third Party: Evaluation Reports FL2037_R3_AE_13030702.pdf

2037.2 Celcore MF Foam Concentrate Foam Concentrate for making Cellular Insulating Concrete

Limits of Use Approved for use in HVHZ: Yes Approved for use outside HVHZ: Yes Impact Resistant: N/A Design Pressure: +0/-262.5 Other:

Installation Instructions FL2037_R3_II_13030702.pdf Verified By: Miami-Dade BCCO - EVL Created by Independent Third Party: Evaluation Reports FL2037_R3_AE_13030702.pdf

Back Next

Contact Us :: 1940 North Monroe Street, Tallahassee FL 32399 Phone: 850-487-1824

The State of Florida is an AA/EEO employer. Copyright 2007-2013 State of Florida. :: Privacy Statement :: Accessibility Statement :: Refund Statement

Under Florida law, email addresses are public records. If you do not want your e-mail address released in response to a public-records request, do not send electronic mail to this entity. Instead, contact the office by phone or by traditional mail. If you have any questions, please contact 850.487.1395. *Pursuant to Section

455.275(1), Florida Statutes, effective October 1, 2012, licensees licensed under Chapter 455, F.S. must provide the Department with an email address if they have one. The emails provided may be used for official communication with the licensee. However email addresses are public record. If you do not wish to supply a personal address, please provide the Department with an email address which can be made available to the public. To determine if you are a licensee under Chapter 455, F.S.,

please click here .

Product Approval Accepts:

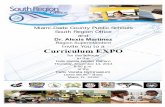

MIAM~~ (3.lilb., iiiII

DEPAR1MENT OF REGULATORY AND ECONOMIC RESOURCES (RER) BOARD AND CODE ADMlNlSTRA TlON DIVISION

NOTICE OF ACCEPTANCE (NOA) Celcore Incorporated 3148 US HWY 70 Street Black Mountain, NC 28711

SCOPE:

M1AMI-DADE COUNTY

PRODllCT CONTROL SECTION 11805 SW 26 Stree~ Room 208

Miami, Florida 33 175·2474 T (786)315-2590 F (786) 3 1525-99

www.miamidadc.gov/cconomv

This NOA is being issued under the applicable rules and regulations governing the use of construction materials. The documentation submitted has been reviewed and accepted by Miami-Dade County RER -Product Control Section to be used in Miami Dade County and other areas where allowed by the Authority Having Jurisdiction (AHJ).

This NOA shall not be valid after the expiration date stated below. The Miami-Dade County Product Control Section (In Miami Dade County) and/or the AHJ (in areas other than Miami Dade County) reserve the right to have this product or material tested for quality assurance purposes. If this product or material fails to perform in the accepted manner, the manufacturer will incur the expense of such testing and the AHJ may immediately revoke, modify, or suspend the use of such product or material within their jurisdiction. RER reserves the right to revoke this acceptance, if it is determined by Miami-Dade County Product Control Section that this product or material fails to meet the requirements oftbe applicable building code.

This product is approved as described herein , and has been designed to comply with the Florida Building Code including the High Velocity Hurricane Zone of!he Florida Building Code.

DESCRIPTION: Lightweight Insulating Concrete.

LABELING: Each unit shall bear a permanent label with the manufacturer's name or logo, city, state and following statement: "Miami-Dade County Product Control Approved", unless otherwise noted herein.

RENEWAL of tlIis NOA shall be considered after a renewal application has been fi led and there has been no change in the applicable building code negatively affecting the performance of this product.

TERMINATION ofthis NOA will occur after the expi ration date or if there has been a revision or change in the materials, use, and/or manufacture ofthe product or process. Misuse of this NOA as an endorsement of any product, for sales, advertising or any otber purposes shall automatically terminate this NOA. Failure to comply with any section of this NOA shall be cause for termination and removal of NOA.

ADVERTISEMENT: The NOA number preceded by the words Miami-Dade County, Florida, and followed by the expiration date may be di splayed in advertising literature. If any portion of the NOA is displayed, then it shall be done in its entirety.

INSPECTION: A copy of this entire NOA shall be provided to the user by the manufacturer or its distributors and shall be available for inspection at the job site at the request of the Building Official.

This NOA renews and revises NOA No. 09-0928.06 and consists of pages 1 through 8. The submitted documentation was reviewed by Jorge L. Acebo.

NOA No.: 13-0307.02 Expiration Date: 10/19/18

Approval Date: 09126113 Pagel of8

ROOFING COMPONENT APPROVAL

Ca tegorY: Roofing Sub-Category: Materials:

Lightweight Insulating Concrete Cellular

Maximum Design Pressure: -262.5 psf.

TRADE NAMES OF PRODUCTS MANUFACTURED OR LABELED BY ApPLICANT:

Product

Celcore Foam Concentrate

Celeore MF Concentrate

Celeore PVA Curing Compound

Dimensions

various

varIOUS

vanous

Test Specifications

ASTM C869

ASTM C869

Proprietary

Prodnct Description

Foaming agents used in making preformed foam for use in li ghtweight cellular concrete.

Foaming agents used in making preformed foam for use in lightweight cellular concrete.

Emulsion curing agent

TRADE NAMES OF PRODUCTS MANUFACTURED BY OTHERS:

Test Product Dimensions S~ccificatioDS

Expanded Polystyrene Min. I" x 2' x 4' ASTM C578 1.0 pef density

Portland Cement vanous ASTM C l50

CR Base Felt Fastener 1.75" Standard TAS 114

FM-90 Base Ply 1.7" Standard TAS 114 Fastener

Drill-Tec Base Sheet 1.75" Standard TAS 114 Fastener

Tri-Fix Fastening 1.7" Standard TAS 11 4 System

Product Description Manufacturer

Expanded polystyrene Generic with a minimum of8 21/." (with current NOA) holes (3.7% of surface area) to provide monolithic bonding of topping to board slurry.

