NTPC Project KORBA(SUPER THEMAL POWER PLANT)

-

Upload

rajan-kumar-choudhary -

Category

Documents

-

view

55 -

download

6

Transcript of NTPC Project KORBA(SUPER THEMAL POWER PLANT)

INDUSTRIAL TRAINING REPORT NATIONAL THERMAL POWER CORPORATION

KORBA (C.G.)

REPORT SUBMITTED BY:

Rajan kumar choudhary 6th Semester Scholar No. 091116012 Mechanical Engineering Maulana Azad National Institute Of Technology Bhopal, 462051

2

DECLARATION

I hereby declare that this project is being submitted in fulfilment of

the VOCATIONAL TRAINING PROGRAMME in NTPC Sipat, and

is the result of self done work carried out by me under the guidance of

various Engineers and other officers.

I further declare that the structure and content of this project are

original and have not been submitted before for any purpose.

SUBMITTED BY:

RAJAN KUMAR CHOUDHARY

SCHOLAR NO. 091116012

B.TECH. (6TH SEMESTER)

MAULANA AZAD NATIONAL INSTITUTE OF TECHNOLOGY

BHOPAL (MADHYA PRADESH), 462051

3

THERMAL POWER PLANTS

In thermal power stations, mechanical power is produced by a heat

engine that transforms thermal energy, often from combustion of a fuel,

into rotational energy. Most thermal power stations produce steam,

and these are sometimes called steam power stations. Not all thermal

energy can be transformed into mechanical power, according to the

second law of thermodynamics. Therefore, heat loss to the environment

is always there. If this loss is employed as useful heat, for industrial

processes or district heating, the power plant is known as a

cogeneration power plan or CHP (combined heat and power) plant. In

countries where district heating is common, there are dedicated heat

plants called heat-only boiler stations. In thermal power stations,

mechanical power is produced by a heat engine that transforms thermal

energy, often from combustion of a fuel, into rotational energy.

4

COAL FIRED THERMAL POWER PLANTS

More than half of the electricity generated in the world and three-fourth

generated in India is by using coal as primary fuel.

The function of the coal fired thermal power plant is to convert the chemical

energy available in the coal to Electricity. Several steps are involved in

transforming the energy stored in coal to usable electricity that powers almost

all the amenities of our modern lifestyle.

The conversion from coal to electricity takes place in three stages:

Stage I

The first conversion of energy takes place in the boiler. Coal is burnt in the

boiler furnace to produce heat. Carbon in the coal and Oxygen in the air

combine to produce Carbon Dioxide and heat.

STAGE II

The second stage is the thermodynamic process:

1. The heat from combustion of the coal boils water in the boiler to produce

steam. In modern power plant, boilers produce steam at a high pressure

and temperature.

2. The steam is then piped to a turbine.

3. The high pressure steam impinges and expands across a number of sets of

blades in the turbine.

4. The impulse and the thrust created rotate the turbine.

5. The steam is then condensed and pumped back into the boiler to repeat

the cycle.

STAGE III

In the third stage, rotation of the turbine rotates the generator rotor to produce

electricity based on Faraday’s Principle of Electromagnetic Induction.

5

NATIONAL THERMAL POWER

CORPORATION LIMITED

NTPC Limited is the largest power generation company in India. Forbes

Global 2000 for 2011 ranked it 348th in the world. It is an Indian public sector

company listed on the Bombay Stock Exchange although at present the

Government of India holds 84.5% of its equity. With a current generating

capacity of 39,174 MW, NTPC has embarked on plans to become a 75,000 MW

company by 2017. It was founded on November 7, 1975.

NTPC’s core business is engineering, construction and operation of power

generating plants and providing consultancy to power utilities in India and

abroad.

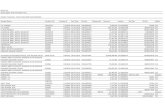

The total installed capacity of NTPC in India is as follows at present:

NO. OF PLANTS CAPACITY (MW)

NTPC Owned

Coal 15 25,375

Gas/Liquid Fuel 7 3,955

Total 22 29,330

Owned By JVs

Coal & Gas 5 3,364

Total 27 32,694

NTPC has been operating its plants at high efficiency levels. Although the

company has 18.10% of the total national capacity, it contributes 28.60% of

total power generation due to its focus on high efficiency.

6

Coal Based Power Stations:

With 15 coal based power stations, NTPC is the largest thermal power generating company in

the country. The company has a coal based installed capacity of 25,375 MW.

