Nnfcc market review bio based products issue twentyfive april 2014

Transcript of Nnfcc market review bio based products issue twentyfive april 2014

Welcome to the April 2014 issue of our biobased products

market review! Each month we review the latest news from

across the biobased chemicals and materials sector. This service

is exclusively for NNFCC members.

Contents Policy 3

Markets 3

Research & Development 4

Platform Chemicals 6

Fine Chemicals 9

Polymers 11

Consumer Applications 11

Events 14

Prices 16

Issue Twenty Five

April 2014

NNFCC Market Review | Biobased Products

NNFCC Market Review, April 2014, Page 2 of 17

Foreword

Welcome to the April 2014 issue of our bio-based

products market review!

Declining demand for printing paper, together with a promising future for new

climate-friendly products, drive a reconstruction of the paper industry. Last

month Innventia published the latest Innventia Global Outlook “Papermaking

towards the future”. Based on an expert survey with 150 respondents from 21

different countries, interviews, workshops and teamwork, the outlook report

identifies the key drivers and trends that will be increasingly important as the

industry moves towards year 2030. According to the survey, 42 percent of the

respondents predicted biorefining to be the most profitable investment over

the coming ten years. The publication is available free of charge.

An example of innovative wood biorefining is the production of filaments and

carbon fibres from lignin derived from a pulp & paper mill or an

advancedbioethanol refinery.

Staying with wood biorefining, In March Stockholm hosted the 5th Nordic

Wood Biorefinery Conference. The conference gathered 240 delegates

representing 26 countries from the chemical, energy, pulp and paper

industries, as well as recognised representatives from the global research

community.

In those three days, the conference hosted presentations of the latest ideas

and developments in biorefinery separation and conversion processes as well

as new biobased products from the wood based biorefinery: energy, chemicals

and materials.

The next Nordic Wood Biorefinery Conference will take place in Helsinki on

20-22 October, 2015.

Read on for the latest market news

NNFCC Market Review, April 2014, Page 3 of 17

Policy European Parliament Takes Aim at

Plastic Bags

Members of the European Parliament’s

Environment Committee have approved a report

for reducing the use of single-use lightweight

plastic carrier bags. The report recommends a

two-stage reduction target for plastic bags across

the EU’s 28 Member States.

The report advances the MEPs’ process of

amending the law on packaging and waste to limit

the negative impacts of plastic bags on the

environment, based on a proposal by the

European Commission, the executive branch of

the EU government.

The goal of the amendment is to encourage waste

prevention and reduce the number of lightweight

plastic bags, defined as 50 microns or less in

thickness, that litter European lands and waters.

The report recommends introducing a two-stage

reduction target for plastic bags by 50 percent

within three years after the proposed law enters

into force, and 80 percent within five years, which

would come around the year 2020.

To achieve the target, Member States should

ensure that, at the very least, food retailers charge

for plastic bags handed out at the cash register,

instead of providing them free of charge, the

report advises. The exact design of such charges is

left up to Member States.

Click here for more information.

Market The American Chemistry Council

creates a new Biobased Chemistry

Network

Source: IlBioEconomista

The American Chemistry Council (ACC),whose

focus is on anticipating and preventing accidents,

as well as on educating the public about how to

use chemical products safely, has created a new

Biobased Chemistry Network to help educate

policymakers on how to develop workable

regulatory programs for the growing biobased

chemistry industry. Global sales of this segment

range from $13.5 billion to $20 billion, with the US

accounting for approximately 20 percent of those

sales, or $2.7 billion to $4 billion.

According to the American Chemistry Council,

biobased chemistry is a subcategory of industrial

biotechnology. It includes the manufacture of

chemical products using enzymes, micro-

organisms, fermentation, or bio-catalysis at any

stage of production, and also includes the

manufacture of chemical products from renewable

resources.