Portland Cement Generic

Steel base sheet fastener OMG, Inc. for light wei ght concrete with integral plate

Steel base sheet fastener ES Products Tnc. for light weight concrete with 2.7" integral pl ate

Steel base sheet fastener GAF for light weight concrete with integral pl ate

Steel sheet fastener Soprema, Inc. for lightweight concrete with 3" steel plate.

NOA No.: 13-0307.02 Expiration Date: 10/19/18

Approval Date: 09126/13 Page 2 or8

EVIDENCE SUBMITTED:

Test Agency

Underwriters Laboratories, Inc.

Factory Mutual Research Corporation

Certified Testing Laboratories

Test Identifier

R 11599

OM2A6.AM OP3A6.AM 2P3A9.AM lZ5A6.AM 2B8A4.AM

3002416

CTLA 105R-C

Deck Type 21: Steel 1 Concrete

Deck Description: 18-22 gao steel 26 gao Steel

Test NamelRel!ort Date

ANSIIUL 263 03119112

4454 03110/86 4454 03115/89 4454 03 /07/89 4454 10/25 /96 4454 07/02/97 4454 05/06/99

TAS 114-J/ FM 4454 09/24/0 8

2S00-psi structural concrete or concrete plank

System A:

Cast Density Range:

Dry Density Range:

28 Day Compressive Strength Range:

Cellular

Minimum 36 PCF

Minimum 26 PCF

175 - 350 psi

Minimum Characteristic Resistance Force with Approved Fasteners:

Components:

2-4 Days: 15 Days: 21 Days: 28 Days:

461bf. 77 Ibf. 1l21bf. 141 Ibf.

Portland Cement ASTM C150 Foaming Agent ASTM C869:

7- 94 lb. sacks; see tabl e below

Water (max chloride level 250 ppm):

(40:1 Water/Concentrate) 3.5 lbs.!ft' preformed foam 5 gal./sack

Wet densities and dry densities nsing the following range of proportioned ingredients:

Table 1 Wet Density Dry Density

PSI Range Range Range Foam

160-249 30-40 pcf 22-34.5 pcf 19.70-17.70 ( Il; d)'

250-350 36-50 pcf 30-40 pcf 17.70-15.60 (ftl d)'

Cement Range

663-730 lbs. 730-870 lbs.

Mixing Water Min. Range Thickness

267-350 lbs. 2" 350-432 lbs. 2"

NOA No.: 13-0307.02 Expiration Date: 10119/18

Approval Date: 09/26/13 Page 3 of 8

Application; Materials shall be mixed in a horizontal paddle drum mi xer and pumped to the roof at the indicated density, and in compliance with manufacturer specifications. Cast densities shall be checked and recorded as it comes out of the hose, at a minimum interval of onehour. Alternately, the slurry coat and insulation panels shall be allowed to cure for 24 hours prior to the application of the topcoat. For steel deck applications the slurry coat and insulation boards shall be left undi sturbed to cure for a minimum of 24 hours before the application ofthe topcoat. See Maximum Design Pressure li sting herein.

Polystyrene Insulation

Minimum Density:

1.0 pcf

Minimum Dimensions:

I" x2'x 4'

Holes and slots for keying:

8 - 2'/." holes per 2' x 4' board (3.7% of surface area) minimum required to provide monolithi c bonding of topping board to slurry. (With current NOA).

Rigid insulati on panels shall be placed in a minimum 1/8" slurry-coat of insulating concrete, while the material is still in a plastic state. (With current NOA)

Insulation panels and slurry coat shall be left to cure overnight before the installation of tbe topcoat.

The following day a 2" minimum topcoat shall be poured and screeded to a smooth finish surface free of ridges and at the proper thickness and slope prior to the installation of the roofing membrane.

After setting of the topcoat to support foot traffic, Celcore PYA compound shall be applied at a minimum rate of 300 ft' per gallon (7.2m2/1).

SUBSTRATE REQUIREMENTS: Note: Refer to Maximum Design Pressures Section of this Notice of Acceptance for specific

substrate or substrate treatment requirements.

New Construction: Concrete:

Steel Deck:

Existing Construction:

Strucrurally designed in compliance with applicable Building Code.

Minimum 22 gage galvanized G-90 attached to supports in compliance with appli cable Building Code. (See Table 2 herein for maximum design pressures and attachments)

Concrete: Broom cleaned and free of any materials or covering that may impede bonding. Substrate shall be in compliance with applicable Building Code.

Gravel Surfaced BUR: Loose gravel shall be removed, and adhesion of existing roof system shall be tested in compliance with TAS 124 to meet the design pressure requirements determined in compliance with applicable Building Code.

Smooth Surface BUR: adhesion of existing roof system shall be tested in compliance with TAS 124 to meet the design pressure requirements determined in compliance with applicable Building Code.

NOA No.: 13-0307.02 Expiration Date: 10/19/1 8

Approval Date: 09/26/13 Page 4 of 8

Granule Surface Cap: adhesion of ex isting roof system shall be tested in compliance with T AS 124 to meet the design pressure requirements determined in compliance with applicable Building Code.