COAL BASED(Owned

by NTPC) STATE

COMMISSIONED

CAPACITY(MW)

1. Singrauli Uttar Pradesh 2,000

2. Korba Chhattisgarh 2,600

3. Ramagundam Andhra Pradesh 2,600

4. Farakka West Bengal 2,100

5. Vindhyachal Madhya Pradesh 3,760

6. Rihand Uttar Pradesh 2,500

7. Kahalgaon Bihar 2,340

8. NCTPP, Dadri Uttar Pradesh 1,820

9. Talcher Kaniha Orissa 3,000

10. Feroze Gandhi, Unchahar Uttar Pradesh 1,050

11. Talcher Thermal Orissa 460

12. Simhadri Andhra Pradesh 1,500

13. Tanda Uttar Pradesh 440

14. Badarpur Delhi 705

15. Sipat Chhattisgarh 2,980

Total 31,995

Coal Based Joint Ventures:

COAL BASED

(Owned by JVs) STATE

COMMISSIONED

CAPACITY

1. Durgapur West Bengal 120

2. Rourkela Orissa 120

3. Bhilai Chhattisgarh 574

4. Kanti Bihar 110

5. IGSTPP, Jhajjar Haryana 500

Total 1,424

7

BASIC POWER PLANT CYCLE

RANKINE CYCLE The Rankine cycle is a cycle that converts heat into work. The heat is supplied

externally to a closed loop, which usually uses water. This cycle generates about

80% of all electric power used throughout the world, including virtually all

solar thermal, biomass, coal and nuclear power plants. It is named after William

John Macquorn Rankine, a Scottish polymath. The Rankine cycle is the

fundamental thermodynamic underpinning of the steam engine.

8

There are four processes in the Rankine cycle; the processes are identified by

number in the diagram above:

Process 1-2: The working fluid is pumped from low to high pressure, as

the fluid is a liquid at this stage the pump requires little input energy.

Process 2-3: The high pressure liquid enters a boiler where it is heated at

constant pressure by an external heat source to become a dry saturated

vapour. The input energy required can be easily calculated using [] or h-s

chart or enthalpy-entropy chart also known as steam tables.

Process 3-4: The dry saturated vapour expands through a turbine,

generating power. This decreases the temperature and pressure of the

vapour, and some condensation may occur. The output in this process can

be easily calculated using the Enthalpy-entropy chart or the steam tables.

Process 4-1: The wet vapour then enters a condenser where it is

condensed at a constant pressure to become a saturated liquid.

In an ideal Rankine cycle the pump and turbine would generate no entropy and

hence maximize the net work output. Processes 1-2 and 3-4 would be

represented by vertical lines on the T-S diagram and more closely resemble that

of the Carnot cycle. The Rankine cycle shown here prevents the vapor ending

up in the superheat region after the expansion in the turbine.

Reasons for Considering Rankine Cycle as an Ideal Cycle

For Steam Power Plants:

1) It is very difficult to build a pump that will handle a mixture of liquid and

vapour at state 1’ (refer T-s diagram) and deliver saturated liquid at state 2’. It is

much easier to completely condense the vapor and handle only liquid in the

pump.

2) In the rankine cycle, the vapor may be superheated at constant pressure from

3 to 3” without difficulty. In a Carnot cycle using superheated steam, the

superheating will have to be done at constant temperature along path 3-5.

During this process, the pressure has to be dropped. This means that heat is

transferred to the vapor as it undergoes expansion doing work. This is difficult

to achieve in practice.

9

Variations of the basic Rankine cycle:

The overall thermodynamic efficiency (of almost any cycle) can be increased by

raising the average heat input temperature of that cycle.

Increasing the temperature of the steam into the superheat region is a simple

way of doing this. There are also variations of the basic Rankine cycle which

are designed to raise the thermal efficiency of the cycle in this way; two of these

are described below.

Rankine cycle with reheat

In this variation, two turbines work in series. The first accepts vapor

from the boiler at high pressure. After the vapor has passed through the first

turbine, it re-enters the boiler and is reheated before passing through a second,

lower pressure turbine. Among other advantages, this prevents the vapor from

condensing during its expansion which can seriously damage the turbine blades,

10

and improves the efficiency of the cycle, as more of the heat flow into the cycle

occurs at higher temperature.

0mixed with the fluid at 4 (both at the same pressure) to end up with the

saturated liquid at 7. This is called "direct3

+. contact heating". The Regenerative Rankine cycle (with minor variants) is

commonly used in real power stations.

Another variation is where 'bled steam' from between turbine stages is sent to

feedwater heaters to preheat the water on its way from the condenser to the

boiler. These heaters do not mix the input steam and condensate, function as an

ordinary tubular heat exchanger, and are named "closed feed water heaters".

The regenerative features here effectively raise the nominal cycle heat input

temperature, by reducing the addition of heat from the boiler/fuel source at the

relatively low feedwater temperatures that would exist without regenerative

feedwater heating. This improves the efficiency of the cycle, as more of the heat

flow into the cycle occurs at higher temperature.

THERMAL EFFICIENCY OF A POWER PLANT

11

The efficiency of the power plant can be calculated by using the

formula:

EFFICIENCY = (WT - WP ) / QH

Where,

WP = work done by pump.

WT = work done by turbine.

QH = heat energy given to the boiler.

Any thermal power plant should be able to maintain a high

efficiency of the cycle, as it will indicate the fraction of heat being

utilized usefully. There are several ways of increasing the thermal

efficiency of the power plant. Some of the ways are mentioned below:

a) An increase in the initial pressure of the steam can raise the

efficiency of the power plant.

b) The efficiency of the plant can be increased by raising the

initial temperature of the steam without raising the steam pressure.

c) Intermediate re-heating of the steam improves the thermal

efficiency of the plant. An increase in the initial pressure of the steam

increases the efficiency, but the wetness fraction of such a steam also

grows at the end of expansion. Such a high wetness can cause wear of

the blades of the last stages of a steam turbine. Therefore, the steam

from boiler after partial expansion in the first stage of turbine is fed to

the re-heater.

d) Thermal efficiency of the plant can be increased by carrying

out regenerative heating of the feed water. Such heating of the water is

carried out by using the heat of steam partly tapped from the turbine.

