Npeo 1 2%20finalrevised%202

-

Upload

kmi-media-group -

Category

Documents

-

view

223 -

download

0

description

Transcript of Npeo 1 2%20finalrevised%202

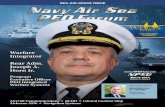

Carrier Craftsman

Rear Adm. Thomas J. Moore

U.S. Navy Program Executive OfficerPEO Aircraft Carriers

UCLASS O Undersea Warfare O Asia-Pacific O LCS

The Communication Medium for Navy PEOs

www.NPEO-kmi.com

December 2013Volume 1, Issue 2

Special Section:Close-in Defense

View from the HillCongressman Jo Bonner, R-Ala.

You Are reAding the Second iSSue of KMi MediA group’S 12th MilitArY title

This is the new hardhitting publication in the Navy field featuring the Program Executive Officers and

their very important programs.

2,400 copies have been sent to the Hill

Don’t let your programs be shot down by Congress for lack of information about the positive aspects of

your offerings.

To advertise, contact Terry Harrington 301-670-5700 x158 • [email protected]

GO NAVY!

www.NPEO-kmi.com

Cover / Q&AFeatures

ReaR admiRal THomas J. mooRe

U.S. Navy Program Executive Officer

PEO Aircraft Carriers

16

December 2013Volume 1, Issue 2navy air/sea peo forum

8UndeRsea WaRfaReAn excerpt of a statement by Rear Admiral Richard P. Breckenridge, director of Undersea Warfare, and Rear Admiral David C. Johnson, program executive officer for Submarines, before the House Armed Services Committee, Subcommittee on Seapower, September 13, 2013.

5indUsTRy PRofile:An exclusive interview with Jim Dale, Business Area Director at Engility who discussed Engility’s ongoing relationship with NAVAIR and NAVSEA involving system engineering, unmanned aircraft system integration and support, acquisition and program management to name a few.

11Unmanned aiRcRafT on caRRieRs Becoming RealiTyUCLASS is a system comprised of three major segments: the carrier segment, the control system and connectivity segment, and the air segment.By Brian O’Shea

13PRogRam sPoTligHT:Littoral Combat Ship Austal USA’s Independence variant of the littoral combat ship meets performance parameters in terms of speed, range and endurance with minimal fuel burn.

Industry InterviewR. scoTT foRney iii Senior Vice PresidentElectromagnetic Systems GroupGeneral Atomics

28

Departments2 ediToR’s PeRsPecTiVe3 UndeRWay4 PeoPle14 main deck27 ResoURce cenTeR

6

2224

“CVN 78 is the first aircraft carrier to be completely built using a 3-D model that allows every space on the ship to be visualized before drawings

are issued to construction crews,

allowing issues to be resolved before costs are

incurred.”

close-in defenseToday’s shipboard close-in defense systems came to be developed, deployed and improved, in many cases, in reaction to specific incidents.By Peter BuxBaum

VieW fRom THe HillCongressman Jo Bonner, R-Ala., discussed the benefits of the Littoral Combat Ship program for the U.S.

Special Section: asia-PacificTestimony to the House Armed Services Committee, Subcommittee on Seapower and Projection Forces from Dr. Andrew Erickson, Associate Professor, U.S. Naval War College, regarding U.S. Asia-Pacific strategic considerations.

U.S. Secretary of State John Kerry recently announced that the U.S. will increase maritime assistance aid to countries in Southeast Asia during his first visit to Vietnam as the United States’ top diplomat. In this announce-ment Kerry said the U.S. has pledged an additional $32.5 million for members of the Association of Southeast Asian Nations (ASEAN) in an effort to protect their territorial waters in the South China Sea, where four states have competing claims with China. This brings the U.S. maritime security assistance to the region to more than $156 million over the next two years.

Kerry said this was not a “quickly conceived reaction to any events in the region,” but that it was a “gradual and deliberate expansion” of U.S. support as part of the Obama administration’s strategy to shift focus to the Asia-Pacific region. This announcement was made after a recent near collision between U.S. and Chinese naval vessels in the South China Sea.

“Peace and stability in the South China Sea is a top priority for us and for countries in the region,” said Kerry. “We are very concerned by and strongly opposed to coercive and aggressive tactics to advance territorial claims.”

Kerry’s announcement comes shortly after a visit by Coast Guard Commandant Admiral Bob Papp, who became the first commandant to visit Vietnam as part of an official international outreach initiative. Over the past three years, the Coast Guard, in coordination with the Department of State and the U.S. Embassy in Hanoi, has been aiding the Vietnam Marine Police (Vietnam Coast Guard) through training assistance focusing on maritime law enforcement, search and rescue, and operational planning.

The U.S. claims neutrality over the many territorial disputes in the South China Sea. However, China regards the South China Sea and the island groups as its own and has stepped up naval activity in that region, which is raising concerns from the 10 members of the ASEAN.

In an area with several territorial disputes, it’s difficult for the U.S. to remain neutral when they increase their assistance to different parties. Giving financial aid and training can be a great thing, but I can only hope China and contesting members of the ASEAN come to a mutual under-standing—and soon. If you have any questions regarding Navy Air/Sea PEO Forum please contact me at any time.

The Communication Medium for Navy PEOs

EditorialEditorBrian O’Shea [email protected]

Managing EditorHarrison Donnelly [email protected]

Online Editorial ManagerLaura McNulty [email protected]

Copy EditorSean Carmichael [email protected]

CorrespondentsPeter Buxbaum • Henry Canaday Nora McGann • Melanie Scarborough Marc Selinger

art & dEsignArt DirectorJennifer Owers [email protected]

Senior Graphic DesignerJittima Saiwongnuan [email protected]

Graphic Designers Scott Morris [email protected] Paquette [email protected]

advErtisingAccount ExecutiveTerry Harrington [email protected]

KMi MEdia groupChief Executive OfficerJack Kerrigan [email protected]

Publisher and Chief Financial OfficerConstance Kerrigan [email protected]

Editor-In-ChiefJeff McKaughan [email protected]

ControllerGigi Castro [email protected]

Trade Show CoordinatorHolly Foster [email protected]

opErations, CirCulation & produCtion

Operations AdministratorBob Lesser [email protected]

Circulation & Marketing AdministratorDuane Ebanks [email protected]

CirculationBarbara Gill [email protected]

Data SpecialistsRaymer Villanueva [email protected]

subsCription inforMation

Navy Air/Sea PEO Forumis published by KMI Media Group.

All Rights Reserved. Reproduction without permission is strictly forbidden. © Copyright 2013.

Navy Air/Sea PEO Forum is free to qualified members of the U.S. military, employees of the U.S. government and

non-U.S. foreign service based in the U.S.All others: $65 per year.Foreign: $149 per year.

CorporatE offiCEsKMI Media Group

15800 Crabbs Branch Way, Suite 300Rockville, MD 20855-2604 USA

Telephone: (301) 670-5700Fax: (301) 670-5701

Web: www.NPEO-kmi.com

navy air/sEa pEo foruM

Volume 1, Issue 2 • December 2013

eDiTor’s perspeCTive

www.GIF-kmi.com

Geospatial Intelligence

Forum

www.BCD-kmi.com

June 2012Volume 1, Issue 1

www.BCD-kmi.com

Border Threat Prevention and CBRNE Response

Border Protector

Michael J. Fisher

ChiefU.S. Border PatrolU.S. Customs and Border Protection

Wide Area Aerial Surveillance O Hazmat Disaster ResponseTactical Communications O P-3 Program

Integrated Fixed Towers

Leadership Insight:Robert S. BrayAssistant Administrator for Law EnforcementDirector of the Federal Air Marshal Service Transportation Security Administration

SPECIAL SECTION:

Border & CBRNE Defense

www.MAE-kmi.com

Military AdvancedEducation

www.MIT-kmi.com

Military Information Technology

www.GCT-kmi.com

Ground Combat

Technology

www.MLF-kmi.com

Military Logistics Forum

www.M2VA-kmi.com

Military Medical & Veterans

Affairs Forum

www.MT2-kmi.com www.NPEO-kmi.com

Military Training Technology

Navy Air/Sea PEO Forum

www.SOTECH-kmi.com

Special Operations Technology

www.TISR-kmi.com

Tactical ISR Technology

www.CGF-kmi.com

U.S. Coast Guard Forum

KMI MedIa Group LeadershIp MaGazInes and WebsItes

Brian O’SheaeditOr

Compiled by Kmi media Group staffunDerWay

The Navy concluded another round of carrier testing November 19 to further demonstrate and evaluate the X-47B unmanned air system integration within the aircraft carrier environment.