Substrate

Concrete

18-22 gao vented steel

18-22 gao vented steel

18-22 gao vented steel

18-22 gao vented steel

Table 2: Maximum Design Pressures Applications

NEW CONSTRUCTION Substrate Min. Compressive Treatment Strength

None 200 psi

Steel deck shall be 200 psi secured to '/." thick structural supports spaced a maximum of 4 ft. on centers with ITW Buildex TraxxJ5 at the bottom of each rib (6" o/c.)

Steel deck shall be 200 psi secured to ';." thick structural supports spaced a maximum of 5 ft. on centers with ITW Buildex TraxxJ5 at the bottom of each rib f6" o/c.)

Steel deck shall be 200 psi secured to structural supports spaced a maximum of 5 ft. on centers with Y, puddle welds and washers. Steel deck shall be 300 psi secured to structural supports spaced a maximum of 5 ft. on centers with 'h puddle welds and washers.

Apache Holey Maximum Design Board Pressure

min. 1 II thick -262.5 psf min. 1.0 pcf

min. I" thick -90 psf min. 1.0 pcf

mm. I" thick min. 1.0 pcf

min. 1" thick min. 1.0 pcf

min. I" thick min. 1.0 pcf

-82.5 psf

-75 psf

-75psf

NOA No.: 13-0307.02 Expiration Date: 10/ 19/18

Approval Date: 09/26/13 Page 5 or8

NEW CONSTRUCTION (continned)

Substrate Substrate Min. Com pressive Apacbe Holey Maximum Design Treatment Strengtb Board Pressure

18-22 gao vented Steel deck shall be 200 psi min. I " thick -{i0 psf steel secured to !I." thick min. 1.0 pcf

structural supports spaced a maximum of 6 ft. on centers with ITW Bui ldex Traxx/5 at the bottom of each rib

i{6" o/c.)

18-22 gao vented Steel deck sball be 200 psi min. )" thick -60psf steel secured to min. 1.0 pcf

structural supports spaced a maximum of 5 ft. on centers with Vz puddle welds and washers.

18-22 gao vented Steel deck shall be 200 psi min. ]" thick -{i0 psf steel secured to supports min. 1.0 pcf

spaced a maximum of 6 ft. on centers with Vz" puddle welds at every corrugation (6" o.c.). Deck side laps fastened with ITW Buildex Traml at midspan.

26 gao vented steel Steel deck shall be 200 psi min. 1" thick -52.5 psf secured to supports min. 1.0 pcf spaced a maximum of 5 ft. on centers with Vz" puddle welds and washers at every other corrugation. Deck side laps fastened with ITW Buildex Traxx/I at midspan.

Note: Maximum Design Pressures noted berein shall be used in conjunction witb those maximum design pressures published in the Roof System Assembly Notice of Acceptance for Approved Systems over lightweight concrete decks.

NOA No. : 13-0307.02 Expiration Date: 10/19/18

Approval Date: 09/26/13 Page 6 of8

RECOVER

Substrate Substrate Min. Compressive Apache Holey Maximum Design Treatment Strenl!:th Board Pressure

Smooth surface BUR None 300 ps i None -262.5 psf

Smooth surface BUR None 300 psi min. 1" thick -262.5 psf min. 1.0 pcf

Smooth surface None 300 psi None -262.5 psf modi tied cap sheet Smooth surface None 300 psi min. 1" thick -262.5 psf modified cap sheet min. 1.0 pcf Mineral surface cap None 300 psi None -1 35psf sheet Mineral surface cap None 300 psi min. 1" thick -135 psf sheet min. 1.0 pcf Mineral surface cap None 300 psi None -75 psf sheet Mineral surface cap None 300 psi min. 1" thick -75 psf sheet min. 1.0 pcf Gravel surface BUR None 300 psi None -75 psf

Gravel surface BUR None 300 psi min. 1" thick -75 psf min. 1.0 pcf

Gravel surface BUR None 300 psi None -75 psf

Gravel surface BUR None 300 psi min. I" thick -75 psf min. 1.0 pcf

Note: Maximum Design Pressures noted herein shall be used in conjunction with those maximum design pressures published in the Roof System Assembly Notice of Acceptance for Approved Systems over lightweight concrete decks.

NOA No.: 13-0307.02 Expiration Date: 10/19/18

Approval Date: 091261\3 Page 7 of 8

GENERAL LIMITATIONS: 1. Any excess water on the lightweight concrete shall be removed prior to roof installation. 2. Applicator shall maintain ajob log and make it available to the Building Official upon request. The

job log shall contain cast densities recordings taken at a minimum interval of one-hour. a. Cast densities shall be measured with calibrated scale accurate from I to 50 Ibs. The scale

shall display weight in increments of V. lb. and be accurately calibrated to 1116 lb. b. The measuring bucket shall be of 5 quarts or larger

3. Lightweight insulating concrete installation shall demonstrate its suitability to perform as a satisfactory substrate during "walkability inspection". If the deck or a portion of the deck is determined to be out of compliance, the Building Official may call for further testing (if applicable for the roof system) to confirm fastener spacing or provide data for the roof system manufacturer to calculate a new fastener pattern. Fastener testing (ifapplicable for the roof system) shall be required. Any areas where fasteners will not hold a minimum 40 Ibf.. after 5 days of cure shall be removed and recast.