Currently, the network includes 19 member

companies: Akzo Nobel Chemicals, BASF Corp.,

Braskem America, Inc., Chevron Oronite Company,

Dow Chemical, DuPont, Eastman Chemical,

ExxonMobil Chemical Company, Future Fuel

Chemical, Galata Chemicals, Lanxess Corp.,

NNFCC Market Review, April 2014, Page 4 of 17

MeadWestvaco, Metabolix, Myriant Corporation,

OPX, Biotechnologies, Shell Chemical, Solvay NA,

Virent.

Click here for more information.

RSB launches simplified certification

process for Bonsucro certified entities

The Roundtable on Sustainable Biomaterials (RSB)

is pleased to announce that Bonsucro certified

operators will now be able to access RSB

certification through a simplified audit process to

demonstrate compliance, therefore saving costs

and time.

An RSB study released today concludes that RSB

and Bonsucro sustainability standards have

significant overlap on most of their requirements.

Supported by the ISEAL Alliance, the comparison

reveals that Bonsucro certified sugarcane could be

de facto considered compliant with most of the

RSB's twelve Principles and Criteria. RSB has

additional requirements for Rural and Social

Development and Food Security.

This collaboration between RSB and Bonsucro will

enhance the development of advanced

biomaterial pathways by increasing the supply of

sustainable sugar products and ethanol material

to biofuel and bioenergy producers.

Click here for more information.

New ecommerce site makes purchasing

biobased and bio-preferred products

easier

6R Supply has announced the launch of its new

ecommerce site opening its biobased industrial

product line for online purchasing. This site offers

clients more sustainable options for industrial

hydraulic fluids, lubricants, cleaners and solvents

that are readily biodegradable and reduce the use

of petroleum or its derivatives as base ingredients.

The USDA’s BioPreferred Program was adopted

through the 2002 Farm Bill to promote the

increased purchase and use of biobased products

that provide opportunities to increase domestic

demand for renewable commodities and decrease

dependence on foreign oil.

Click here for more information.

Research and

Development Mass production of chemicals from

biomass-derived oil by directly

atmospheric distillation coupled with

co-pyrolysis

Production of renewable commodity chemicals

from bio-oil derived from fast pyrolysis of biomass

has received considerable interests, but has been

hindered by the presence of innumerable

components in bio-oil.

In a research paper published by Nature,

researchers from China proposed and

experimentally demonstrated an innovative

approach combining atmospheric distillation of

bio-oil with co-pyrolysis for mass production of

renewable chemicals from biomass, in which no

waste was produced.

NNFCC Market Review, April 2014, Page 5 of 17

It was estimated that 51.86 wt.% of distillate just

containing dozens of separable organic

components could be recovered using this

approach. Ten protogenetic and three epigenetic

compounds in distillate were qualitatively

identified by gas chromatography/mass

spectrometry and quantified by gas

chromatography. Among them, the recovery

efficiencies of acetic acid, propanoic acid, and

furfural were all higher than 80 wt.%. Formation

pathways of the distillate components in this

process were explored. This work opens up a

fascinating prospect for mass production of

chemical feedstock from waste biomass.

Click here for more information.

The next step for sustainable

chemistry: a centre for industrial

biotechnology in Scotland

A new Centre for Industrial Biotechnology has

been launched in Scotland. The centre (IbioIC) is

forecast to increase IB-related turnover to up to

£3 billion by 2030, create 1500 jobs within five

years and put Scotland at the forefront of a global

transformation.

IBioIC will be a single portal for IB projects,

assisting with everything from securing funding to

project management and collaboration. It will be

open to companies of all sizes – from start-ups to

multinational giants.

The centre will focus on projects that develop

solutions for the manufacturing of high-value

products including speciality and commodity

chemicals. Whether that’s process intensification

or making development cycles shorter, these IB

projects will make businesses more competitive. IB

will enable companies to use less water, less

energy, more renewable raw materials and

compact production pathways, as well as reduce

their waste.

Click here for more information.