12

RAW MATERIALS USED FOR POWER

GENERATION:

Basic Raw Materials Used Are:

1. FUEL

2. WATER

3. AIR

FUEL:

a. LDO (Light Diesel Oil): It is used for ignition purpose

only.

b. HFO (Heavy Furnace Oil): It is used to raise the

temperature inside the furnace up to the ignition

temperature of coal. When ignition temperature is

reached, combustion of coal starts. HFO is highly

viscous in nature.

c. Pulverised Coal: The most important fuel for thermal power

generation is coal. Coal is converted into pulverised coal by

mills. It is a mixture of carbon, sulphur, hydrogen, oxygen,

nitrogen, etc.

WATER: Beside producing steam from water in the boiler it is alse used for

condensing vapour in the condenser. The water used for condensing

purpose is the demineralised water

AIR: There are 4 types of air used in NTPC:

a. Primary Air: This is used to remove moisture from coal and to

transport coal from mill to coal nozzles. This is done with the

help of P.A Fans.

b. Secondary Air: This is also known as combustion air as it helps

in combustion. It provides oxygen and extra air (over fire air)

from reduction processes during combustion. It is preheated to

help in combustion.

13

GENERAL LAYOUT OF POWER PLANT:

LEGEND:

1. Cooling tower 10. Steam governor valve 19. Superheater

2. Cooling water pump 11. High pressure turbine 20. Forced draught fan

3. Transmission line (3-phase) 12. Deaerator 21. Reheater

4. Unit transformer (3-phase) 13. Feed heater 22. Air intake

5. Electric generator (3-phase) 14. Coal conveyor 23. Economiser

6. Low pressure turbine 15. Coal hopper 24. Air preheater

7. Boiler feed pump 16. Pulverised fuel mill 25. Precipitator

8. Condenser 17. Boiler drum 26. Induced draught fan

9. Intermediate pressure turbine 18. Ash hopper 27. Chimney Stack

14

DESCRIPTION:

Coal is conveyed (14) from an external stack and ground to a very fine powder

by large metal spheres in the pulverised fuel mill (16). There it is mixed with

preheated air (24) driven by the forced draught fan (20). The hot air-fuel

mixture is forced at high pressure into the boiler where it rapidly ignites. Water

of a high purity flows vertically up the tube-lined walls of the boiler, where it

turns into steam, and is passed to the boiler drum, where steam is separated

from any remaining water.

The steam passes through a manifold in the roof of the drum into the pendant

superheater (19) where its temperature and pressure increase rapidly to around,

sufficient to make the tube walls glow a dull red. The steam is piped to the high

pressure turbine (11), the first of a three-stage turbine process. A steam

governor valve (10) allows for both manual control of the turbine and automatic

set-point following. The steam is exhausted from the high pressure turbine, and

reduced in both pressure and temperature, is returned to the boiler reheater (21).

The reheated steam is then passed to the intermediate pressure turbine (9), and

from there passed directly to the low pressure turbine set (6).

The exiting steam, now a little above its boiling point, is brought into thermal

contact with cold water (pumped in from the cooling tower) in the condensor

(8), where it condenses rapidly back into water, creating near vacuum-like

conditions inside the condensor chest. The condensed water is then passed by a

feed pump (7) through a deaerator (12), and pre-warmed, first in a feed heater

(13) powered by steam drawn from the high pressure set, and then in the

economiser (23), before being returned to the boiler drum. The cooling water

from the condensor is sprayed inside a cooling tower (1), creating a highly

visible plume of water vapor, before being pumped back to the condensor (8) in

cooling water cycle.

The three turbine sets are sometimes coupled on the same shaft as the three-

phase electrical generator (5) which generates an intermediate level voltage

(typically 21 kV). This is stepped up by the unit transformer (4) to a voltage

more suitable for transmission (typically 410 kV) and is sent out onto the three-

phase transmission system (3).

Exhaust gas from the boiler is drawn by the induced draft fan (26) through an

electrostatic precipitator (25) and is then vented through the chimney stack (7).

15

There are four main circuits in any thermal power plant and these are:

1. Coal & Ash Circuit: This circuit deals mainly with feeding the boiler

with coal for combustion purposes and taking care of the ash that is

generated during the combustion process and includes equipment that is

used to handle the transfer of coal and ash.

2. Air & Gas Circuit: We know that air is one of the main components of

the fire triangle and hence necessary for combustion. Since lots of coal is

burnt inside the boiler it needs a sufficient quantity of air which is

supplied using either forced draught or induced draught fans. The exhaust

gases from the combustion are in turn used to heat the ingoing air through

a heat exchanger before being let off in the atmosphere. The equipment

which handles all these processes fall under this circuit.