Tests aboard USS Theodore Roosevelt (CVN 71) included deck handling, carrier approaches and landings in off-nominal wind conditions, digitized ship systems interfaces, and concept of operations development.

“The X-47 was tested in winds of higher magnitude and differing directions than seen in previous detachments,” said Program Manager for Unmanned Carrier Aviation Captain Beau Duarte. “This resulted in more stimulus provided to the aircraft’s guidance and control algorithms and a more robust verification of its GPS autoland capability.”

This test phase, which began November 9, also provided an opportunity for the second X-47B to make an appearance, marking the first time both aircraft appeared together in a carrier environment.

Over the flight test period, the X-47Bs performed 26 total deck touchdowns: 21 precise touch-and-goes and five arrested landings, as well as five catapults, five

commanded and two autonomous wave-offs. While one X-47B operated in the vicinity of CVN 71, the second air vehicle conducted flight operations between ship and shore. Both X-47Bs are assigned to Air Test and Evaluation Squadron (VX) 23 at Naval Air Station Patuxent River.

“The Navy and industry team once again conducted productive flight opera-tions in the CVN environment,” said Barbara Weathers, Unmanned Combat Air System deputy program manager. “The carrier systems installation and system checkouts were performed in record time, quite an amazing feat.”

The Navy will operate the X-47B throughout FY14 to conduct further land- and carrier-based testing to mature unmanned technologies and refine concept of operations to further inform future unmanned carrier requirements.

“The Navy is committed to developing, maturing, and fielding unmanned carrier aviation capabilities into our carrier air wings and carrier environments. This week’s successful carrier operations demon-strated the feasibility and realistic path to achieving the manned/unmanned air wing

of the future,” said Rear Admiral Mat Winter, program executive officer for Unmanned Aviation and Strike Weapons (PEO[U&W]), which oversees the UCAS program.

Raytheon Company and its Japanese partner, Mitsubishi Heavy Industries, have completed the Standard Missile-3 (SM-3) Block IIA guided missile Critical Design Review (CDR). The CDR verified that the missile’s design will meet the stringent, specific opera-tional performance requirements necessary to defeat the projected threats. The SM-3 Block IIA will defeat incoming ballistic missile threats by colliding with them in space, and the program is on track to begin flight testing in 2015.

In a precedent-setting co-development effort between allies, the U.S. and Japan have determined an equitable workshare agreement that defines by missile section the development responsibility between each country.

“This milestone is critical because it moves the SM-3 Block IIA program from design to build,” said Taylor W. Lawrence, Ph.D.,

president of Raytheon Missile Systems. “Once deployed, SM-3 Block IIA will provide the U.S. and Japan capability to defend larger geographic areas from longer-range ballistic missile threats.”

The SM-3 Block IIA program plan included building hardware early, supporting comple-tion of critical subsystem testing prior to CDR. This “hardware rich” approach coupled with the design commonality with previous versions of SM-3 reduces integration risk.

“We worked closely with the Missile Defense Agency to ensure our design plan was well thought out, allowing us to build a little and test a little along the way. This method will go a long way toward lowering our risk during future flight testing,” said Tim Lardy, Raytheon Missile Systems’ SM-3 Block IIA program director.

Over the course of 18 months, the Raytheon-Mitsubishi Heavy Industries team, along with various subcontractors, successfully completed more than 80 rigorous subsystem reviews leading up to the final “system” CDR.

SM-3s destroy incoming ballistic missile threats in space using nothing more than sheer impact of collision, which is equivalent to a 10-ton truck traveling at 600 mph. The SM-3 Block IIA is the third evolution of the SM-3 family of guided missiles and builds on the successful legacy of the first two variants: SM-3 Blocks IA and IB.

SM-3 Block IIA will have two distinct new features: 21-inch second and third stage rocket motors, and a larger, more capable kinetic warhead. SM-3 Block IIA will be deployed at sea and on land. More than 155 SM-3s have been delivered to U.S. and Japanese navies.

Standard Missile-3 IIA Completes Critical Design Review

Navy X-47B Unmanned Combat Air System Completes Carrier Tests

www.NPEO-kmi.com NPEO 1.2 | 3

Rear Admiral Thomas E. Beeman will be assigned as assistant deputy surgeon general for Reserve Affairs, Falls Church, Va. Beeman previously served as deputy commander, Navy Medicine National Capital Area, Bethesda, Md.

Rear Admiral Paula C. Brown will be assigned as deputy commander, Naval Facilities

Engineering Command, Washington, D.C. Brown previously served as deputy commander, First Naval Construction Division, Virginia Beach, Va.

Rear Admiral (lower half) Christina M. Alvarado will be assigned as deputy commander, Navy Medicine East, Portsmouth, Va. Alvarado previously served deputy chief of

staff, Navy Medicine East, Norfolk, Va.

Rear Admiral (lower half) William M. Crane will be assigned as deputy commander, Naval Air Force Atlantic, Norfolk. Crane previously served as chief staff officer, Navy Reserve Chief of Naval Operations, Operations and Plans (N3/N5), Washington, D.C.

Rear Admiral (lower half) Mark J. Fung will be assigned as deputy for naval construction force, Navy Expeditionary Combat Command, Virginia Beach. Fung previously served as deputy chief of staff, First Naval Construction Division, Virginia Beach.

Huntington Ingalls Industries (HII) recently announced that Irwin F. Edenzon will retire

on December 1, 2014. Edenzon is currently corporate vice president and president of Ingalls Shipbuilding, a division of HII. Edenzon will step down as president on March 31, 2014, and the HII board of direc-tors has elected Brian Cuccias to succeed Edenzon in the posi-tions of corporate vice president and president of Ingalls Shipbuilding, effective April 1, 2014.

Compiled by Kmi media Group staffpeopLe

Compiled by Kmi media Group staffunDerWay

General Dynamics Bath Iron Works successfully launched the Navy’s first Zumwalt-class destroyer October 28 at their Bath, Maine, shipyard.

The future USS Zumwalt (DDG 1000) will be the lead ship of the Navy’s newest destroyer class, designed for littoral operations and land attack.

The ship began its translation from Bath Iron Works’ land-level construction facility to a floating dry dock. Once loaded into the dry dock, the dock was flooded and the ship was removed from its specially designed cradle. The dock was then flooded and the ship was floated off and tied to a pier on the Kennebec River.

“This is the largest ship Bath Iron Works has ever constructed and the Navy’s largest destroyer. The launch was unprecedented in both its size and complexity,” said Captain Jim Downey, the Zumwalt-class program manager for the Navy’s Program Executive Office, Ships. “Due to meticulous planning and execution, the operation went very smoothly. I’m extremely pleased with the results and applaud the combined efforts of the Navy-industry team.”

Construction began on DDG 1000 in February 2009, and the Navy and its industry partners have worked to mature the ship’s design and ready their industrial facilities to build this advanced surface combatant. Zumwalt is currently more than 87 percent complete, and the shipbuilder will continue remaining construction work on the hull prior to planned delivery late next year.

Because of the complexity of the first-of-class ship, the Navy will perform a two-phase delivery process. Bath Iron Works will deliver the ship itself to the Navy in late 2014. Upon delivery, the Navy will then conduct combat systems activation, tests and trials, to include multiple underway periods. The ship is expected to reach its initial operating capability in 2016.

The ship, the first of three Zumwalt-class destroyers, will provide independent forward presence and deterrence, support special operations forces and operate as part of joint and combined expeditionary forces.

The Navy has incorporated many new technologies into the ship’s unique tumblehome hull, including an all-electric integrated power system and an advanced gun system, designed to fire rocket-powered, precision projectiles 63 nautical miles.

The shape of the superstructure and the arrangement of its antennas significantly reduce the ship’s radar cross section, making the ship less visible to enemy radar at sea. The design also allows for optimal manning, with a standard crew size of 130 and an aviation detachment of 28 sailors, thereby decreasing life cycle operations and support costs.

The lead ship and class are named in honor of former Chief of Naval Operations Admiral Elmo R. “Bud” Zumwalt Jr., who served as chief of naval operations from 1970-1974.

As one of the Defense Department’s largest acquisition organizations, PEO Ships, an affiliated PEO of the Naval Sea Systems Command, is respon-sible for executing the development and procurement of all major surface combatants, amphibious ships, special mission and support ships, and special warfare craft.