4. Fastener spacing for mechanical attachment of anchor/base sheet or membrane attachment is based on a minimum fastener resistance value as calculated in conjunction with the maximum design value li sted within specific roof membrane manufacturer's NOA. Should the fastener resistance be less than that required, as determined by the Building Official, a revised fastener spacing, prepared, signed and sealed by a Florida registered Professional Engineer, Registered Architect, or Registered Roof Consultant may be submitted. Said revised fastener spacing shall utilize the withdrawal resistance value taken from Testing Application Standards TAS 105 and calculations in compliance with Roofing Application Standard RAS 11 7. If continued noncompliance is observed and the roof deck and associated roof system cannot be corrected based on additional testing and attachment calculations, the Building Official may call for the removal of all or portions of the deck.

5. Roofing contractor shall consult with roofing system manufacturer for compatibili ty with all surface coatings or treatments listed in this NOA.

6. Direct-adhered single ply systems shall be installed in strict compliance with membrane manufacturer's specifications and roof assembly manufacturer NOA.

7. Maximum Design Pressures noted in this NOA shall be used in conjunction with the maximum design pressures published in the Roof Assembly Product Control Notice of Acceptance for Approved Systems over li ghtweight concrete decks.

8. All coatings or surface preparation materials applied to the lightweight insulating concrete shall be listed as an approved interface material with the roof assembly manufacturer.

9. A sl urry coat lightweight insulating concrete shall be applied with insulation boards immediately adhered in the minimum 1/8" slurry coat. Slurry coat and insulation boards shall be left undisturbed to cure overnight before the application of the topcoat. If install ation is interrupted due to incl ement weather or other situations beyond the control ofthe contractor, the installed insulation board shall be inspected to confi rm adhesion to the substrate. Over solid substrates, topping installation shall not be delayed over 24 hours.

10. All products listed herein shall have a quality assurance audit in accordance with the Florida Building Code and Rule 9N-3 of the Florida Administrative Code.

END OF THIS ACCEPTANCE

NOA No.: 13-0307.02 Expiration Date: 10/19/ 18

Approval Date: 09/26/ 13 Page 8 of 8

Submittal Approval Form

PROJECT: CLAY SPRINGS ELEMENTARY SCHOOL

DATE: _ __________________ ______

SUBCONTRACTOR NAME: __

SUBCONTRATOR ADDRESS: ______________________________ ____

NUMBER AND TITLE OF SPECIFICATION SECTION:

Contractor’s Submittal Stamp Architect/ Engineer’s Submittal Stamp

Cellucrete Corp

03 52 16 - Lightweight Insulating Cellular Concrete - Mix Designs

2/6/15

2/6/15

CELCORE Roof Insulation Systems | Mix Designs Thermal Value Calculations

Typical Mix Designs

Cast Density 36 pcf 38 pcf 40 pcf 42 pcf 45pcf

Type I Cement 663 lbs 703 lb s 742 lbs 782 lbs 850 lbs

Mix Water 29 gals 31 gals 32 gals 34 gals 37 gals

Celcore Foam cu.ft. 19.80 19.32 18.94 18.51 17.75

Concrete Yield 1 cu.yd 1 cu.yd 1 cu.yd 1 cu.yd 1 cu.yd

Theoretical PSI 200 psi 225 psi 250 psi 300 psi 350 (+) psi

Thermal Calculations Minimum R-Value (U-Value)

Wet (cast) Density 42 to 50 pcf

Air Dry Density 22 to 50 pcf

Compressive Strength

Drying Shrinkage 0.20 - 0.40 %

Coefficient of Thermal Expansion 5.0 to 7.0 x 10-6

per ºF

COMPONENT

MEAN

TEMPRATURE DENSITY

BTU-IN/HR

FT.20F

R-VALUE

(Per 1-

inch)

MINIMUM

THICKNESS R-VALUE

CELCORE

0.700

2.25

EPS INSULATION 75 º I

3.60

OUTSIDE AIR FILM SUMMER CONDITION na

0.25 Na 0.00

INSIDE AIR FILM SUMMER CONDITION na

0.92 Na 0.00

ROOF MEMBRANE NA na

0.33 Na 0.00

HORIZONTAL HEAT FLOW

OMIT IF NO CEILING na Na 0.00

ROOF DECK ASSEMBLY MINIMUM R-VALUE

Submittal Approval Form

PROJECT: CLAY SPRINGS ELEMENTARY SCHOOL

DATE: _ __________________ ______

SUBCONTRACTOR NAME: __

SUBCONTRATOR ADDRESS: ______________________________ ____

NUMBER AND TITLE OF SPECIFICATION SECTION:

Contractor’s Submittal Stamp Architect/ Engineer’s Submittal Stamp

Cellucrete Corp

03 52 16 - Lightweight Insulating Cellular Concrete - Shop Drawings

2/6/15

2/6/15

Submittal Approval Form

PROJECT: CLAY SPRINGS ELEMENTARY SCHOOL

DATE: _ __________________ ______

SUBCONTRACTOR NAME: __

SUBCONTRATOR ADDRESS: ______________________________ ____

NUMBER AND TITLE OF SPECIFICATION SECTION:

Contractor’s Submittal Stamp Architect/ Engineer’s Submittal Stamp

Cellucrete Corp

03 52 16 - Lightweight Insulating Cellular Concrete - Product Data

2/6/15

2/6/15

CELCORE Roof Insulation Systems | Product Data

1. PRODUCT NAME

Celcore Foam Concentrate for Concrete & Celcore Cellular Concrete

2. MANUFACTURER

CELCORE INCORPORATED 775 US Hwy 70 West Black Mountain, N.C. 28711 (828) 669-4875 | (828) 669-4874 Fax

3. PRODUCT DESCRIPTION

Basic Use: Celcore Foam Concentrate is mixed with water and generated into a preformed foam for

addition to cement/water slurry mixtures to create a closed cell cellular concrete of a specific density.