3. Feed Water & Steam Circuit: This section deals with supplying of

steam generated from the boiler to the turbines and to handle the outgoing

steam from the turbine by cooling it to form water in a condenser so it

can be reused in the boiler plus making good any losses due to

evaporation, etc.

4. Cooling Water Circuit: This part of the thermal power plant deals with

handling of the cooling water required in the system. Since the amount of

water required to cool the outgoing steam from the boiler is substantial, it

is either taken from a nearby water source such as a river, or it is done

through evaporation if the quantity of cooling water available is limited.

16

NTPC KORBA

Capacity : 3 X 220 MW Stage-I

: 2 X 500 MW Stage-II

1 X 500 MW Stage-III

Water Source : From Hasdeo right bank canal

Coal Mines : Gevra Mines of SECL Korba.

Coal Trans : By dedicated MGR (34.8 Kms)

17

MAJOR SUB-SYSTEMS

1) COAL HANDLING PLANT (C.H.P): It is the place

where everything associated with coal is taken care of, right from its

arrival from the coal mines, to its treatment and finally it being fed to the

boiler. For the plant at Sipat, the coal is provided by the Gevra mines

under the S.E.C.L, with the help of a merry-go-round (MGR).When the

coal is supplied at the CHP, the coal is moved along the track hopper

towards the crusher, where the lumps of coal are crushed into 20 mm

sized particles, from where they may be stored in the stack-yard, or sent

to the bunkers before being fed into the boilers.

An important thing to be noted is that, before feeding the coal to be

fired, we employ light diesel oil (LDO) and heavy furnace oil (HFO) to

fire the boiler and create a stable flame. For this we employ oil guns,

which are placed near the boilers, which release oil for being fired.

Thus, the function of the CHP is to improve the heating value of coal,

and to make its handling easier. Coal is supplied through conveyor belt

systems.

2) MILL: The coal particles are ground into finer sized granules.

The coal which is stored in the bunker is sent into the mill, which is

primarily a ball type, in which a drum contains a ball, and when the drum

rotates the ball also does, and this causes the coal particles caught in

between to be ground.

After grinding, the coal is then passed through a desired size of

mesh, so that any coal particle not properly ground is not allowed

through. Then the coal is forced by a blast of air coming from the primary

air fans to enter the boiler. Coal is fed to the mills from the bunkers via

the raw coal feeders.

18

Another type of mill is the ball and race mill, in which the coal passes

between the rotating elements again and again until it has been pulverized

to the desired degree of fineness. However, there is greater wear in this

mill as compared to other pulverisers.

INTERIOR OF BOWL MILL

Bowl Mill Structure

19

(3) BOILER: A boiler is the central component of a power plant,

and it is the unit where the steam required for driving the turbine is

generated.

Boilers are categorized according to several parameters. They may be

classified on the basis of the presence of a drum, on the no. of passes, on

the type of firing used to burn the fuel, on the type of tubing used, and so

on.

The components of a boiler and their functions are given below:

a) DRUM: It is a type of storage tank much higher than the level at

which the boiler is placed, and it is also a place where water and steam

are separated. First the drum is filled with water coming from the

economizer, from where it is brought down with the help of down-

comers, entering the bottom ring headers. From there they enter the riser,

which carries the water (which now is a liquid-vapor mixture), back to

the drum. Now, the steam is sent to be superheated.

b) SUPER HEATERS: The steam is then sent for superheating. This

takes place in three stages. In the first stage, the steam is sent to a simple

super heater, known as the low temperature super heater, after which the

second stage consists of several divisional panels. The final stage

involves further heating in a Platen super heater, after which the steam is

released for driving the turbine. After the HP stage of the turbine the

steam is re-heated and then again released.

Super heated steam also has several merits such as increased working

capacity, ability to increase the plant efficiency, lesser erosion and so on.

It is also of interest to know that while the super heater increases the

temperature of the steam, it does not change the pressure. There are

different stages of superheaters besides the sidewalls and extended

sidewalls. The first stage consists of LTSH(low temperature superheater),

which is conventional mixed type with upper & lower banks above the

economiser assembly in rear pass. The other is Divisional Panel

Superheater which is hanging above in the first pass of the boiler above

the furnace. The third stage is the Platen Superheater from where the

steam goes into the HP turbine through the main steam line. The outlet

20

temperature & pressure of the steam coming out from the super-heater is

540 degrees Celsius & 147 kg/cm2.

c) WATER WALLS: The water from the bottom ring header is then

transferred to the water walls, where the first step in the formation of

steam occurs. This steam then enters the drum.

d) ECONOMIZER: The economizer is a tube-shaped structure

which contains water from the boiler feed pump. This water is heated up

by the hot flue gases which pass through the economizer layout, which

then enters the drum. The economizer is usually placed below the second

pass of the boiler, below the Low Temperature Superheater. As the flue

gases are being constantly produced due to the combustion of coal, the

water in the economizer is being continuously being heated up, resulting

in the formation of steam to a partial extent. Economiser tubes are

supported in such a way that sagging, deflection & expansion will not

occur at any condition of operation.

e) DEAERATOR:

21

A de-aerator is a device that is widely used for the removal of air and

other dissolved gases from the feed water to steam-generating boilers.