First Zumwalt Class Destroyer Launched

www.NPEO-kmi.com4 | NPEO 1.2

Jim Dale is responsible for successfully delivering high quality program manage-ment and engineering support to our Navy customers, particularly in NAVAIR (Naval Air Systems Command) and NAVSEA (Naval Sea Systems Command).

Q: What are your primary business areas with the Navy?

A: Engility, through its legacy com-panies, has a proud history of serving NAVAIR and NAVSEA. Our people sup-port the NAVAIR mission across a broad spectrum that includes system engineer-ing, unmanned aircraft system integra-tion and support, engineering fabrication and rapid prototyping, acquisition and program management, training and edu-cation life cycle support and IT. With NAVSEA, it is safe to say we have per-sonnel at nearly every shipyard and Navy port, concentrating primarily on testing and integration. Our engineers and tech-nicians have provided T&E, IT, produc-tion engineering and quality assurance to new construction shipbuilding programs for carriers, cruisers submarines, DDG, and a host of other Navy and U.S. Coast Guard vessels.

Q: How have you adjusted your Navy-related business to maximize efficiencies and help keep costs down?

A: Engility was created as a result of spin-off in July 2012 and that move really allowed us to build an industry best gov-ernment services company. Through our legacy companies we already had the best people, and they are working for the Navy and our other customers today. We were able to create a more efficient and stream-lined structure to support our customers and our people by reducing bureaucracy and empowering our experts in the field to make decisions and work more closely with our customers. The result is great service at a highly attractive price.

There are innumerable examples of how our teams have helped the Navy

maximize its own efficiencies. Take for example the Resource Allocation Management Program (RAMP). Engineers in one of our legacy companies designed RAMP for internal use and it has since transitioned to government control. RAMP provides program managers and maintenance planners with a single repos-itory for all pertinent aircraft data and information for long-range planning and forecasting of aircraft inventory require-ments, configurations, operational sched-ules, budget planning, aircraft workload and management processes. Today, RAMP supports 11 PMAs and 12 different rotary wing and fixed wing aircraft.

Q: How do you coordinate your business development efforts to make sure they match what the Navy is looking for?

A: The key is knowing your customer and delivering exactly what they need. Engility is an active partner with the Navy in supporting planning and investment. So for example, the Aircraft Survivability Investment Strategy (OASIS) process was developed by Engility staff in response to an OPNAV task assigned to NAVAIR. The requirement was to establish an ongoing process by which investment decisions are optimized to increase combat effective-ness across the portfolio of naval aircraft. Engility is developing a relational data-base that, when complete, will support OPNAV requirements decisions with sta-tistically significant, repeatable and trace-able analytical results.

I would also add that our spin-off, which made us a pure play government

services company, allowed us to remove OCI issues. We can provide our customers a direct path to cost effective engineering and program management services in an on-demand fashion.

Q: What do you see as major challenges over the next 12 months and how are you addressing them?

A: Federal budget pressures and the poten-tial of a yearlong continuing resolution in 2014 likely will create delays in contract awards and subsequent modifications. This means companies must have an even greater emphasis on cost accountability while still providing the Navy with the flexibility it has come to expect. Engility was created with this kind of environment in mind and the key to success will be pro-viding technical assistance and innovative solutions while remaining cost-conscious in this ever-changing cost-driven environ-ment. We provide this kind of service reg-ularly, and in fact, one of our engineers just received an employee of the quarter award from the government because his inventiveness and ingenuity provided a 66 percent cost savings for the program he was supporting.

Q: How do you measure success?

A: Any formal recognition of success is first and foremost based on our everyday performance and the close relationships we have with our customers. Regular vis-its by our program managers and senior managers encourage accurate and direct feedback, which helps to drive a contin-ual circle of improvement to sustain a strong performance. This helps to ensure we are meeting the requirement and are always looking for ways to be both consistent and innovative. We encour-age this in our employees. This proactive approach engages contractual, technical, financial and individual aspects of being a front-line contractor executor and falls under our philosophy of “Your Mission. Our Commitment.” O

inDusTry profiLe

Jim DaleBusiness Area Director

Engility

www.NPEO-kmi.com NPEO 1.2 | 5

During a May 7, 2013, Navy budget hearing, one of my con-gressional colleagues cited a year-old report calling into question the integrity of one of the Navy’s most adaptive new vessels, the Littoral Combat Ship (LCS). The report and news coverage it has generated are focused on a mixture of outdated concerns and lin-gering disagreements over future naval strategy, and as a result, a very good ship is being sold short. In response, I extended an invi-tation to fellow members of the House Defense Appropriations Subcommittee to personally visit the LCS shipyards to see first-hand the capabilities of one of the future workhorses of the United States Navy.

In recent history, it is hard to find such a transformative vessel that has been as maligned and unfairly discounted, even before a single ship was christened, as the LCS. From its incep-tion, the LCS has been labeled by many as not survivable and less capable of performing its mission than the frigates and var-ious minesweeping vessels it is designed to replace. Much like the armchair quarterbacking so popular in my favorite foot-ball conference—the SEC—the talk has gotten ahead of the game. Critics have pronounced the LCS program dead on arrival because they fail to understand the Navy’s new game plan, which is different from anything in the previous playbook.

Viewed through the lens of the current Navy, the LCS is a significant departure from the more traditional and narrowly defined roles of many of the fleet’s ships. With a reconfigurable mission platform built on speed and agility, it combines the size of a frigate with the maneuverability of a patrol boat, but with the versatility to perform the mission of three different vessels. The LCS offers a platform adaptable to the varied littoral missions of countering mines, small speed boats and diesel-electric subma-rines, and it is upgradable to integrate new technologies. It fits well within the Navy’s new strategy to counter asymmetrical, anti-access, near-shore threats. Yet opponents continue to view the LCS out of the context of its mission environment.

Navy Undersecretary Robert Work commented on this dis-connect in a January 2013 paper.

Some compare the ship to a guided missile frigate, and are left wanting. Others complain that there are bet-ter, less expensive, better-armed inshore gunboats. Others think the Navy would be better served with fast attack craft or small corvettes festooned with anti-ship missiles. Still others believe a purpose-built ship is the only and best choice for the mine warfare mission. All of these alter-natives might be potentially attractive choices—provided

the Navy’s future fleet architecture had a need for such ships. However, the FORCEnet/TFBN operational construct and architectural framework calls for a different ship alto-gether: an affordable, self-deployable, multirole ship opti-mized for battle network operations in the forward littorals. And that is precisely what the Department of the Navy got in the LCS.

The LCS is not designed to operate in all contested environ-ments alone. In an effort to keep the cost per ship down and to meet the new concept of operations defined in FORCEnet, the Navy intentionally designed the LCS to a Level I+ survivability standard, allowing for it, as Admiral Greenert put it in our Navy hearing, to take a direct hit and limp home. The LCS and the LCS mission modules were designed to provide the capabilities cur-rently offered by frigates (Level II), mine countermeasures ships (Level I) and coastal patrol craft (Level I), most of which will decommission over the next several years. It’s also important to recognize that in situations where the threat of anti-ship missiles is high, the LCS will be operating with a battle group designed to enhance its strengths and protect its weaknesses.

As we assign levels of survivability in the traditional sense—with a scale of one to three, including several different mea-sured areas beyond armored plating—we must also consider the environment in which the vessel is operating. While a DDG may be survivable at the highest level in a blue-water environ-ment, it certainly does not have the same level of survivability in the brown-water, littoral environment. After all, speed and agil-ity are not considered advantages possessed by our destroyers or even our aging frigates. The LCS excels best in these close-in engagement scenarios.

The LCS will be capable of surviving most anti-access envi-ronments on its own through its use of speed and new weapon technologies. One promising example of new technology is the development of the Advanced Low Cost Munitions Ordnance Program, or ALaMO. ALaMO is a 57 mm guided smart munition developed to counter small boat threats, whether in the Straits of Hormuz or off the Horn of Africa. This hit-to-kill guided bul-let, still in the testing phase with promising results so far, can be utilized by the LCS’s Mk110 57 mm gun to take out approach-ing small boats before their weapons pose a threat. Each ALaMO munition uses built-in radar to guide and redirect the round to compensate for gun pointing errors, allowing for more efficient firing and providing the LCS with standoff capability from small swarming threats.