Composition and Materials: Celcore Foam Concentrate contains no synthetic surfactants. It is comprised of natural saponified rosins and is protein stabilized. Celcore Foam Concentrate is non-corrosive, non-hazardous and readily biodegradable. It is packaged in (5) gallon [18.93 L] pails and displays the UL and FMRC mark on the product label.

Applicable Standards:

ASTM C-796 “Testing Foaming Agents for Use in Producing Cellular Concrete Using Preformed Foam”

ASTM C-513 “Test Method for Obtaining and Testing Specimens of Hardened Lightweight Insulating Concrete for Compressive Strength”

ASTM C-495 “Test for Compressive Strength of Lightweight Insulating Concrete” modified only in the method of molding the test specimen, size of the mold and initial curing. (A copy of the suggested modifications is available upon request.)

ASTM C-518 “Test Method for Steady - State Heat Flux Measurement and Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus”

5. TESTING AGENCIES & APPROVALS

DADE-COUNTY PRODUCT APPROVAL FACTORY MUTUAL RESEARCH CORPORATION UNDERWRITERS LABORATORIES SREF 423 MISSILE IMPACT & WATERTIGHTNESS SREF 423 EHPA’s (ENAHNCED HURRICAINE PROTECTION AREAS FLORIDA BUILDING CODE FLORIDA BUILDING HIGH VELOCITY HURRICANE ZONES FLORIDA PRODUCT APPROVAL IBCC APPROVALS

CELCORE Roof Insulation Systems | Mix Designs Thermal Value Calculations

Typical Mix Designs

Cast Density 36 pcf 38 pcf 40 pcf 42 pcf 45pcf

Type I Cement 663 lbs 703 lb s 742 lbs 782 lbs 850 lbs

Mix Water 29 gals 31 gals 32 gals 34 gals 37 gals

Celcore Foam cu.ft. 19.80 19.32 18.94 18.51 17.75

Concrete Yield 1 cu.yd 1 cu.yd 1 cu.yd 1 cu.yd 1 cu.yd

Theoretical PSI 200 psi 225 psi 250 psi 300 psi 350 (+) psi

Thermal Calculations Minimum R-Value (U-Value)

Wet (cast) Density 42 to 50 pcf

Air Dry Density 22 to 50 pcf

Compressive Strength

Drying Shrinkage 0.20 - 0.40 %

Coefficient of Thermal Expansion 5.0 to 7.0 x 10-6

per ºF

COMPONENT

MEAN

TEMPRATURE DENSITY

BTU-IN/HR

FT.20F

R-VALUE

(Per 1-

inch)

MINIMUM

THICKNESS R-VALUE

CELCORE

0.700

2.25

EPS INSULATION 75 º I

3.60

OUTSIDE AIR FILM SUMMER CONDITION na

0.25 Na 0.00

INSIDE AIR FILM SUMMER CONDITION na

0.92 Na 0.00

ROOF MEMBRANE NA na

0.33 Na 0.00

HORIZONTAL HEAT FLOW

OMIT IF NO CEILING na Na 0.00

ROOF DECK ASSEMBLY MINIMUM R-VALUE

Thermal Calculations Roof Area 1 and 2 At Roof Drains (Sumps) EPS Insulation Type IX ASTM C-578 2.0 lb/cu.ft. R-Value 4.76 per one inch

NOTE TO CONTRACTOR / SPECIFIER: To reduce the overall thickness at roof drains (sumps

4’x4’ per 03 52 16 -5 Part 3 Execution, 3.2 Mixing and Placing, A-1) and along the walls where

the roof crickets are placed to provide adequate wall and or curb heights for roof flashing, the

installer has elected to use a greater density Insulfoam high-R value insulation board as tested

and certified by ASTM.

Insulation Manufacturer will provide and additional 20 year 100% R-Value warranty in

addition to the insulating concrete manufacturer’s 20 year NDL warranty that includes R-Value.

COMPONENT

TYPE DENSITY

R-VALUE (Per 1-inch)

THICKNESS R-

VALUE

Foam Concentrate

CELCORE 42-50 Lbs/ft³ .86 2.25 1.94

EPS INSULATION

INSULFOAM TYPE IX

2.0 Lbs/ft³ 4.76 6.00 28.56

OUTSIDE AIR FILM

na

0.25 Na 0

INSIDE AIR FILM

na

0.92 Na 0

ROOF MEMBRANE

na

0.33 Na 0

HORIZONTAL HEAT FLOW

na

Na

ROOF DECK ASSEMBLY AVERAGE R-VALUE 30.50

Thermal Calculations Roof Area 3 and 4 Tapered-Lightweight Roof Insulation System

1 03 52 16 -5 Paragraph C, Line 3; Average Overall R-Value: Minimum average overall R-Value for roof

areas shall be 30.0

COMPONENT

TYPE DENSITY

R-VALUE (Per 1-inch)

1Overall

Average Thickness

R-VALUE

Foam Concentrate

CELCORE 42-50 Lbs/ft³ .86 2.75 2.36

EPS INSULATION

INSULFOAM TYPE I

.90 Lbs/ft³ 3.6 7.74 27.86

OUTSIDE AIR FILM

na

0.25 Na 0

INSIDE AIR FILM

na

0.92 Na 0

ROOF MEMBRANE

na

0.33 Na 0

HORIZONTAL HEAT FLOW

na

Na

ROOF DECK ASSEMBLY AVERAGE R-VALUE 30.22

InsulFoam® IX

DescriptionInsulFoam IX is a high-performance insulation consisting of a superior closed-cell, lightweight and resilient expanded poly-styrene (EPS). InsulFoam IX meets or exceeds the require-ments of ASTM C578, Type IX, Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation. InsulFoam IX has a nominal density of 2.0 lb/ft3. In addition, InsulFoam IX offers a long-term, stable R-Value and has excellent dimen-sional stability, compressive strength and water resistant properties.