Most de-aerators are designed to remove oxygen down to levels of 7

ppb by weight (0.005 cm³/L) or less.

There are two basic types of de-aerators, the tray-type and the spray-

type:

The tray-type (also called the cascade-type) includes a vertical

domed de-aeration section mounted on top of a horizontal cylindrical

vessel which serves as the de-aerated boiler feed water storage tank.

The spray-type consists only of a horizontal (or vertical)

cylindrical vessel which serves as both the de-aeration section and the

boiler feed water storage tank.

Turbine: After the boiler the most vital unit is the turbine, which works on

the steam generated from the boiler. Thus a turbine employed in a thermal

power plant is a steam turbine. The initial steam is admitted ahead of the

blading via two main stop and control valve combinations. The turbine unit of

any thermal power plant is not a single stage operation, rather it consists of

three stages:

a) High Pressure Turbine Stage (HPT Stage): This stage takes

place immediately after the Platen super heater stage. This is the first

stage of the turbine operation.

b) Intermediate Pressure Turbine Stage (IPT Stage): After the

HPT stage, the steam gets saturated and, consequently, gets cooled. It is,

therefore, first sent back to the boiler unit to be reheated, after which it is

sent to the IPT stage. Its section is of double flow construction with

horizontally split casings.

c) Low Pressure Turbine Stage (LPT Stage): After the IPT, the

steam gets cooled to an intermediate extent, thus directly entering the

LPT, where it gets saturated. Its casing is of the three-shell design. After

this stage the water enters the condenser, which is connected to a

condensate extraction pump.

22

The shaft of the turbine is connected to the generator. The purpose of

the generator is to convert the mechanical shaft energy it receives from

the turbine into electrical energy. Steam turbine driven AC synchronous

generators (alternators) are of two or four pole designs. Large generators

have cylindrical rotors with minimum heat dissipation surface and so they

have forced ventilation to remove the heat. Such generators generally use

an enclosed system with air or hydrogen coolant. The gas picks up the

heat from the generator and gives it up to the circulating water in the heat

exchanger.

Every turbine, except the LPT, has a stop valve and a regulating valve

attached to it. The stop valve is used to stop the flow of steam, whenever

required, whereas the regulating valve is also a kind of a flow controlling

device. Each turbine also has an inlet and an outlet pipe for the steam to

enter and exit, respectively. Between the HPT-IPT combine and the IPT-

LPT combine is attached a bearing assembly. It is constructed using a

cross around pipe.

After the steam leaves the turbine, it enters the condenser . The

condenser is meant to receive the steam from the turbine, condense it and

to maintain a pressure at the exhaust lower than the atmospheric pressure.

The functions of each of these auxiliary units are self-explanatory.

ASH HANDLING AND DISPOSAL:

Any power plant which does not have a proper planning for handling

of ash and its subsequent disposal may not be able to get the necessary

clearance from the authorities, as it may be detrimental to the safety of

the environment.

There are two types of ash handling methods: dry ash handling and

wet ash handling. Dry ash handling is carried out by storing the ash

deposited in large pits, where in the wet ash handling method, the ash is

deposited into large reservoirs or ponds.

Fly ash is captured from the flue gas by using electrostatic

precipitators, which are located at the outlet of the furnace and before the

ID fans. Also at the bottom of every boiler, a hopper is provided for

23

collection of the bottom ash from the bottom of the furnace. This hopper

is always filled with water to quench the ash and clinkers falling from the

furnace. There is an arrangement for the crushing of the clinkers and for

conveying the crushed clinkers and bottom ash to the storage site.

ASSOCIATED SYSTEMS IN A POWER PLANT

There are several systems in a power plant which assist the main units

to carry out their functions properly:

1) PA FANS: The primary air fans are used to carry the pulverized

coal particles from the mills to the boiler. They are also used to

maintain the coal-air temperature. The specifications of the PA fan used

at the plant under investigation are: axial flow, double stage, reaction

fan. A PA fan uses 0.72% of plant load for a 500 MW plant.

2) FD FANS: The forced draft fans, also known as the secondary air

fans are used to provide the secondary air required for combustion, and

to maintain the wind box differential pressure. Specifications of the FD

fans are: axial flow, single stage, impulse fan.

FD fans use 0.36% of plant load for a 500 MW plant.

24

3)ID FANS:

The main purpose of an ID fan is to suck the flue gas through all the

above mentioned equipments and to maintain the furnace pressure. ID

fans use 1.41% of plant load for a 500 MW plant.

3) SCANNER AIR FAN: Scanner air fan is used to provide air to the

scanner. For a tangentially fired boiler, the vital thing is to maintain a

stable ball of flame at the centre. A scanner is used to detect the flame,

to see whether it is proper and stable. The fan is used to provide air to

the scanner, and it is a crucial component which prevents the boiler

from tripping.

4) BOILER FEED PUMP: The auxiliary component which consumes

the maximum amount of power earmarked for such purposes is the

boiler feed pump.

5) AIR PRE-HEATERS: Air pre-heaters are used to take heat from

the flue gases and transfer it to the incoming air. They are of two types:

a) Regenerative

b) Recuperative

25

6) ELECTROSTATIC PRECIPITATORS: They are used to

separate the ash particles from the flue gases. In this the flue gas is

allowed into the

ESP, where

there are several

metallic plates

placed at a

certain distance

from each other.