By Congressman Jo Bonner, r-ala.

vieW from The hiLL

Littoral Combat ShipWidespread misunderstanding of its mission remains Biggest hurdle for lCs.

www.NPEO-kmi.com6 | NPEO 1.2

Many critics have also pointed out the logistical hurdles of maintaining and man-ning the LCS. Thus far, the Navy’s answer has been to forward deploy these vessels in host nations with a complement of support crew and materials. However, there may be an even simpler solution just over the hori-zon. The Joint High Speed Vessel (JHSV) has recently been touted as a logistics plat-form that could be positioned to support the LCS mission, carrying maintenance crews, spares, modules and other supplies. We often have to worry about the diplomacy of forward deploying vessels in host nations, but with a JHSV serving the role of host, the game may be a little less complicated.

As with the development of any new ship, there will be growing pains. Early issues of cracks in the LCS-1 Freedom variant, built by Lockheed Martin of Marinette, Wis., and corrosion in the LCS-2 Independence vari-ant, built by Austal USA in Mobile, Ala., have been addressed. Mission packages are also being improved to keep pace with the Navy’s evolution of LCS strategy and improved performance.

The LCS Council was created to address weaknesses in the program, and Council Chairman Vice Admiral Richard Hunt recently voiced confidence in both the improvements and the role of the LCS. “LCS will be an important part of our future surface force. The focus of the coun-cil has been to utilize feedback and infor-mation gathered from program reviews and fleet operations to identify areas of improvement. We understand what is at stake and will get this right. I have great confidence in the LCS program.”

While sequestration presents added challenges to the Defense Department and the Navy’s plans to expand the fleet, the LCS program has demonstrated that it can be built on budget and on time. Responding to criticism of the program’s cost, Secretary Ray Mabus told House appropriators on May 7, the LCS has expe-rienced a “dramatic” decline in cost from the first ships, and the program is well within congressional cost cap. The LCS repre-sents execution of one of the Navy’s best acquisition strategies, providing lower cost, improved delivery and enhanced capabili-ties over legacy platforms.

With the support and confidence of Navy leadership, the LCS program is pushing ahead in the shipyards, in the halls of Congress and at sea. The Navy is calling for a total of 52 LCSs, down only three ships from the original plan based on a change to the presence requirement in the 2012 Defense Strategic Guidance. The Navy’s FY14 budget includes a $1,793,014,000 request to keep the program on pace. As noted previously, the House Defense Appropriations subcommittee heard budget

testimony from the Navy chiefs in May and hopes to mark up the defense appropriations bill in June.

LCS 1 arrived in Singapore on April 17 and LCS 2 and LCS 3 continue to operate and conduct testing out of homeport San Diego. Secretary Mabus noted that four LCS will be deployed in Singapore by 2016.

As the LCS evolves to meet the Navy’s new littoral mission strategy, the LCS is poised to deliver a knockout punch at the right time in the right places. It is absolutely prudent to keep a strong focus on cost, on-time delivery and quality control going forward. I am confident, however, the LCS will not only stand up to such scrutiny, but will live up to high expectations it has cre-ated within the Navy’s top ranks. O

U.S. Representative Jo Bonner, R-Ala., is a member of the House Defense Appropriations Committee.

For more information, contact NPEO Editor Brian O’Shea at [email protected] or search our online archives

for related stories at www.npeo-kmi.com.

Top: Independence-class littoral combat ship (LCS) designed by General Dynamics consortium.Bottom: The Lockheed Martin-designed Freedom variant of the U.S. Navy’s LCS program. [Photos courtesy of the U.S. Navy]

www.NPEO-kmi.com NPEO 1.2 | 7

undersea Warfare

Undersea warfare consists of mili-tary operations that originate from the undersea or are directed into the under-sea, ranging from survivable nuclear deter-rent patrols by ballistic missile submarines to intelligence collection by attack subma-rines to surveillance by undersea sensors. It includes antisubmarine warfare by aircraft, tomahawk strikes like those conducted by the guided missile submarine (SSGN) USS Florida in Operation Odyssey Dawn against Libya, and mine-hunting operations by small unmanned vehicles near the Strait of Hormuz.

Not all undersea warfare is done by undersea forces. For instance, antisubma-rine warfare and maritime mine warfare are often done by airborne or surface sys-tems and platforms. These cross-domain operations require careful coordination of efforts between undersea forces and sur-face ships, aircraft, space assets, communi-cations systems and headquarters facilities, but they often yield outstanding results

and greatly improved efficiency. This is an area where we are applying greater empha-sis in our maritime operations around the globe.

Today, though, I intend to focus on how undersea forces—the platforms and their crews that operate in the depths—contrib-ute to undersea warfare.

the unique strengths of stealthy undersea forCes

The stealth of our undersea forces pro-vides an advantage that no other part of the joint force can provide: persistent, undetected, assured access far forward and the ability to do valuable things with that access. By leveraging concealment, our undersea forces can deploy forward without being provocative, penetrate anti-access/area denial perimeters and conduct unde-tected operations. These operations might be precautionary preparatory ship move-ments, intelligence collection and surveil-lance, special forces support, or nuclear deterrent patrols.

Should it be necessary, these forces can exploit the element of surprise and attack at the time and place of our choosing to maximize the desired effect while mini-mizing risk. These attacks could include efforts specifically focused on helping gain access for follow-on general purpose forces. Concealment enables survivability while operating independently with maga-zines focused on offensive payloads. Finally, stealth enables undersea forces to exploit ambiguity to sow disruption and uncertainty in adversary operations, diverting adversary resources and creating confusion.

Feedback from our operational com-manders indicates that the demand for this capability is strong. As the threat grows from advances in sensors and weapons such as cruise missiles, anti-ship ballistic missiles and integrated air defense systems, more pressure will be placed on undersea forces. This pressure will be further amplified by the proliferation of these advanced systems to more adversaries and more regions.

In addition, the role of the undersea to the globalized industrial economies of the

Coordination of Cross domain operations By undersea forCes.The following is an excerpt of a statement by Rear Admiral Richard P. Breckenridge, director of Undersea Warfare, and Rear Admiral

David C. Johnson, program executive officer for Submarines, before the House Armed Services Committee, Subcommittee on Seapower.

www.NPEO-kmi.com8 | NPEO 1.2

world is hard to overstate and is growing. The intercontinental telecommunications backbone of the world rides on the seabed, with undersea cables carrying over 95 per-cent of all traffic. Offshore oil and gas pro-duction is growing rapidly, and undersea pipeline infrastructure is proliferating to service fields in Asia, the Middle East, the Gulf of Mexico, off Brazil and Africa, and in the North Sea. Transportation infrastruc-ture such as tunnels, piers, bridge supports are accessible from the undersea, and the expansion of shipping traffic and oil drilling into the Arctic as ice-cover shrinks will fur-ther expand the importance of the undersea to the global economy.

Considering these factors, it is clear that the importance of the undersea will con-tinue to grow, both in economic and in mili-tary terms, for the foreseeable future.

trends in undersea forCe struCture

Against this backdrop of unique undersea force value and continued strong demand, we must consider the trends in undersea force structure—the long-term number and type of vessels we can expect in our future undersea forces. The Navy has worked hard to arrest the downward trajectory in overall Navy force structure and stabilize the Navy near or slightly above its current level. Even this stabilized force, though, includes as part

of its baseline a reduction in submarine plat-forms of more than 25 percent over the next 15 years. This decline is not the result of some recent decision; it is the consequence of budget decisions taken over years and indeed decades. There were only two sub-marines procured from 1991 to 1998, pro-ducing two undesirable results. First, the expertise for submarine construction was dismantled and has only recently begun to recover to full strength. Second, it resulted in the loss of nearly a dozen nuclear pow-ered attack submarines (SSNs) in the force. Today’s attack submarine force of 55 SSNs will drop to 42; the 4 SSGNs will drop to 0; and the 14 ballistic missile submarines will drop to 10. The total submarine force will drop from 73 to 52 ships—a cut of 29 per-cent—before rebounding in the 2030s. The vertical strike payload volume provided by the undersea force will drop by well over half. This trough is borne of the submarine ship-building hiatus of the 1990s, and no realistic build plan could now prevent it.

shortfalls in undersea forWard presenCe

Undersea forces will also suffer degraded forward presence. As a way of maximizing the deployed presence of U.S. nuclear sub-marines, the Navy uses a different rotational duty pattern for SSNs, SSGNs, ballistic mis-sile submarines (SSBNs) and Guam-based

SSNs. Over the next 15 years, the forward presence of SSNs and SSGNs taken together will fall by over 40 percent. Roughly half of this reduction is due to the decline in the number of SSNs and half is due to the retire-ment of the SSGNs. One SSN will move to Guam to help mitigate this decline; addi-tional increases in the number of SSNs in Guam, however, are constrained by the unavailability of infrastructure on the island and on the risks associated with concentrat-ing too much of the force in one potentially vulnerable place.