UsesInsulFoam IX is a high-performance EPS product and is used in numerous building construction applications. Roofing: InsulFoam IX is well suited for single ply roof appli-cations that employ ballasted, mechanically fastened TPO, PVC, EPDM and CSPE with a slip sheet, as well as low-sloped built-up, modified bitumen and fully adhered single ply roofs that incorporate cover boards. Please consult local building codes and membrane manufacturers for system requirements.Other Construction Applications: InsulFoam IX is used in assorted building applications, including pre-stressed and pre-cast structural concrete panels, metal roof flute-fill, sid-ing backer board, building sheathing, roads and bridge fill, below-slab and perimeter insulation, and numerous other OEM applications.

AdvantagesEnvironmentally Friendly. It contains no formaldehyde or ozone-depleting CFCs or HCFCs, may contain recy-cled material, and is 100% recyclable if ever removed or replaced.Stable R-Value. Designers are well served knowing the product’s thermal properties will remain stable over its entire service life. There is no thermal drift, so the product is eligible for an Insulfoam 20-year thermal performance warranty.Proven Performance. The same fundamental EPS chem-istry has been in use since the mid-1950s, so the actual performance of the product is well known.Water-Resistant. InsulFoam IX does not readily absorb moisture from the environment.Code Approvals. InsulFoam IX is recognized by the Inter-national Code Council Evaluation Service (ICC-ES) and has numerous code approvals. Please contact your local Insulfoam representative for details.

SizesInsulFoam IX is typically available in 4' x 4' and 4' x 8' sizes with thickness from 1/4" to 40", and is readily available in cus-tom lengths and widths with little to no impact on lead time. It is also available in tapered panels.

Typical Tested Physical Properties*

3103 - 11/12

*Properties are based on data provided by resin manufacturers, independent test agencies and Insulfoam.

Property Test Method ValueDensity (nom. pcf) ASTM C303 2.00

C-Value (Conductance) - per inchBTU/(hr•ft2•°F)

@ 25 °F@ 40 °F@ 75 °F

ASTM C518or

ASTM C1770.2000.2100.230

R-Value (Resistance) - per inch(hr•ft2•°F)/BTU

@ 25 °F@ 40 °F@ 75 °F

ASTM C518or

ASTM C1775.004.764.35

Compressive Strength(psi, 10% deformation) ASTM D1621 25-33

Flexural Strength (min. psi) ASTM C203 50

Dimensional Stability (maximum %) ASTM D2126 2.0

Water Vapor Permeance(max. perm., 1 inch) ASTM E96 2.0

Water Absorption (max. % vol.) ASTM C272 2.0

Capillarity – none

Flame Spread ASTM E84 < 20

Smoke Developed ASTM E84 150-300

Insulfoam • 19727 57th Avenue East, Puyallup, WA 98375 • Toll Free: (800) 248-5995 • www.insulfoam.com

CELCORE Roof Insulation Systems | Installation Procedures

SCOPE The approved Celcore Applicator shall furnish all labor, materials, equipment and supervision for the installation of the complete insulating roof deck system (including corrugated metal deck when Applicable) as noted on drawings, and as detailed in the specifications.

GENERAL Surfaces on which Celcore is to be placed shall be clean of foreign objects, and free of standing water. It is the responsibility of the Celcore Applicator to inspect and approve the substrate prior to the placement of the Celcore deck system. All expansion joints, bulkheads, wood nailers, angles and the framing of openings or perimeters shall be provided by others.

MATERIALS

Insulating Concrete 1. Foaming agent - Celcore Foam Concentrate shall be manufactured and strictly controlled

by Celcore Inc. The concentrate shall have clear identification on each container, and shall bear the UL and FM marking.

2. Cement - Portland cement shall be Type I, II, III ASTM - C150 unless otherwise approved. 3. Water for mixing and curing shall be clean, fresh, and free from injurious quantities of

acid, alkali, salt, oil, organic matter or other impurities. Installation during cold weather may require the use of heated water.

4. Admixtures - No admixtures shall be used without the approval of Celcore, Inc., the Architect, and/or the Engineer. Approved admixtures shall be used in strict accordance with the manufacturer’s recommendations.

Corrugated Metal Deck The galvanized high strength corrugated steel deck shall be of type and quality that is recommended by its manufacturer for use as a supporting deck for insulating concrete. The steel deck shall have a minimum thickness of 22 gauge, and shall meet ASTMA525 G-90 minimum galvanizing treatment, and be of type and gauge to properly carry the live and dead loads. Attachment of the deck to the supporting members shall be by welding or by screw fastening, done in accordance to the recommendations of the Product Approval manufacturer and the Building Code requirements, the Architect and/or the Engineer. Slotted or perforated deck, if used, shall not exceed .50% opening.

Insulation Board The insulation board used in the Celcore roof deck system shall be a product of expanded polystyrene having a nominal weight of one pound per cubic foot. The Board shall be fabricated in 2 ft. by 4 ft. size in specified thickness with 6 or 8 - 2 1/2 inch (+/- 1/2") diameter holes to provide a positive keying action. All insulation board shall be manufactured in accordance with ASTM C578.

