Noiseless Fast Transport

-

Upload

scott-bergquist -

Category

Documents

-

view

218 -

download

0

Transcript of Noiseless Fast Transport

-

7/29/2019 Noiseless Fast Transport

1/2

Noiseless Fast Transport

Post Maker Faire 2013 by Scott Bergquist

Please go to my latest work on this concept: a Scribd file titled Noiseless Fast Transport Further Development.

When people discuss High Speed Rail in California, there is no question that a substantialportion of the opposition to the project originates in the potential for a huge permanent increase

in noise. Some sound is inevitable, as anything moving through air will make some sound.However, unnecessary noise is to be relentlessly pursued, to promote everyone's well-being.

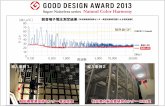

My Maker Faire exhibit was a monorail track example. It exhibited a design that attempts toreduce noise and energy use as the primary design targets, while keeping the capital costs andoperating costs of the rail system minimized. The design is aimed for initial adoption in areasof the world such as national parks, high-latitude arctic regions, where roads and railways areprohibited by scenery, preservation, or climate considerations, as well as the cost. In Africa,South America, and Asia, lack of money in local budgets preclude anything but animal carts orfoot traffic. This system would be an inexpensive, useful upgrade.

Instead of wheels, the passenger carrying cars (carriages) as well as the propulsion units rideon a skid plate (ski) which extends the length of each carriage as well as the drive units,situated at the front and back of each train. The ski is made of Ultra High Molecular WeightPolyethylene, (UHMW). While UHMW is one of the world's most slippery and abrasive-resistant materials known, the ski itself does not ride on the stainless-steel surface (red line) ofthe monorail track that is below it. Instead, the ski is supported on a thin layer of water (blueline), which acts as a hydrostatic bearing.

Shown below is a diagram of the original design of the Vee track with its horizontal barcomponent, as show at Maker Faire. While the carriage load (blue arrow) rests on thehorizontal bar, additional force is applied to the Vee part of the track (as needed) by

keepers at the points shown by the red arrows to keep the carriage secured to the track. Thekeepers also ride against strips of stainless-steel in the original design.

Now I have adopted a superior configuration to the half-inch-by-one-inch bar, which isdiscussed in detail in a new paper: Noiseless Fast Transport- Further Development.

-

7/29/2019 Noiseless Fast Transport

2/2

In discussions with viewers at Maker Faire, I realized during my explanation that a softerrubber interface not subjected to the weight of the carriage and passenger, could be so soft as toobviate the need for a belt in order to get a sufficient contact patch to achieve the necessarytraction. A 28-cm wheel (about 11 inches in diameter) would do as well as the belt, andsimplify the design and maintenance. This will be explored in the months ahead.

It has been my repeated experience that designs and implementations progress with mistakesand observations that occur during the build. My next version of the new monorailconfiguration is underway, published as Noiseless Fast Transport- Further Development, on

June 1 2013.