Bio Base Europe Pilot Plant is European

front runner in industrial

biotechnology

In 2009 Europe defined six Key Enabling

Technologies: Industrial Biotechnology,

Nanotechnology, Nano- and Microelectronics,

Photonics and Advanced Materials. Europe invests

in these technologies to enable the shift to a low

carbon, knowledge-based economy ensuring the

competitiveness of European industries and the

creation of jobs.

To support this policy, the European Commission

launched the multi-KETs Pilot Lines project; multi-

KETs Pilot Lines combine several KETs under one

roof. In the frame of this project, four promising

European pilot facilities will be scrutinized,

resulting in a tentative implementation roadmap

that can be used for the further development of a

systematic EU policy to support pilot and other

KETs activities.

Bio Base Europe Pilot Plant is one of the four

selected demonstrator projects. During the

coming months, its entire eco-system will be

mapped out: best practices, hurdles encountered,

technological and organizational aspects,

financing mechanisms.

Bio Base Europe Pilot Plant will (1) organize

monthly guided tours for interested parties: SME’s,

large companies, policy makers, and (2) host

workshops to give participants insight into its

daily operations.

Click here for more information.

NNFCC Market Review, April 2014, Page 6 of 17

Platform

chemicals Global 1,4-butanediol market 2014 to

2020: Industry size players

outlook,analysis and forecast

The global market for 1,4-butanediol (1,4-BDO) is

expected to reach USD 6,947.1 million by 2020,

according to a new study by Grand View Research.

Growth of footwear industry, mainly in Asia Pacific,

is expected to drive the market for 1,4-BDO over

the forecast period. In addition, 1,4-BDO is used

for manufacturing tetrahydrofuran (THF) which is

further used for manufacturing spandex, a raw

material for sports apparel. Growing number of

global sporting events is expected to augment

sport apparel demand, which is likely to reflect in

1,4-BDO market. However, volatile raw material

prices coupled with stringent environment

regulations, mainly in North America and Europe

is expected to be a key challenge for market

participants over the next six years.

In order to overcome these challenges, the

industry has shifted its focus towards developing

bio-based 1,4-BDO which along with providing an

eco-friendly solution also provides cost

competitiveness against its synthetic counterpart.

Some major companies developing bio-based

routes to 1,4-BDO include BASF, Purac, DSM,

Mitsubishi Chemicals, Myriant and Genomatica.

Click here for more information.

Global bioenergies: key patents

granted in first country

Global Bioenergies, a French company, developing

a process to convert renewable resources into

hydrocarbons through fermentation, has

announced that the Australian Intellectual

Property Office has granted two patents that

protect key steps of its process for converting

renewable resources into isobutene.

Global Bioenergies holds exclusive exploitation

rights to about twenty families of patent

applications which protect its processes for

converting renewable resources into isobutene,

butadiene and propylene. Recently, Global

Bioenergies announced that the first two

applications have resulted in the granting of two

patents in Australia, registered AU2009265373

and AU2010297362.

Each of the granted patents protects one essential

enzymatic reaction of the isobutene production

pathway constructed by Global Bioenergies. The

particularity of this process is that isobutene is

directly produced by fermentation. It therefore

differs from the only other known competing

process which is much more complex as it involves

a liquid precursor that must be extracted and then

purified before it is finally chemically converted

into isobutene.

These granted patents are part of two applications

that have now reached the national phase in many

more territories including Europe, the United-

States, China and Brazil.

Click here for more information.

NNFCC Market Review, April 2014, Page 7 of 17

Mitsui Leads Investment in LanzaTech’s

$60M Series D Round

Source: Lanzatech

LanzaTech, a company changing the way the

world thinks about waste carbon, has attracted

new strategic investors in key target markets.

LanzaTech’s disruptive carbon capture and

utilization technology provides a capital-efficient

and cost-effective alternative to traditional carbon

capture and storage (CCS). Waste gas streams

captured from industrial factories can be directly

converted on-site to low-carbon liquid fuels and

chemicals by adding a LanzaTech facility at the

source, offering the potential to reduce global CO2

levels while accessing multi-billion dollar

commodities markets.

Click here for more information.