Today, the SSN force is at 55 SSNs—above the 48-SSN minimum requirement defined by force structure analysis. Despite this nominal excess in SSN capacity, the combatant commander unconstrained demand for SSN forward presence greatly exceeds that which can be provided.

In 2006 Congress tasked the Navy with how it would provide the required SSN for-ward presence of a 48-SSN Navy with a force that would drop as low as 40 SSNs. In 2007, CNO Mullen [Chief of Naval Operations Admiral Mike Mullen] testified about the tools available to him to reduce the impact of letting the SSN force dip below the required 48 level. The three tools he outlined were: (1) reducing the time to build each Virginia-class submarine to about 60 months; (2) extending the service lives of selected Los Angeles-class SSNs beyond 33 years as fuel and material condition allow; and (3) using

www.NPEO-kmi.com NPEO 1.2 | 9

deployments as long as 7 months to increase deployed availability. Since the first of the Block II Virginias was delivered in 2008, we have been making significant progress in reducing the construction time of our sub-marines. Getting to below 60 months on PCU North Dakota will help to add one to two effective SSNs to the force level. SSN fuel and material condition are being care-fully managed to maximize the chance that some life extensions will be possible. If cur-rent trends continue it may be possible to fill about one-third of the ship-years of SSN shortfall. Lengthened deployments above seven months, as mentioned, are already in use.

The undersea forces have a demon-strated willingness to exploit creative oper-ational concepts and basing schemes, and will continue to investigate potentially effec-tive means to improve the presence of our limited number of SSNs during the shortfall time period. It bears noting, however, that most of the available measures discussed increase SSN forward presence but do not increase the number of SSNs available to surge in the event of conflict.

the navy’s integrated approaCh to future undersea CapaBility

Facing a long-term trend of increasing undersea importance and decreasing under-sea force capacity, the Navy developed an integrated approach to providing as much of the necessary future undersea capabil-ity as would be possible within realistic con-straints on force size, budgets, shipyard capacity, practical maintenance limits and technical realism. This integrated approach does not solve all of the capability and capacity shortfalls faced by the Navy, but it focuses attention on providing specific stra-tegic effects while remaining closely in touch with acquisition realism.

I would like to describe the key interlock-ing pieces that represent the backbone of the Navy’s lean integrated undersea invest-ment strategy:

1. It is mandatory that we sustain our survivable sea-based nuclear deterrent with about the same level of at-sea presence as today—this is priority number one. This requires a force no smaller than 10 operational SSBNs. The Navy has done everything possible to delay SSBN replacement procurement as long as possible and reduce its scope

as much as possible while still providing the required deterrent coverage. Collectively, Ohio life extensions, force level reductions, maintenance efficiency and risk management enabled the Ohio replacement first patrol to be delayed by 20 years to 2031. This driver determines that we procure the first Ohio replacement SSBN in 2021 so we can achieve that first patrol in 2031. It also fixes the start dates of the later ships as necessary to stay at 10 SSBNs during the transition from Ohio to Ohio replacement, and to restore the inventory to 12 to retain 10 operationally available as Ohio replacement submarines enter extended depot availabilities

2. All three submarine types go through large drops between 2025 to 2030 that are beyond fiscal and shipyard capacity to address. Between 2025 and 2030, the SSN force drops to 42, all four SSGNs retire and the SSBN force drops from 14 to 10. Top priority is placed on the SSBNs. Building new SSGNs from the keel up would require designing and starting construction of two large submarine classes (SSBNs and SSGNs) simultaneously—a task which exceeds the capacity of our design workforce. Converting four more SSBNs into SSGNs is not possible because there are no surplus SSBNs to draw on. This determines that SSGN capacity, if it is to be retained, must be built into future SSNs. The SSN force structure trough coupled with this undersea strike capacity shortage dictates that SSN procurement must be our second priority.

3. In order for SSNs to carry strike missiles displaced from SSGNs and future payloads that extend the influence inherent to our assured access, added SSN payload volume is required. Adding more SSNs to the build plan beyond two per year is fiscally unlikely, would challenge yard capacity, and is not necessary. Instead the needed volume can be achieved by adding modules to SSNs already in the build plan, covering most of the lost SSGN capacity and providing UUV carrying capacity—thereby solving two problems at once. To mitigate the loss of strike capacity when SSGNs retire in the next decade, the Navy requested fiscal year 2014 research and development funding to continue

the design for a modification to the Virginia Class SSN, the Virginia payload module. Modified Virginia Class SSNs could be procured starting no earlier than fiscal year 2019. Our challenge will be executing this option affordably alongside competing priorities within the overall shipbuilding program.

4. As the SSN force gets smaller and as the importance of its unique forward access becomes clearer, additional payloads are likely to emerge. The strategic impact of each SSN being able to carry a family of different capabilities without any discernible external difference in the ship is daunting to an adversary planner, and therefore not only valuable to military capability but to deterrence value as well. It is not necessary to field all of these payloads soon—but the ability of the module to support them in the future will give future force commanders much flexibility. Additionally, the insert may allow for incorporation of sensors and stealth advancements to maintain dominance over capable undersea adversaries. This determines the need for the large tube payload volume to be flexible for maximum strategic and deterrent value.

5. The smaller SSN force structure will require each SSN to cover more physical territory and also cover more potential new types of undersea targets. Combined with the shortfall in torpedo inventory and the fact that there has not been a U.S. heavyweight torpedo produced since 1996, this creates a compelling need to restart torpedo production. Not only is there a shortfall in numbers, there is also no proven facility capable of producing weapons with a new capability. In the short term, this allows us to address the shortfall and capacity issues. More importantly, in the long term this provides a foundation for us to adapt our undersea weapons with new, expanded target set capabilities. This determines the need to restart torpedo production soon with emphasis on modularity. O

For more information, contact NPEO Editor Brian O’Shea at [email protected] or search our online archives for related stories at www.npeo-kmi.com.

www.NPEO-kmi.com10 | NPEO 1.2

Northrop Grumman’s X-47B Unmanned Combat Air System (UCAS) demonstrator completed its first carrier-based arrested landing on board USS George H.W. Bush (CVN 77) off the coast of Virginia on July 10.

“It isn’t very often you get a glimpse of the future. Today, those of us aboard USS George H.W. Bush got that chance as we wit-nessed the X-47B make it’s first-ever arrested landing aboard an aircraft carrier,” said Secretary of the Navy Ray Mabus. “The oper-ational unmanned aircraft soon to be developed have the opportu-nity to radically change the way presence and combat power are delivered from our aircraft carriers.”

The recent demonstration was the first time a tailless, unmanned autonomous aircraft landed on a modern aircraft carrier.

“For UCLASS we are in the final throes of reviewing the draft RFP with senior Navy leadership,” said Rear Admiral Mat Winter, PEO Unmanned Aviation and Strike Weapons. “We anticipate that draft RFP being released to industry before Christmas. Industry will have a period of time to review and assess, and we will conduct an industry day in late January or early February of next year. We will have the dialogue with them on that. We will take those inputs and we will incorporate other senior leadership efforts inputs and we will submit and release the final RFP late second quarter/early third quarter fiscal year 2014, [in April], so that’s the timeframe of next year. Then we’ll go 90 days to get the proposals back, we’ll go into a source selection period and we anticipate being able to award to a single air vehicle segment contractor in the early first or sec-ond quarter of FY15. That’s the timeline.”

Naval Air Systems Command released a request for proposal to four companies on June 10, 2013, for further design studies on the Navy’s planned Unmanned Carrier Launched Airborne Surveillance and Strike (UCLASS) system. Those companies include Northrop Grumman, General Atomics Aeronautical Systems Inc. (GA-ASI), Boeing and Lockheed Martin—the four UCLASS industry partners that previously had been awarded broad agency announcement study contracts to advance their concepts for the program.

UCLASS is a system comprised of three major segments: the carrier segment; the control system and connectivity segment; and the air segment. The UCLASS system will provide persistent unmanned semi-autonomous, carrier-based ISR (intelligence, surveillance and reconnaissance) and targeting, and strike capa-bility to support 24/7 carrier operational coverage.

