NIVELCO CASE STUDIES · fixed-bed bio-film that grows on root structures. These plant roots are...

Transcript of NIVELCO CASE STUDIES · fixed-bed bio-film that grows on root structures. These plant roots are...

N I V E L C O C A S E S T U D I E SEasyTREK ultrasonic level transmittersin the water industry

The ever-growing demand of the effluent waste-water treatment requires continuous improve-ments in the treatment technologies. In 2012 the South-Pest wastewater treatment plant of Budapest Sewage Works established a new IFAS (Integrated Fixed-Film Activated Sludge) treatment technology called Organica FCR (Food-Chain Reactor).

The main characteristic of this new technology is that on the surface of the activated sludge basins there are vegetation planted utilizing a fixed-bed bio-film that grows on root structures. These plant roots are growing deep into the biological reactors. The primary role of the plants root system is providing large living space to microorganisms which are decomposing organic materials and for even higher-level organisms. Besides the plants as a natural bio-film carrier there are artificial bio-film carriers too and the water level in the activated sludge basin is significantly raised. In accor-dance to the above described the hydraulic conditions of the biological purification stage are dramatically changed due to the raised water level and the water swelling effect of the bio-film carriers. This way the water level control of the activated sludge basins has became necessary to be able to transfer the proper water amount to the biological stage in accordance to the actual biological treatment capacity.

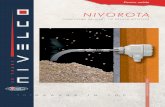

The water level control is done with a motorized floodgate in the drainage of the activated sludge basins. The level control is based on the water level in the launder channel of the pre-settling pool so the level transmitter unit has been in-stalled about one meter (3.3 feet) above the channel using an long armed mounting bracket.

The water level is continuously measured by an EasyTREK SPA-360-4 type integrated ul-trasonic level transmitter. The analogue (4-20 mA) output signal of the instrument transmitted to the PLC controlling the biological purification stage. The PLC controls the activated sludge

basins floodgates on the basis of the measured level values. The ultrasonic level transmitter ensures the adequate water supply for the FCR (Food-Chain Reactor) technology flawlessly since the installation.

Tibor AsztalosDomestic Sales Engineer

NIVELCO [email protected]

Level measurement in Activated Sludge Basin