Gevo report Fourth Quarter 2013

Financial Results of Luverne plant from

producing isobutanol and ethanol

Reports EPS of ($0.35)

Ended the fourth quarter with cash and cash

equivalents of $24.6 million

Transitioning Luverne plant to the production

of both isobutanol and ethanol

Produced isobutanol from mash using our

yeast biocatalyst and GIFT®

Signed licensing LOI with Porta Hnos S.A. to

become exclusive licensee in Argentina

Began selling bio-isooctane for high

performance fuel applications

Gevo has announced its financial results for the

three months ended December 31, 2013 and

provided an update on recent corporate

highlights.

Gevo has also announced that it is transitioning

the Luverne plant to the production of both

isobutanol and ethanol. Gevo's decision to

transition to the simultaneous production of both

products is a direct result of

(1) the steady progress made in executing Gevo's

flexible production technology strategy and

(2) today's high ethanol margin environment.

Producing both ethanol and isobutanol allows

Gevo to fully utilize the Luverne plant and increase

cash flow as Gevo continues to commercialize its

isobutanol production capabilities.

Click here for more information.

JM Davy and Rennovia in collaboration

on bio-based glucaric acid and adipic

acid

Renewable feedstocks used to produce chemicals for

bio-based glucaric acid and adipic acid production

NNFCC Market Review, April 2014, Page 8 of 17

Johnson Matthey Davy Technologies Ltd. (JM

Davy), an advanced process technologies

company and Rennovia, Inc., a producer of

chemicals from renewable feedstocks, have

announced they are teaming up to undertake a

start-to-finish catalytic process technologies

project.

The companies will develop, demonstrate and

commercialise the project, which will concentrate

on the production of bio-based glucaric acid and

adipic acid.

Together, the aim is to create and jointly license a

technology package that allows these chemical

products to be produced on a commercial level.

Rennovia will implement their technology, which

consists of the catalytic aerobic oxidation of

glucose to glucaric acid, and the catalytic

hydrogenation of glucaric acid to adipic acid.

Click here for more information.

Novozymes launches LpHera, an

enzyme to make starch conversion

more efficient

Novozymes headquarters; Source: IlBioeconomista

Novozymes – the Danish biotech company which

is world leader in industrial enzymes - announced

yesterday the launch of a new enzyme solution

(LpHera) that helps make starch conversion more

efficient. The starch industry is one of the longest-

standing markets for enzymes, and within the

food industry helps to produce a wide range of

sweeteners and ingredients used in products

ranging from soft drinks to sauces.

“Customers have been asking for new ways to

make starch conversion more efficient. LpHera

simplifies the process and offers significant

savings to starch processors,” says Thomas

Nilsson, Global Launch Manager for food at

Novozymes. “Through boosting yields, cutting

chemical usage in half and facilitating water and

energy savings, LpHera saves a starch processor

up to 1 USD per metric ton of substrate. Starch

plants vary in size and can process from 0.2 to

over 1 million ton of substrate each year. So if a

plant process 0.5 million ton of substrate, they can

so save up to 0.5 million dollars per year

compared to today’s technology.”

Click here for more information.

Fine chemicals

Specialty alcohol technology with

CRIBE

Green Field Mobile Extruder; Source: NetNewsLedger

CRIBE is partnering with GreenField Specialty

Alcohols to test and develop a technology that, if

successful, will lead to significant economic and

operational gains for pulp mills by providing new

revenue streams as well as a more efficient way to

perform current processes.

This is a natural extension to an earlier GreenField

project supported by CRIBE, which focused on the

NNFCC Market Review, April 2014, Page 9 of 17

conditioning and pre-treatment of a variety of

biomass including underutilized northern

hardwood such as poplar.

The practical application of this technology is to

take GreenField’s patent pending equipment – a

modified twin screw extruder used to extract and

recover clean sugars – and apply it in a pulp and

paper mill demonstration project at two mills

including AV Terrace Bay Inc. GreenField’s

technology may be beneficial as the Terrace Bay

mill moves towards converting the facility from

conventional NMSK pulp to a dissolved pulp

process.