Reinforcing Mesh When required, mesh reinforcements shall be equal to keydeck Type 21602-1619.

APPLICATION

Physical Properties The mix proportions shall be designed by Celcore, Inc. to yield the proper physical properties, i.e compressive strength, density and thermal conductivity.

Mixing & Placing 1. Celcore insulating concrete shall be mixed and pumped into place by an approved

Celcore batch plant. All ingredients of the mix shall be thoroughly blended before being discharged from the mixer.

2. A minimum wet density of 42 pcf unless specified otherwise or required by the Product Approval.

3. The consistency of the mix shall be such as to provide a flowable mixture that can be screeded to a smooth finish.

4. Celcore insulating concrete shall have a minimum thickness of 2" over the top of the corrugations, concrete substrate or insulation board.

5. Two-density casting and double casting shall be acceptable per the specific manufacturer's recommendations.

6. When the air temperature is predicted to be above 40ºF for the first 24 hours after the placement of the Celcore insulating deck, normal placing procedures shall apply.

7. Cold weather placement (40ºF and falling) of Celcore should be avoided due to the possibility of freezing of the concrete prior to final set. If cold weather installations are required, then special considerations must be met. Contact your Celcore representative.

Insulation Board Placement

1. Prior to placement of the insulation board, the substrate shall be filled with Celcore Insulating Concrete to a minimum thickness of 1/8”. On a corrugated metal deck this fill shall be 1/8” minimum above the tops of the corrugation.

2. The insulation board shall be placed into the plastic slurry coat immediately upon the placement of the slurry coat on the substrate.

3. The insulation board shall be placed in the slurry in such a manner as to cause full contact of the slurry with the board, and to cause the slurry to enter the keying holes in the board. The board shall be placed in a brick-like pattern of staggered joints. All joints shall be butted tightly together.

4. Polystyrene boards, particularly in thicknesses of 2" or more, have a tendency to float if the top surface is applied prior to the adequate bonding of the polystyrene board to the substrate. It is the responsibility of the Celcore applicator to install the board in a manner that assures the proper thickness of the Celcore concrete.

Roof Slopes

When not provided by the roof structure, roof slope will be ¼-inch per foot. Slope will be achieved by a combination of stair-stepped EPS insulation board and Celcore insulating concrete fill. Step board increments will be one-inch +- one-half inch. Double casting per building code is permitted. Roof crickets and saddles and between roof drains or primary scupper will provide a finish slope of ¼-inch per foot.

Curing Apply a Celcore (PVA) Curing Compound film over deck surface as early as is practical once the deck has developed strength sufficient to support foot traffic. Curing is most effective when applied within 24 hours after topping placement. This (PVA) film shall be an integral part of the deck system. Prevent excess roof traffic for 24 hours.

Testing Celcore Insulating Concrete shall be tested in accordance with ASTM C-495-12, as modified below:

1. Installer certified by the manufacturer shall take one set of cylinders for every 5,000

to square feet or as specified.

2. Test specimens may be cylinders 6" in diameter and 12" in length or test cubes not

smaller than 2" x 2", or larger than 6"x 6".

3. In molding the specimens, the concrete shall be placed in two approximately equal

layers. The cylinders or cubes shall be raised and dropped approximately (1) in. three

times on a hard surface after placing each layer. The concrete shall not be rodded.

4. Specimens shall not be removed from the molds for at least 7 days.

5. Test cylinders for cellular insulating concrete shall not be oven-dried.

6. Testing for compressive strength and density shall be done by an independent facility

certified to conduct ASTM C-495-12 and ASTM C-513. Certification is included in this

submittal.

Testing Facility:

Universal Engineering Sciences

3532 Maggie Blvd

Orlando Florida 32811

CMEC Accreditation: 1001065

AASHTO R18

This is to certify that this laboratory has been accredited fortechnical competence and found to meet the requirements forperforming the test methods listed below for the inspection andtesting of construction materials.

Accreditation ID: 1001831

Reinspection Due Date: 8/12/2015

Universal Engineering Sciences, Inc.3532 Maggie Boulevard

Orlando, FL 32811United States

AggregateASTM Methods: ASTM C117, ASTM C127, ASTM C128, ASTM C136, ASTM C142, ASTM C29, ASTM C40, ASTM C702, ASTM D4791, ASTM D5821, ASTM Specification C1077 - Aggregate,ASTM Specification E329 - AggregateAASHTO Methods: AASHTO T11, AASHTO T112, AASHTO T19, AASHTO T21, AASHTO T248, AASHTO T27, AASHTO T84, AASHTO T85State Methods: FM 5 555

ConcreteASTM Methods: ASTM C1064, ASTM C1231, ASTM C138, ASTM C143, ASTM C172, ASTM C173, ASTM C231, ASTM C31, ASTM C39, ASTM C42, ASTM C495, ASTM C511, ASTM C513,ASTM C567, ASTM C617, ASTM C78, ASTM C803, ASTM C805, ASTM Specification C1077 - Concrete, ASTM Specification E329 - ConcreteAASHTO Methods: AASHTO R60, AASHTO T119, AASHTO T121, AASHTO T152, AASHTO T196, AASHTO T22, AASHTO T23, AASHTO T231, AASHTO T24, AASHTO T309, AASHTO T97

Hot Mix AsphaltASTM Methods: ASTM D2726, ASTM D5444, ASTM D6307, ASTM Specification E329 - Hot Mix AsphaltAASHTO Methods: AASHTO T166, AASHTO T30, AASHTO T308

MasonryASTM Methods: ASTM C1019, ASTM C1314, ASTM C140, ASTM Specification C1093 - Masonry, ASTM Specification E329 - Masonry

