NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE SR Vacuum Systems and Front...

-

Upload

corey-neal -

Category

Documents

-

view

213 -

download

0

Transcript of NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE SR Vacuum Systems and Front...

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

SR Vacuum Systems and Front Ends

Design Goals & Vacuum Cell Layout

Cell Chambers

Cross section updates

3-pole wigglers, IR chambers

Ray tracing and with canted damping wigglers

Absorbers, space allocation

Vacuum pumping and pressure profiles

Front Ends

Summary and Plan

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Design GoalsAdequate Apertures and Low Impedance• BSC aperture - 25mm (V) x 76 mm (H)• Chamber cross section and straightness/flatness to < 1 mm / 5m• Smooth cross section changes (10:1 ratio)• Surface finish to ~ μm• Clearance between chambers and magnet poles ~ 2mm

Low Pressure of < 1 nTorr (> 50% H2), (beam-gas) > 40 hrՇ

• Low outgassing and desorption after in-situ bake and beam conditioning• Intercept photons at discrete absorbers away from the source • High effective pumping speed (IP+TSP) at absorber locations

• 15 IP+TSP per superperiod– Distributed NEG strips in ante-chambers for active gases

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

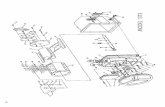

30 vacuum cells of ~ 19m each

straights: 8.6m x15 + 6.6m x 15

Isolatable with 60 gate valves

Cell chamber material: extruded Al 6063-T5

Based on extensive experience at NSLS and APS

Developing fabrication procedures with help from APS

50 + 5 + 5 bending chambers - 6o, ~ 3m long (3+ types, 3 lengths)

90 multipole chambers of 3 lengths, 4m, 5m & 3.7m

~ 40 day-one straight section chambers of various lengths

extruded Al with similar cross sections as multipole chambers

Absorber locations

Vacuum Cell Layout

IP+TSP locations

3PW Front End

DW Front End

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Changes since last review•Thicker wall at gap and at NEG slots• Relocated cooling channels

After machining

Bending Chamber Cross Section

Extruded cross sectionsBSC: 25 x 76 mm2

3mm wall

Bending chamber, ~ 3m long

SM=45 MPa

DY=0.35mm x 2

SY = 145 MPa

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Multipole chamber extruded cross section

@ sextupole

@ quadrupole

BSC: 25 x 76 mm2

Multipole Chamber Cross Sections

DY = 0.33mm x 2

SM = 94 MPa

SY = 145 MPa

3-D FEA at the sextupole

2.9mm

3.1mm

w/ thicker wall

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Details on BPM machining, mounting and supports

Detailing chamber cross sections for prototype extrusion

Detail dimensions w/ tolerances

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

3-Pole Wiggler and IR Chambers at BM2

IR Vacuum chambers: 5 x 90mm in 90mm dipoles + 5 x 35mm in regular dipoles Impact to vacuum: outgassing, HOM heating, pumping, etc.

3 Pole Wigglers: 32/35mm gap x 20cm at u/s BM2 ~ 2.5 mm wall at center pole

Conceptual design of IR chamber in 90mm dipole gap

Ray tracing at absorber locations

BM2 fan

BM1 fan

Crotch absorber d/s of 3-pole wiggler

3PW fan±1 mrad

BM2

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Damping wiggler absorber and crotch absorber at BM1

Crotch AbsorberDW power 65 kW with ± 2.3 mrad fan, canted ± 1 mrad

Absorber: 4.5 kW @ 0.5 mrad x 2; 11 kw @ 1 mrad x 2

Need to clip 1 mrad x 2: to shadow the FE beam pipes

Wiggler Absorber

Canted Damping Wiggler Fans

BM1

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Flange absorber or stick absorber at center of straight to trim u/s BM2 fan and protect d/s bellows and gate valve

Crotch absorbers: 2 per cell for BM radiation

Stick absorbers (or flange absorber): 4 per cell for BM radiation

Wiggler absorbers: for damping wigglers

No ring absorbers needed for undulator (and 3 pole wiggler) fans

Ray Tracing and Absorbers

Stick absorber at 23mm to trim u/s BM1 fan and protect d/s flanges

FM to clip DW fan at FEDW fan after 1mrad x 2 by wiggler absorber

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

• The crotch absorber intercepts 814 W at a normal peak power density of 0.25kW/mm2. A maximum temperature of 105 ºC is calculated.