CRIBE is providing up to $1.3 Million in funding to

this project to leverage a total project cost of

almost $2.7 Million.

Click here for more information.

Valensa supplier launches major

expansion of natural astaxanthin

biomass capacity

A covered greenhouse facility with runways for

cultivation of microalgae; Source: Contract Biotics

Valensa International and Contract Biotics have

announced that Contract Biotics has started

construction of an additional six acres of algae

production units at the company's San Diego

County facility.

Slated to come on-line in the fall of this year, the

expansion will more than triple Contract Biotics'

current biomass production and thus play a crucial

role in helping Valensa meet the market demand

for its line of formulated, condition-specific

Astaxanthin-based products.

Contract Biotics is a U.S. based wholesale

producer of a wide variety of high quality algae

biomass. The California facility is unique because it

employs a hybrid greenhouse technology to

protect the production ponds from outside

contamination unlike other producers who

employ "open" ponds. The use of U.S.-sourced

biomass combined with its Florida-based organic

certified extraction facilities makes Valensa the

only "Made in America" Astaxanthin supplier on

the market today.

As one of the most powerful known fat-soluble

antioxidants, Astaxanthin has long been

recognized for its ability to protect against cell

damage caused by oxidative stress.

Click here for more information.

Algatechnologies Invests $20 million in

Natural Astaxanthin Production in

Israel

State-of-the-art facility in the Arava Desert, Israel;

Source: AlgaTechnologies

Algatechnologies ("Algatech") has announced a

more than 100% expansion of its production

capacity of AstaPure® brand natural astaxanthin.

This doubling of capacity follows an investment of

$20 million in its state-of-the-art facility in the

Arava Desert, Israel.

NNFCC Market Review, April 2014, Page 10 of 17

This significant step is only part of the

transformation by Algatech' new owners,

Grovepoint, since the UK investment group

acquired control of Algatech in 2013. Grovepoint's

distinct aim is development and capitalization of

the potential business in natural astaxanthin and

related products.

Click here for more information.

First product from Stepan and Elevance

joint development agreement is now

commercially available

Stepan Company, one of the leading global

surfactant manufacturers, today introduced

STEPOSOL® MET-10U, a novel surfactant derived

from natural oils that is targeted to displace

solvents.

This powerful new cleaning solution is the first

commercial product launched by Stepan as part of

its joint development agreement with Elevance

Renewable Sciences, Inc. The Development

Agreement was established to develop and

commercialize new surfactants and other products

by combining Elevance’s novel Inherent™ building

blocks with Stepan’s derivatization and application

capabilities.

This innovative solution utilizes a naturally

derived, metathesized feedstock to form a next

generation bio-based surfactant that achieves

sustainability goals while improving cleaning

performance. The applications for STEPOSOL®

MET-10U are broad, including adhesive removal,

paint and coating removal systems, kitchen

degreasers and all-purpose cleaners for both

consumer and industrial uses.

Click here for more information.

Polymers

The first spool with lignin

multifilaments

Award winner, Hannah Schweinebarth, from Innventia

Innventia has successfully produced its first spool

of lignin multifilaments for further converting to

carbon fibres. The filaments are based on 100%

softwood kraft lignin, were produced without

additives, and had an average diameter of just

over 10 micrometre.

Innventia is now investing in new equipment for

multifilament spinning and thus enhances the

establishment of a Swedish test bed for lignin-

based carbon fibre.

Click here for more information.

Novamont buys majority stake in

Mater Biopolymer

Bioplastics firm Novamont SpA has acquired a

majority stake in Mater-Biopolymer, a unit of PET

resin maker Grupo Mossi & Ghisolfi that operates

a resin plant in Lazio, Italy.

NNFCC Market Review, April 2014, Page 11 of 17

Novara, Italy-based Novamont will own 78% of

Mater-Biopolymer, including the 83-employee

Lazio plant. The plant will work exclusively for

Novamont and M&G, with one line producing PET

for M&G and another making Origo-Bi, a line of

renewably sourced polyesters.