When these

gases enter, a

very high

potential

difference is

applied, which

causes the gas

particles to

ionize and stick to the plates, whereas the ash particles fall down and

are collected in a hopper attached to the bottom of the ESP. The flue gas

is allowed to cool down and is then released to the ID fan to be sent to

the chimney.

7) COOLING TOWERS: Cooling towers are used to remove the

heat from the condensers. In this cooling water is discharged to the

condenser with the help of a cooling water pump. This water enters the

condenser through several tubes. Steam entering the condenser from the

turbine after expansion further loses heat and condenses, while the

water circulating inside the tube gains heat and goes back to the cooling

tower. Inside the tower is a cooling fan which takes the heat from this

batch of water, which is then sent back again for the cycle to be

repeated. It is hence known as a regenerating cycle.

26

8) CHIMNEY: These are tall RCC structures with single & multiple

flues. Here, for I & II we have 1 chimney, for unit III there is 1 chimney

& for units & V there is 1 chimney. So number of chimneys is 5 and the

height of each is 275 metres.

9) COAL BUNKER: These are in process storage used for storing

crushed coal from the coal handling system. Generally, these are made

up of welded steel plates. Normally, these are located on top of mills to

aid in gravity feeding of coal.

27

10) REHEATER: The function of reheater is to reheat the steam

coming out from the high pressure turbine to a temperature of 540

degrees Celsius. It is composed of two sections: the rear pendant section

is located above the furnace arc & the front pendant section is located

between the rear water hanger tubes & the Platen super-heater section.

BOILER

A boiler is a closed vessel in which water or other fluid is heated. The heated or

vaporized fluid exits the boiler for use in various processes or heating

applications.

28

The Basic Theory Behind All

Volume of one unit mass of steam is thousand times that of water. When water

is converted to steam in a closed vessel the pressure will increase. Boiler uses

this principle to produce High Pressure steam.

Conversion of Water to Steam Evolves in three stages:

Heating the water from cold condition to boiling point or saturation

temperature – Sensible Heat Addition.

Water boils at saturation temperature to produce steam – Latent Heat

Addition.

Heating steam from saturation temperature to higher temperature called

Superheating to increase the power plant output and efficiency.

TANGENTIAL TYPE BOILER

In a tangential firing system the coal is pulverized in coal mills and is carried by

primary air to the furnace through coal pipes. The mills are usually a constant

airflow mill and have a specific output in mass of coal ground depending on

coal properties like hardness, moisture, and fineness which affect the mill

output. In direct tangential firing systems, the pulverized coal from the coal

mills is directly taken to the furnace. The total quantity of coal to be pulverized

for a specified size of boiler at a designed efficiency will depend on the calorific

value of coal. The secondary air required for combustion is sent into the furnace

through a wind box housing the coal nozzles, oil guns, and the secondary air

29

nozzles. Behind the coal nozzles there are fuel-air dampers which are used for

keeping the flame front away from the coal nozzles by at least one meter from

the tip. This is required to prevent the coal nozzle tips from getting burnt due to

radiation from coal flame. The flame front is predominantly affected by the

volatile matter in coal and the fuel air damper is modulated for controlling the

flame front. As the fuel air dampers are opened, more secondary air goes

through this damper and physically pushes the flame front away. However,

when the flame front is already away from the nozzle tip, the fuel air damper

needs to be closed fully.

Boiler Fittings And Accessories:

Safety Valve: It is used to relieve pressure and prevent possible

explosion of a boiler.

Water Level Indicators: They show the operator the level of fluid in

the boiler, also known as a sight glass, water gauge or water column is

provided.

Bottom Blowdown Valves: They provide a means for removing solid

particulates that condense and lie on the bottom of a boiler. As the

name implies, this valve is usually located directly on the bottom of the

boiler, and is occasionally opened to use the pressure in the boiler to

push these particulates out.

Continuous Blowdown Valve: This allows a small quantity of water to

escape continuously. Its purpose is to prevent the water in the boiler

becoming saturated with dissolved salts. Saturation would lead to

foaming and cause water droplets to be carried over with the steam - a

condition known as priming. Blowdown is also often used to monitor

the chemistry of the boiler water.

Flash Tank: High pressure blowdown enters this vessel where the

steam can 'flash' safely and be used in a low-pressure system or be

vented to atmosphere while the ambient pressure blowdown flows to

drain.

Automatic Blowdown/Continuous Heat Recovery System: This

system allows the boiler to blowdown only when makeup water is

flowing to the boiler, thereby transferring the maximum amount of heat

possible from the blowdown to the makeup water. No flash tank is

generally needed as the blowdown discharged is close to the

temperature of the makeup water.

30

Hand holes: They are steel plates installed in openings in "header" to

allow for inspections & installation of tubes and inspection of internal

surfaces.

Steam Drum Internals: A series of screen, scrubber & cans (cyclone

separators).