• The intercepted power by the wiggler absorber is 11 kW (at 1 mrad x 2) out of 65 kW. This results in a maximum temperature of 427 ºC . The actual temperature is 15 to 20% lower because of scattering. A fatigue life of > 10,000 cycles is expected.

SR Absorbers – Thermal Analyses

Stick Absorber Flange Absorber Crotch Absorber Wiggler Absorber

Chamber heating?

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Available space for ID at straight sections

Space for pumps at girder #3

= Lattice length – 1.5m

End box/transition, BPMs,

bellows, gate valve, etc.

GV End box

Bellows/ fast correctors

UBPM w/ isolated stand?

Girder stability?

DW / EPU

BPM

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

UHV Pumping and Pressure Profiles

Pavg < 1 nTorr

In-situ baking of entire cells at 120 C x 40 hrs

To reduce thermal outgassing to < 1x10-12 Torr.l/s/cm2

Whole ring thermal gas load of < 1x10-5 Torr.l/s

Pressure will be dominated by photon stimulated desorption (PSD)

# photons from 60 BM ~ 1x10+21/s ≈ 7x10-5 Torr.l/s (Assuming η (PSD) = 2x10-6 mol/hv for Cu after ∫hv > 1024/m )

# photons from one 7m DW ~ 6x10+20/s

with 15% intercepted by the ring absorber ➱ 7x10-6 Torr.l/s (each DW)

NEG strips ~ 1,400 m @ > 100 l/s/m for active gases

Reside in ante-chambers as in APS

Pump thru the photon slots ( C = ~ 200 l/s/m)

Ion pumps and TSP of ~ 500 l/s at absorbers

15 IP/TSP per supercell + 4 at four front ends on day one

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Pressure Profiles with and w/o Damping Wiggler Radiation

By E. Hu & F. Makahleh

Pavg ~ 0.27 nTorr

w/o DW

Pavg ~ 0.3 nTorr

w/ DW

AbsorberIP/TSP

To b

e updat

ed

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

SR Front Ends – Design Concept

FE with insertion devices: One fixed mask (FAPM); two safety shutters (SS) one photon shutter (PS); two X-ray BPMs

Day one FE: One photon shutter (PS) for BM radiation

Typical APS front end

Pressure of a few nTorr to protect the SR UHV

Bakeable to 200 C (all metal, UHV material, etc)

IP/TSP combination at high heat load components

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

IP/TSP

GV

BPM

BPM

SS x 2

COFM

PS

IP/TSP

GV

FVFM: fixed mask; CO: collimator; PS: photon shutter; BDA: beam defining aperture; SS: safety shutter

Typical layout of hard/soft x-ray beam line front end.

GV: gate valve; FV: fast valve;

IP/TSP: ion & titanium sublimation pumps

IP/TSP

APS fixed mask design

Collimator Photon shutterSafety shutters

Need thermal analysis of all high heat load components for each FE

X-BPM

NSLS-II ASAC Review, 4/23-24/07 H-C. Hseuh,…, SR Vacuum Systems & FE

Cell chamber layout with updated lattice – continuing effort

Good progress in chamber detail and cross sections with ray tracing

Ensure adequate locations and space for absorbers and pumps

Extrusion development

Detail cell chamber cross sections for prototype extrusion this year

Interface with two potential vendors (Taber, Tailien)

4 APS cell chambers and 3 bellows for R&D and evaluation

NEG support and assembly R&D, mechanical and fast corrector test

2007+ Plan

Continue detail design of chambers, absorbers and FE components

collaboration with APS on extrusion details

Hire ME, MD and VT, set up vacuum lab

MOUs with APS and TLS

with access to APS drawings, and TLS Al cleaning development

Prototype extrusion of both cross sections with two vendors

Summary and Work Plan for 2007