“The warfighter’s requirement is to provide the carrier strike group with persistent, enduring, relevant ISR capability,” said Winter. “In two orbits at tactically significant ranges from the carrier, 24 hours a day, seven days a week. That’s the requirement. So the goal of UCLASS, the goal of the acquisition community, is to put together a logical, affordable, executable program plan that delivers that capability to the warfighter, as outlined in the capa-bility development document, on the timeline, within the budget, that the CNO [Chief of Naval Operations] has directed us to do.”

Information concerning this highly competitive contract is difficult to come by as the four companies are not keen on dis-cussing their entrants in detail.

u.s. navy’s Competition for unmanned aerial system providing isr and strike CapaBility.By Brian o’shea, npeo editor

www.NPEO-kmi.com NPEO 1.2 | 11

The X-47B may have a leg up on the competition as it was selected for the demonstrator aircraft and has had multiple carrier launch and landings under its belt. The X-47B is a tailless, strike fighter-sized unmanned air-craft currently under development by Northrop Grumman as part of the U.S. Navy’s Unmanned Combat Air System Carrier Demonstration (UCAS-D) program. Under a con-tract awarded in 2007, the company designed, produced and is currently flight testing two X-47B aircraft. The UCAS-D program will also mature relevant carrier landing and inte-gration technologies.

The Lockheed Martin UCLASS air vehicle concept inte-grates proven technologies from F-35C, RQ-170 Sentinel and other operational systems to provide both the lowest devel-opment risk and greatest ISR mission capability. Lockheed’s approach is expected to leverage the experience of the Skunk Works and their cross-corporation team to meet the Navy’s requirements for a versatile and supportable carrier-based unmanned aircraft. UCLASS will balance endurance, early operational capability and inherent growth that will enable operations in any environment or threat scenario.

Key features of Lockheed’s possible UCLASS entrant include integration of proven technologies, persistent 24/7 ISR operations, full spectrum adaptability, signature con-trol, open systems architecture, reduced manpower require-ments for command, control and maintenance, and future growth provisions.

While Boeing will not discuss details of its UCLASS UAV, Phantom Ray does play a significant role in Boeing’s knowl-edge of unmanned systems as well as their ability to rap-idly prototype an aircraft, said Deborah VanNierop, Boeing spokesperson.

“Boeing knows carrier aviation,” said VanNierop. “We bring 90-plus years of naval aviation history including deliv-ering carrier-based aircraft to the U.S. Navy, and more than three decades of unmanned systems experience. When combined, Boeing’s capabilities-based approach, Naval and unmanned systems experience, and rapid prototyping will allow us to create an afford-able and low-risk solution for our customers. We have been very busy exploring the UCLASS trade space, but due to the competi-tive nature of the program, we are not prepared to discuss details of our work at this time. I can tell you that Boeing will give the Navy a UCLASS system that can provide a persistent CVN (Carrier Vessel Nuclear)-based ISR and strike capability supporting carrier air wing operations.”

General Atomics Aeronautical Systems Inc., a leading manufac-turer of unmanned aircraft systems (UAS), tactical reconnaissance radars and surveillance systems, introduced Sea Avenger in 2010, a carrier-based derivative of its Predator C Avenger UAS, to fulfill the U.S. Navy’s need for a UCLASS system. While General Atomics declined to comment for this article, they did say the Sea Avenger will likely be their entrant into the UCLASS competition.

Like Predator C Avenger, Sea Avenger presents a low-risk, high technology ready procurement option as it leverages more than 18 years of Predator-series UAS development, manufacturing and sys-tem support, along with 1 million flight hours of operational expe-rience. In addition, many Predator-series elements, components and subsystems already provide mature, proven and affordable mis-sion capabilities desired by the Navy for a UCLASS system.

Anticipating a future requirement for a carrier-based UAS, GA-ASI designed specific features into its Predator C Avenger to facilitate subsequent development of an aircraft uniquely suitable for carrier operations that would also integrate seamlessly into the carrier air wing. These include a highly fuel-efficient engine and inlet design, retractable electro-optical/infrared sensor, inter-nal weapons bay, and folding wings. The aircraft’s structure was also designed with the flexibility to accommodate carrier-suitable landing gear, tail hook, drag devices and other provisions for car-rier operations.

“The Navy is committed to maturing and fielding relevant and capable unmanned carrier aviation capability into our carrier air wings and into our carrier environment,” said Winter. “We are abso-lutely committed to that and we are committed at the highest lev-els, from the secretary of the Navy and CNO. It’s exciting, it is truly historic and it’s achievable with the program plan that we’re putting together, and we will see unmanned carrier aviation in our airwings and on our flight decks in the 2018-2020 timeframe.” O

For more information, contact NPEO Editor Brian O’Shea at [email protected] or search our online archives

for related stories at www.npeo-kmi.com.

An artist’s rendering of the Predator C Avenger to facilitate the subsequent development of an aircraft suitable for carrier operations. [Photo courtesy of General Atomics]

Boeing’s unmanned aerial system, the Phantom Ray. [Photo courtesy of Boeing]

www.NPEO-kmi.com12 | NPEO 1.2

austal and the trimaran design

Austal has been a successful designer and builder of commercial high-speed alu-minum passenger and car ferries for almost 25 years. For many years, the catamaran has been the hull form of choice for high-speed ferries. Despite this, on exposed routes some high-speed vessels were recognized as a fast mode of travel that regularly made many pay-ing customers violently ill with motion sick-ness. In the late ’90s, Austal embarked on a significant research and development effort to design a high-speed hull form that would dramatically out-perform the existing high-speed monohulls and catamarans already on the market.

The trimaran concept was initially expected to provide a substantial improve-ment in passenger comfort over other high-speed platforms available in the marketplace. Our initial work also suggested a potential speed improvement over comparable catama-rans, and certainly over an equivalent mono-hull. Austal carried out model tests at a small scale, and then at a large scale as the research and development program matured. We also built a manned and instrumented 11-meter model in order to assess the maneuverability and seakeeping ability of the hull form.

Austal engineers optimized the hull shape using shipflow, analyzing over 300 variations of hull and ama (side hull) shapes before commencing a rigorous program of numerical analysis and model tank testing.

A U.S. Navy (USN) concept study for a focused mission high speed ship (FMHSS) in late 2002 resulted in the award of three lit-toral combat ship (LCS) preliminary design contracts in July 2003. The most signifi-cant feature of the FMHSS was its ability to employ modular mission packages or mod-ules that could easily be swapped to sup-port specific missions. The three preliminary design teams were:

1. Lockheed Martin, with a high-powered steel monohull based on the Fincantieri Destriero design

2. Raytheon, with a fiber reinforced plastic surface-effect ship based on the Norwegian Skjold Class design

3. General Dynamics, with the Austal aluminum trimaran design.

Following completion of preliminary design, each team submitted a proposal for final design and construction. Both the Lockheed Martin and General Dynamics teams were awarded final design and even-tually detail design and construction con-tracts for the first two LCS. In 2010, when the USN wanted to downselect to a single variant, Austal led the team, with General Dynamics Advanced Information Systems as selected ship systems agent. In a last-minute twist, USN awarded both Lockheed Martin and Austal teams with block buy contracts for 10 LCS each on December 29, 2010.

fast

The propulsion system is simple and reliable with two General Electric LM2500 gas turbines and two MTU 20V 8000 die-sel engines, each driving one of the four steerable and reversing Wartsila water jets. Austal’s Independence-variant LCS makes speed easily with excellent maneuverability. The long, slender center hull of the trimaran is perfectly tuned for high speeds and excel-lent seakeeping.

effiCient

In an age of economic uncertainty, the U.S. Navy needs efficient ships to keep total ownership cost to a minimum. The effi-cient trimaran hull form combined with the lightweight aluminum construction of the Independence-variant LCS meets all key per-formance parameters for speed, range and endurance with minimal fuel burn.

affordaBle

Austal has invested well over $300 mil-lion to bring the best automotive, aerospace and shipbuilding manufacturing practices to the Alabama Gulf Coast. Our purpose-built module manufacturing facility houses four assembly lines using linear workflow to bring the work to the worker in fixed workstations. High levels of automation and advanced

structural extrusions further reduce acquisi-tion cost by reducing labor. Serial production allows us to apply lessons learned on early ships to follow on vessels.