SoilASTM Methods: ASTM D1140, ASTM D1556, ASTM D1557, ASTM D2166, ASTM D2216, ASTM D2434, ASTM D2435, ASTM D2487, ASTM D2488, ASTM D2844, ASTM D2850, ASTM D421,ASTM D422, ASTM D4318 (1), ASTM D4318 (2), ASTM D4767, ASTM D4944, ASTM D5084, ASTM D558, ASTM D6938, ASTM D698, ASTM D854, ASTM Specification E329 - SoilAASHTO Methods: AASHTO R58, AASHTO T100, AASHTO T134, AASHTO T146, AASHTO T180, AASHTO T190, AASHTO T191, AASHTO T208, AASHTO T215, AASHTO T216, AASHTO T217,AASHTO T265, AASHTO T267, AASHTO T296, AASHTO T297, AASHTO T310, AASHTO T88, AASHTO T89, AASHTO T90, AASHTO T99State Methods: FM 5 515, FM 5 550, FM 5 551, FM 5 552, FM 5 553

Miscellaneous

Expiration Date: 11/10/2015

The current scope of accreditation can be obtained by viewing the CMECDirectory of Accredited Laboratories (www.cmec.org)

DDaavviidd AA.. SSaavvaaggeeDavid A. SavageDirector of Accreditation

CChhrriissttoopphheerr JJ.. RRoobbiinnssoonnChristopher J. Robinson. P.E.

Executive Director

JULY 26, 2013

DECK SYSTEMS, INC. 1005 Orienta Avenue, Suite 1500Altamonte Springs, FL 32701

Subject: Quality Control & Test Specimen CastingProject: All Projects Attn: Ken Poe, Vice President

To Whom It May Concern,

May this letter serve as a statement for the manufacturer, Celcore Incorporated, that employee Nicholas “Nick”Fluty of Approved Contractor, Deck Systems Inc., has received training and is manufacturer approved to sampleand cast test specimens of Celcore Cellular Insulating Concrete.

Celcore Approved contractors are regularly engaged in the production and placement of insulating concrete. Assuch, Celcore encourages each contractor to designate field personnel for conducting placement quality control.Having placement personnel trained to properly obtain test specimens allows the sampling of a project to occurcoordinated with its progress, finding compliance with scheduled or specified sampling intervals.

Deck Systems also maintains the proper equipment and supplies for making representative placement specimens.Jobsite curing boxes are used to assure that the specimens are cast and then not disturbed during the initial setperiod. Cylindrical specimens are cast in proper sized molds, and in the quantities required by ASTM C495, forphysical property determinations such as oven-dry-density and (28) day compressive strength. All subsequentphysical property testing of the specimens shall be conducted by an independent test firm having third partyaccreditation, affirming their competency, for conducting Standard Test Method ASTM C495. Thank you for the opportunity to provide this statement. Please feel free to contact my office should you have anyquestions.

With Kind Regards,CELCORE INCORPORATED

William R. Mac DonaldTechnical Director

Sent via e-mail attachment w/digital signature: [email protected] [email protected]

3148 US Hwy 70 West • Black Mountain, NC 28711(828) 669-4875 • Fax (828) 669-4874 • website www.celcoreinc.com

DECEMBER 01, 2014

DECK SYSTEMS, INC. 1005 Orienta Avenue, Suite 1500Altamonte Springs, FL 32701

Subject: Manufacturer Approved Contractor Attn: Ken Poe, Vice President

To Whom it may Concern,

May this letter serve as a statement from the foam concentrate manufacturer, CELCOREINCORPORATED, that DECK SYSTEMS, INC of Altamont Springs, FL is an Approved cellular concreteproduction and placement contractor. DECK SYSTEMS has been an active and Approved cellularinsulating concrete production/placement contractor during a period greater then (5) years.

Manufacturer Approved contractors are required to properly produce and place, cellular lightweightinsulating concrete that complies with the requirements of the foam concentrate manufacturer, as wellas the project specifications for properties such as post placement curing, cast density, compressivestrength and oven dry density.

This statement shall be considered current for a period of (6) months from the issued date above.

Celcore Incorporated is pleased to have the opportunity to provide this statement. Should you require anyadditional information, please do not hesitate contacting our office.

With Kind Regards,CELCORE INCORPORATED

William R. Mac DonaldTechnical Director

Sent via e-mail attachment w/digital signature: [email protected]

3148 US Hwy 70 West • Black Mountain, NC 28711(828) 669-4875 • Fax (828) 669-4874 • website www.celcoreinc.com

Submittal Approval Form

PROJECT: CLAY SPRINGS ELEMENTARY SCHOOL

DATE: _ __________________ ______

SUBCONTRACTOR NAME: __

SUBCONTRATOR ADDRESS: ______________________________ ____

NUMBER AND TITLE OF SPECIFICATION SECTION:

Contractor’s Submittal Stamp Architect/ Engineer’s Submittal Stamp

Cellucrete Corp

03 52 16 - Lightweight Insulating Cellular Concrete - Mix Designs

2/6/15

2/6/15

![Geographic Response Plan Map: SFL-41 !( [] Miam Key Totten ...ocean.floridamarine.org/acp/MIAACP/Maps/GRP_Maps/SFL-41.pdf · 1000' of shallow water containment boom. Use open water](https://static.fdocuments.in/doc/165x107/5e7bb69400c1876c1a7ffb97/geographic-response-plan-map-sfl-41-miam-key-totten-ocean-1000-of-shallow.jpg)