Origo-Bi is used to improve the characteristics of

Novamont’s Mater-Bi biodegradable and

compostable bioplastics. The Origio-Bi production

line has been modified over the last four years

using proprietary Novamont technology, officials

said in the news release.

Novamont has an option to buy the remainder of

Mater-Biopolymer by the end of 2016. Officials

said that the plant — known as the Patrica plant

— had become too small for the economies of

scale of M&G’s PET production, but was an ideal

size for Novamont. After the technological

conversion, including the second production line,

the plant “will be perfectly suited” to large-scale

production of Origo-Bi, they added.

Click here for more information.

Consumer

Applications Tetra Pak launches first bio-based cap

for gable top packages

Tetrapak’s new biobased opening for gable top

packages

Manufactured using high density polyethylene

(HDPE) derived from sugar cane, the bio-based

version of TwistCap OSO 34 marks another step

forward in Tetra Pak’s ambition to make fully

renewable packages. In 2013, the company

delivered 1.1 billion bio-caps globally, an increase

of more than 80% over the previous year.

80% of the material in a one-litre Tetra Rex®

carton is paperboard, which is made from wood, a

renewable resource. By introducing the new bio-

based cap, the content of renewable material in

the package increases by an additional 4%,

helping to further improve the environmental

performance of the package without

compromising its functionality or recyclability.

Tetra Pak customers using the standard TwistCap

OSO 34 can easily transfer to the bio-based

version without the need for any additional

investment or modification to their existing filling

machines.

Click here for more information.

UPM and Metropolia present 'The

Biofore Concept Car'

Metropolia Biofore Concept Car; Source: UPM

The Biofore Concept Car showcases the use of

UPM’s innovative biomaterials in the automotive

industry. The majority of parts traditionally made

from plastics are replaced with high quality, safe

and durable biomaterials, UPM Formi and UPM

Grada, which can significantly improve the overall

environmental performance of car manufacturing.

NNFCC Market Review, April 2014, Page 12 of 17

The Biofore Concept Car is designed and

manufactured by students from the Helsinki

Metropolia University of Applied Sciences.

Parts made of UPM Grada thermoformable wood

material are the passenger compartment floor,

centre console, display panel cover and door

panels. Grada technology revitalises the forming

of wood with heat and pressure, and opens up

new opportunities for designs not achievable with

traditional methods.

Parts made of UPM Formi biocomposite include

front mask, side skirts, dashboard, door panels

and interior panels. UPM Formi is a durable, high

quality biocomposite for injection moulding,

extrusion and thermoforming production.

Consisting of renewable fibres and plastic, the

material is non-toxic, odourless and uniform in

quality.

Click here for more information.

ADM Evolution Chemicals™ and

Hawkins introduce chill-pro biobased

heat transfer fluid

Archer Daniels Midland Company and Hawkins

have introduced Chill-Pro, a USDA Certified

Biobased heat transfer fluid made using ADM

Evolution Chemicals™ propylene glycol. Chill-Pro

is designed to maintain a constant temperature

and provide superior freeze protection for closed-

loop, water-based HVAC systems. It is formulated

with a comprehensive food-grade inhibitor

package that provides corrosion protection

without reducing the efficiency of the system

components. The corrosion inhibitors first

passivate the surface of the metal to maximize the

corrosion resistance and then buffer the organic

acids formed through the glycol oxidation process

to prevent the fluids from becoming too acidic.

Click here for more information.

DSM's EcoPaXX is selected by Dytech

for Ferrari and Maserati fuel vapor

separators

AVA Biochem; Sounrce: BiomassMag

Royal DSM, the global Life Sciences and Materials

Sciences company, announces that its bio-based

high performance EcoPaXX® polyamide 410 has

been selected by Dytech-Dynamic Fluid

Technologies for the fuel vapour separators it

produces for Ferrari and Maserati sports cars. This

solution, in halogen-free flame retardant EcoPaXX

Q-KGS6, will increase the fire safety of the cars by

combining flame retardancy with a high level of

chemical resistance, essential for this application.