On the ship, high levels of automation reduce manning requirements. An integrated command and control center combines tra-ditional bridge and combat command spaces into a single unit, allowing flexibility of oper-ation with fewer sailors. Through-life costs are minimized by the efficient trimaran hull form and use of weight-saving alumi-num. The advanced open architecture com-bat system, developed by General Dynamics Advanced Information Systems, allows fast and affordable upgrades to accommodate future technologies.

austal lCs today

USS Independence (LCS 2) is home-ported in San Diego, Calif., and has been working for the last two and a half years to complete advanced mission package test-ing for the LCS Program. Coronado (LCS 4) was recently delivered to the Navy from the Austal USA shipyard in Mobile, Ala., and is expected to commission in Coronado, Calif., in early 2014.

Jackson (LCS 6), Montgomery (LCS 8), Gabrielle Giffords (LCS 10), and Omaha (LCS 12) are at various stages of construction at Austal’s purpose-built manufacturing facil-ity. Engineering and purchasing efforts are underway to support start of construction of Manchester (LCS 14) and Tulsa (LCS 16) in 2014. With steady state production, Austal can really capitalize on production and eco-nomic efficiencies to reduce cost for the U.S. Navy. After all, this is about putting the best ships in the hands of tomorrow’s U.S. Navy sailors as quickly and affordably as possi-ble. O

Article provided by Austal USA

program spoTLighT

LCS: Capability Counts

For more information, contact NPEO Editor Brian O’Shea at [email protected]

delivering the World’s first trimaran surfaCe ComBatant.

www.NPEO-kmi.com NPEO 1.2 | 13

The future amphibious assault ship USS America (LHA 6) completed build-er’s trials November 9, marking a significant milestone as the ship progresses toward acceptance trials and delivery to the Navy.

The trials took place off the coast of the Huntington Ingalls Industries’ shipyard in Pascagoula, Miss.

“The ship performed well at sea and largely exceeded my expectations. The state of completion is right where it should be for builder’s trials,” said Captain Chris Mercer, amphibious warfare program manager for the Program Executive Office, Ships. “Our joint government and industry team comprehensively tested every aspect of the ship’s equipment and systems, and the results leave us with a clear path to a successful acceptance trials and delivery next year.”

America will be the first of the Navy’s next generation of “big deck” amphibious ships that are designed to replace the aging Tarawa class. This new class has been designed to accommodate the future needs of the Marine Corps’

aviation combat element with additional aviation maintenance capability, increased fuel capacity and a significant increase in available stowage for parts and support equipment.

LHA 6 provides a flexible, multi-mission platform with capabilities that span the range of military operations from forward-deployed crisis response to forcible entry operations. The class uses the same fuel and energy-saving propulsion plant, zone electrical distribution and electric auxiliary systems designed and built for USS Makin Island (LHD 8).

The ship’s keel was laid in 2009 and the shipbuilder plans to deliver the ship in fiscal year 2014. The ship will be homeported in San Diego, Calif.

As one of the Defense Department’s largest acquisition organizations, PEO Ships is responsible for executing the development and procurement of all destroyers, amphibious ships, special mission and support ships, and special warfare craft.

The U.S. Naval Research Laboratory (NRL), with funding from SwampWorks at the Office of Naval Research (ONR) and the Department of Defense Rapid Reaction Technology Office, demonstrated the launch of an all-electric, fuel cell-powered, unmanned aerial system (UAS) from a submerged submarine. From concept to fleet demonstration, this idea took less than six years to produce results at significant cost savings, compared to traditional programs, which often take decades to produce results.

“Developing disruptive technologies and quickly getting them into the hands of our sailors is what our SwampWorks program is all about,” said Craig A. Hughes, acting director of innovation at ONR. “This demonstration really underpins ONR’s dedication and ability to address emerging fleet priorities.” The successful submerged launch of a remotely deployed UAS offers a pathway to providing mission critical intelligence, surveillance and reconnaissance (ISR) capabili-ties to the U.S. Navy’s submarine force.

Operating under support of the Los Angeles class USS Providence (SSN 719) and the Naval Undersea Warfare Center-Newport Division (NUWC-NPT), the NRL-developed XFC UAS—eXperimental Fuel Cell Unmanned Aerial System—was fired from the submarine’s torpedo tube using a Sea Robin launch vehicle system. The Sea Robin launch system was designed to fit within an empty Tomahawk launch canister (TLC) used for launching Tomahawk cruise missiles already familiar to submarine sailors. Once deployed from the TLC, the Sea Robin launch vehicle with integrated XFC rose to the ocean surface, where it appeared as a spar buoy.

Upon command of Providence’s commanding officer, the XFC then vertically launched from Sea Robin and flew a successful several-hour mission demonstrating live video capabilities streamed back to Providence, surface support vessels and Norfolk before landing at the Naval Sea Systems Command Atlantic Undersea Test and Evaluation Center, Andros, Bahamas. “This six-year effort represents the best in collaboration of a Navy laboratory and industry to produce a technology that meets the needs of the special operations community,” said Warren Schultz, Ph.D., program developer and manager,

NRL. “The creativity and resourcefulness brought to this project by a unique team of scientists and engineers represent an unprecedented paradigm shift in UAV propulsion and launch systems.”

The NRL Chemistry and Tactical Electronic Warfare Divisions team includes the design-builder of the Sea Robin, Oceaneering International Inc., Hanover, Md.; the fuel cell developer Protonex Technology Corp., Southborough, Mass.; and NUWC-NPT’s Autonomous and Defensive Systems Department for Temporary Alteration and test demonstration support. The XFC is a fully autonomous, all electric fuel cell powered folding wing UAS with an endurance of greater than six hours. The non-hybridized power plant supports the propulsion system and payload for a flight endurance that enables relatively low cost, low altitude ISR missions. The XFC UAS uses an electrically assisted take off system that lifts the plane vertically out of its container, and therefore enables a very small footprint launch such as from a pickup truck or small surface vessel.

Navy Launches UAV from Submerged Submarine

General Dynamics Electric Boat christened North Dakota (SSN-784), the U.S. Navy’s newest and most advanced nuclear-attack submarine, on November 2. Electric Boat is a wholly owned subsidiary of General Dynamics.

The submarine North Dakota is the 11th ship of the Virginia class, the first U.S. Navy combatants designed for the post-Cold War era. Unobtrusive, non-provocative and connected with land, air, sea and space-based assets, North

Dakota and the other Virginia-class submarines are equipped to wage multi-dimensional warfare around the globe, providing the Navy with continued dominance in coastal waters or the open ocean.

Electric Boat and its construction partner, Newport News Shipbuilding, have delivered 10 Virginia-class submarines to the Navy, and have contracts for eight additional ships.

U.S. Navy’s Most Advanced Submarine Christened

LHA 6 Completes Builder’s Trials

www.NPEO-kmi.com14 | NPEO 1.2

main DeCK

The U.S. Navy marked a significant mile-stone November 5, as the service joined defense contractor Raytheon Missile Systems in celebrating the delivery of the 3,000th Tactical Tomahawk (TACTOM) missile.

TACTOM, also known as Tomahawk Block IV, is a deep-strike, long-range cruise missile often used for land-attack warfare and employed from U.S. Navy surface combatants and U.S. Navy and United Kingdom Royal Navy submarines.

“More than 40 years ago, few could have imagined the viability of a long-range cruise [missile] with the precision and lethality to achieve strategic objectives,” said Captain Joe Mauser, program manager for the Tomahawk Weapons Systems Program Office (PMA-280), in videotaped remarks included at a ceremony in Tucson, Ariz., where Raytheon Missile Systems is based. “Over the past three decades, Tomahawk has evolved, but remained a key component of combat opera-tions with over 2,000 combat shots.”

The TACTOM missile is capable of loitering over a target area in order to respond to emerging targets or, with its on-board camera, provide battle damage informa-tion to war fighting commanders. TACTOM can also provide an on-scene commander with the flexibility to attack long-range fixed targets or support special operations forces with a lethal, responsive, precision weapon system.

“To get to this point was no accident,” Mauser said. “Rather, it is a direct reflection of the skill and dedication that each member of this incredible team has brought forward. This is an incredibly complex weapon requiring the unique talents of diverse vendor base and the discipline to bring it all together in Tucson to deliver a reliable and effective weapon to the fleet. And yet it consistently happens like clockwork, as evidenced by years of early deliveries and high quality.”