Low- Water Cutoff: It is a mechanical means (usually a float switch)

that is used to turn off the burner or shut off fuel to the boiler to

prevent it from running once the water goes below a certain point. If a

boiler is "dry-fired" (burned without water in it) it can cause rupture or

catastrophic failure.

Surface Blowdown Line: It provides a means for removing foam or

other lightweight non-condensible substances that tend to float on top

of the water inside the boiler.

Circulating Pump: It is designed to circulate water back to the boiler

after it has expelled some of its heat.

Feedwater Vheck Valve or Clack Valve: A non-return stop valve in

the feedwater line. This may be fitted to the side of the boiler, just

below the water level, or to the top of the boiler.

Top Feed: A check valve (clack valve) in the feedwater line, mounted

on top of the boiler. It is intended to reduce the nuisance of limescale.

It does not prevent limescale formation but causes the limescale to be

precipitated in a powdery form which is easily washed out of the

boiler.

Desuperheater Tubes or Bundles: A series of tubes or bundles of

tubes in the water drum or the steam drum designed to cool

superheated steam. Thus is to supply auxiliary equipment that doesn't

need, or may be damaged by, dry steam.

Chemical Injection Line: A connection to add chemicals for

controlling feedwater pH.

SUPERHEATED BOILERS

Most boilers produce steam to be used at saturation temperature; that is,

saturated steam. Superheated steam boilers vaporize the water and then

further heat the steam in a super-heater. This provides steam at much higher

temperature, but can decrease the overall thermal efficiency of the steam

generating plant because the higher steam temperature requires a higher flue

gas exhaust temperature. There are several ways to circumvent this problem,

typically by providing an economizer that heats the feed water, a combustion

31

air heater in the hot flue gas exhaust path, or both. There are advantages to

superheated steam that may, and often will, increase overall efficiency of

both steam generation and its utilisation: gains in input temperature to a

turbine should outweigh any cost in additional boiler complication and

expense. There may also be practical limitations in using wet steam, as

entrained condensation droplets will damage turbine blades.

Super-heater operation is similar to that of the coils on an air conditioning

unit, although for a different purpose. The steam piping is directed through

the flue gas path in the boiler furnace. The temperature in this area is

typically between 1,300–1,600 degree Celsius (2,372–2,912 °F). Some super-

heaters are radiant type; that is, they absorb heat by radiation. Others are

convection type, absorbing heat from a fluid such as a gas. Some are a

combination of the two types. Through either method, the extreme heat in the

flue gas path will also heat the super-heater steam piping and the steam

within. While the temperature of the steam in the super-heater rises, the

pressure of the steam does not: the turbine or moving pistons offer a

continuously expanding space and the pressure remains the same as that of

the boiler.

TURBINE

A steam turbine is a mechanical device that extracts steam energy from

pressurized steam, & converts it into useful mechanical work. The simplest

turbines have one moving part, a rotor assembly, which is a shaft or drum with

blades attached. Moving fluid acts on the blades, or the blades react to the flow,

so that they move and impart rotational energy to the rotor.

32

TYPES OF TURBINE:

IMPULSE TURBINE: These turbines change the direction of flow of a

high velocity fluid or gas jet. The resulting impulse spins the turbine and

leaves the fluid flow with diminished kinetic energy. There is no pressure

change of the fluid or gas in the turbine rotor blades (the moving blades),

as in the case of a steam or gas turbine, all the pressure drop takes place

in the stationary blades (the nozzles). Before reaching the turbine, the

fluid's pressure head is changed to velocity head by accelerating the fluid

with a nozzle. Pelton wheels and de Laval turbines use this process

exclusively. Impulse turbines do not require a pressure casement around

the rotor since the fluid jet is created by the nozzle prior to reaching the

blading on the rotor. Newton's second law describes the transfer of

energy for impulse turbines.

REACTION TURBINE: These turbines develop torque by reacting to

the gas or fluid's pressure or mass. The pressure of the gas or fluid

changes as it passes through the turbine rotor blades. A pressure casement

is needed to contain the working fluid as it acts on the turbine stage(s) or

the turbine must be fully immersed in the fluid flow (such as with wind

turbines). The casing contains and directs the working fluid and, for water

turbines, maintains the suction imparted by the draft tube. Francis

turbines and most steam turbines use this concept. For compressible

working fluids, multiple turbine stages are usually used to harness the

expanding gas efficiently. Newton's third law describes the transfer of

energy for reaction turbines.

33

TURBINES USED IN NTPC: Steam Turbines of the following make are

being used in NTPC:

LMZ (Russia)

KWU, Siemens (Germany)

ABB- Alstom (Germany)

GEC- Alstom (U.K)

MHI (Japan)

GE (USA)

ANSALDO (Italy)

Turbine Layout in NTPC

There are 3 types of Turbines used in Thermal Power Plants:

1) HP TURBINE:

Single Flow Cylinder

Double Casing

Thermal expansion up to 16mm

2) IP TURBINE:

Double Flow

Double Casing

Axially Split Design In Both Casings

Rigid Coupling

Blade Shrouded & Inverted T-Root Design

34

3) LP TURBINE:

Largest Turbine

Pressure is Very Less

Three Shell Design

Double Flow

All Casings Axially Split

Exhaust Hood Spray Arrangement

2 Free Standing Blades in the end

35

ASH HANDLING SYSTEM

Types of ash generated:

1. Fly ash ( approx. 20%)

2. Bottom ash ( approx. 80%)

BOTTOM ASH SYSTEM:

The systems used in Bottom Ash System below a furnace are:

1. Intermittent type , water impounded hoppers & jet pump system

2. Continuous type dry bottom ash hopper and submerged scrapper

conveyor

Intermittent Type, Water Impounded Hoppers & Jet Pump System:

Flow diagram of hopper overflow water in jet Flow diagram of hopper overflow water in jet

pump systempump system

BA

HOPPER Over

Flow

Tank

Settling

TankSurge

Tank

Sludge to ash

Slurry pump

House

Over

Flow pump

Sludge

Pump

To ash water

P/p house by

Gravity

36

BOTTOM ASH HANDLING SYSTEM

Continuous Type Dry Bottom Ash Hopper & Submerged

Scrapper Conveyor:

This system of ash disposal is entirely different from previous one. In

this system water along with the ash is collected in the hopper. Ash

absorbs the sufficient moisture, excess water is taken out with the help

of overflow tank, ash is taken into the scrapper conveyor, from where it

is send to grinder with the help of conveyor belt, then with the help of

trench it is send to the bottom ash transfer slurry pump, which leads it to

the ash slurry pump house from where it is send to the ash dykes.

Fly Ash Handling System

The fly ash handling system consists of two modes, namely:

1. Wet mode & 2.Dry mode

37

Ash evacuation from ESP hoppers:

Ash evacuation from ESP hopper can be either:

1.Vacuum evacuation with the help of vacuum pump

2.Pressure evacuation by evacuation compressor and air lock tank

system

Flow diagram of wet fly ash systemFlow diagram of wet fly ash system

Trench to A.S. P. House

Air outlet

MHVPlate valve

Vacuum

pump

Wetting

head

Air washer

Air in

DESCRIPTION:-

The fly ash is collected in the ESP hopper are send into wetting head

where they are changed from dry to wet condition then these mixture is

subjected to air washer which is connected to vacuum pump which

sucks off the air and thus in turn create vacuum. Then finally it travels

from discharge pipe, seal box, through fly ash slurry trench into A.S.

pump house.

38

ELECTROSTATIC PRECIPITATORS:

They are used to separate the ash particles from the flue gases. In this the flue

gas is allowed into the ESP, where there are several metallic plates placed at a

certain distance from each other. When these gases enter, a very high

potential difference is applied, which causes the gas particles to ionize and

stick to the plates, whereas the ash particles fall down and are collected in a

hopper attached to the bottom of the ESP. The flue gas is allowed to cool

down and is then released to the ID fan to be sent to the chimney.

LOSSES DURING OPERATION & MAINTAINANCE OF PLANT

1) SURFACE ROUGHNESS:

It increases friction & resistance. It can be due

to Chemical deposits, Solid particle damage, Corrosion Pitting & Water

erosion. As a thumb rule, surface roughness of about 0.05 mm can lead to

a decrease in efficiency of 4%.

2) LEAKAGE LOSS: Inter-stage Leakage Turbine end Gland Leakages About 2 - 7.5 kW is lost per stage if clearances are increased by

0.025 mm depending upon LP or HP stage.

3) WETNESS LOSS: Drag Loss: Due to difference in the velocities of the steam & water

particles, water particles lag behind & can even take different

trajectory leading to losses. Sudden condensation can create shock disturbances & hence losses. About 1% wetness leads to 1% loss in stage efficiency.

39

4) OFF DESIGN LOSSES:

Losses resulting due to turbine not operating with design terminal

conditions. Change in Main Steam pressure & temperature.

Change in HRH pressure & temperature.

Condenser Back Pressure

Convergent-Divergent nozzles are more prone to Off Design losses

then Convergent nozzles as shock formation is not there in

convergent nozzles.

5) PARTIAL ADMISSION LOSSES: In Impulse turbines, the controlling stage is fed with means of nozzle

boxes, the control valves of which open or close sequentially.

At some partial load some nozzle boxes can be partially open /

Completely closed.

Shock formation takes place as rotor blades at some time are full of

steam & at some other moment, devoid of steam leading to

considerable losses.

6) LOSS DUE TO EROSION OF LP LAST STAGE BLADES:

Erosion of the last stage blades leads to considerable loss of energy.

Also, It is the least efficient stage.

Erosion in the 10% length of the blade leads to decrease in 0.1% of

efficiency.

The Operational Efficiency of this thermal project is about

31%.

40

CONCLUSION

All the minor & major sections in the thermal project had been

visited & also understood to the best of my knowledge. I believe that

this training has made me well versed with the various processes in

the power plant.

41

![NTPC Korba stacker Installation.ppt - Sheetal Wireless Communication at...Microsoft PowerPoint - NTPC Korba_stacker Installation.ppt [Compatibility Mode] Author Sukinavas Created Date](https://static.fdocuments.in/doc/165x107/5aa0b3127f8b9a84178e90f8/ntpc-korba-stacker-sheetal-wireless-communication-atmicrosoft-powerpoint-.jpg)