The fuel vapor separator is an important element

of the complete fuel delivery system in road

vehicles. It separates vapors from liquid fuel

coming out from the fuel tank, and prevents the

liquid fuel reaching - and contaminating - the fuel

vapor canister.

EcoPaXX has, in addition to its unique technical

performance, an extra advantage in that

polyamide 410 is 70% derived from renewable

resources and is certified Carbon Neutral from

cradle to gate.

Click here for more information.

NNFCC Market Review, April 2014, Page 13 of 17

Solazyme Launches New Product Line:

Encapso

Solazyme, a renewable oil and bioproducts

company, has announced its entry into the oil and

gas drilling fluids additive market. Building upon

its proprietary platform of high performance,

sustainable TailoredTM oils, Solazyme has

introduced EncapsoTM

, the world's first

encapsulated biodegradable lubricant for drilling

fluids designed to deliver high-grade lubricant

precisely at the point of friction where and when

needed most.

Encapso's efficacy has been demonstrated both in

the lab and in the field in over a dozen

commercial wells in a number of basins including

the Williston Basin, Denver-Julesburg, and the

Permian Basin. Encapso™ increases drilling speed

and control, and protects valuable equipment. The

majority of work so far has been done in

horizontal wells, helping demonstrate Encapso's

strong performance capabilities when it comes to

"building the curve"—or the point where an

unconventional well transitions from vertical to

horizontal. This is often when drilling engineers

find the most difficulty managing drilling friction.

Improving the speed and efficiency of drilling

translates directly to cost savings for well

operators.

Click here for more information.

Events LCA Workshops on 29-30 April in York,

UK

Following the success of our

previous Life Cycle Assessment

(LCA) workshops, NNFCC and North

Energy bring you two new training workshops

providing you with insight into how LCA's work

and their applications. The workshops take place

over two days;

Day 1: 29 April 2014. Introduction to LCA

Workshop

Day 2: 30 April 2014. Advanced LCA

Workshop.

Seaweed for Biofuel on 21 May in

Oban, Scotland

Seaweed for Biofuel is organised by the Algal

Bioenergy Special Interest Group and Innovation

Norway and is aimed at enhancing collaboration

and addressing supply chain challenges around

developing a sustainable and robust algal biofuel

network.

This is an

NNFCC

Event

NNFCC Market Review, April 2014, Page 14 of 17

Biochemicals & Bioplastics Conference

2014 on 10-11 Jun in Düsseldorf,

Germany

Through a combination of informative

presentations, interactive discussions

and sessions this event will explore the

key opportunities and challenges

facing the biochemicals and bioplastics industries.

The Algae Event on 25 Jun in Hamburg,

Germany

Providing a better understanding on how algae fit

into the current biomass industry and how they

could contribute to a sustainable bioeconomy in

the future.

EnAlgae is co-organising a stand-alone

conference session on algae within the EU

Biomass Conference and Exhibition in Hamburg.

European Biorefining Training School

2014 on 7-10 Jul in Budapest, Hungary

The 3rd Biorefining Training School

will be organized under the Climate-

KIC’s European-wide umbrella with the

cooperation of the founding institutes.

Having realized the importance of the

bioeconomy, the EU is focusing its efforts on the

development of a variety of enabling technologies

and the collection of the necessary knowledge

required to bring biorefineries into the industrial

arena.

Opportunities in Fuels and Chemicals

from Syngas and Methane

Fermentation on 16 Jul in London, UK

Organised by the SCI Science and

Enterprise group and Bio Base

NWE, the main theme of the

conference will be gasification of biomass and

wastes to produce synthesis gas (syngas), and

conversion of syngas and methane from a variety

of sources into liquid fuels and chemicals. This

conference will explore the technologies being

developed and their commercial potential.