The Naval Aviation Center for Rotorcraft Advancement (NACRA) recently collaborated with the Marine Corps Systems Command (MARCORSYSCOM) to successfully test a new mobile communications system here.

Christine Liou and Tom Staley from Space and Naval Warfare Systems Command (SPAWAR) Pacific created the network on the move (NOTM) command and control system for both ground and air tactical vehicles. Liou and Staley conducted the ground-based testing inside a mine-resistant ambush protected vehicle at Naval Air Station Patuxent River.

Basil Moncrief, manager of the Extensible Marine Air-Ground Task Force, said the testing had three objectives:

• Validate and demonstrate the ability to integrate a NOTM staff vehicle kit into a UH-1 using off-the-shelf components such as standard tactical radios

• Conduct late developmental testing of a new 50-W amp for the radios

• Validate automated “healing” of a broken digital communications network between ground vehicles via airborne node

The NOTM system provides extended capability for command and control networking and data transfer applications in non-line-of-sight situations. The equipment is part of a staff vehicle kit, which is loaded onto aircraft and ground vehicle plat-forms and integrated into a flight certified rack.

“If we lose connectivity between two ground vehicles, we can use a helicopter as a relay to heal a broken network on the ground,” Moncrief said.

Marine pilot Captain Alexis Harvey and communications officer Major Keith Kovats conducted the test opera-tions in-flight on the UH-1N T-Rex helicopter, communicating via laptop with Liou and Staley to prove connec-tivity capabilities. Team members from NACRA, MARCORSYSCOM and SPAWAR met all three objectives during the two-day testing period and tested distance limitations.

Created in 2008, NACRA is respon-sible for short-term rapid response testing that relies on cross-compe-tency collaboration rather than a program to advance rotorcraft design. The group supports advanced concepts such as NOTM and develops innova-tive logistical analysis that reduces cost and risk for helicopter programs.

U.S. Navy Celebrates Delivery of 3,000th Tactical Tomahawk

Missile

Team Collaboration Proves Rapid Response Capabilities

www.NPEO-kmi.com NPEO 1.2 | 15

Compiled by Kmi media Group staff

A second-generation naval officer, Rear Admiral Thomas J. Moore graduated from the United States Naval Academy in 1981 with a Bachelor of Science degree in math/operations analysis. He also holds a degree in information systems man-agement from George Washington University and a Master of Science and an Engineer’s degree in nuclear engineering from the Massachusetts Institute of Technology.

As a surface nuclear trained officer for 13 years, he served in various operational and engineering billets aboard USS South Carolina (CGN 37) as machinery division officer, reactor train-ing assistant and electrical officer; USS Virginia (CGN 38) as main propulsion assistant; USS Conyngham (DDG 17) as weap-ons officer, and USS Enterprise (CVN 65) as the #1 plant station officer responsible for the de-fueling, refueling and testing of the ship’s two lead reactor plants during her 1991-1994 refueling complex overhaul (RCOH). Additionally, ashore he served two years as a company officer at the United States Naval Academy.

In 1994, he was selected for lateral transfer to the engineer-ing duty officer community, where he served in various staff engineering, maintenance, technical and program manage-ment positions including: carrier overhaul project officer at the Supervisor of Shipbuilding, Newport News, Va., where he led the overhaul of the Enterprise, USS Theodore Roosevelt (CVN 71) and the first year of the USS Nimitz (CVN 68) RCOH; assis-tant program manager for in-service aircraft carriers (PMS 312) in the office of the Program Executive Officer, Aircraft Carriers, Aircraft Carrier Hull, Mechanical and Electrical (HM&E); requirements officer on the staff of the chief of naval operations Air Warfare Division (OPNAV N78); and five years in command as the major program manager for In-Service Aircraft Carriers, where he was responsible for the new construction of the USS George H.W. Bush (CVN 77), the RCOH of the USS Dwight D. Eisenhower (CVN 69) and the USS Carl Vinson (CVN 70) and the life cycle management of all in-service aircraft carriers.

In April 2008, he reported to the staff of the chief of naval operations as the deputy director, Fleet Readiness, OPNAV N43B. In May 2010, he assumed his duties as the director, Fleet Readiness, OPNAV N43.

Moore assumed command as Program Executive Officer for Aircraft Carriers August 11, 2011.

Moore’s personal awards include the Legion of Merit (three awards), Meritorious Service Medal (four awards), and the Navy and Marine Corps Commendation Medal (three awards).

Q: Could we start with a look at the carrier fleet in terms of number deployed, number readying for deployment, major maintenance schedule, and production timeframe for work underway and planned?

A: With the inactivation of Enterprise [CVN 65] in November 2012, there will be 10 aircraft carriers until the Gerald R. Ford [CVN 78] is commissioned into active service in 2016. PEO Carriers is working closely with the fleet and carefully man-aging aircraft carrier maintenance schedules to ensure opera-tional needs are met. At any given time, approximately one-third of the CVN [nuclear-powered aircraft carrier] force is deployed, one-third is in maintenance availability or just returned from deployment, with one-third preparing for deployment, and one in refueling and complex overhaul [RCOH].

Q: How would you characterize the construction progress for the USS Gerald R. Ford? Are there lessons learned that will improve the process for the second in the class?

A: Gerald R. Ford is over 90 percent structurally complete, and the Island was landed on January 26, 2013. We have encountered “first in class” issues that have affected cost and schedule perfor-mance. For example, CVN 78 uses thinner steel plates for decks

Rear Admiral Thomas J. MooreU.S. Navy Program Executive Officer

PEO Aircraft Carriers

www.NPEO-kmi.com16 | NPEO 1.2

Carrier CraftsmanManaging Aircraft Carrier Operations Within the U.S. Navy

Q&AQ&A

and bulkheads compared with Nimitz class aircraft carriers to reduce overall ship weight and restore growth mar-gin in the ship’s life cycle. The thin-ner plate design has necessitated use of temporary bracing to allow han-dling of the modules as well as caus-ing rework to flam straighten plates. Although shipbuilder actions to resolve first-of-class issues have retired some technical and schedule risk, NNS-HII has been unable to retire all schedule risk, and we expect a four-month delay to the launch and a subsequent deliv-ery of CVN 78. In order to ensure that lessons learned from CVN 78 are incor-porated into the rest of the class, PEO Carriers has stood up a new program office, PMS 379, to bring the class into serial production, driving down cost and maximizing contractor and gov-ernment performance. I expect John F. Kennedy [CVN 79] to be completed at significantly less cost CVN 78 and with fewer man-hours than CVN 77, and I expect that trend to continue for Enterprise [CVN 80].

Q: For a new ship design like the Ford, how important is modeling and simulation to the naval architects putting the puzzle of an aircraft carrier together? How did this affect the development and construction strategy?

A: The advance of 3-D modeling design allows us to compress the time span for ship design and reduce the time it takes for the traditional design spiral. It also provides benefits through-out the carrier’s life cycle. CVN 78 is the first aircraft carrier to be completely built using a 3-D model that allows every space on the ship to be visualized before drawings are issued to con-struction crews, allowing issues to be resolved before costs are incurred. The construction crew uses the 3-D model to plan and rehearse complex tasks. Operators have a virtual “walk-through” environment to enhance training and qualification, while maintenance activities use the capability for maintenance and modernization.

Q: Can you elaborate a bit more on the benefits of the carrier’s life cycle in regards to the use of 3-D modeling and simulation?

A: By employing a 3-D product model, the PEO and shipbuilder can easily redesign systems that are updated frequently, pro-vide schematics wherever and whenever necessary, compare and contrast arrangement options, and test new arrangements before installation. This enables greater sharing of information, reduces rework and lowers costs.

The Navy in general is moving toward more of the 3-D prod-uct modeling of our systems. We’ve started with the Virginia class submarine. The benefit of 3-D product modeling is that once you get the models and you start to build the ship, it gives the folks that are building the ship the ability to go in and look

in advance at what they’re about to put together. They can actu-ally have a dry run of how they’re going to put the ship together. We’ve already found with CVN-78 significant benefit to that. They have a room set up where they put goggles on and they’ll sit there with certain portions of the ship and they’ll go in and allow the deck plate guys to look at the arrangements. The other thing is when they look at the arrangements, they have the abil-ity to make suggestions and say, ‘That’s going to be a problem’ and ‘You might want to think about changing this.’ So we’ve made updates to the design before we put the pipe and other things in place. In the past, we would have put it in and they would have said, ‘That pipe doesn’t fit’ and we’d have to reroute it over here.