NUT, BOLT, GASKET KIT

Transcript of NUT, BOLT, GASKET KIT

246 Visit us at www.fnw.com

FigureNBGPIPING PRODUCTS

NUT, BOLT, GASKET KITSpecificationsNon-Asbestos Gaskets• ManufacturedFromAramidandOtherSyntheticFibersBondedwithNitrileRubber(NBR)

• Color:Green• MeetsASMEB16.21for150#&300#gaskets• Dimensions:ASMEB16.5• Max.Temperature:750°F(400°C)• Max.ContinuousTemperature:460°F(240°C)• Max.Pressure:1595PSI(110Bar)• Max.ContinuosPressure:725(50Bar)• ASTMF104LineCallOut:F712120E22M5• Density:109lb/ft³(1.75gm/cc)• Compressibility:7-17%• Recovery:min45%• TensileStrengthAcrossGrain:1670psi(11.5N/mm²)• IgnitionLoss:max34%• ThicknessIncreaseAfter5HourImmersion

○ ASTMIRM903@300°F(150°C):max12%○ ASTMFuelB@77°F(25°C):max10%

• WeightIncreaseAfter5HourImmersion○ ASTMIRM903@300°F(150°C):max15%○ ASTMFuelB@77°F(25°C):max15%

• CreepRelaxation:25%• Sealabilityat1000PSI:0.25ml/h

Red Rubber Gaskets• ManufacturedFromStyrene-Butadiene(SBR)• Color/Finish:RedtoReddishOrange/Smooth• MeetsASMEB16.21for150#gaskets• Dimensions:ASMEB16.5• DurometerHardness:ShoreA±5:75• TensileStrength:400PSI• Elongation:150%• TemperatureRange:-20°Fto170°F(-29°Cto77°C)• Max.Pressure:200PSI(13.8Bar)• Max.PressurexTemperature(°FxPSIG):20,000• CompressionSetfor22Hrs@158°F(70°C)(ASTMD395B):35%

• HeatAgingfor94Hrs@158°F(70°C)(ASTMD573)

◦ ChangeinHardness:+5ShoreA◦ ChangeinTensile:-15%◦ ChangeinElongation:-35%

Bolts• Material:CarbonSteelASTMA307GradeA• Coating:ZincPlated• Dimensions:ASMEB18.2.1• Tensile:60KSIMinimum• Elongation:18%Minimum• RockwellHardness:69-100Rb

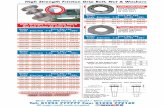

Kit Types / Size Ranges*

NOTE:Physicalpropertiesarenominalvaluesobtainedfromlaboratorytestsamples.Actualproductionvaluesmayvary.Pleaseensuretheproductmeetsyourapplicationspecificationspriortoplacinganorder.

* NOTE:Eachkitcontainscomponentsforoneflange.** NOTE:Notallconfigurationsofmodelnumbersmaybeavailable.Contactyoursupplierforspecificmaterial,

ratingandsizecombinations.

Figure Number Matrix**FNW NBG Z 1 NA F 6 Size

2-1/2=L 3=M 4=P 5=S 6=U 8=X

1/2=D 3/4=F 1=G1-1/4=H1-1/2=J 2=K

10=10 12=12 14=14 16=16 18=18 20=20

SIZECODE 150#=1 300#=3

PRESSURENon-Asbestos=NA RedRubber=R

MATERIAL Ring=RFullFace=F

TYPE

Nuts• Material:CarbonSteelASTMA563GradeA• Coating:ZincPlated• Dimensions:ASMEB18.2.2

Non-Asbestos Kits Red Rubber Kits150#1/16"RingGaskets 1/2"to20" 150#1/16"RingGaskets 2"to12"300#1/16"RingGaskets 1/2"to20" 150#1/16"FullFaceGaskets 2"to16"

Ch. 8 Piping Products 242-267.indd 246 5/11/12 May 11, 2012 8:49 AM