2nd UK Conference on Supercritical

Fluids on 20-22 Jul in Bangor Wales

It is now ten years since the first UK conference on

supercritical fluids was held at Birmingham

University in 2004 and many new applications

have been developed since this event. This year

also marks the 25th anniversary of the

BioComposites Centre at Bangor University and

we are therefore pleased to announce that we will

be hosting a supercritical fluids conference in July

2014.

This is an

NNFCC

Event

NNFCC Market Review, April 2014, Page 15 of 17

Ghent Bioeconomy Summer School

2014 on 25-28 Aug in Ghent, Belgium

This annual summer school offers a

comprehensive overview of the biobased

economy, addressing its technological as well as

societal aspects. Previous editions attracted over

50 participants from all over the world, who got to

interact with experts from both academia and

industry.

2nd International Conference on Algal

Biorefinery on 27-29 Aug in

Copenhagen, Denmark

This international conference aims to share

research experience on aquatic biomass resources,

both micro-, and macroalgae as a potential source

of food, feed, biochemical, biofuels and

biofertlizers.

The Bioenergy from Forest Conference

on 15-18 Sep in Helsinki, Finland

The Conference will focus on the factors affecting

the future of bioenergy and biobased modern

technologies and business solutions, including

logistic systems, management, total procurement

chains, the effects of the energy markets, the

influence of green marketing and other trends

affecting forestry, agriculture, industry and

climate.

EFIB 2014 on 30 Sep – 2 Oct in reims,

France

EFIB 2014 will be the 7th European Forum for

Industrial Biotechnology and the Biobased

Economy. The conference gives an insight

into this exciting and rapidly evolving

landscape and be part of the process of

building a stronger more sustainable

biobased economy.

9th European Bioplastics Conference

on 2-3 Dec 2014 in Brussels, Belgium

European Bioplastics is delighted to announce the

9th European Bioplastics Conference - the leading

international business forum for the bioplastics

industry in Europe. Each year, about 400 experts

from around the globe come together and

demonstrate the conference’s tremendous

effectiveness in information exchange and

networking.

NNFCC Market Review, April 2014, Page 16 of 17

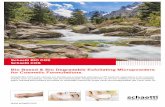

Price Information

Item Price, US$ (Mar 09) Price, US$ (Feb 14) % Price Change

Crude oil (petroleum, barrel) 46.95 ↑ 104.82 145

Maize (corn, metric ton) 164.52 ↑209.32 22

Sugar (pound) 0.1293 ↑ 0.1666 16

Rapeseed oil (metric ton) 731.63 ↑ 974.82 24

Soybean oil (metric ton) 694.16 ↑ 873.66 18

Ethanol (gallon) 1.62 ↓ 2.02 30

Arrows indicate rise (↑), constant (–) or fall (↓) from previous month.

For details on indexes please see www.indexmundi.com/commodities: Crude Oil (petroleum), simple average of three

spot prices; Dated Brent, West Texas Intermediate, and the Dubai Fateh; Sugar free market price.

Historic ethanol prices available at http://www.neo.ne.gov

For details on the nature of these commodities please see http://www.imf.org

Credits and Disclaimer

NNFCC Market Review is edited by Dr Efthalia Arvaniti for NNFCC members. Feedback is welcome. The

Review has been compiled in good faith and NNFCC does not accept responsibility for any inaccuracies or

the products or services shown.

0

50

100

150

200

250

300

Pri

ce i

nd

ex (

rela

tive t

erm

s)

Comparison of Price Indexes (2005 = 100)

Agricultural Raw

Materials

Food

Crude Oil

(Petroleum)

NNFCC Market Review, April 2014, Page 17 of 17

NNFCC are partners in Bio Base NWE, an INTERREG IVB project

designed to accelerate the growth of the bio-based economy in North

West Europe

For more information on the project click here and to learn about

funding opportunities click here.

NNFCC

The Bioeconomy Consultants

NNFCC, Biocentre, Phone: +44 (0)1904 435182

York Science Park, Fax: +44 (0)1904 435345

Innovation Way, E: [email protected]

Heslington, York, Web: www.nnfcc.co.uk

YO10 5DG.